There are many different types of panel roll forming machines, and when you’re looking to purchase one, it can be hard to know what kind is right for you. We’ve created this article to give you 5 questions that you’ll want to ask yourself before purchasing a panel roll forming machine – these will help you identify what type of machine is most suitable for your needs.

What is a Panel Roll Forming Machine?

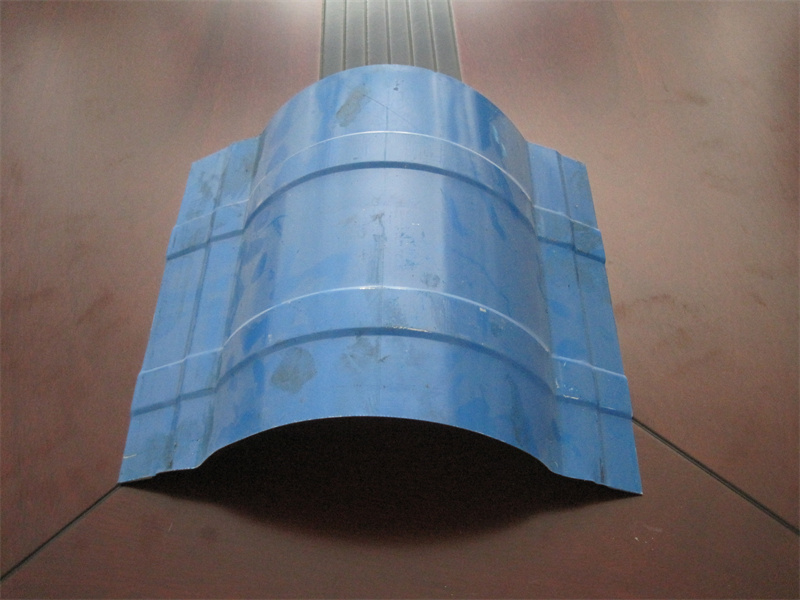

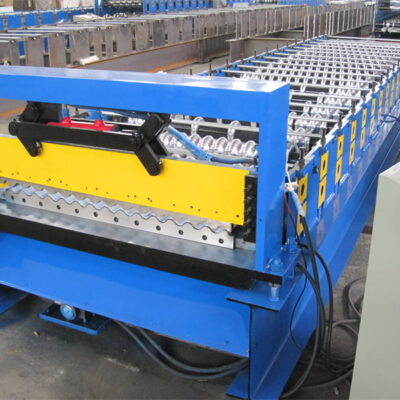

A panel roll forming machine is a type of construction equipment that is used to create metal panels. These machines are very versatile and can be used to create a variety of different types of panels, including roof panels, wall panels, and floor panels.

Panel roll forming machines are typically composed of a series of rollers that are connected to an electronic control unit. The rollers work together to slowly deform the metal sheet into the desired shape. The electronic control unit allows the operator to input the desired dimensions and specifications for the panel.

What are the most important considerations in purchasing a roll forming machine?

When you’re looking at roll forming machines, there are a few key factors that you’ll want to keep in mind. Here are some of the most important considerations:

- The width of the machine: This is one of the most important specs to look at when choosing a machine. You’ll need to know the maximum width that the machine can handle, as well as the minimum width.

- The speed of the machine: Another critical factor to consider is the speed of the machine. You’ll want to make sure that it can produce enough panels per minute to meet your production needs.

- The material thickness: The thickness of the material is also an important consideration. You’ll need to make sure that the machine can handle the thickness of material that you plan on using.

- The power requirements: Finally, you’ll need to consider the power requirements of the machine. Make sure that it can be powered by your existing electrical system.

-

Trapezoidal Panel Roll Forming Machine

Trapezoidal Panel Roll Forming Machine -

Double Layer Panel Roll Forming Machine

Double Layer Panel Roll Forming Machine -

Roof Tile Panel Roll Forming Machine

Roof Tile Panel Roll Forming Machine -

Corrugated Panel Roll Forming Machine

Corrugated Panel Roll Forming Machine -

Trapezoidal panel roll forming machine

Trapezoidal panel roll forming machine -

Corrugated Panel Double Layer Machine丨 Trapezoidal &

Corrugated Panel Double Layer Machine丨 Trapezoidal & -

Standing Seam Roof Panel Forming Machine

Standing Seam Roof Panel Forming Machine -

Roof Panel Double Layer Machine丨Tile &

Roof Panel Double Layer Machine丨Tile & -

Roof Tile Roll Forming Machine

Roof Tile Roll Forming Machine

When to use a Panel Roll Forming Machine?

When it comes to panel roll forming machines, there are a few different scenarios in which you might want to use one. Here are a few examples:

If you need to produce panels for a construction project, a panel roll forming machine can be a great option. This type of machine is especially well-suited for projects that require a large number of panels, such as office buildings or warehouses.

Another scenario in which you might want to use a panel roll forming machine is if you need to produce panels for an industrial application. For example, if you need to create panels for a food processing plant, this type of machine can be a good choice.

Finally, if you need to produce panels for a commercial application, such as signage or displays, a panel roll forming machine can be a good option. This type of machine is typically used to create thinner panels than what is required for construction or industrial applications.

5 Questions To Ask When Purchasing A Panel Roll Forming Machine

There are many different types of panel roll forming machines on the market, and it can be difficult to decide which one is right for you and your needs. Here are a few important questions to ask yourself when you’re considering purchasing a panel roll forming machine:

- What type of panels do you need to produce?

There are different types of panel roll forming machines that are designed to produce different types of panels. You’ll need to make sure that the machine you choose is capable of producing the type of panels you need.

- What is your budget for the machine?

Panel roll forming machines can vary significantly in price, so it’s important to have a budget in mind when you’re shopping around. This will help you narrow down your options and find a machine that fits your needs and budget.

- What features are important to you?

Some panel roll forming machines come with more features than others. Make a list of the features that are most important to you and use it as a guide when comparing different machines.

- What size panels do you need to produce?

Different panel roll forming machines can produce panels of different sizes. You’ll need to make sure that the machine you choose can handle the size panels you need to produce.

- How often will I need to maintain or repair my machine?

The frequency of maintenance and repairs needed for a panel roll forming machine depends on the make and model of the machine, as well as how often it is used. Generally, however, these machines require very little maintenance and can run for years without issue.

Conclusion

A panel roll forming machine is a versatile tool that can be used to create a variety of products. With the right machine, you can create panels for roofs, walls, floors, and more. If you’re looking for a panel roll forming machine, this guide will help you find the perfect one for your needs.