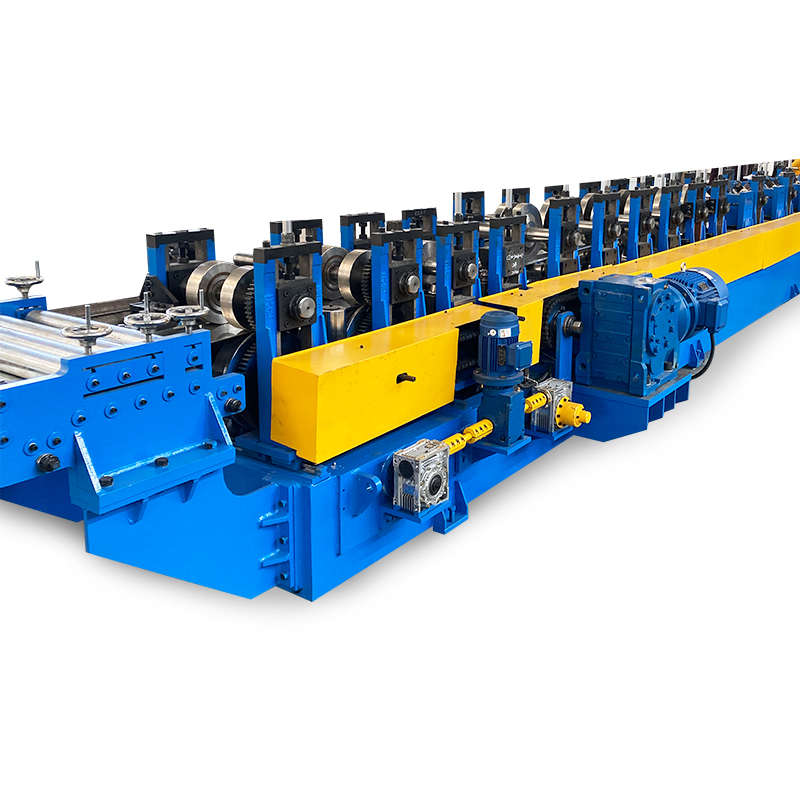

Manufacturing efficiency is critical for businesses looking to stay competitive in today’s fast-paced global marketplace. One way to improve efficiency is by incorporating the use of C channel roll forming machines into your manufacturing process. These machines are designed to produce high-quality C channels in a continuous process, resulting in increased productivity and reduced labor costs. In this post, we’ll explore the various ways C channel roll forming machines can improve your manufacturing efficiency and help your business thrive.

Customization of C channel roll forming machines

One of the most significant benefits of using C channel roll forming machines is their ability to be customized to meet specific manufacturing needs. These machines can be programmed to create different shapes and sizes of C channels, making them incredibly versatile and adaptable to a variety of manufacturing processes.

The customization process starts with designing the specific C channel shape needed for the manufacturing process. Once the design is complete, the machine can be programmed to produce the exact shape and size required. This flexibility means that manufacturers can create a wide range of C channel products to meet their customers’ unique needs and specifications.

Moreover, C channel roll forming machines can produce complex shapes with high precision, which would be difficult to achieve with traditional manufacturing methods. This precision also ensures that the resulting C channels are consistent in size and shape, reducing waste and saving on material costs.

In addition to customization for shape and size, C channel roll forming machines can also be customized for various types of materials, including steel, aluminum, and copper. This versatility in material options allows manufacturers to create C channels with varying strengths, weights, and other properties that are essential for different applications.

In conclusion, the ability to customize C channel roll forming machines to meet specific manufacturing needs is a significant advantage for businesses looking to improve their efficiency and productivity. With the versatility and precision of these machines, manufacturers can produce high-quality C channels that meet their customers’ unique needs and specifications, ultimately increasing their competitiveness in the market.

Durability of C channel roll forming machines

Another advantage of using C channel roll forming machines in manufacturing is their durability. These machines are designed to withstand high-volume production and harsh environments, making them a reliable and cost-effective solution for long-term manufacturing needs.

C channel roll forming machines are built with sturdy materials, such as steel and other high-strength alloys, which allow them to handle heavy loads and withstand the wear and tear of high-volume production. They are also designed with precision components that are built to last, reducing the need for frequent repairs or replacements.

Moreover, C channel roll forming machines are designed to operate continuously, which minimizes downtime and increases production efficiency. This feature is particularly important for manufacturers with large production volumes and tight deadlines, as it ensures that the production process runs smoothly without any interruptions.

In addition to their durability and continuous operation, C channel roll forming machines can also be equipped with various safety features to protect operators and ensure compliance with safety regulations. These features include sensors, alarms, and automatic shut-off mechanisms, among others.

Overall, the durability of C channel roll forming machines makes them an excellent investment for businesses looking to improve their manufacturing efficiency in the long term. With their ability to withstand high-volume production and harsh environments, these machines provide a reliable and cost-effective solution for meeting manufacturing needs.

Using C channel roll forming machines for Material Savings

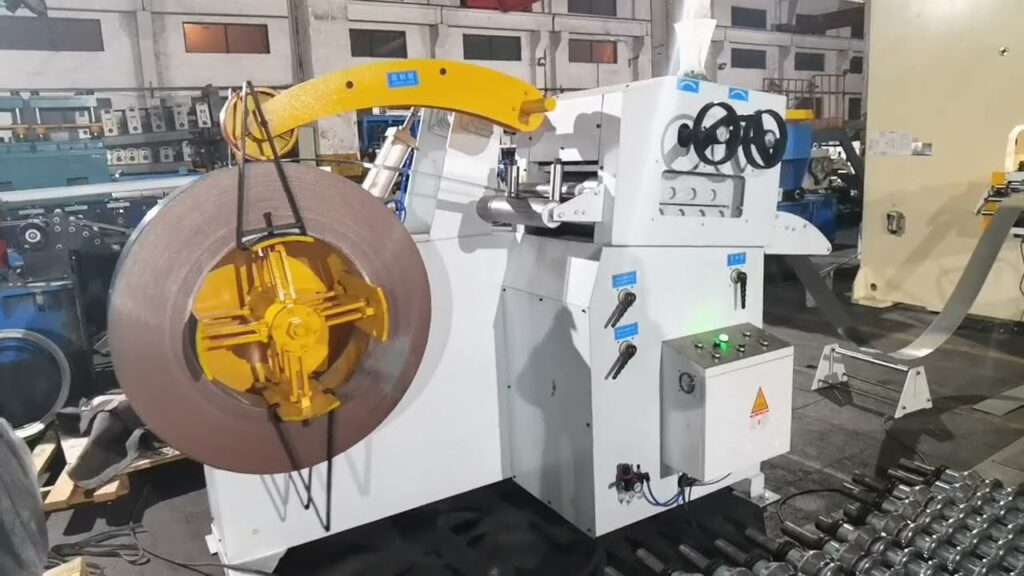

Another significant advantage of using C channel roll forming machines in manufacturing is the potential for material savings. These machines use a continuous process to create the desired shape, resulting in less waste and more efficient use of materials.

Traditional manufacturing methods, such as stamping and cutting, can result in significant material waste due to the use of large sheets of metal and the need to discard excess material. In contrast, C channel roll forming machines can create C channels from coils of metal, which reduces the amount of waste generated during the manufacturing process.

Moreover, the continuous process of C channel roll forming machines means that the same shape can be created multiple times without the need to stop and restart the process, reducing material waste even further. This results in significant cost savings, as less material is needed to produce the same number of C channels, reducing material costs and minimizing scrap.

Additionally, C channel roll forming machines can be programmed to optimize material usage by minimizing the amount of material needed for each product. By creating C channels with precise measurements, these machines ensure that the material is used efficiently, reducing waste and ultimately lowering material costs.

In conclusion, the use of C channel roll forming machines can help businesses save on material costs by minimizing waste and optimizing material usage. By using a continuous process to create the desired shape, these machines provide a more efficient and cost-effective solution for manufacturing C channels, ultimately improving the profitability of manufacturing operations.

Using C channel roll forming machines for Quality Control

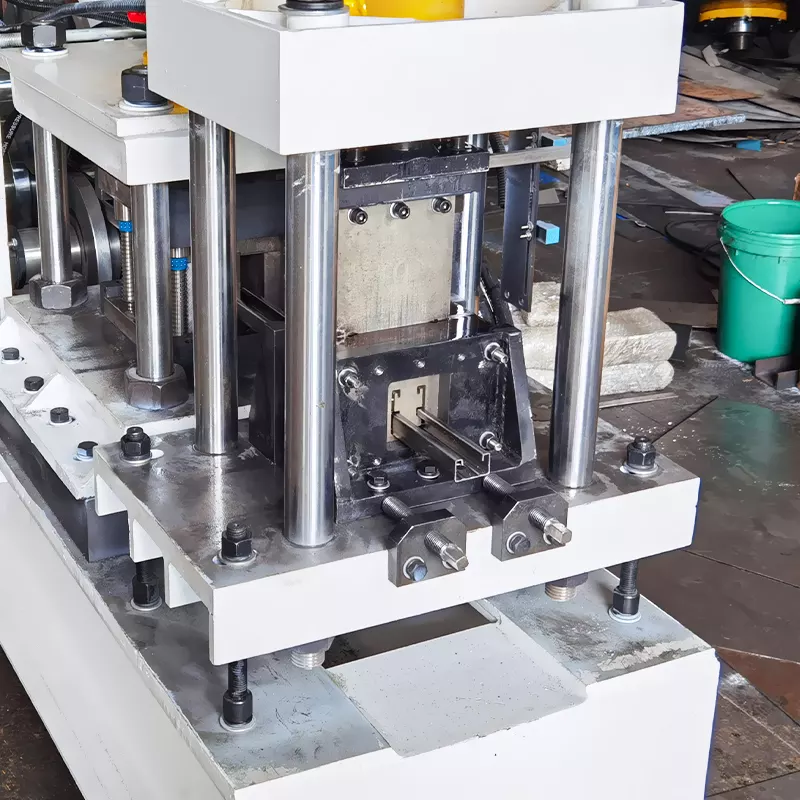

C channel roll forming machines can significantly improve quality control in manufacturing operations by producing consistent and accurate C channels every time. These machines are designed to create C channels with high precision and tight tolerances, ensuring that the resulting products meet the desired specifications and quality standards.

The continuous process used by C channel roll forming machines ensures that each C channel produced is identical to the previous one, with consistent dimensions, angles, and shapes. This level of consistency reduces the risk of defects or variations in product quality, ensuring that the final product is of high quality and meets the customer’s specifications.

Moreover, C channel roll forming machines can be programmed to produce C channels with high accuracy, ensuring that the resulting products are within the desired tolerances. This feature is particularly important for applications that require precise measurements, such as construction or automotive industries.

The use of C channel roll forming machines in manufacturing also reduces the risk of human error in the production process. With the automation provided by these machines, the risk of mistakes or variations in product quality due to human error is significantly reduced, further improving the quality of the final product.

In addition to consistent and accurate production, C channel roll forming machines can also be equipped with various sensors and monitoring systems to ensure that each product meets the desired quality standards. These systems can detect any variations or defects in the production process and alert operators to make any necessary adjustments, further improving the quality of the final product.

In conclusion, C channel roll forming machines can significantly improve quality control in manufacturing operations by producing consistent and accurate C channels every time. With the precision and automation provided by these machines, manufacturers can ensure that their products meet the desired specifications and quality standards, ultimately improving the competitiveness and profitability of their businesses.

In summary, C channel roll forming machines are an excellent investment for manufacturers looking to improve their efficiency and productivity. These machines can be customized to produce different shapes and sizes of C channels, allowing manufacturers to meet specific manufacturing needs. C channel roll forming machines are also durable, withstanding high-volume production and harsh environments, while providing material savings and quality control through consistent and accurate production. By incorporating C channel roll forming machines into their manufacturing process, businesses can increase their competitiveness and profitability while providing high-quality products to their customers.