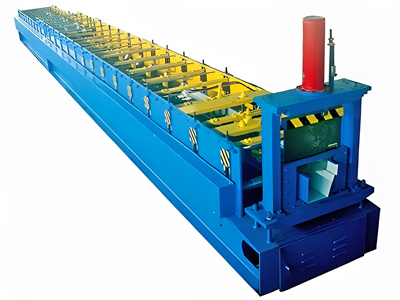

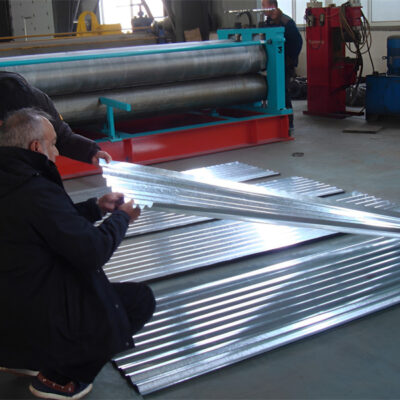

Gutter Roll Forming Machine Features:

We are not only offer customers a wonderful gutter roll forming machine for making, but also the abundant experience, precision making, stable automatic manufacture by hydraulic power, hi-tech control system, and our enthusiasm.

Applications

The products produced by the gutter roll forming machine is widely used in factory, workshop, garage, warehouse, locomotive shed, hanger, exhibition building, cinema, theatre, stadium, garden etc.

Process Flow

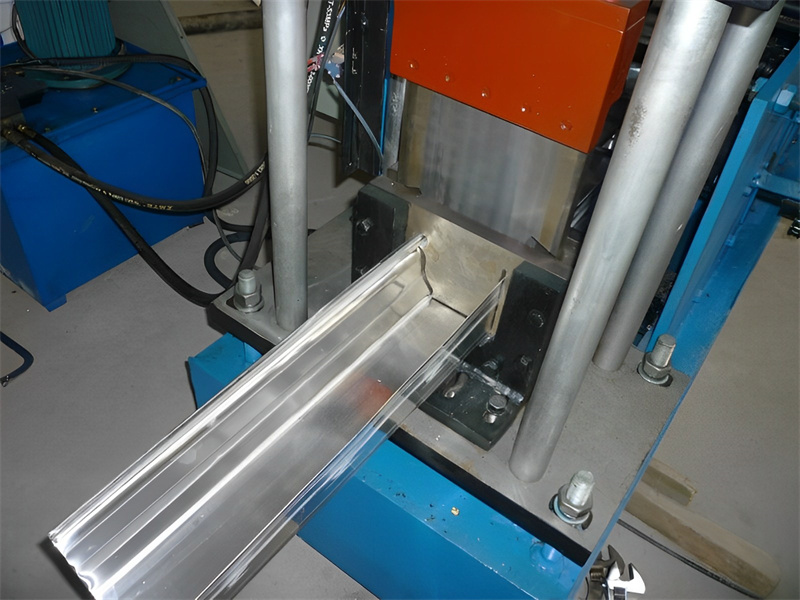

Uncoiler — Feeding — Roll Forming — Cutting — Exit Rack

Machine Configurations

| 1. Uncoiler |

2. Feeding Device

|

| 3. Roll Forming Machine |

4. Hydraulic Cutting

|

| 5. PLC Control System | 6. Exit Rack |

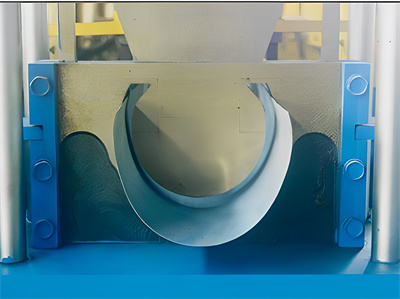

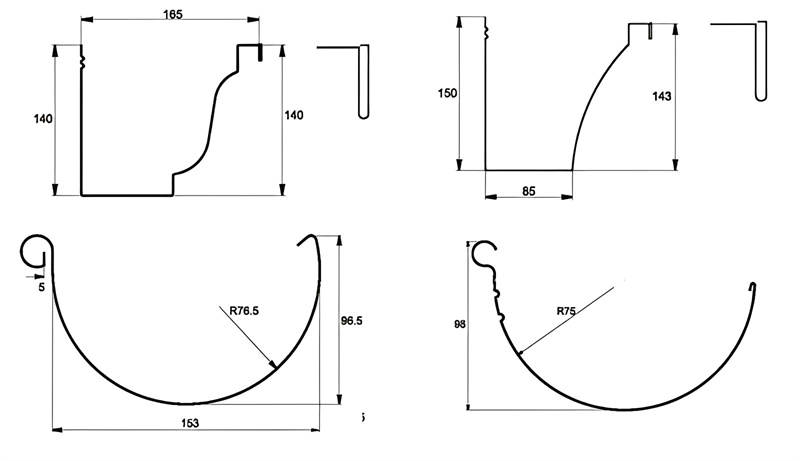

Profile Drawings for Reference

type of gutter roll forming machine

There are several types of gutter roll forming machines used in the manufacturing industry. The specific type of machine used may depend on the desired shape and size of the gutter, as well as the production requirements. Here are some common types of gutter roll forming machines:

- K-Style Gutter Roll Forming Machine: This type of machine is used to produce K-style gutters, which are commonly used in residential and commercial buildings. K-style gutters have a flat bottom and a decorative shape on the front.

- Half-Round Gutter Roll Forming Machine: This machine is designed to produce half-round gutters, which have a semicircular cross-section. Half-round gutters are often used in historical or architectural applications.

- Box Gutter Roll Forming Machine: Box gutters are typically used for industrial or commercial buildings with large roof areas. A box gutter roll forming machine is used to produce gutters with a rectangular or square shape, allowing for greater water capacity.

- Fascia Gutter Roll Forming Machine: Fascia gutters are integrated into the roofline, typically hidden behind the fascia board. This type of machine is used to produce gutters that blend seamlessly with the building’s exterior.

- Custom Gutter Roll Forming Machines: Depending on specific requirements, custom roll forming machines can be designed and manufactured to produce gutters with unique shapes or profiles.

These are just a few examples of gutter roll forming machines. The actual type of machine used may vary based on the manufacturer, region, and specific industry needs.

Which fields are the main applications of rain gutter roll forming machine?

The main application of a rain gutter roll forming machine is in the field of construction and building materials. It is specifically designed to manufacture rain gutters, which are essential components of residential and commercial buildings for effective water drainage.

Here are the main fields where rain gutter roll forming machines are commonly used:

- Construction Industry: Rain gutters are crucial for managing rainwater and preventing water damage to buildings. The construction industry extensively utilizes rain gutter roll forming machines to produce gutters of various sizes, shapes, and materials, such as aluminum, steel, or PVC.

- Roofing Contractors: Roofing contractors often require rain gutter roll forming machines to complement their services. They can fabricate custom rain gutters on-site to match the specific requirements of each roofing project, ensuring proper water management and drainage.

- Building Material Manufacturers: Manufacturers specializing in building materials, such as metal fabrication companies, utilize rain gutter roll forming machines to produce rain gutters on a larger scale. These gutters can be supplied to construction companies, contractors, or sold directly to the market as ready-made products.

- Home Improvement and Renovation: Rain gutter roll forming machines also cater to the home improvement and renovation sector. Contractors or homeowners looking to replace or install new gutters can benefit from the customizability and efficiency offered by these machines.

- Sheet Metal Fabrication: Rain gutter roll forming machines are often utilized in sheet metal fabrication processes. These machines can produce gutters with precise dimensions, shapes, and profiles, meeting the specific requirements of architects, engineers, and contractors.

Overall, the primary application of rain gutter roll forming machines lies within the construction industry and related sectors where the production of rain gutters is essential for effective water management and building protection.

How to choose water gutter roll forming machine?

When choosing a water gutter roll forming machine, there are several factors to consider to ensure you select the right machine for your needs. Here are some key points to consider:

- Gutter Profile: Determine the specific gutter profile you require, such as K-style, half-round, box gutter, or custom profiles. Make sure the machine you choose can produce the desired gutter profile accurately and consistently.

- Material Compatibility: Consider the types of materials you will be working with, such as aluminum, steel, or copper. Ensure that the machine is compatible with the materials you plan to use and can handle the required thickness and width.

- Production Capacity: Assess your production requirements in terms of the volume of gutters you need to manufacture within a specific time frame. Choose a machine with the appropriate speed and capacity to meet your production needs.

- Machine Flexibility: Determine if you will be producing gutters of various sizes and profiles. Look for a machine that offers flexibility in terms of adjusting the gutter dimensions easily to accommodate different customer requirements.

- Quality and Accuracy: Ensure that the machine is capable of producing gutters with high precision and consistent quality. Look for features such as sturdy construction, precision components, and advanced control systems that contribute to accurate and reliable production.

- Customization Options: If you have specific requirements or unique gutter profiles, consider whether the machine can be customized or adapted to meet your specific needs. Some manufacturers may offer customization options or additional tooling options for different gutter profiles.

- After-Sales Support and Service: Research the reputation of the manufacturer and their customer support services. Look for a reliable supplier that offers technical support, training, spare parts availability, and warranty coverage for the machine.

- Cost and Return on Investment: Compare the prices of different machines while considering the features, quality, and support offered. Evaluate the potential return on investment based on the expected production output and the market demand for the gutters you will be manufacturing.

By considering these factors and conducting thorough research, you can make an informed decision and choose a water gutter roll forming machine that suits your specific requirements and offers long-term value for your business.

How Does Gutter Roll Forming Machine Work And What Are Its Benefits?

Reviews

There are no reviews yet.