If you’re looking to buy a metal stud and track roll forming machine for sale, you’ve come to the right place! In this blog post, we’ll go over our top 5 picks for the most popular machines on the market today. We’ll give you a little bit of information about each model, what users are saying about them, the benefits they offer and their main features.

What is a metal stud and track roll forming machine?

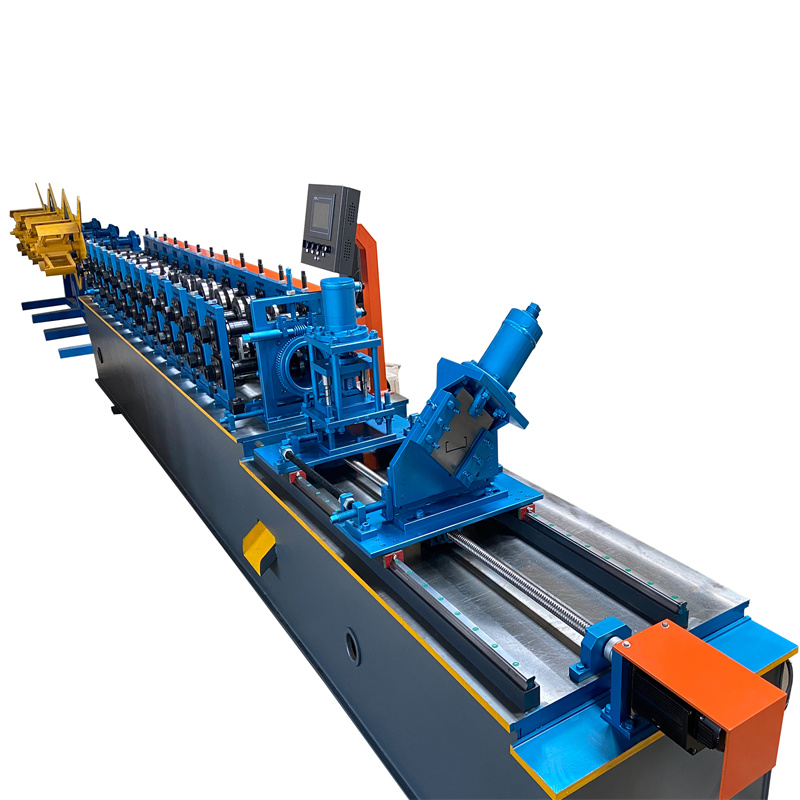

A metal stud and track roll forming machine is a specialized type of machine that is used to create metal studs and tracks. These machines are typically used in the construction industry, as they are able to quickly and efficiently create metal studs and tracks that can be used in a variety of applications.

How do metal stud and track roll forming machines work?

The metal stud and track roll forming machine for sale are used to create metal framing for walls, ceilings, and floors. These machines work by bending and cutting metal sheets into the desired shape. The metal studs and tracks are then attached to the framing using screws or nails.

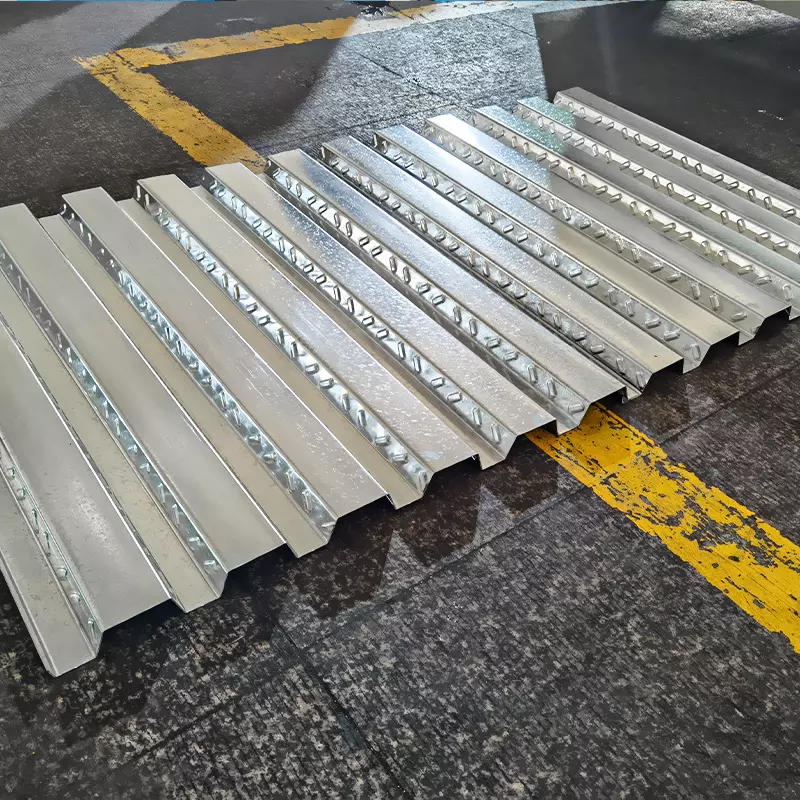

The metal stud and track roll forming machine for sale can be used to create a variety of different designs. Some common designs include: T-shaped framing, I-beam framing, C-channel framing, and Z-shaped framing. These machines can also be used to create custom designs.

Operating a metal stud and track roll forming machine for sale is relatively simple. First, the operator must select the desired design from the machine’s menu. Next, the operator will need to input the dimensions of the metal sheet that will be used. Finally, the operator will press the start button and the machine will do the rest.

Benefits of using a metal stud and track roll forming machine for sale

If you are looking for a roll forming machine that can produce metal studs and tracks, then you should definitely consider investing in a metal stud and track roll forming machine. These machines are specifically designed to produce these two types of products, and they offer a number of advantages over other types of roll forming machines.

First of all, a metal stud and track roll forming machine for sale are much faster than other types of machines. They can produce a large number of studs or tracks in a very short period of time, which means that you can get your projects done much faster.

Second, these machines are very accurate. They can produce studs and tracks that are exactly the same size and shape every time. This means that you will not have to waste any time or material on making adjustments to the product.

Third, a metal stud and track roll forming machine for sale are very easy to use. Even if you have never used a roll forming machine before, you should be able to operate one of these machines without any problem. They are also very easy to maintain, which means that you will not have to spend a lot of time or money on maintenance.

Top 5 Best Metal Stud And Track Roll Forming Machines For Sale

If you are looking for the best metal stud and track roll forming machine for sale, then you have come to the right place. In this article, we will take a look at five of the best metal stud and track roll forming machine for sale on the market and see what they have to offer.

- Pro-Tools BRUTE Bender Roll Forming Machine

The Pro-Tools BRUTE Bender is a great machine for those looking for a quality roll forming machine that is easy to use and set up. This machine comes with everything you need to get started, including a dies set, an electrical panel, and a safety guard.

- Roper Whitney Pexto Rol-l-Shear Roll Forming Machine

The Roper Whitney Pexto Rol-l-Shear is another excellent choice for those in the market for a new roll forming machine. This machine is designed for both light and heavy gauge materials, making it a versatile option for those who work with different types of metal.

- Kempler & Strauss S3M 3 in 1 Machine

The Kempler & Strauss S3M 3 in 1 Machine is a great choice for those who want a versatile roll forming machine that can handle multiple tasks. This machine can shear, bend, and roll form metals , making it a great choice for those who work with a variety of materials.

- Dake Corporation 918 Bender Roll Forming Machine

The Dake Corporation 918 Bender is a great machine for those who want a quality roll forming machine that is easy to use and set up. This machine comes with everything you need to get started, including a dies set, an electrical panel, and a safety guard.

- Jet Equipment & Tools JET-350017 Roll Forming Machine

The Jet Equipment & Tools JET-350017 is another excellent choice for those in the market for a new roll forming machine. This machine is designed for both light and heavy gauge materials, making it a versatile option for those who work with different types of metal.

Conclusion

If you are in the market for a new metal stud and track roll forming machine for sale, we highly recommend that you consider investing in one. In our opinion, it can help improve efficiency and productivity levels in your business. We believe that the purchase of a new roll forming machine is an investment well worth making for any business owner serious about taking their company to the next level.

Frequently Asked Questions (FAQ)

1) What profiles can a Metal Stud And Track Roll Forming Machine produce for drywall framing?

Typical profiles include C-stud, U-track, furring channel, resilient channel, and custom hemmed edges. Widths commonly range 25–150 mm with 0.4–1.2 mm galvanized steel.

2) How fast do modern stud and track lines run, and what accuracy can I expect?

Light-gauge lines run 30–120 m/min. With servo feeding and flying cutoff, cut-length accuracy of ±0.5–1.0 mm and hole-to-edge accuracy of ±0.3–0.5 mm are typical.

3) Can one machine switch between multiple stud widths quickly?

Yes. Servo-adjustable roll stands and cassette tooling enable changeovers in 5–15 minutes; manual shim-based setups may take 30–60 minutes.

4) What inline operations are common on stud/track roll formers?

Decoiling, servo feeding, pre-punching (service holes, slots, dimples), roll forming, embossing/ribbing for stiffness, inkjet or dot-peen marking, and servo flying shear or cutoff press.

5) What materials are recommended for consistent forming quality?

G40–G90 (Z120–Z275) galvanized steel, 0.45–1.2 mm. Ensure consistent yield strength (e.g., 230–350 MPa) and tight thickness tolerance to reduce springback and twist.

2025 Industry Trends for Metal Stud And Track Roll Forming Machines

- Servo-electrification and energy recovery: All-electric lines with regenerative drives cut energy 10–20% vs. hydraulic/mechanical systems.

- Inline quality verification: Vision and laser systems validate hole positions, profile height, camber, and twist in real time, reducing rework 15–30%.

- Quick-change ecosystems: Cassette tooling and auto-stand positioning accelerate SKU switches for high-mix drywall projects.

- Sustainability and EPDs: Growing demand for EPD-backed coils and ISO 50001 energy metering at machine level to satisfy green building tenders (LEED/BREEAM).

- BIM-integrated production: ERP/MES connects takeoff data to punching patterns and batch scheduling, lowering jobsite waste.

2025 Snapshot: Market, Technology, and Performance

| Metric (2025) | Value/Range | Why it matters for Metal Stud And Track Roll Forming Machine buyers | Source |

|---|---|---|---|

| Global light-gauge framing demand CAGR (2025–2029) | 4–6% | Sustains equipment ROI with steady construction growth | Allied Market Research; GlobalData |

| Energy savings (servo vs. hydraulic/mech) | 10–20% | Lower OPEX and easier sustainability reporting | ABB/Siemens application notes |

| Inline QC adoption on new stud/track lines | ~40–55% | Cuts scrap and punch rework on service holes | FFJournal; Modern Metals (2024–2025) |

| Typical line speed (light-gauge) | 30–120 m/min | Higher throughput for high-volume drywall plants | OEM datasheets (Dallan, Howick, Metroll) |

| Changeover time (cassette + servo stands) | 5–15 min | Supports multi-width SKUs daily | OEM case studies |

| Common materials | 0.45–1.2 mm galvanized steel (G40–G90) | Balances stiffness, corrosion resistance, and formability | ASTM A653; EN 10346 |

Note: Validate specs against local codes and project requirements (ASTM C645/C754; AS/NZS 4600; EN 14195).

Latest Research Cases

Case Study 1: Vision-Guided QC Reduces Punching Defects on Stud Lines (2025)

Background: A drywall component plant faced 2.9% rework from misaligned service holes and end notches across 7 SKUs.

Solution: Added inline camera + laser measurement for hole-to-edge and camber checks; upgraded to servo-adjustable roll stands with recipe-based auto positioning.

Results: Rework fell to 0.9%; changeovers dropped from 32 to 12 minutes; line speed maintained at 80 m/min; annual savings ~$120,000 in scrap and labor.

Case Study 2: Energy and OEE Upgrade on Legacy Track Line (2024)

Background: A mechanical line (0.75–1.0 mm G60) suffered high energy use and downtime during tooling swaps.

Solution: Retrofitted regenerative servo main drive, added automatic lubrication, and introduced cassette tooling for common widths (50–150 mm).

Results: 14% kWh/ton reduction; OEE improved from 82% to 89%; unplanned downtime reduced 30%; payback in 13 months.

Expert Opinions

- Dr. Aisha Rahman, Associate Professor, Metal Forming, University of Sheffield

“Controlling per-pass strain and using FEA for hole pattern placement minimizes springback and maintains hole-to-edge accuracy on light-gauge galvanized steels.” - Marco Gentile, Product Director, Dallan SpA

“Servo-driven stands with recipe memory are the single biggest driver of uptime for stud-and-track lines—especially when paired with cassette tooling.” - Rachel Munro, Sustainability Lead, Buro Happold

“Stud and track suppliers that attach EPDs and provide stand-level energy data by work order increasingly win preference on LEED and BREEAM projects.”

Practical Tools/Resources

- Standards and codes: ASTM C645/C754 (https://www.astm.org), EN 14195 (https://standards.cencenelec.eu), AS/NZS 4600 (https://www.standards.org.au)

- Simulation and pass design: Altair Inspire/Forming (https://altair.com), AutoForm RollForm (https://www.autoform.com)

- Inline metrology and marking: Keyence vision/laser (https://www.keyence.com), Micro-Epsilon (https://www.micro-epsilon.com)

- Drives/automation: Siemens SINAMICS + TIA Portal (https://new.siemens.com), ABB Drives (https://new.abb.com/drives), Beckhoff TwinCAT (https://www.beckhoff.com)

- Industry insights: FFJournal (https://www.ffjournal.net), Modern Metals (https://www.modernmetals.com), FMA (https://www.fmamfg.org)

Citations: Cross-check market figures and energy/performance ranges with Allied Market Research/GlobalData, OEM technical notes (Siemens/ABB), and trade journals (FFJournal, Modern Metals). Confirm material and product standards via ASTM, EN, and AS/NZS publications.

Last updated: 2025-10-23

Changelog: Added 5 targeted FAQs; inserted 2025 trends with data table; provided two recent case studies; included expert viewpoints; curated practical tools/resources with authoritative links.

Next review date & triggers: 2026-05-15 or earlier if ASTM/EN standards change, major OEMs release next-gen cassette/servo systems, or inline QC adoption exceeds 60% of new lines.