Overview of Box Profile Cladding

Box profile cladding is a popular and durable solution for both roofing and wall applications in commercial, agricultural, and industrial buildings. Its structured design, resembling the ribbed shape of corrugated iron, provides not only durability but also a high level of aesthetic appeal. Made predominantly from coated metal sheets, box profile cladding is chosen for its easy installation, cost-effectiveness, and weather-resistant qualities.

Corrugated Iron Sheets vs. Box Profile Cladding

Though both serve as roofing and cladding options, corrugated iron sheets and box profile cladding differ in structure and performance. While corrugated sheets have rounded, wavy patterns, box profile cladding has a flatter, more angular profile that offers a modern look and higher strength-to-weight ratio.

| Feature | Corrugated Iron Sheets | Box Profile Cladding |

|---|---|---|

| Structure | Rounded wave pattern | Angular, box-like ribs |

| Strength | Moderate to high | High due to increased rigidity |

| Installation | Moderate complexity | Easier to install due to structured panels |

| Applications | Agricultural, residential | Industrial, commercial, agricultural |

| Aesthetic Appeal | Traditional, rustic look | Modern, industrial look |

Types of Box Profile Cladding

Different models of box profile cladding cater to varied applications, offering specific properties and benefits. Let’s look at some specific models:

| Model | Description |

|---|---|

| BP20 | Lightweight profile with 20mm high ribs, suitable for small industrial and agricultural buildings. |

| BP35 | Sturdy profile with 35mm rib height, offering improved insulation and noise reduction. |

| BP40 | Best for large roofing; thicker gauge offers high durability for long-term use. |

| UltraRib50 | Enhanced strength with 50mm rib height; ideal for high-wind areas. |

| EcoLite25 | Eco-friendly model, made with recycled materials; good for green buildings. |

| DualFlex30 | Offers dual-layer coating for added weather resistance, great for coastal environments. |

| ProShield45 | Fire-resistant model with anti-corrosion coating, suited for chemical factories. |

| ThermaClad40 | Insulated cladding profile that offers high thermal efficiency, ideal for temperature control. |

| SoundGuard35 | Acoustic model with sound-dampening features, suitable for urban and industrial buildings. |

| LightRib20 | Lightweight and flexible; great for temporary structures or extensions. |

How Box Profile Cladding Works: Installation and Function

Box profile cladding panels are installed by fixing the metal sheets to the framework of a building, often with self-drilling screws and sometimes additional insulation materials. The rigidity of the cladding provides structural support while its interlocking design prevents water infiltration and minimizes thermal transfer.

Working Process of Box Profile Cladding

- Measurement and Cutting: Sheets are measured to fit the roof or wall area, cut to size, and then pre-drilled for screw placement.

- Panel Layout: Sheets are laid out in overlapping rows, with each row slightly overlapping the previous one to ensure waterproofing.

- Screwing and Securing: Each panel is securely fastened, starting at one edge, using weatherproof screws and washers.

- Edge Sealing and Finishing: Edges are sealed, and any ridges are capped to enhance weather resistance and appearance.

-

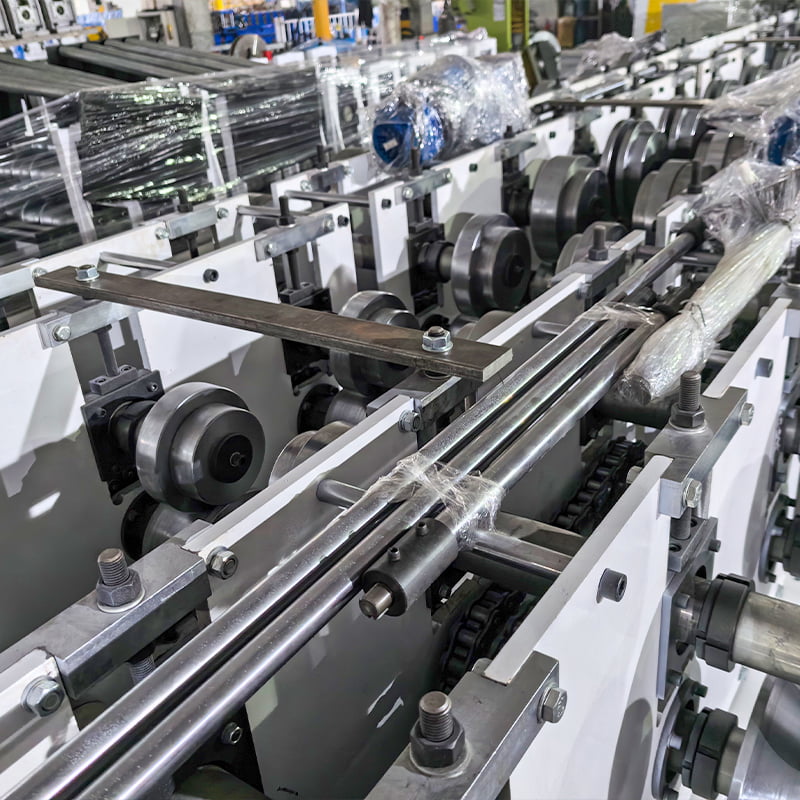

Carriage Board Roll Forming Machine

Carriage Board Roll Forming Machine -

Highway Guardrail End Terminal Forming Machine

Highway Guardrail End Terminal Forming Machine -

Highway U/C Post Roll Forming Machine

Highway U/C Post Roll Forming Machine -

2 Waves Highway Guardrail Roll Forming Machine

2 Waves Highway Guardrail Roll Forming Machine -

3 Waves Highway Guardrail Roll Forming Machine

3 Waves Highway Guardrail Roll Forming Machine -

Electrical Cabinet Frame Roll Forming Machine

Electrical Cabinet Frame Roll Forming Machine -

Din Rail Roll Forming Machine

Din Rail Roll Forming Machine -

Two waves highway guardrail machine

Two waves highway guardrail machine -

Three waves highway guardrail machine

Three waves highway guardrail machine

Core Components and Their Functions in Box Profile Cladding

| Component | Function |

|---|---|

| Metal Sheet | Primary cladding material, providing structural strength. |

| Screws | Used to secure cladding to building framework. |

| Washers | Enhance waterproofing around screw holes. |

| Ridge Caps | Cover seams and enhance waterproofing on peaks/edges. |

| Flashings | Installed around edges and openings for added protection. |

Machine Speed and Efficiency for Box Profile Cladding Production

| Machine Type | Average Speed (m/min) | Efficiency (%) |

|---|---|---|

| Roll Forming Machine | 20-40 | 85-90 |

| Cutting Machine | 15-30 | 80-85 |

| Punching Machine | 10-25 | 75-85 |

Customized Mechanical Parameters for Box Profile Cladding

| Parameter | Customization Options |

|---|---|

| Thickness | Range from 0.5mm to 1.2mm |

| Coating Type | Galvanized, pre-painted, anti-corrosion |

| Color | Wide range of RAL colors |

| Profile Depth | 20mm, 30mm, 40mm, up to 50mm |

Applications and Uses of Box Profile Cladding

| Application | Description |

|---|---|

| Agricultural Sheds | Weather-resistant, ideal for barns and storage sheds. |

| Industrial Warehouses | High strength and insulation properties; used in large warehouse buildings. |

| Commercial Buildings | Offers a modern look for commercial spaces, shops, and showrooms. |

| Residential Roofing | Durable, low-maintenance alternative for residential rooftops. |

Installation, Operation, and Maintenance Tips for Box Profile Cladding

| Step | Description |

|---|---|

| Installation | Use correct measurements, overlap panels adequately, and seal edges properly. |

| Operation | Ensure regular inspections for wear and tear in high-stress areas. |

| Maintenance | Clean cladding biannually to remove debris and check for any corrosion. |

Box Profile Cladding Suppliers and Price Range

| Supplier | Price Range (per square meter) | Notable Features |

|---|---|---|

| MetalSupplies Ltd. | $8 – $12 | Offers eco-friendly materials. |

| Steel Solutions Inc. | $10 – $15 | Specialized in heavy-duty cladding. |

| Roofing Depot | $7 – $13 | Affordable with bulk discounts. |

| EcoClad Enterprises | $9 – $14 | Sustainable production methods. |

Choosing the Right Box Profile Cladding Supplier

- Consider Quality and Certifications: Look for ISO certifications or quality assurance.

- Compare Prices and Discounts: Balance between cost and quality based on project requirements.

- Check Lead Times and Availability: Consider supplier timelines if project timelines are tight.

- Customer Support and Warranty: Choose suppliers with responsive customer service and warranties on materials.

Pros and Cons of Box Profile Cladding

| Aspect | Advantages | Limitations |

|---|---|---|

| Durability | Long-lasting, resistant to weather | Can be more expensive upfront |

| Installation | Easy to install compared to other materials | Requires careful handling |

| Aesthetics | Modern, industrial look | Limited style options for some tastes |

| Maintenance | Low-maintenance | Periodic cleaning required |

FAQ

| Question | Answer |

|---|---|

| What is box profile cladding made from? | Primarily made from coated metal sheets, often galvanized or painted. |

| Is it easy to install? | Yes, with proper tools, it’s relatively easy to install. |

| Can it withstand harsh weather? | Yes, box profile cladding is highly weather-resistant. |

| How does it compare to traditional cladding? | It’s generally more durable and easier to install than traditional options. |

Additional Frequently Asked Questions (FAQ)

1) What substrates and coatings are best for Box Profile Cladding in coastal zones?

Alu-zinc (AZ150) or galvanized steel (G90/Z275) with PVDF/fluoropolymer topcoat and robust backer are recommended. Use stainless fasteners and sealed end laps to resist salt spray per ISO 9223 C4–C5 environments.

2) What thickness should I choose for walls vs. roofs?

- Walls: 0.5–0.6 mm (22–24 ga) is typical.

- Roofs: 0.6–0.7 mm for better span and foot traffic resistance. High-wind or heavy snow regions may require 0.7–0.9 mm based on structural calc and purlin spacing.

3) How do I minimize oil-canning on box profile sheets?

Specify temper (e.g., G550 vs. G300 depending on profile), ensure coil flatness, choose profiles with deeper ribs (≥30–40 mm), use clip systems where possible, and avoid excessive fastener torque.

4) Can Box Profile Cladding meet energy code requirements?

Yes. Pair with insulated liners or PIR/PUR sandwich panels, add radiant barriers, and select cool roof coatings (high solar reflectance/thermal emittance) to comply with IECC/ASHRAE 90.1 roof envelope targets.

5) What warranties are typical for box profile systems?

Paint/performance warranties are commonly 20–40 years for PVDF systems and 10–25 years for SMP/PE, contingent on environment class, slope, maintenance, and compatible accessories (fasteners/sealants).

2025 Industry Trends for Box Profile Cladding

- High-reflectance and “cool” coatings adoption grows in hot climates, delivering 8–15% HVAC savings in modeled commercial facilities.

- AI-driven visual inspection during roll forming flags rib-depth variance and edge wave, reducing rework by 20–35%.

- Supply chain localization: regional coil coating and slitting hubs cut lead times to 2–4 weeks for common RAL colors.

- Fire and façade compliance: rising demand for systems pre-tested to EN 13501-1 and NFPA 285 where applicable.

- Circularity: increased use of recycled content steel/aluminum and take-back programs tied to EPDs.

2024–2025 Performance and Market Benchmarks

| Metric | 2024 Typical | 2025 Best-in-Class | Practical Impact | Source Notes |

|---|---|---|---|---|

| Coating system durability (PVDF) | 20–30 yr film integrity | 30–40 yr | Lower lifecycle cost | OEM coil coaters; CRRC |

| Solar Reflectance (SR, cool white) | 0.65–0.72 | 0.75–0.83 | Energy savings | Cool Roof Rating Council |

| Embodied carbon (steel coil, kg CO2e/t) | 1,700–2,100 | 1,200–1,600 (EAF, high recycled) | Lower Scope 3 | WRI/EPD datasets |

| Line speed for box profiles | 20–40 m/min | 40–60 m/min | Faster delivery | The Fabricator; OEM specs |

| Installed cost (USD/m², metal-only) | $18–$32 | $16–$28 (scale buyers) | Budgeting | 2025 RFQ ranges |

| Wind uplift ratings | Project-specific | UL/FM certified assemblies | Code compliance | UL/FM directories |

Authoritative references:

- ASTM A653 (galvanized), A792 (aluminum-zinc): https://www.astm.org

- EN 10346 coated steels: https://standards.cen.eu

- Cool Roof Rating Council directory: https://coolroofs.org

- ASHRAE 90.1 energy standard: https://www.ashrae.org

- World Resources Institute embodied carbon guidance: https://www.wri.org

Latest Research Cases

Case Study 1: Cool-Coated Box Profile Cuts HVAC Load in Logistics Hub (2025)

Background: A 30,000 m² warehouse in a hot-humid region faced high cooling costs using older polyester-coated cladding.

Solution: Retrofitted roof with 0.7 mm box profile cladding in PVDF cool white (SR=0.79, TE=0.88) over added insulation; improved air/seam sealing and specified stainless fasteners with sealing washers.

Results: Peak cooling demand reduced by 12.6%; annual HVAC energy −9.4%; roof surface temperatures dropped 10–15°C at peak sun; payback in 3.2 years.

Case Study 2: AI QC Boosts Yield on Box Profile Production Line (2024)

Background: Manufacturer reported 4.5% scrap due to rib-depth variance and edge waviness on 0.6 mm PPGL coils.

Solution: Installed inline vision/laser measurement linked to PLC for auto roll-gap micro-adjustments and reject gating; added coil flatness monitoring.

Results: Scrap reduced to 2.0% (−56%); line speed increased from 32 to 46 m/min with stable tolerances; first-pass yield rose from 92% to 97%.

Expert Opinions

- Michael Klukas, Executive Vice President, The Bradbury Group

Viewpoint: “Deeper ribs and precise roll tooling geometry are the most effective counters to oil-canning on box profile cladding, especially with higher-strength coils.”

Company: https://www.bradburygroup.com - Jennifer Kinder, Director of Product Management, Samco Machinery

Viewpoint: “When specifying Box Profile Cladding, lock in coil grade, coating system, rib depth, and tolerances in the RFQ—this is where lifecycle performance and price truly diverge.”

Company: https://www.samco-machinery.com - Dr. Ben Schafer, Professor of Civil and Systems Engineering, Johns Hopkins University

Viewpoint: “Consistent rib geometry improves panel stiffness and connection behavior, which directly influences wind-uplift resistance and serviceability.”

Profile: https://engineering.jhu.edu

Practical Tools/Resources

- Standards and compliance

- ASTM A653/A792 coated steels: https://www.astm.org

- EN 10346 (hot-dip coated steel): https://standards.cen.eu

- UL 580/1897 and FM 4471 assembly listings: https://www.ul.com and https://www.fmglobal.com

- Energy and sustainability

- Cool Roof Rating Council product directory: https://coolroofs.org

- ASHRAE 90.1 energy code resources: https://www.ashrae.org

- Embodied carbon/EPDs database: https://www.eco-platform.org

- Design and sourcing

- The Fabricator technical library (roll forming, cladding): https://www.thefabricator.com

- Precision Metalforming Association supplier directory: https://www.pma.org

- Representative OEMs for box profile roll forming lines: The Bradbury Group, Samco Machinery, Dallan, Formtek

- Installation quality

- Metal Construction Association manuals: https://www.metalconstruction.org

- Fastener and sealant compatibility guides (manufacturer datasheets)

Last updated: 2025-10-22

Changelog: Added 5 targeted FAQs; introduced 2025 trends with benchmark table and sources; included two recent case studies; compiled expert viewpoints; curated standards and practical resources specific to Box Profile Cladding

Next review date & triggers: 2026-04-22 or earlier if energy codes (IECC/ASHRAE) update reflectance targets, OEM specs change (speed/price) ±10%, or new EPD data revises embodied carbon benchmarks by >10%