Box profile cladding sheets have become increasingly popular in modern construction due to their durability, versatility, and cost-effectiveness. This guide dives deep into everything you need to know about box profile cladding sheets—from their types, applications, and installation process to comparisons with other cladding options. By the end, you’ll have all the details to make an informed choice.

What Are Box Profile Cladding Sheets?

Box profile cladding sheets are durable, corrugated metal sheets used as protective and aesthetic layers for buildings. Typically made of steel or aluminum, these sheets feature a “boxy” ribbed profile, offering enhanced structural integrity and modern appearance. They’re widely used for roofing and wall cladding in industrial, commercial, and agricultural buildings.

Why Choose Box Profile Cladding Sheets?

Box profile cladding sheets are preferred for their high strength-to-weight ratio, long-lasting finish, and low maintenance requirements. Available in various metal types and finishes, they can match different architectural styles and stand up against tough environmental conditions.

Types of Box Profile Cladding Sheets

Choosing the right box profile cladding sheet involves understanding the types available and how they differ. Let’s explore some popular models, materials, and their specific uses.

| Type of Box Profile Cladding Sheet | Material | Rib Height (mm) | Thickness (mm) | Best Use Case |

|---|---|---|---|---|

| BPC 32/1000 | Galvanized Steel | 32 | 0.5-1.2 | Agricultural buildings |

| BPC 40/1000 | Pre-coated Steel | 40 | 0.5-1.2 | Industrial wall cladding |

| BPC 45/1000 | Aluminum | 45 | 0.5-1.0 | Coastal applications |

| BPC 50/1000 | Stainless Steel | 50 | 0.6-1.5 | High-humidity environments |

| BPC 55/1000 | Color-Coated Zinc | 55 | 0.7-1.2 | Large-scale commercial roofing |

| BPC 60/1000 | Zincalume | 60 | 0.8-1.3 | Warehouses and storage facilities |

| BPC 65/1000 | Galvalume | 65 | 0.7-1.4 | Residential projects |

| BPC 70/1000 | Copper | 70 | 0.8-1.0 | High-end architectural projects |

| BPC 75/1000 | Powder-Coated Steel | 75 | 0.9-1.2 | Heavy-duty industrial applications |

| BPC 80/1000 | Painted Steel | 80 | 0.6-1.2 | Multi-use commercial cladding |

Corrugated Iron Sheets vs. Box Profile Cladding Sheets

While both corrugated iron sheets and box profile cladding sheets serve similar purposes, they differ in design and application. Corrugated sheets have a wavy profile, which may offer flexibility but lacks the structural rigidity of box profiles. In contrast, box profile sheets are sturdier and provide better load-bearing capabilities, making them suitable for robust industrial and agricultural uses.

Comparison of Key Features

| Feature | Corrugated Sheets | Box Profile Cladding Sheets |

|---|---|---|

| Structural Rigidity | Moderate | High |

| Load-Bearing Capacity | Lower | Higher |

| Appearance | Traditional | Modern |

| Installation Complexity | Easier | Moderate |

| Best For | Lightweight applications | Heavy-duty and long-lasting needs |

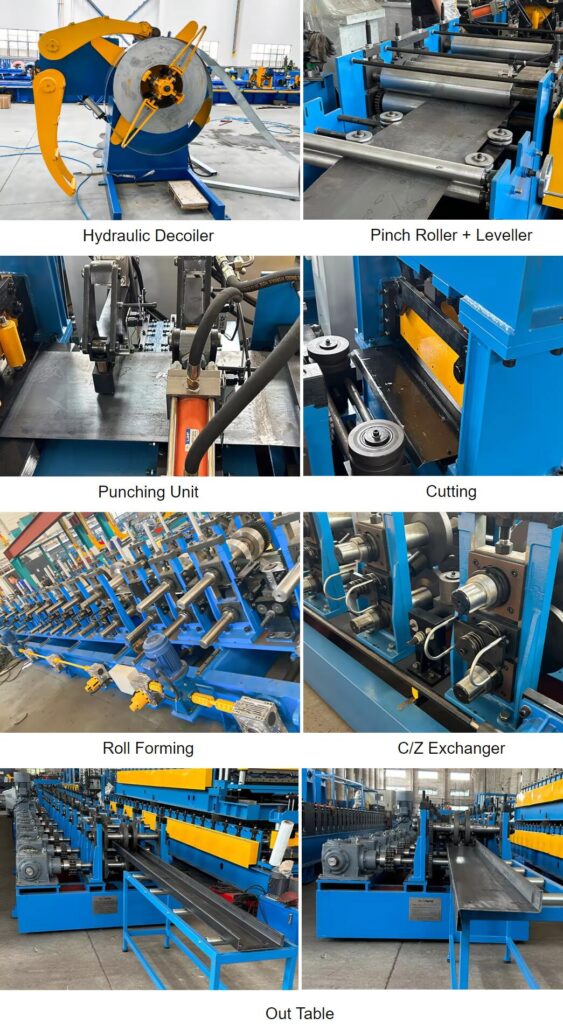

Working Process of Box Profile Cladding Sheets

The manufacturing process for box profile cladding sheets involves cutting, corrugating, and coating the metal to ensure longevity and resistance to weather. This step-by-step process ensures a high-quality product:

- Metal Selection: The process starts with selecting the appropriate metal (e.g., galvanized steel, aluminum) based on end-use.

- Corrugation Process: The metal sheets are fed through rollers to achieve the characteristic box-like ridges.

- Coating and Finishing: Finally, the sheets are coated with protective finishes, which may include powder coating, color-bonding, or galvanization, depending on requirements.

Key Components and Their Functions

| Component | Function |

|---|---|

| Base Metal | Provides the core strength of the sheet |

| Protective Coating | Enhances corrosion resistance |

| Box Profile Design | Adds structural integrity and visual appeal |

| Rib Height | Impacts load-bearing capacity and water drainage |

| Fastening Points | Secures the sheets in place, preventing movement |

-

Carriage Board Roll Forming Machine

Carriage Board Roll Forming Machine -

Highway Guardrail End Terminal Forming Machine

Highway Guardrail End Terminal Forming Machine -

Highway U/C Post Roll Forming Machine

Highway U/C Post Roll Forming Machine -

2 Waves Highway Guardrail Roll Forming Machine

2 Waves Highway Guardrail Roll Forming Machine -

3 Waves Highway Guardrail Roll Forming Machine

3 Waves Highway Guardrail Roll Forming Machine -

Vineyard Post Roll Forming Machine

Vineyard Post Roll Forming Machine -

Auto Size Changeable Sigma Purlin Roll Forming Machine

Auto Size Changeable Sigma Purlin Roll Forming Machine -

Auto Size Changeable C Z Purlin Roll Forming Machine

Auto Size Changeable C Z Purlin Roll Forming Machine -

Auto Size Changeable Z Purlin Roll Forming Machine

Auto Size Changeable Z Purlin Roll Forming Machine

Machine Speed and Efficiency

When producing box profile cladding sheets, efficiency is key. Modern machines allow high-speed production without sacrificing quality.

| Machine Type | Production Speed (m/min) | Efficiency |

|---|---|---|

| Standard Roll-Former | 15-25 | Moderate |

| High-Speed Roll-Former | 30-40 | High |

| Automated Roll-Former with Laser | 40-50 | Very High |

Applications and Uses of Box Profile Cladding Sheets

Box profile cladding sheets are widely used across several industries due to their robustness and versatility.

| Application | Use Case |

|---|---|

| Industrial Roofing | Factories, warehouses |

| Agricultural Cladding | Barns, livestock shelters |

| Residential Projects | Modern homes, garages |

| Commercial Buildings | Retail centers, office blocks |

| High-Humidity Environments | Swimming pools, spa buildings |

Installation, Operation, and Maintenance of Box Profile Cladding Sheets

Proper installation and maintenance are essential for the longevity of box profile cladding sheets.

| Process | Details |

|---|---|

| Installation | Requires specialized fasteners and precise alignment |

| Operation | Operate machines at recommended speeds for safety |

| Maintenance | Regular cleaning, especially in coastal or polluted areas |

Choosing the Right Supplier for Box Profile Cladding Sheets

Selecting a supplier involves several considerations, such as product quality, delivery speed, and customer service. Here’s a guide to help you choose:

| Supplier Criteria | Importance | Why It Matters |

|---|---|---|

| Quality of Materials | Very High | Ensures durability and reliability |

| Delivery Timelines | High | Reduces project delays |

| Customer Support | Moderate | Provides necessary assistance in case of issues |

| Price Range | High | Helps you stay within budget |

Comparing Pros and Cons of Box Profile Cladding Sheets

| Aspect | Advantages | Disadvantages |

|---|---|---|

| Durability | Highly durable, withstands harsh climates | Heavier compared to some materials |

| Cost | Cost-effective compared to alternatives | Initial installation may require expertise |

| Aesthetic Options | Modern look, available in various finishes | Limited flexibility in design |

FAQs

| Question | Answer |

|---|---|

| What is the average lifespan of a box profile cladding sheet? | Typically 20-30 years, depending on maintenance and environmental conditions |

| Are these sheets suitable for coastal areas? | Yes, especially aluminum and coated steel variants |

| Can box profile sheets be customized? | Yes, they can be ordered in custom sizes, colors, and finishes |

| Do they require any special maintenance? | Regular cleaning and inspection are recommended, particularly in salty environments |