If you are looking for a c purlin roll forming machine to make the construction process easier, then make sure to read this article and learn about the top 6 models available on the market. You will find reviews on each one, with specific pros and cons in order to help you make your decision.

What is the C Purlin Roll Forming Machine?

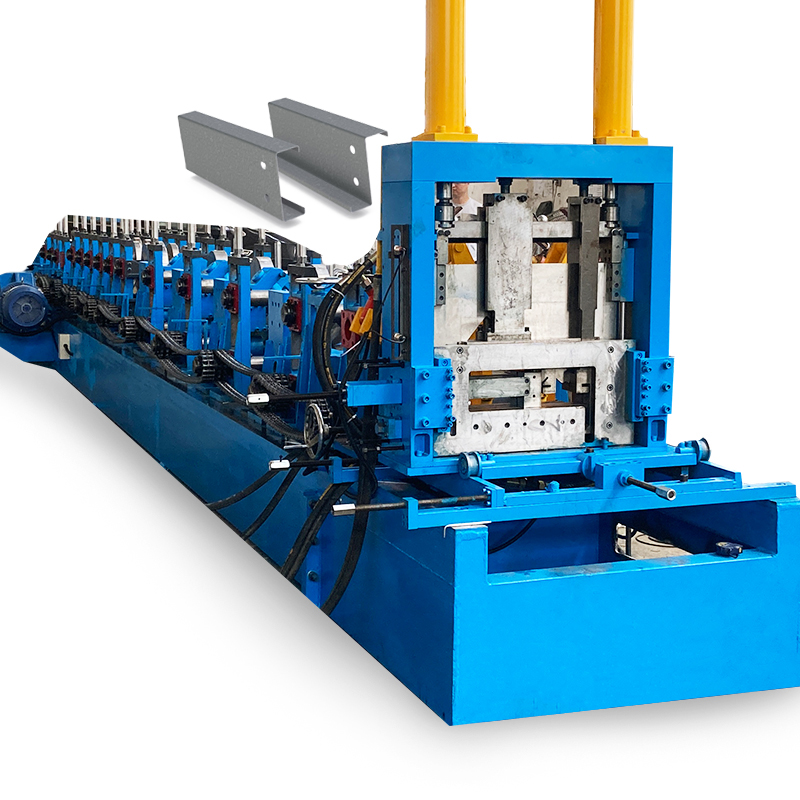

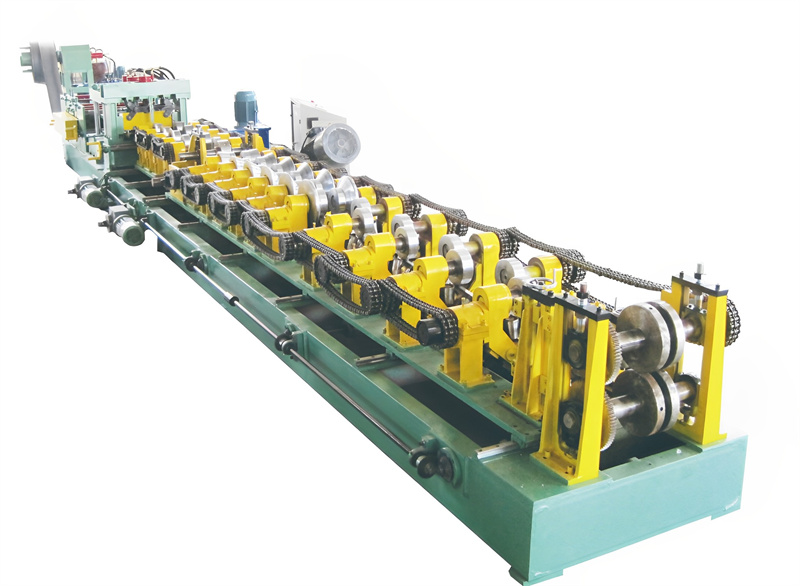

A C purlin roll forming machine is a type of construction equipment that is used to create C-shaped purlins. These purlins are often used in the construction of roofs, as they provide support for roofing materials. The C purlin roll forming machine works by feeding a sheet of metal through a series of rollers, which shape the metal into the desired C-shape.

There are many different types of C purlin roll forming machines available on the market, each designed for specific applications. For example, some machines may be designed for use with specific types of metals, while others may be more versatile and able to work with a variety of materials. When choosing a C purlin roll forming machine, it is important to select one that is best suited for the task at hand.

How does a C Purlin Roll Forming Machine work?

A C purlin roll forming machine is a type of equipment used to create C-shaped purlins, which are commonly used in the construction industry.

C purlins are typically made from metal, and they are used to support roofs, walls, and other structures. The roll forming machine bends and shapes the metal into the desired shape.

There are various types of C purlin roll forming machines available on the market, and each one has its own unique features and benefits. When choosing a machine, it is important to select one that is best suited for the specific project requirements.

Types of C Purlin Roll Forming Machines

A C purlin roll forming machine is a type of construction machinery used to create C-shaped Purlin sections out of sheet metal.

There are several different types of C purlin roll forming machines available on the market, each designed to produce a specific type or size of C purlin. The most common types of machines are:

- Single-stage machines: These machines are the simplest and most economical option for small-scale production. They can only produce one size or type of C purlin at a time, so if you need to produce multiple sizes or types, you will need multiple machines.

- Multi-stage machines: These machines are more expensive than single-stage machines, but they offer greater flexibility as they can be configured to produce multiple sizes or types of C purlins.

- Fully automatic machines: These are the most expensive type of machine, but they offer the highest level of efficiency as they can be left to run unattended for long periods of time.

What are the top 6 C Purlin Roll Forming Machines used in construction projects?

C-Purlin Roll Forming Machine is one of the most popular machines used in construction projects. There are many reasons for its popularity. First, C-Purlin is an excellent product for use in construction. It is strong and durable, yet lightweight and easy to work with. Second, C-Purlin Roll Forming Machine is very versatile. It can be used to create a variety of different shapes and sizes of purlins, which makes it ideal for use in a wide range of construction projects. Third, C-Purlin Roll Forming Machine is relatively easy to operate, making it a good choice for those who are new to roll forming or who do not have a lot of experience with this type of equipment.

The following are six of the most popular C-Purlin Roll Forming Machines used in construction projects:

- Apex Machinery APEX C Purlin Machine

- Baileigh Industrial BRF-5216M C Purlin Roller

- Chicago Steel Tapered Flange C Purlin Machine

- Dalian Huarui Heavy Industry HRBMLD1530 C Purlin Making Machine

- Faccin B3108 HPK CNC Hydraulic Punching Machine

- Jiangsu Hero Way Rolling Co., Ltd HW150-250 Type C Purlin Roll Forming Machine

How to Use a C Purlin Roll Forming Machine?

A C purlin roll forming machine is a great way to create strong, consistent metal C purlins for your construction project. Here’s how to use one:

- Place the coil of metal on the infeed table of the machine.

- Thread the end of the coil through the rollers and into the pre-punch station.

- Adjust the guide rails so that the metal is aligned correctly for punching.

- Activate the machine and watch as it punches holes in the metal according to your settings.

- Continue feeding the metal through the machine until you have enough C purlins for your project.

Conclusion

If you’re in the construction business, then you know that a c purlin machine is an essential piece of equipment. In this article, we’ve compiled a list of the top 6 c purlin machines on the market today. We hope that this list will help you find the perfect machine for your next construction project. Do you have any experience with these machines? Let us know in the comments below!