Overview

Metal sheet corrugated is a versatile and durable material widely used in construction and manufacturing industries. It provides strength, flexibility, and an aesthetically pleasing appearance, making it ideal for roofing, siding, and various other applications. This comprehensive guide will explore the intricacies of metal sheet corrugated, including types, manufacturing processes, key components, efficiency metrics, and much more.

Roll Forming Machine Guide

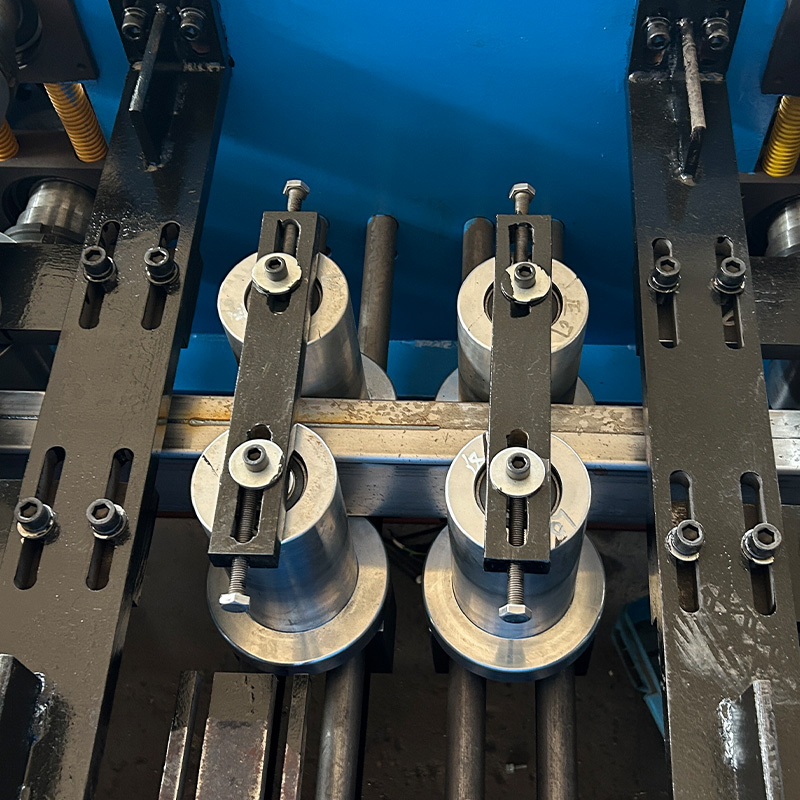

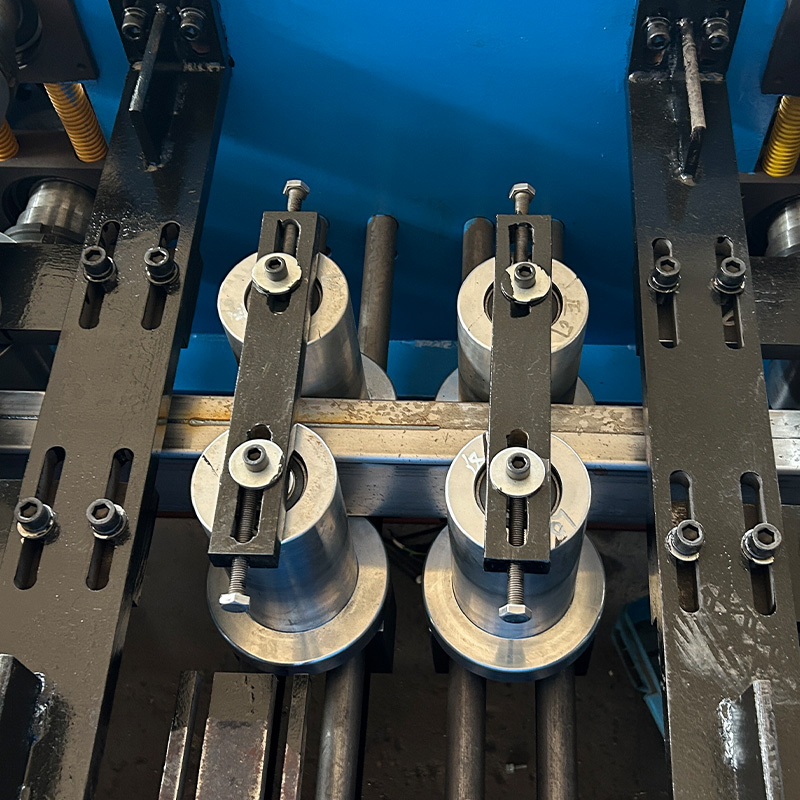

Roll forming machines are essential for producing corrugated metal sheets. These machines form metal sheets by passing them through a series of rollers that shape the metal into the desired corrugated profile.

Key Points:

- Roll forming machines can handle various metal types, including steel, aluminum, and copper.

- The process ensures high precision and uniformity in the corrugated sheets.

- These machines are equipped with features like automatic feeding, cutting, and stacking.

Types of Metal Sheet Corrugated

| Type | Description |

|---|---|

| Galvanized Steel | Coated with zinc to prevent rust and corrosion, suitable for outdoor use. |

| Aluminum | Lightweight, corrosion-resistant, ideal for coastal environments. |

| Copper | Offers a unique aesthetic, excellent durability, and resistance to corrosion. |

| Stainless Steel | High strength, corrosion-resistant, suitable for harsh environments. |

| Polycarbonate | Lightweight, translucent, and impact-resistant, often used in skylights. |

| Fiberglass | Durable, lightweight, and translucent, used in roofing and cladding. |

| Zinc | Long-lasting, self-healing properties, and eco-friendly. |

| Pre-painted Steel | Available in various colors, provides both aesthetic appeal and protection. |

| Tin | Lightweight, corrosion-resistant, commonly used in DIY projects. |

| PVC | Cost-effective, easy to install, and available in various colors and profiles. |

Working Process of Metal Sheet Corrugated

The corrugation process involves several key steps to ensure the final product meets industry standards. Here’s a detailed look at how it works:

- Material Selection: Choosing the appropriate metal type based on the application requirements.

- Cutting: Cutting the metal sheets to the required size using precision cutting tools.

- Heating: Heating the metal to make it more malleable for the corrugation process.

- Rolling: Passing the heated metal through a series of rollers to create the corrugated pattern.

- Cooling: Allowing the metal to cool and harden in its new shape.

- Finishing: Applying any additional coatings or treatments for enhanced durability and aesthetics.

- Quality Control: Inspecting the final product for consistency, strength, and quality.

Key Components and Their Functions

| Component | Function |

|---|---|

| Rollers | Shape the metal sheets into the desired corrugated profile. |

| Feeder System | Automatically feeds metal sheets into the roll forming machine. |

| Cutting System | Precisely cuts the sheets to the required length. |

| Heating Element | Heats the metal to make it malleable for shaping. |

| Cooling System | Cools the metal sheets to set the corrugated shape. |

| Control Panel | Allows operators to control and monitor the machine’s operations. |

| Quality Control Sensors | Inspect the finished product for defects and ensure consistency. |

-

Storage Rack Shelf Box Panel Making Machine Steel Storage Rack System Box Beam Roll Forming Line

Storage Rack Shelf Box Panel Making Machine Steel Storage Rack System Box Beam Roll Forming Line -

Highway Guardrail End Terminal Forming Machine

Highway Guardrail End Terminal Forming Machine -

Highway U/C Post Roll Forming Machine

Highway U/C Post Roll Forming Machine -

2 Waves Highway Guardrail Roll Forming Machine

2 Waves Highway Guardrail Roll Forming Machine -

3 Waves Highway Guardrail Roll Forming Machine

3 Waves Highway Guardrail Roll Forming Machine -

Auto Size Changeable Sigma Purlin Roll Forming Machine

Auto Size Changeable Sigma Purlin Roll Forming Machine -

Auto Size Changeable C Z Purlin Roll Forming Machine

Auto Size Changeable C Z Purlin Roll Forming Machine -

Auto Size Changeable Z Purlin Roll Forming Machine

Auto Size Changeable Z Purlin Roll Forming Machine -

Auto Size Changeable C U Purlin Roll Forming Machine

Auto Size Changeable C U Purlin Roll Forming Machine

Machine Speed and Efficiency

| Parameter | Value |

|---|---|

| Speed Range | 15-30 meters per minute |

| Efficiency | High precision with less than 1% material waste |

| Automation Level | Fully automated systems available for increased productivity |

| Downtime | Minimal with regular maintenance |

| Energy Consumption | Energy-efficient models available with reduced power usage |

Customized Mechanical Parameters

| Parameter | Range/Option |

|---|---|

| Sheet Thickness | 0.3mm – 1.2mm |

| Width | 600mm – 1500mm |

| Material Type | Steel, Aluminum, Copper, Stainless Steel, etc. |

| Coating Options | Galvanized, Pre-painted, Zinc, etc. |

| Profile Depth | 18mm – 76mm |

| Corrugation Pitch | 76mm – 305mm |

Applications and Uses

| Application | Details |

|---|---|

| Roofing | Durable and weather-resistant, ideal for both residential and commercial buildings. |

| Siding | Provides an attractive and protective exterior finish. |

| Fencing | Strong and long-lasting, often used in industrial settings. |

| Cladding | Enhances the aesthetics and insulation of buildings. |

| Shelters | Used in temporary or permanent structures for protection against elements. |

| Greenhouses | Polycarbonate and fiberglass sheets provide insulation and light transmission. |

| Interior Design | Adds a rustic or industrial look to interiors. |

| Vehicle Bodies | Used in manufacturing truck and trailer bodies due to its strength and light weight. |

Installation, Operation, Maintenance

| Aspect | Details |

|---|---|

| Installation | Ensure proper alignment and secure fastening to prevent leaks and damage. |

| Operation | Follow manufacturer guidelines for safe and efficient machine use. |

| Maintenance | Regular inspections and maintenance to ensure longevity and performance. |

| Safety Measures | Use protective gear and follow safety protocols to prevent accidents. |

Suppliers and Price Range Details

| Supplier | Location | Price Range (per sq. meter) |

|---|---|---|

| ABC Metals | USA | $5 – $15 |

| XYZ Steels | UK | $7 – $18 |

| PQR Industries | China | $4 – $12 |

| MNO Supplies | Germany | $6 – $16 |

| DEF Corp | India | $3 – $10 |

Choosing the Right Supplier

When selecting a supplier for corrugated metal sheets, consider the following factors:

- Reputation: Look for suppliers with positive reviews and a solid track record.

- Quality: Ensure the materials meet industry standards and your specific requirements.

- Pricing: Compare prices from multiple suppliers to get the best deal without compromising quality.

- Delivery: Check the supplier’s delivery options and timelines to ensure timely project completion.

- Support: Choose suppliers who offer good customer support and after-sales service.

Advantages and Limitations of Metal Sheet Corrugated

| Aspect | Advantages | Limitations |

|---|---|---|

| Durability | Long-lasting and resistant to weather and corrosion. | Can be susceptible to dents and scratches. |

| Aesthetics | Available in various colors and finishes to match design preferences. | Some materials may fade over time with prolonged sun exposure. |

| Installation | Relatively easy and quick to install. | Requires proper alignment to avoid leaks. |

| Cost | Generally cost-effective compared to other roofing and siding materials. | Initial cost can be high for premium materials like copper. |

| Maintenance | Low maintenance, especially galvanized and stainless steel options. | May require periodic inspection and minor repairs. |

FAQ

| Question | Answer |

|---|---|

| What is metal sheet corrugated used for? | Mainly used for roofing, siding, fencing, cladding, and greenhouses. |

| How long does corrugated metal roofing last? | Typically lasts 40-70 years depending on the material and maintenance. |

| Is corrugated metal roofing noisy? | It can be, but proper insulation and installation can reduce noise. |

| Can corrugated metal sheets be painted? | Yes, they can be painted with appropriate metal paint. |

| Are corrugated metal sheets environmentally friendly? | Many are recyclable and made from recycled materials, making them eco-friendly. |

| How do I maintain corrugated metal sheets? | Regular inspections, cleaning, and minor repairs as needed. |

| What thickness of corrugated metal is best for roofing? | Generally, 0.5mm to 0.7mm is suitable for most roofing applications. |

| Can I install corrugated metal sheets myself? | Yes, with the proper tools and safety precautions, DIY installation is possible. |

| What is the cost of corrugated metal roofing? | Prices vary widely depending on the material, ranging from $3 to $18 per square meter. |

| Are there different profiles of corrugated metal sheets? | Yes, various profiles and pitches are available to suit different needs and aesthetics. |