Imagine driving down a highway, the wind whipping through your hair (or sunroof, if you prefer) as the scenery unfolds before you. But what if, instead of a smooth asphalt ribbon, the road abruptly ended? Thankfully, that’s where highway guardrails come in – those ubiquitous metal barriers lining our roadways, silently ensuring our safety. But have you ever wondered how these crucial components are actually made? Enter the fascinating world of highway guardrail making machines.

Components of Highway Guardrail Making Machine

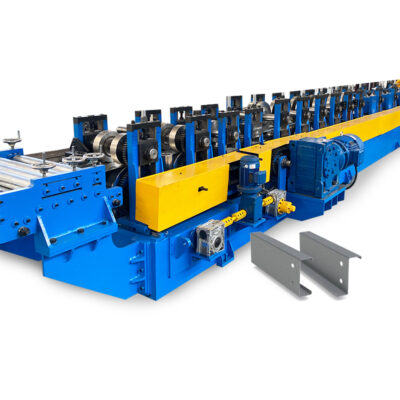

These machines are marvels of modern engineering, efficiently transforming sheets of steel into the distinctive shapes that line our highways. Here’s a breakdown of their key components:

- Decoiler/Uncoiler: This is the starting point, a large reel that holds the long, flat sheets of steel used to create the guardrails.

- Flattener/Leveler: As the name suggests, this component ensures the steel sheet is perfectly flat and free of any bends or waves. Any inconsistencies here could affect the final shape of the guardrail.

- Material Feed System: This precisely meters the steel sheet, ensuring a continuous flow of material into the forming process. Imagine it as a conductor controlling the tempo of a metal symphony.

- Punching System: Strategic punches are made in the steel sheet to create holes for fasteners and to accommodate the specific guardrail design. Think of a cookie cutter, but for metal and with much higher pressure.

- Guiding Device: This ensures the steel sheet travels along the correct path throughout the forming process. Precision is key here, as any deviations could result in a warped or malformed guardrail.

- Roll Forming Mill: The heart of the machine, this intricate series of rollers progressively bends and shapes the steel sheet into the final guardrail profile. Imagine a rolling pin specifically designed to create complex shapes, not just flatten dough.

- Post Cutting Device: Once the desired length is reached, a cutting mechanism precisely severs the formed guardrail from the steel sheet. Accuracy is crucial to ensure uniform guardrail sections.

- Output Table: The finished guardrails are deposited onto a designated table for easy collection and stacking.

- Hydraulic System: This powerful system provides the necessary pressure to operate the punching and roll forming processes. Think of it as the muscles behind the machine’s operation.

- Electric Control System: The brain of the operation, this sophisticated system controls all aspects of the machine’s operation, from feeding speed to roll forming sequences.

Industrial Applications of Highway Guardrail Making Machine

Highway guardrail making machines are workhorses in the metal fabrication industry. Their primary function, of course, is to produce the guardrails that line our highways, bridges, and other transportation infrastructure. These guardrails play a vital role in:

- Preventing Roadside Departures: By absorbing the impact of a vehicle veering off the road, guardrails can prevent it from plunging down embankments or colliding with fixed objects.

- Mitigating Head-On Collisions: Guardrails can separate opposing lanes of traffic, preventing head-on collisions that are often catastrophic.

- Shielding Pedestrians and Cyclists: Guardrails can protect vulnerable road users from straying vehicles, providing an extra layer of safety.

Beyond highways, guardrail making machines have various industrial applications. They can be used to manufacture:

- Safety Fencing: For construction sites, industrial facilities, and other areas where fall protection is required.

- Metal Posts and Sign Supports: From road signs to traffic lights, guardrail making machines can create the sturdy posts needed for proper installation.

- Metal Cladding and Trim: Certain guardrail profiles can be adapted for use in building construction and architectural applications.

The Intricacies of Guardrail Design and Material

The effectiveness of guardrails hinges on two crucial factors: design and material.

- Guardrail Design: Guardrails come in various shapes and sizes, each optimized for specific applications. Common designs include the W-beam, thrie-beam, and box beam profiles. The thickness of the steel sheet and the spacing between posts also play a role in the guardrail’s strength and deflection capabilities.

- Guardrail Material: High-strength, low-alloy (HSLA) steel is the preferred material for guardrails due to its excellent combination of strength, flexibility, and weather resistance. The specific grade of steel used will depend on the guardrail’s intended use and the environmental conditions it will face.

-

Electrical Cabinet Frame Roll Forming Machine

Electrical Cabinet Frame Roll Forming Machine -

Din Rail Roll Forming Machine

Din Rail Roll Forming Machine -

Cable Ladder Roll Forming Machine

Cable Ladder Roll Forming Machine -

PV Mounting Bracket C Shape Profile Roll Forming Machine

PV Mounting Bracket C Shape Profile Roll Forming Machine -

Cable Tray Roll Forming Machine

Cable Tray Roll Forming Machine -

Light Keel Wall Angle Roll Forming Machine Protector Corners Wall Angle Forming Machine

Light Keel Wall Angle Roll Forming Machine Protector Corners Wall Angle Forming Machine -

Light Keel Corner Bead Making Machine V Keel Angle Iron Roll Forming Machine

Light Keel Corner Bead Making Machine V Keel Angle Iron Roll Forming Machine -

Full Automatic C Z Purlin Machine Steel Metal Former Frame & Purlin Machines

Full Automatic C Z Purlin Machine Steel Metal Former Frame & Purlin Machines -

Fully Automatic Hydraulic Easy Operation 80-300 Adjustable C Purlin Making Machine Roll Forming Machinery

Fully Automatic Hydraulic Easy Operation 80-300 Adjustable C Purlin Making Machine Roll Forming Machinery

Considering a Highway Guardrail Making Machine: Factors to Ponder

If you’re contemplating investing in a highway guardrail making machine, here are some key considerations:

- Production Capacity: How many linear meters of guardrail do you plan to produce per hour or day? Consider your target market and projected demand to determine the optimal production capacity for your needs. Machines come in a range of capabilities, from smaller, more economical options suited for niche markets to high-volume machines geared towards large-scale production.

- Machine Features: Evaluate the specific features offered by different machines. Do you require a machine capable of handling a variety of guardrail profiles, or will you focus on a single design? Look for features like automatic punching and shearing systems for increased efficiency, and computer-controlled interfaces for ease of operation.

- Floor Space and Power Requirements: These machines are not exactly compact. Ensure you have adequate factory space to accommodate the machine and its operation. Additionally, consider the machine’s power requirements and ensure your electrical system can handle the load.

- Maintenance and Support: Like any complex machinery, regular maintenance is crucial to ensure optimal performance and longevity. Research the availability of spare parts, after-sales support, and preventative maintenance programs offered by potential machine suppliers.

- Cost and Return on Investment (ROI): Highway guardrail making machines are a significant investment. Carefully evaluate the initial cost of the machine, as well as ongoing operational expenses like labor and materials. Factor in projected production volume and guardrail selling price to determine your estimated ROI timeline.

Additional Considerations for Guardrail Production

Owning a highway guardrail making machine is just one piece of the puzzle. Here are some additional factors to consider for a successful guardrail production operation:

- Raw Material Sourcing: Establish reliable suppliers for high-quality steel coils in the required thickness and grade. Negotiate competitive pricing and ensure timely deliveries to avoid production bottlenecks.

- Quality Control Procedures: Implement a robust quality control program to ensure your guardrails meet all relevant safety standards. This may involve investing in testing equipment and employing qualified personnel to conduct inspections.

- Storage and Logistics: Having adequate storage space for raw materials and finished guardrails is essential. Additionally, develop a reliable logistics network for efficient delivery of your guardrails to customers.

The Future of Highway Guardrail Making Machines

The world of highway guardrail making machines is constantly evolving. Here are some trends shaping the future of this industry:

- Automation and Robotics: Expect to see increased automation and integration of robotics in guardrail production lines. This will lead to higher production efficiency, improved consistency, and reduced reliance on manual labor.

- Advanced Materials: Research and development in new, high-strength steel alloys and composite materials could lead to the creation of even more robust and lightweight guardrail designs.

- Sustainability: Manufacturers are increasingly focusing on designing machines that are more energy-efficient and minimize waste generation. Additionally, there may be a shift towards using recycled steel content in guardrail production.

FAQ

Q: What is the typical cost of a highway guardrail making machine?

A: The cost of a highway guardrail making machine can vary widely depending on factors like production capacity, features, and brand. A basic machine might start around $50,000, while high-end, fully automated machines can cost upwards of $500,000.

Q: Where can I find suppliers of highway guardrail making machines?

A: Several manufacturers around the world specialize in highway guardrail making machines. You can find them through online directories, industry trade shows, or by contacting metal fabrication equipment suppliers.

Q: What are the safety regulations for highway guardrails?

A: Highway guardrails must comply with specific safety standards established by government agencies like the Federal Highway Administration (FHWA) in the United States. These standards define guardrail strength, deflection characteristics, and performance criteria in crash scenarios.

Q: How long do highway guardrails typically last?

A: The lifespan of a highway guardrail depends on several factors, including environmental conditions, exposure to road salts, and the frequency of impacts. Generally, well-maintained guardrails can last for 15 to 20 years before requiring replacement.

Conclusion

Highway guardrail making machines are the unsung heroes of road safety, quietly churning out the metal barriers that keep us safe on our journeys. By understanding the intricacies of these machines, the factors involved in guardrail production, and the trends shaping the future of this industry, you can make informed decisions if you’re considering entering this niche manufacturing sector.