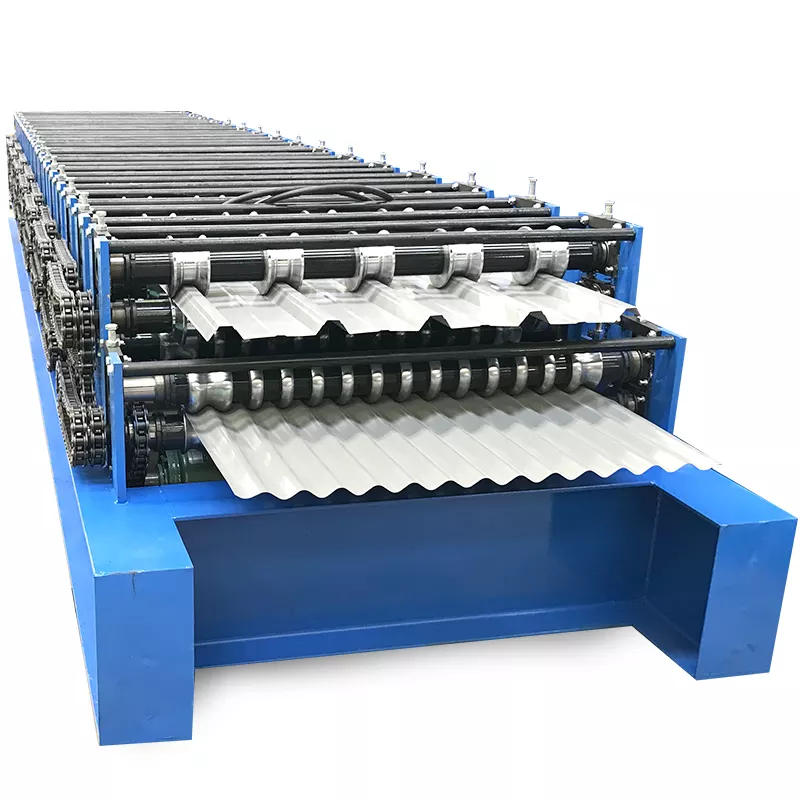

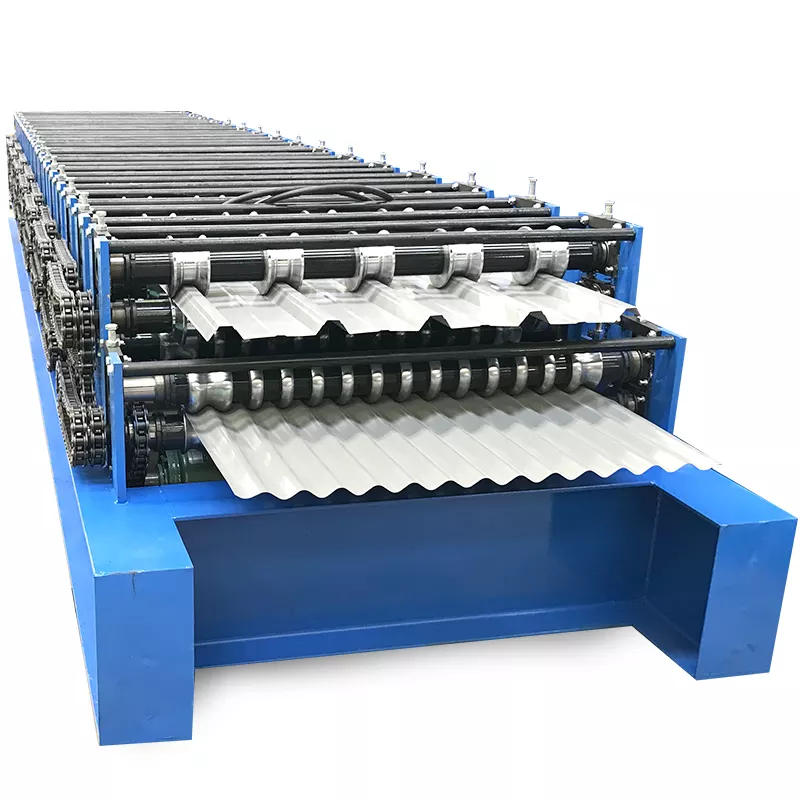

Roofing sheets roll forming machine is a metal sheet metal processing equipment, mainly used to produce the perimeter edge of the roof and the steel frame of the building. The main component is rolling machine for production, it can process metal materials such as cold-rolled steel sheet, galvanized steel sheet, tinplate steel sheet and copper coated steel sheet. Read on to find out all the benefits of using one!

What is a Roofing Sheets Roll Forming Machine?

A roofing sheets roll forming machine is an automated machine that is used to create long, continuous sheets of metal roofing. These machines are fed coils of metal roofing material, and they use a series of rollers to form the metal into the desired shape. Roofing sheets roll forming machines can produce sheets that are either corrugated or flat.

What are the Benefits of Using a roofing sheets Roll Forming Machine?

Roofing sheets Roll forming machines are beneficial for anyone who needs to produce long, continuous runs of metal roofing or siding. These machines can produce large quantities of material quickly and efficiently, making them ideal for high-volume production. Roll forming also offers a number of other benefits, including:

– Reduced waste: Roll forming produces very little scrap, so you can maximize your material usage and minimize waste.

– Increased accuracy: With roll forming, the sheets are formed to the exact dimensions you need, so there is less trimming and waste.

– Greater consistency: Roll forming produces consistent results sheet after sheet, so your finished product will have a professional look.

– Increased speed: A roofing sheets roll forming machine can produce large quantities of material quickly and efficiently.

If you are in the market for a roofing or siding solution that is both economical and efficient, a roofing sheets roll forming machine may be the right choice for you.

Types of roofing sheets

There are many types of roofing sheets available in the market, each with its own advantages and disadvantages. The most common types of roofing sheets are made from asphalt, metal, tile, and plastic. Asphalt roofing sheets are the most inexpensive option and are easy to install. However, they are not as durable as other types of roofing sheets and can be damaged by severe weather conditions.

Metal roofing sheets are more expensive than asphalt roofing sheets but are much more durable. They can withstand severe weather conditions and will not be damaged by hail or high winds. Tile roofing sheets are the most expensive option but are also the most durable. They can last for decades with proper maintenance and can withstand even the most severe weather conditions. Plastic roofing sheets are a relatively new option and are becoming increasingly popular due to their low cost and easy installation.

-

Standing Seam Roof Panel Curving Machine

Standing Seam Roof Panel Curving Machine -

Barrel Corrugated Roll Forming Machine

Barrel Corrugated Roll Forming Machine -

Hydraulic Roof Sheet Curving Machine

Hydraulic Roof Sheet Curving Machine -

Stand Seaming Roof Panel Roll Forming Machine

Stand Seaming Roof Panel Roll Forming Machine -

Downspout Pipe Roll Forming Machine

Downspout Pipe Roll Forming Machine -

Gutter Roll Forming Machine

Gutter Roll Forming Machine -

Trapezoidal Panel Roll Forming Machine

Trapezoidal Panel Roll Forming Machine -

Ridge Cap Roll Forming Machine

Ridge Cap Roll Forming Machine -

Double Layer Panel Roll Forming Machine

Double Layer Panel Roll Forming Machine

How to Choose the Right Roofing Sheets for Your Roof?

When it comes to choosing roofing sheets for your home, there are a few things you need to take into consideration. The first is the type of material you want your roofing sheets to be made out of. There are a few different options to choose from including aluminum, steel, and even plastic. Each option has its own set of benefits and drawbacks that you’ll need to weigh before making a decision.

Another thing to consider is the thickness of the sheet. This will affect both the price and the durability of the sheet. You’ll want to make sure you choose a thickness that’s appropriate for the climate you live in as well as the overall structure of your home.

Finally, you’ll need to decide on a style for your roofing sheets. There are plenty of different designs and colors available, so take some time to browse through all of your options before making a final decision. With so many choices available, you’re sure to find the perfect roofing sheets for your home.

The importance of roof safety

A roof is one of the most important parts of a house or any other type of building. It protects the occupants from the elements and keeps the structure safe and sound. However, roofs can be dangerous places to work, especially if they are not properly maintained. That’s why it’s important to always follow safety procedures when working on or near a roof.

Some common roofing hazards include falling off the roof, being hit by flying debris, slipping and falling, and being electrocuted by exposed wires. To avoid these hazards, always use proper safety equipment such as harnesses, ladders, and protective clothing. Make sure you are aware of your surroundings and know where potential hazards are located. And always follow the manufacturer’s instructions for safe use of any roofing products or tools.

By following these simple safety tips, you can help keep yourself and others safe while working on or around roofs.

Conclusion

If you are considering using a roofing sheets roll forming machine, then you should definitely weigh the pros and cons before making your final decision. Overall, there are many benefits that come with using a roofing sheets roll forming machine, including increased productivity, improved accuracy, and reduced waste. However, you will need to make sure that you find a reputable manufacturer who can provide you with a quality product. Do your research and consider all of your options before making your final decision.

FAQ

Which is best sheet for roofing?

PVC Plastisol coated corrugated sheets are very durable. They comprise steel sheets treated with primer paint and PVC rolled on their surface. These roofing sheets don’t scratch or fade easily and typically can last for around 25-30 years.