C Purlin Roll Forming Machine

Product categories

- Profile roll forming machine (6)

- Purlin roll forming machine (4)

- Roll Former (15)

- Electric & Energy (9)

- Racking & Shelving (5)

- Steel Structure (24)

- Metal Wall & Roofing (28)

- Highway Engineering & Vehicle (6)

- Door & Windows (1)

- Cut To Length Line (3)

- Roll Forming Machine (4)

C Purlin Roll Forming Machine

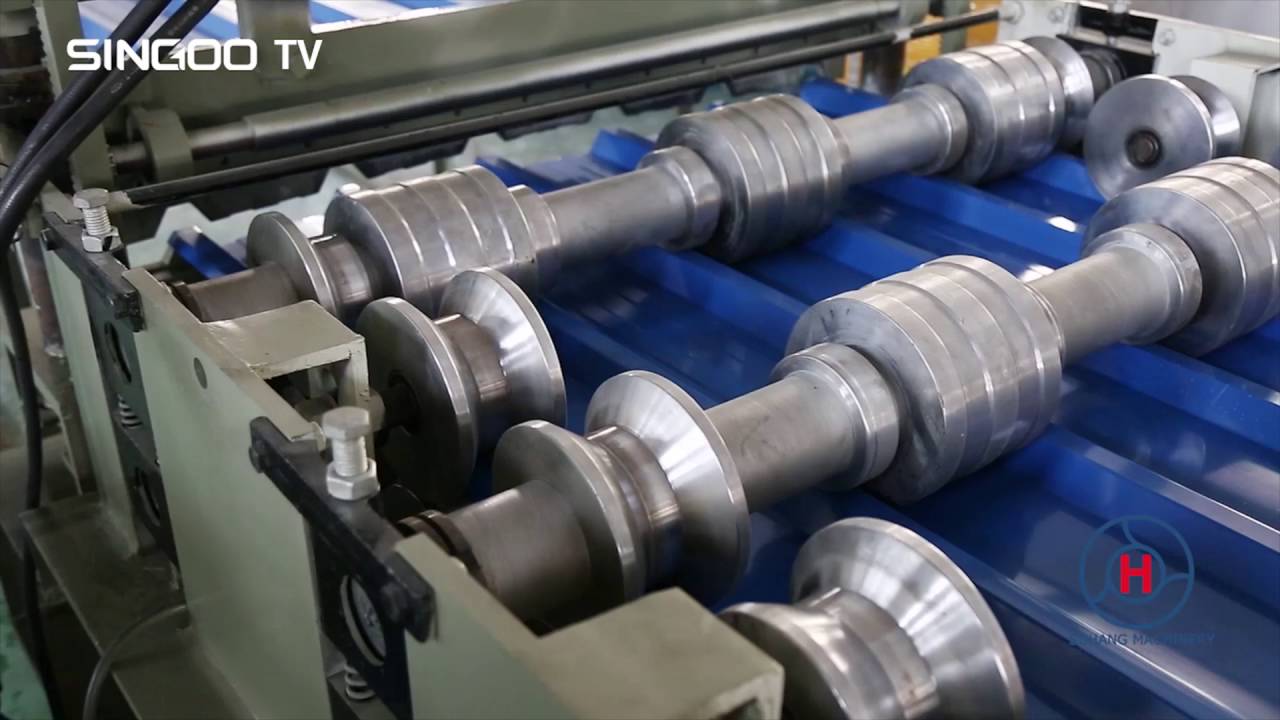

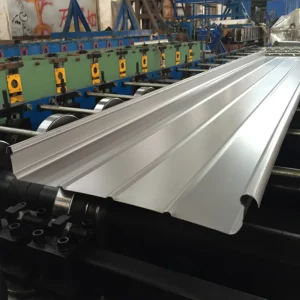

C Purlin Roll Forming Machine is a specialized piece of equipment designed to produce C-shaped steel purlins for various construction applications. These machines transform flat steel coils into precisely shaped C purlins through a series of bending and shaping processes. The machine typically consists of an uncoiler, leveling and guiding system, roll forming unit, punching and cutting system, hydraulic system, control system, and a run-out table. The C Purlin Roll Forming Machine streamlines the production of C purlins, offering high efficiency, productivity, and consistency in purlin dimensions.

What Are The Main Components Of A C Purlin Roll Forming Machine?

The main components of a C Purlin Roll Forming Machine include:

- Uncoiler: Holds and feeds the steel coil into the machine.

- Leveling and guiding system: Ensures the flatness and correct alignment of the steel strip before entering the roll forming unit.

- Roll forming unit: Consists of a series of rollers that progressively bend and shape the steel strip into the desired C purlin profile.

- Punching and cutting system: Responsible for creating holes and cutting the formed C purlin to the required length.

- Hydraulic system: Powers the machine’s punching, cutting, and other hydraulic-driven components.

- Control system: Manages and monitors the machine’s operation and process parameters.

- Run-out table: Collects the finished C purlins as they exit the machine.

What Are The Advantages Of Using C Purlins In Construction?

Using C purlins in construction offers several advantages:

a. Lightweight and strong: C purlins are lighter than traditional construction materials like wood or concrete, yet still provide excellent strength and durability.

b. Easy installation: C purlins can be quickly and easily installed on-site, reducing construction time and labor costs.

c. Versatility: C purlins can be used in various applications, such as roofing, wall support structures, and framing for industrial, commercial, and residential buildings.

d. Customizable: C Purlin Roll Forming Machines can produce C purlins in different sizes and thicknesses, allowing for customization to meet specific project requirements.

e. Cost-effective: C purlins are relatively inexpensive and provide long-lasting, low-maintenance solutions for various construction applications.

What materials can be used to produce C purlins with a C Purlin Roll Forming Machine?

C Purlin Roll Forming Machines can process various materials, including:

- Cold-rolled steel: A common material for C purlins due to its strength, durability, and ease of forming.

- Hot-rolled steel: Less commonly used but still suitable for producing C purlins, offering increased strength at the expense of a rougher surface finish.

- Galvanized steel: Provides additional corrosion resistance, making it ideal for use in humid or corrosive environments.

How do I choose the right C Purlin Roll Forming Machine for my specific needs?

When choosing a C Purlin Roll Forming Machine, consider the following factors:

- Production capacity and speed: Ensure the machine can meet your production requirements in terms of output and efficiency.

- Material compatibility and thickness range: Confirm the machine can process the specific materials and thicknesses you plan to use.

- Level of automation and control: Choose a machine with user-friendly controls and, if desired, automated features to streamline production and reduce manual labor.

- Manufacturer reputation and after-sales support: Research the manufacturer’s track record and customer reviews to ensure they provide reliable equipment and responsive support for any maintenance or troubleshooting needs.

- Budget and return on investment: Evaluate the machine’s cost relative to its potential benefits, such as increased production efficiency, reduced labor costs, and improved product quality.

Can a C Purlin Roll Forming Machine produce different sizes and thicknesses of C purlins?

Yes, a C Purlin Roll Forming Machine can produce C purlins in various sizes and thicknesses by adjusting the machine’s settings and parameters. This flexibility allows manufacturers to produce customized C purlins to meet specific project requirements, providing a versatile solution for a wide range of construction applications.

What is the typical production speed of a C Purlin Roll Forming Machine?

The production speed of a C Purlin Roll Forming Machine can vary depending on the machine’s design, material being processed, and desired purlin dimensions. However, typical production speeds range from 10 to 30 meters per minute, ensuring efficient and rapid production of C purlins for various construction applications.

What are the maintenance requirements for a C Purlin Roll Forming Machine?

Routine maintenance for a C Purlin Roll Forming Machine includes:

- Regular inspection of machine components for wear or damage b. Lubrication of moving parts, such as bearings and rollers, to reduce friction and wear

- Cleaning and maintenance of the hydraulic system to prevent contamination and maintain optimal performance

- Periodic calibration of the control system to ensure accurate purlin dimensions and consistent production

Are there any safety precautions to consider when operating a C Purlin Roll Forming Machine?

When operating a C Purlin Roll Forming Machine, follow these safety precautions:

- Wear appropriate personal protective equipment (PPE), such as safety glasses, gloves, and hearing protection.

- Ensure all machine guards and safety features are in place and functioning correctly.

- Train operators on proper machine operation, maintenance, and safety procedures.

- Keep the work area clean and free of debris to prevent accidents.

- Implement a lockout/tagout procedure when performing maintenance or repairs to ensure the machine is powered off and cannot be accidentally activated.

What factors should I consider when comparing different C Purlin Roll Forming Machine manufacturers?

When comparing different C Purlin Roll Forming Machine manufacturers, consider the following factors:

- Experience and expertise: Assess the manufacturer’s industry experience, technical knowledge, and understanding of customer requirements to ensure they can provide a high-quality, reliable machine.

- Quality and performance: Evaluate the machine’s build quality, durability, and production capabilities to ensure it meets your specific needs.

- Customization options: Determine if the manufacturer offers customizable features or designs to accommodate unique production requirements.

- After-sales support and service: Confirm the manufacturer provides responsive support for troubleshooting, maintenance, and spare parts to minimize downtime and maintain optimal performance.

- Customer reviews and testimonials: Research customer feedback and reviews to gain insight into the manufacturer’s reputation and the quality of their products and services.

Auto Size Changeable C U Purlin Roll Forming Machine

Our auto size changeable C/U purlin roll forming machine produces high-quality C and U shape purlins, with width ranging from 80-300mm and material thickness of 1.5-3mm. It’s versatile, easy to operate, and requires minimal maintenance.We offer high-quality equipment & after-sales

High Speed C Purlin Machine

High Speed C Purlin Machine Features High Speed C Purlin Machine is designed for the high production capacity requirements. And the speed can be more than 40m/min Applications The finished products are widely used for building construction and PV solar mounting

Full automatic C purlin roll forming machine quick-change

Full automatic quick-change C purlin roll forming machine Name:C Size Auto Change Machine Model:YX Series The C size auto change roll forming machine for C purlin profile is designed for the purpose of automatic size changing via both frames being

C purlin roll forming machine price

Features The C shaped purlin formed by C purlin roll forming machine has excellent anti-bending property and are easy to install. Machine adopt cast iron structure, which will increase the strength of the machine. The processing of Punching & Cutting

Auto Size Changeable C U Purlin Roll Forming Machine

Our auto size changeable C/U purlin roll forming machine produces high-quality C and U shape purlins, with width ranging from 80-300mm and material thickness of 1.5-3mm. It’s versatile, easy to

High Speed C Purlin Machine

High Speed C Purlin Machine Features High Speed C Purlin Machine is designed for the high production capacity requirements. And the speed can be more than 40m/min Applications The finished products

Full automatic C purlin roll forming machine quick-change

Full automatic quick-change C purlin roll forming machine Name:C Size Auto Change Machine Model:YX Series The C size auto change roll forming machine for C purlin profile is designed for

C purlin roll forming machine price

Features The C shaped purlin formed by C purlin roll forming machine has excellent anti-bending property and are easy to install. Machine adopt cast iron structure, which will increase the

Recent Update

The Ultimate Guide to Steel Roofing Sheets

Steel roofing sheets are a versatile, durable, and increasingly popular choice for roofing solutions. Whether you’re looking to replace your existing roof or installing a new one, steel roofing sheets

Roll Forming Systems

Overview of Roll Forming Systems Roll forming systems are an essential part of modern manufacturing, particularly in the production of metal components. These systems transform metal sheets into specific shapes

Roll Forming Machinery

Overview of Roll Forming Machinery Roll forming machinery is the cornerstone of modern metalworking, transforming flat metal sheets into complex profiles through a continuous bending process. These machines are integral

Why Sunway

The Global Leader In Roll forming Industry

We pay meticulous attention to each detail from raw material to delivery. It is throughout our constantly effort that our customers get the consistently high level quality products they have to look for. We always make efforts to cut the cost at the same time improve the technological content of products in order to enhance the market competitiveness of the products. In the related diversification development, we increase investment and enhance development of key products and key projects continuously make breakthroughs in technology and product function, to rank at the advanced level in the market.

Providing Innovative Roll forming Machine Solution

- We Use Advance Manufacturing Process

- Provide Unique Technology

- Group Of Certified & Experienced Team

- The Best Services For Multiple Industries

100+

Destination Countries

500+

Finished Project

We are worth your trust

Some Of Our main Advantages

We Own Factory

We have our own factory since established, and with the development, our factory is getting bigger and bigger, and the production capacity of the factory is getting higher and higher. There is no trader between us, which means that we can achieve the most satisfactory level in terms of price, MOQ and product customization services.

Fair Price

We are a cold roll forming machine factory, not a trading company, which means there is no middleman between us. The relationship between you and us is direct, which saves you both money and hassle. The production process of Yupai factory reduces the burden of machinery costs, which minimizes the price on each individual unit. We can give you extremely competitive prices.

Flexible

You can tell us your budget & ideal profile drawing, and we can provide the most suitable solution for you. Sunway will cooperate to ensure you get the best bang for your buck. In accordance with High Quality Assurance and Valued Credibility, we provide customers high qualified and reliable products with complete after-sales service.

One-Stop

Here at Sunway, we have a multitude of cold roll forming machine products to choose from. Our machines feature beautiful appearance, long service life, good performance, and so on. We offer a truly one-stop shopping service. Sunway have years of knowledge in this industry, and are willing to guide you along your way, all while guaranteeing you the best quality goods.

Customer Support

Most factories primarily focus only on manufacturing, which leads to a lacking of sales and service awareness. Sunway have our own sales team, technicians and after-sales staff, which means that not only can we provide faster and better-quality service.

Serve All Customer

Whether it is a customer who has just stepped into the cold roll forming machine industry or a customer who has developed into a large scale, Sunway attach the same importance. We care about the experience of all customers.