Buying a floor deck roll forming machine is not always an easy decision. You have to consider important aspects such as price, size, weight, and construction. Read on to find out which floor deck roll forming machine is the best for you!

What is a Floor Deck Roll Forming Machine?

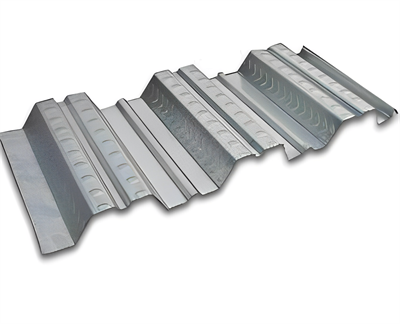

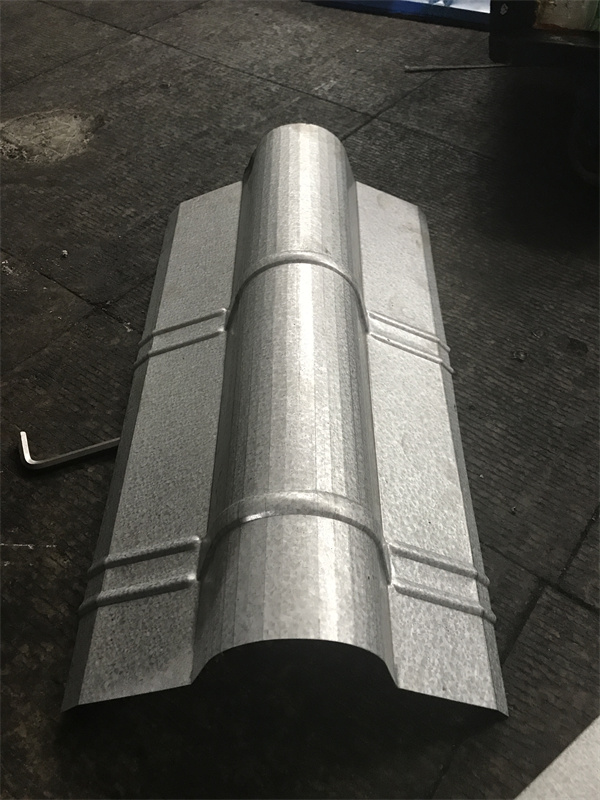

A floor deck roll forming machine is a specialized piece of equipment that helps to create metal floor decks. These machines are designed to create a variety of different decking profiles, including corrugated, ribbed, and even trapezoidal decks. Floor deck roll forming machines can be used to create both new construction projects and retrofit existing structures.

The Advantages of a Floor Deck Roll Forming Machine

If you are in the market for a floor deck roll forming machine, there are a few things you should keep in mind. These machines can offer many advantages, but they also come with some disadvantages. Here are a few of the key advantages to consider:

- Increased Productivity: A floor deck roll forming machine can help to increase productivity in your business. This is because these machines can produce large quantities of decking material in a short amount of time. This can help you to keep up with demand and avoid any production delays.

- Reduced Costs: A floor deck roll forming machine can also help to reduce costs in your business. This is because these machines can produce high-quality decking material at a lower cost than traditional methods. This can help you to save money on materials and labor costs.

- Improved Quality: A floor deck roll forming machine can also improve the quality of your product. This is because these machines can create a smoother and more consistent product. This can help to improve the look of your product and make it more durable.

-

Gutter Roll Forming Machine

Gutter Roll Forming Machine -

Trapezoidal Panel Roll Forming Machine

Trapezoidal Panel Roll Forming Machine -

Floor Deck Roll Forming Machine

Floor Deck Roll Forming Machine -

Steel Box Plate Making Roll Forming Machine

Steel Box Plate Making Roll Forming Machine -

Box Beam Steel Roll Forming Machine For Shelf Column

Box Beam Steel Roll Forming Machine For Shelf Column -

Pallet Racking Step Beam P Beam Roll Forming Machine

Pallet Racking Step Beam P Beam Roll Forming Machine -

Warehouse Shelf Upright Roll Forming Machine

Warehouse Shelf Upright Roll Forming Machine -

Floor decking roll forming machine

Floor decking roll forming machine -

Trapezoidal panel roll forming machine

Trapezoidal panel roll forming machine

The Disadvantages of a Floor Deck Forming Machine

A floor deck forming machine can have several disadvantages. For one, the initial investment for a quality machine can be high. Additionally, floor deck machines are typically large and bulky, making them difficult to transport and store. Finally, because they use rollers to form the metal decking, there is a greater chance of damaging the material if it is not used correctly.

Which Floor Deck Roll Forming Machine Should You Get?

When choosing a floor deck roll forming machine, it is important to consider the type of project you will be working on. For example, if you are creating a new construction project, you will need a machine that can handle the heavy duty demands of the job. On the other hand, if you are retrofitting an existing structure, you may not need as much power and may be able to get by with a smaller machine. It is also important to consider the size of the projects you will be working on. Some machines are better suited for large projects while others are better for smaller jobs.

Once you have considered the type of project you will be working on and the size of the project, you can begin to narrow down your choices for floor deck roll forming machines. There are a variety of different manufacturers that offer these machines, so it is important to do your research and find one that offers a good warranty and customer service. In addition, it is important to find a machine that is easy to operate and maintain.

which Industrie will use a Floor Deck Roll Forming Machine?

Different industries will use a floor deck roll forming machine because it provides an efficient and cost-effective way to produce metal decking. This type of machine is typically used in the construction industry, but can also be used in other industries such as the automotive industry.

Some of the different industries that will use a floor deck roll forming machine include:

-Construction Industry: The construction industry will use this type of machine to create metal decking for buildings. This can be used for both new construction projects and renovations.

-Automotive Industry: The automotive industry can use a floor deck roll forming machine to create parts for vehicles. This can include parts such as floor pans, fenders, and more.

-Other Industries: There are many other industries that can benefit from using a floor deck roll forming machine. Some of these industries include the appliance industry, furniture industry, and more.

Conclusion

Investing in a floor deck roll forming machine is a great way to increase efficiency and productivity in your business. With so many options on the market, it can be difficult to know which one is right for you. We hope that our guide has helped you narrow down your choices and find the perfect machine for your business needs. If you have any questions, please feel free to contact us and we will be happy to help you make the best decision for your business.