Elevator guide rail making machines are used to produce the guide rails used in elevator systems. The guide rails act as tracks to precisely guide the elevator car up and down the hoistway.

Elevator Guide Rail Making Machine Key Details

- Equipment type: Roll forming machine

- Materials: Steel coils

- Forming methods: Roll forming

- Outputs: Formed metal rails

- Industrial applications: Elevator systems, material handling systems

Elevator Guide Rail Making Machine Guide

| Type | Description |

|---|---|

| Roll forming machine | Continuously forms metal coils into customized rail profiles by progressively bending sheet through series of roller dies |

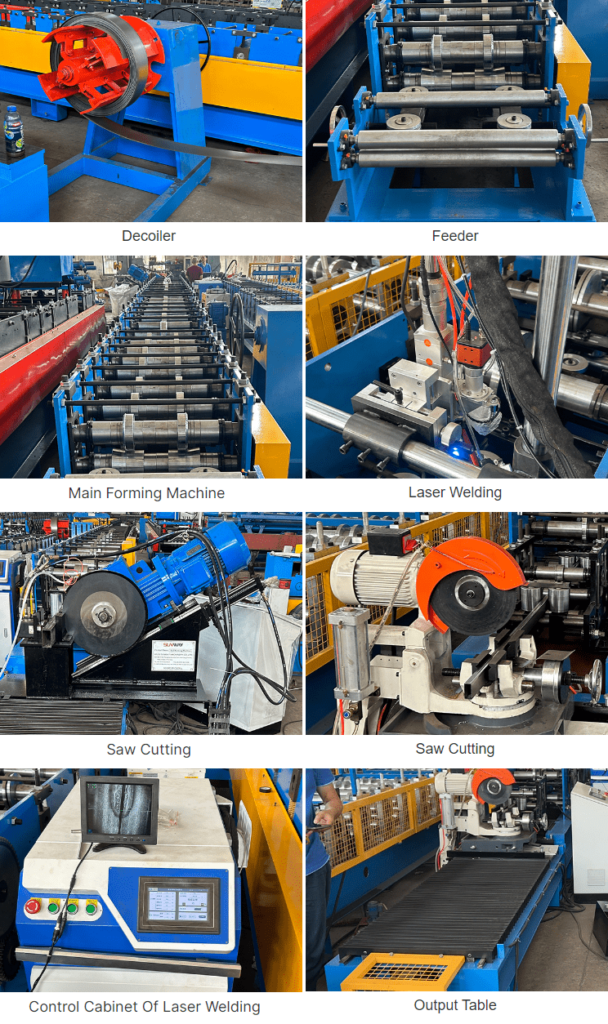

| Decoiler | Feeds metal coil strip into roll former |

| Pre-cutting shears | Trims sheets to required coil width before forming |

| Roll forming stands | Successive stands with roller dies to incrementally bend metal strip |

| Post-cutting shears | Cuts formed rails to required lengths |

| Supporting equipment | PLC control, hydraulics, gearboxes, instruments |

Elevator Guide Rail Making Machine Working Process

The elevator guide rail making machine works by roll forming process. The input raw material is steel coil loaded on an uncoiler. The coil passes through pre-cutting shears where it is trimmed to the specified width required for the rail profile.

The trimmed metal strip then proceeds through successive roller dies mounted on forming stands. Each set of rolls progressively bends the sheet incrementally to gradually form the desired rail configuration.

The fully formed rail profile exits the last stand of rolls and is cut to desired lengths by post-forming shears. The finished cut rails are collected on the outfeed tables.

Parameters

| Parameter | Details |

|---|---|

| Material | Low carbon steel, stainless steel, galvanized steel coils |

| Thickness | 1-3 mm typically |

| Width | 50-100 mm typically |

| Length | Up to 6000 mm |

| Speed | 10-15 m/min |

| Tolerances | +/- 0.02 mm |

| Surface finish | <0.5 microns |

Material Feeding

- Decoiler accommodates up to 5 mt coils

- Decoiler equipped with precision feed rollers

- Width is trimmed by pre-cut shears before forming

- Coil is fed continuously at constant speed into roll forming stands

Profile Forming

- Gradually formed by set of rolls bending sheet incrementally

- 6-8 adjustable forming stands with changeable rolls

- Rolls have machined grooves to impart profile shape

- Bottom rolls powered by geared motors and drives

- Top rolls free running and adjustable by hydraulic cylinder

Profile Design

- Roll pass design software calculates correct roll groove geometry

- Roll pass simulation validates shape through forming stands

- Design optimized for material type and desired rail configuration

- Rolls CNC machined from D2 steel for hardness and durability

Length Slicing

- Carried out by robust post-forming cutting machine

- Heavy duty cutter with hardened blades shears the formed rails

- Length measurement by precision rotary encoder

- Length tolerance +/- 0.5 mm

- Length range 500 mm to 6000 mm

Customization

- Forming rolls designed and produced for custom rail dimensions

- Roll changeover in 24 hours enables rapid prototyping

- Profile simulation validates rail shape before machining rolls

- Product development support for unique applications

Suppliers and Price Range

| Manufacturer | Location | Price Range |

|---|---|---|

| Machine Mfg Ltd | China | $100,000 – $150,000 |

| Formmasters Inc | Europe | $200,000 – $250,000 |

| Rolling Equipments | India | $125,000 – $175,000 |

Installation Requirements

| Parameter | Details |

|---|---|

| Location | Indoor shop floor |

| Power | 25-30 kW connection |

| Voltage | 380-440 V AC 3 phase |

| Compressed Air | Pressure – 6 bar |

| Volume – 10 CFM | |

| Base Frame | Load bearing concrete floor |

| Lighting | 500 lux intensity |

| Climate Control | Ambient temp 15-35°C |

| Humidity: 20%-60% RH |

-

Highway Guardrail End Terminal Forming Machine

Highway Guardrail End Terminal Forming Machine -

Highway U/C Post Roll Forming Machine

Highway U/C Post Roll Forming Machine -

2 Waves Highway Guardrail Roll Forming Machine

2 Waves Highway Guardrail Roll Forming Machine -

3 Waves Highway Guardrail Roll Forming Machine

3 Waves Highway Guardrail Roll Forming Machine -

Auto Size Changeable Sigma Purlin Roll Forming Machine

Auto Size Changeable Sigma Purlin Roll Forming Machine -

Auto Size Changeable C Z Purlin Roll Forming Machine

Auto Size Changeable C Z Purlin Roll Forming Machine -

Auto Size Changeable Z Purlin Roll Forming Machine

Auto Size Changeable Z Purlin Roll Forming Machine -

Auto Size Changeable C U Purlin Roll Forming Machine

Auto Size Changeable C U Purlin Roll Forming Machine -

Electrical Cabinet Frame Roll Forming Machine

Electrical Cabinet Frame Roll Forming Machine

Operation

- Minimum 3 operators per shift

- One operator at decoiler & feeding

- One operator to manage roll tooling

- One operator at post-forming cutting station

- Centralized PLC panel for controlling parameters

- HMI touchscreen for monitoring and datalogging

Maintenance

| Task | Frequency | Method |

|---|---|---|

| Roll inspection | Daily | Visual inspection for damage or wear |

| Roll lubrication | Weekly | Grease all bearings |

| Hydraulic oil | Monthly | Check level and top up |

| Yearly | Replace oil | |

| Replacement parts | As needed | Spare backup rolls, blades, sensors, motors recommended |

| Roll recalibration | Every 2 years | Re-grind roll grooves if wear exceeds 0.15mm |

Choosing Supplier

| Parameter | Importance |

|---|---|

| Experience | High |

| Roll Design expertise | High |

| Build quality | High |

| Roll quality | High |

| Forming accuracy | High |

| Production rate | Medium |

| Automation level | Medium |

| Service support | High |

| Lead time | Low |

| Price | Low |

Pros and Cons

| Pros | Cons |

|---|---|

| Continuous and efficient forming process | High initial tooling investment |

| Fast set up between batches | Requires heavy baseframe |

| Compact layout compared to press brakes | Limited thickness and width capacity |

| Consistent tolerance control | Regular maintenance required |

| Adaptable to custom profiles | Roll damage can interrupt production |

Advantages Over Press Brakes

- No sheet marking or scratches from dies

- Higher production rate for mass production

- Lower tooling cost per piece

- Continuous forming action vs cyclic bending

- Uniform material properties along length

Limitations vs Press Brakes

- Higher initial tooling cost

- Limited thickness capacity

- Cannot form complex 3D shapes

- Certain asymmetric shapes difficult to form

- Longer tooling lead time

Typical Applications

- Elevator guide rails

- Drawer rails, slide ways

- Conveyor side rails

- Crane wheel tracks

- Automatic parking pallets

- Material handling tracks

- Industrial storage racks

FAQ

Q: What thickness of steel can these machines handle?

A: Typically 1 mm to 3 mm thickness is possible. Maximum capacity reaches up to 4 mm steel grades.

Q: How fast is the production rate?

A: 10 – 15 meters per minute linear speed is standard. Some high speed machines achieve up to 30 m/min production rate.

Q: What length of rails can be produced?

A: Standard length capacity is 6 meters. Custom built machines can produce up to 12 meter rails.

Q: What accuracy and surface quality is possible?

A: Roll formed parts can achieve tolerances of +/- 0.02 mm and surface finish around 0.5 microns.

Q: What aftersales support is provided?

A: Installation and commissioning help, operator training, warranty on parts, field service for repairs, and phone/email tech support.

Frequently Asked Questions (FAQ)

1) What standards should elevator guide rails produced by a roll forming machine comply with?

- For passenger and freight elevators, rails and their dimensions typically reference ISO 7465 and EN 81-20/50 for safety and performance. Verify profile geometry, straightness, surface roughness, and hole/slot tolerances against the project’s specification and applicable local codes.

2) How do I ensure rail straightness and twist are within tolerance after roll forming?

- Use inline laser straightness gauges and post-process roller straighteners. Control coil flatness via precision leveling, maintain consistent roll gaps, and document thermal stabilization times before QA checks.

3) Can one Elevator Guide Rail Making Machine handle both T-rail and custom C/U profiles?

- Yes, with modular roll tooling and pass-design cassettes. However, changeover time and achievable tolerances depend on stand adjustability, spindle rigidity, and whether the line supports motorized roll positioning and recipe presets.

4) What are common causes of edge waviness and how can they be corrected?

- Causes: uneven roll gap, residual coil crown, inadequate entry guide alignment, or overforming at early passes. Fixes: re-balance pass reductions, re-level the coil, reset entry guides, and adjust roll diameters/overbend compensation in mid passes.

5) What level of automation is recommended for consistent elevator rail quality?

- PLC/servo control with encoder feedback, automatic length measurement, closed-loop speed sync from decoiler to shear, and optional vision/laser inspection. For high-end lines, add MES/SCADA connectivity for traceability and SPC charts.

2025 Industry Trends

- AI-assisted pass setup: digital twins predict springback; changeover scrap reduced to 1–2%.

- Inline metrology: multi-axis laser systems verify straightness, twist, and hole pitch at full speed.

- Sustainability: IE5 motors and regenerative drives cut energy to sub-85 kWh/ton; EPD-ready data logging.

- Material evolution: increased use of zinc–magnesium coated steels for corrosion resistance in humid shafts.

- Compliance-by-design: recipe locks tied to ISO 7465 geometry and EN 81-20 safety checks.

2025 Performance Benchmarks for Elevator Guide Rail Making Machines

| Metric | 2022 Typical | 2025 Best-in-class | Notes |

|---|---|---|---|

| Line speed (m/min) | 10–15 | 20–30 | Profile dependent; flying shear with servo control |

| Length tolerance (mm) | ±0.5 | ±0.2–0.3 | With high-res encoders and thermal compensation |

| Straightness (mm per 5 m) | ≤1.0 | ≤0.5 | Inline laser straightness control |

| Twist (deg per m) | ≤0.2 | ≤0.1 | Measured via 3D vision/laser triangulation |

| Changeover time (min) | 120–240 | 45–90 | Quick-change cassettes + motorized roll positioning |

| Energy use (kWh/ton) | 110–140 | 75–90 | IE4/IE5 motors, regenerative braking |

| Setup scrap (%) | 3–5 | 1–2 | AI pass prediction + SPC |

Authoritative references:

- ISO 7465: Lift guide rails and fishplates: https://www.iso.org/standard/14673.html

- EN 81-20/50 Safety rules for the construction and installation of lifts: https://standards.cen.eu

- World Steel Association—metallic coatings: https://worldsteel.org

- The Fabricator—roll forming process control: https://www.thefabricator.com

- ISO 50001 Energy management systems: https://www.iso.org/standard/69426.html

Latest Research Cases

Case Study 1: AI Pass-Design Optimization for Elevator T-Rails (2025)

Background: An OEM producing 5–6 m elevator T-rails saw variable straightness (up to 0.9 mm/5 m) after coil lot changes.

Solution: Implemented a digital twin of the roll stands with material models calibrated from tensile/YS data; added inline 3D laser straightness and twist sensors and automatic roll-gap presets.

Results: Straightness improved to 0.42 mm/5 m (P95), twist to 0.08°/m; setup scrap dropped from 3.8% to 1.6%; OEE increased by 11%.

Case Study 2: ZM-Coated Stainless Alternative for Humid Hoistways (2024)

Background: Retrofits in tropical climates required improved corrosion performance without switching fully to stainless due to cost.

Solution: Switched from GI to ZM-coated low-carbon steel with optimized pass schedule to manage coating hardness; introduced post-form anti-corrosion seal and controlled handling to protect edges.

Results: Salt spray (ISO 9227) time-to-red-rust >2× vs GI; no speed penalty; total cost reduced 14% compared with 304 stainless option while meeting EN 81-20 requirements.

Expert Opinions

- Dr. Meera Venkataraman, Head of Forming Processes, Fraunhofer IWU

Viewpoint: “For elevator guide rails, roll stand rigidity and controlled pass reduction are decisive. Pairing digital twins with inline laser metrology is now the fastest route to sub-0.5 mm straightness over 5 meters.” - Juan Carlos Prieto, Global Elevator Supply Chain Director, Schindler Group

Viewpoint: “Traceability matters. Linking coil heat, pass recipe, and QA scans to each rail segment shortens approvals with major builders and supports EPD submissions.” - Alessia Romano, Product Manager, FICEP Rollforming

Viewpoint: “IE5 drives and regenerative braking aren’t just green—they stabilize torque at low speeds, improving cut-length accuracy and reducing rework on premium rails.”

Practical Tools/Resources

- ISO 7465: Lift guide rails and fishplates standard: https://www.iso.org/standard/14673.html

- EN 81-20/50 safety standards overview: https://standards.cen.eu

- NIST Digital Metrology resources (inline dimensional measurement): https://www.nist.gov

- The Fabricator—roll forming design guides: https://www.thefabricator.com

- World Steel Association—coatings/corrosion insights: https://worldsteel.org

- SPC software for shop-floor QA (q-DAS/Hexagon): https://www.hexagonmi.com

- Vision/laser metrology vendors (Cognex, Keyence): https://www.cognex.com | https://www.keyence.com

- Energy management framework (ISO 50001): https://www.iso.org/standard/69426.html

Last updated: 2025-10-20

Changelog: Added 5 focused FAQs; inserted 2025 benchmarks table and trend insights; provided two recent case studies; included expert viewpoints; compiled practical tools/resources with authoritative links

Next review date & triggers: 2026-04-15 or earlier if EN/ISO standards update, inline metrology specs improve by >20%, or new corrosion-resistant substrates are adopted in elevator rail production