Steel decking has become a vital element in construction projects, offering superior strength and versatility. Understanding the dimensions of steel decks is crucial to select the right materials for your project. Whether you’re working on commercial buildings, residential spaces, or industrial sites, steel decking provides an efficient solution for creating robust floor and roof systems. But, what exactly goes into steel decking? How are the dimensions measured, and what variations should you know about? Let’s dive into the world of steel decks to explore their dimensions, types, and how they work.

Overview of dimensions of steel decks

Steel deck dimensions refer to the size, thickness, and other measurements of steel decking panels used in construction projects. These decks are typically made from corrugated steel sheets, which are shaped into ridges and grooves for extra strength and rigidity. Steel decking is mainly used in flooring systems, roofing structures, mezzanines, and as forms for concrete slabs.

When selecting steel decking, understanding the various dimensions and how they impact the functionality of your project is crucial. Several factors such as thickness, width, rib height, and overall depth define the quality and usability of the steel deck.

Key Benefits of Steel Decking

- Strength-to-weight ratio: Steel decks are lightweight yet incredibly strong, making them easy to transport and install without sacrificing durability.

- Flexibility in design: Steel decks come in a range of sizes and shapes, allowing customization based on the specific needs of your project.

- Cost-effectiveness: Compared to other flooring or roofing materials, steel decking is more affordable in terms of both material and labor costs.

- Fire resistance: Steel, by nature, is non-combustible, which adds a layer of fire safety to the structure.

- Sustainability: Steel is highly recyclable, making it an eco-friendly choice.

Now, let’s delve into the core aspects of steel deck dimensions to better understand their working process, key components, and how they fit into various construction applications.

Corrugated Steel Sheets: A Guide

Corrugated steel sheets are commonly used for steel decking due to their wave-like design, which enhances strength and load-bearing capacity. These sheets are fabricated by passing flat steel sheets through a series of rollers, forming a pattern of ridges and valleys. Corrugated sheets are often galvanized or coated with a protective layer to prevent rust and corrosion.

How Corrugated Steel Sheets Are Made

The manufacturing process begins with rolling out steel coils into flat sheets. These sheets are then passed through a series of shaped rollers to form the corrugated profile. After this, the steel sheets may undergo galvanization or coating processes, where they are dipped in zinc or other protective materials.

The dimensions of corrugated steel sheets vary depending on the thickness (measured in gauges), rib height, and overall width of the panel. These factors influence the sheet’s load capacity, making it critical to select the right dimensions based on your structural needs.

Types of Steel Decks and Their Dimensions

Steel decks come in various types, each designed to serve specific purposes. Below is a table showcasing the different types of steel decks and their common dimensions.

| Type of Steel Deck | Rib Height (inches) | Thickness (Gauge) | Width (inches) | Uses |

|---|---|---|---|---|

| Form Decking | 1.5 | 22 to 16 | 36 to 48 | Used as a form for concrete floors |

| Composite Decking | 2 to 3 | 18 to 20 | 36 to 48 | Provides additional reinforcement |

| Roof Decking | 1 to 1.5 | 20 to 22 | 36 to 42 | For creating roof systems |

| Cellular Decking | 2 to 3 | 16 to 18 | 36 to 48 | Offers concealed spaces for wiring |

| Deep Decking | 3 to 4.5 | 16 to 20 | 36 to 48 | High-strength for large span structures |

| Acoustic Decking | 2 to 3 | 18 to 22 | 36 to 48 | Sound-dampening for acoustically sensitive spaces |

Each type of decking has its specific applications. For example, composite decking is often chosen for floors that require extra load-bearing capacity, while roof decking is more suited for roofing systems due to its ability to support insulation and roofing materials.

Working Process of Steel Deck Dimensions

The working process for selecting and installing steel deck dimensions involves several steps. Here’s an overview of the workflow, starting from selecting the appropriate type of steel deck to installation.

Step 1: Determine Load Requirements

The first step in choosing the correct steel deck dimensions is to assess the load requirements of your project. This includes both the dead load (the weight of the deck and other permanent structures) and the live load (the weight of people, furniture, or equipment).

Step 2: Select the Type of Decking

Based on the load requirements, you will select the appropriate type of decking—whether it’s form decking for concrete flooring, composite decking for reinforced structures, or roof decking for roofing systems.

Step 3: Measure and Calculate Dimensions

Once the type is selected, the next step is to determine the right dimensions. Factors to consider include:

- Thickness: Thicker steel decks provide more strength but are heavier.

- Width: Wider panels cover more area but may require additional supports.

- Rib Height: Taller ribs improve the deck’s load-bearing capacity.

Step 4: Install the Steel Decking

Installation involves laying the steel decking across support beams, ensuring that the panels overlap properly for added strength. The decking is then fastened using mechanical fasteners or welding techniques.

Step 5: Add Concrete or Roofing Materials

For floors, concrete is poured over the steel decking to form a composite slab. For roofs, insulation and waterproofing materials are applied over the steel deck.

-

Electrical Cabinet Frame Roll Forming Machine

Electrical Cabinet Frame Roll Forming Machine -

Din Rail Roll Forming Machine

Din Rail Roll Forming Machine -

Cable Ladder Roll Forming Machine

Cable Ladder Roll Forming Machine -

PV Mounting Bracket C Shape Profile Roll Forming Machine

PV Mounting Bracket C Shape Profile Roll Forming Machine -

Cable Tray Roll Forming Machine

Cable Tray Roll Forming Machine -

Light Keel Wall Angle Roll Forming Machine Protector Corners Wall Angle Forming Machine

Light Keel Wall Angle Roll Forming Machine Protector Corners Wall Angle Forming Machine -

Light Keel Corner Bead Making Machine V Keel Angle Iron Roll Forming Machine

Light Keel Corner Bead Making Machine V Keel Angle Iron Roll Forming Machine -

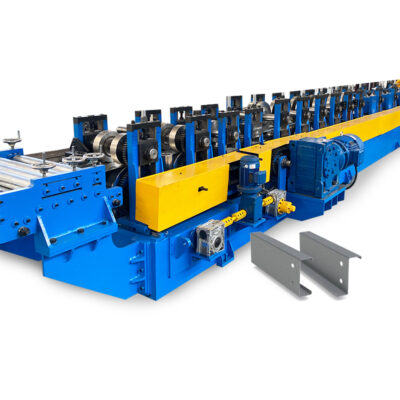

Full Automatic C Z Purlin Machine Steel Metal Former Frame & Purlin Machines

Full Automatic C Z Purlin Machine Steel Metal Former Frame & Purlin Machines -

Fully Automatic Hydraulic Easy Operation 80-300 Adjustable C Purlin Making Machine Roll Forming Machinery

Fully Automatic Hydraulic Easy Operation 80-300 Adjustable C Purlin Making Machine Roll Forming Machinery

Key Components of Steel Deck and Their Functions

When working with steel decks, understanding the key components and their functions will help ensure a successful installation. Below is a detailed table highlighting these components.

| Component | Function |

|---|---|

| Steel Sheets | Base material for the decking, providing the primary strength and rigidity. |

| Ribs | Corrugated ridges that increase the deck’s load-bearing capacity and structural integrity. |

| Fasteners | Bolts, screws, or welds used to secure the steel deck to the supporting structure. |

| Concrete (for floors) | Creates a composite slab when poured over steel decking, adding strength and stability. |

| Insulation (for roofs) | Provides thermal and sound insulation, enhancing energy efficiency. |

| Welded Studs | Used in composite decking to connect steel decking with concrete, improving load transfer. |

Machine Speed and Efficiency in Steel Deck Fabrication

The manufacturing process for steel decks requires high-efficiency machines to ensure precise and quick production. The table below illustrates common machine parameters.

| Machine | Speed (m/min) | Efficiency (%) | Application |

|---|---|---|---|

| Roll Forming Machine | 10-20 | 85-90 | Used for creating corrugated profiles |

| Galvanizing Machine | 8-15 | 80-85 | Coating steel sheets with protective layers |

| Cutting Machine | 15-25 | 90-95 | Cutting steel decks to desired lengths |

Customizing Steel Deck Dimensions: Mechanical Parameters

In some cases, construction projects require steel decks with customized dimensions. Here are some mechanical parameters that can be adjusted during the manufacturing process.

| Parameter | Standard Value | Customizable Range |

|---|---|---|

| Thickness (Gauge) | 22 | 16 to 22 |

| Rib Height | 1.5 inches | 1 to 4 inches |

| Panel Width | 36 inches | 36 to 48 inches |

| Length | 10 feet | 6 to 20 feet |

Applications of Steel Decking

Steel decking finds its use in various construction projects, including floors, roofs, and mezzanines. Here is a detailed table showing common applications.

| Application | Type of Steel Deck | Advantages |

|---|---|---|

| Commercial Building Floors | Composite Decking | Provides strength and flexibility for high-load areas |

| Residential Roofs | Roof Decking | Lightweight and fire-resistant |

| Mezzanines | Cellular Decking | Allows for concealed spaces for electrical wiring |

| Parking Garages | Deep Decking | Supports heavy loads and long spans |

Installation, Operation, and Maintenance of Steel Decks

Proper installation and regular maintenance are crucial to ensuring the longevity of steel decks. The following table outlines installation, operation, and maintenance guidelines.

| Phase | Key Activities |

|---|---|

| Installation | Align and secure steel decks with fasteners or welds; ensure overlap for added strength |

| Operation | Ensure the deck supports the designed loads and inspect for signs of wear and tear |

| Maintenance | Clean and inspect for rust, repaint or re-galvanize if necessary |

Choosing the Right Supplier for Steel Decks

Selecting the right supplier can make a significant difference in your project’s success. Here’s what you should consider:

| Factor | Considerations |

|---|---|

| Reputation | Look for suppliers with strong reviews and a history of reliability |

| Customization Options | Ensure they offer custom sizing if your project requires non-standard dimensions |

| Delivery Speed | Ask about lead times to avoid project delays |

| Cost | Compare pricing across suppliers for the best value without sacrificing quality |

Supplier and Price Range Details

The table below highlights some top steel deck suppliers and their price ranges.

| Supplier | Price Range (per sq. ft.) | Notable Features |

|---|---|---|

| ABC Metal Roofing | $2.50 to $5.00 | Offers custom sizes and quick delivery |

| Steel Deck Direct | $3.00 to $6.50 | Specializes in large-span deep decking |

| Metal Deck Solutions | $2.75 to $5.25 | Provides galvanization and color options |

How to Choose the Best Steel Deck Supplier

When choosing the best supplier, it’s essential to weigh the pros and cons of each option. Consider factors such as cost, delivery times, customization, and customer service. Here’s a comparison between two leading suppliers:

| Supplier | Pros | Cons |

|---|---|---|

| ABC Metal Roofing | Affordable prices, fast delivery times | Limited selection of deep decking |

| Steel Deck Direct | High-quality products, excellent customer service | Slightly higher prices compared to competitors |

Advantages and Limitations of Steel Decking

Steel decking offers numerous advantages but also comes with some limitations.

| Advantages | Limitations |

|---|---|

| Strong, lightweight, and durable | Requires regular maintenance to prevent corrosion |

| Fire-resistant and eco-friendly | Higher initial cost compared to wood or concrete options |

| Customizable for various applications | May require additional insulation for thermal performance |

FAQ

| Question | Answer |

|---|---|

| What are the standard dimensions of steel decking? | Standard widths range from 36 to 48 inches, with thicknesses between 16 to 22 gauge. |

| How is steel decking installed? | Steel decks are installed by aligning them over support beams and fastening them with screws or welds. |

| Can steel decks be customized? | Yes, many manufacturers offer custom sizes to meet the specific requirements of a project. |

| What type of steel decking is best for roofing? | Roof decking, which is thinner and lightweight, is ideal for roofing applications. |

In conclusion, understanding the dimensions of steel decks is vital for the success of any construction project. From choosing the right type of deck to considering thickness, rib height, and width, steel decking offers versatility, strength, and durability across a variety of applications.