Overview: What is Siding Corrugated Metal?

Siding corrugated metal is a versatile and durable building material that’s been making waves in both residential and commercial construction. It’s a material that offers strength, durability, and aesthetic appeal. Imagine having a material that not only protects your building but also adds a sleek, modern, and industrial look to it! That’s exactly what siding corrugated metal offers. Whether you’re considering this for a home project or an industrial structure, this material could be the ideal fit. Let’s dive deep into everything you need to know about siding corrugated metal—how it’s made, its benefits, and how to choose the right type for your project.

What Makes Corrugated Metal Different?

Corrugated metal gets its name from the unique wave-like patterns that add structural integrity to the sheets. It’s crafted from metals like galvanized steel, aluminum, or zinc-coated metals, ensuring both strength and weather resistance. The material has been used for years for roofing, but its application in siding is now gaining immense popularity. Why? It’s affordable, easy to install, long-lasting, and looks modern!

Presenting the Corrugated Metal Siding Guide

Corrugated metal siding is growing in popularity due to its unique combination of utility and aesthetics. The beauty of corrugated metal siding lies in its simplicity. The wave-like design gives the material extra strength without adding extra weight, making it perfect for various applications. So how does corrugated metal work? It’s quite simple: when the sheets are installed with their ridges running vertically or horizontally, they create a durable exterior that can withstand weather extremes while adding a clean, industrial design element.

Types of Siding Corrugated Metal

There are different types of metals and coatings that are used for siding, each with unique characteristics. Some are more suited for industrial use, while others are perfect for residential applications. Below are some of the most popular types of corrugated metal siding:

| Type of Corrugated Metal Siding | Description |

|---|---|

| Galvanized Steel | Made by coating steel with a layer of zinc, this is the most popular type of corrugated metal siding. It’s rust-resistant and durable, perfect for all-weather conditions. |

| Aluminum | Lightweight and resistant to corrosion, aluminum corrugated metal siding is commonly used in areas with high humidity or near oceans. |

| Zinc | A naturally weathering metal, zinc develops a protective patina over time, which means it heals itself and becomes more durable as it ages. |

| Copper | Known for its distinct aesthetic, copper siding is highly durable, though it comes at a premium price. Over time, it develops a unique green patina. |

| Corten Steel | This type of steel is designed to rust over time, creating a protective layer that makes it incredibly durable. It’s often used for a rustic, weathered appearance. |

| Stainless Steel | Resistant to rust and corrosion, stainless steel is commonly used in industrial and coastal environments. It provides a clean and polished look. |

| Painted Corrugated Steel | Steel sheets coated with high-quality paint for added protection and color customization. Available in a variety of colors, it’s great for residential homes. |

| Galvalume Steel | A combination of zinc and aluminum coating that provides superior corrosion resistance compared to galvanized steel. Ideal for coastal areas. |

| Polyester Coated Steel | A budget-friendly option that comes with a polyester coating for added UV and weather protection. Typically used in more cost-conscious projects. |

| Tin | Common in older homes, tin is a softer metal that’s lightweight but requires regular maintenance to prevent corrosion and damage. |

Each of these materials brings its own set of advantages and potential drawbacks, depending on your specific needs. But no matter which one you choose, the process of installing and maintaining corrugated metal siding remains mostly the same.

How Corrugated Metal Siding Works

Corrugated metal siding is fairly simple in concept but highly effective in execution. The main feature that sets corrugated metal apart is the pattern of ridges and valleys formed into the metal sheets. These ridges increase the strength of the sheet and allow it to hold up against various weather conditions such as heavy rain, snow, or strong winds. This pattern also allows for natural water drainage, ensuring that moisture doesn’t accumulate and cause rust or other forms of deterioration.

Key Components and Their Functions

Corrugated metal siding consists of several key components that ensure the material’s strength, durability, and ease of installation. Here’s a breakdown:

| Component | Function |

|---|---|

| Metal Sheets | These are the core components made from steel, aluminum, or other metals. They form the primary siding material. |

| Fasteners | These are used to secure the metal sheets to the building structure, ensuring the siding stays in place. |

| Seam Sealants | To prevent moisture from seeping between the panels, seam sealants are applied. These also protect against corrosion. |

| Flashing | Installed around edges, such as windows or roof lines, flashing directs water away from the structure and protects it from leaks. |

| Trims | Decorative and functional, trims help cover edges and joints, improving both the aesthetic and performance of the siding. |

| Underlayment | This layer beneath the metal sheets acts as a secondary moisture barrier, adding extra protection to the building. |

These components work together to create a resilient barrier that protects your home from the elements while delivering a visually appealing design.

Working Process: Installing Siding Corrugated Metal

The installation process for siding corrugated metal is fairly straightforward, but it requires careful planning and precision. Here’s how it works, step-by-step:

- Preparation: Start by ensuring the wall or structure is clean and dry. Any existing siding should be removed, and the surface should be prepped for the new installation.

- Measuring and Cutting: Measure the area where the metal siding will be installed, then cut the corrugated sheets to fit. Ensure the sheets overlap by at least one ridge to prevent water leakage.

- Installing Underlayment: A moisture barrier or underlayment should be installed over the surface before the corrugated sheets go up. This protects the building from moisture penetration.

- Attaching the Sheets: Starting from the bottom, attach the sheets using screws or nails. Ensure that the fasteners are driven into the valleys of the corrugated sheets, not the ridges, to prevent leaks. Space the fasteners evenly for a secure hold.

- Adding Trims and Flashing: Trims and flashing are added around windows, doors, and roof edges to ensure the entire structure is weatherproof. This also helps enhance the overall look of the installation.

- Sealing and Finishing: Finally, apply seam sealant to any joints or seams to ensure a watertight finish. Inspect for any gaps or areas that may require additional fastening.

-

Carriage Board Roll Forming Machine

Carriage Board Roll Forming Machine -

Highway Guardrail End Terminal Forming Machine

Highway Guardrail End Terminal Forming Machine -

Highway U/C Post Roll Forming Machine

Highway U/C Post Roll Forming Machine -

2 Waves Highway Guardrail Roll Forming Machine

2 Waves Highway Guardrail Roll Forming Machine -

3 Waves Highway Guardrail Roll Forming Machine

3 Waves Highway Guardrail Roll Forming Machine -

Vineyard Post Roll Forming Machine

Vineyard Post Roll Forming Machine -

Auto Size Changeable Sigma Purlin Roll Forming Machine

Auto Size Changeable Sigma Purlin Roll Forming Machine -

Electrical Cabinet Frame Roll Forming Machine

Electrical Cabinet Frame Roll Forming Machine -

Din Rail Roll Forming Machine

Din Rail Roll Forming Machine

Customized Mechanical Parameters of Corrugated Metal Siding

Depending on your project’s specific needs, you may want to customize certain mechanical parameters of your corrugated metal siding. This ensures that the siding performs optimally based on the climate, building structure, and aesthetic preferences.

| Parameter | Custom Options |

|---|---|

| Thickness | 24-gauge, 26-gauge, or 29-gauge (thicker sheets provide more durability but are heavier and more expensive). |

| Profile | Different wave patterns (high corrugations for industrial settings, low corrugations for residential applications). |

| Width | Available in standard widths like 36 inches, but can be customized for specific projects. |

| Length | Sheets can be custom cut to fit any wall height, minimizing waste. |

| Coating | Various options for rust resistance and aesthetics, such as Galvalume, painted finishes, or zinc coatings. |

| Color | Custom color finishes to match your building’s exterior aesthetic. |

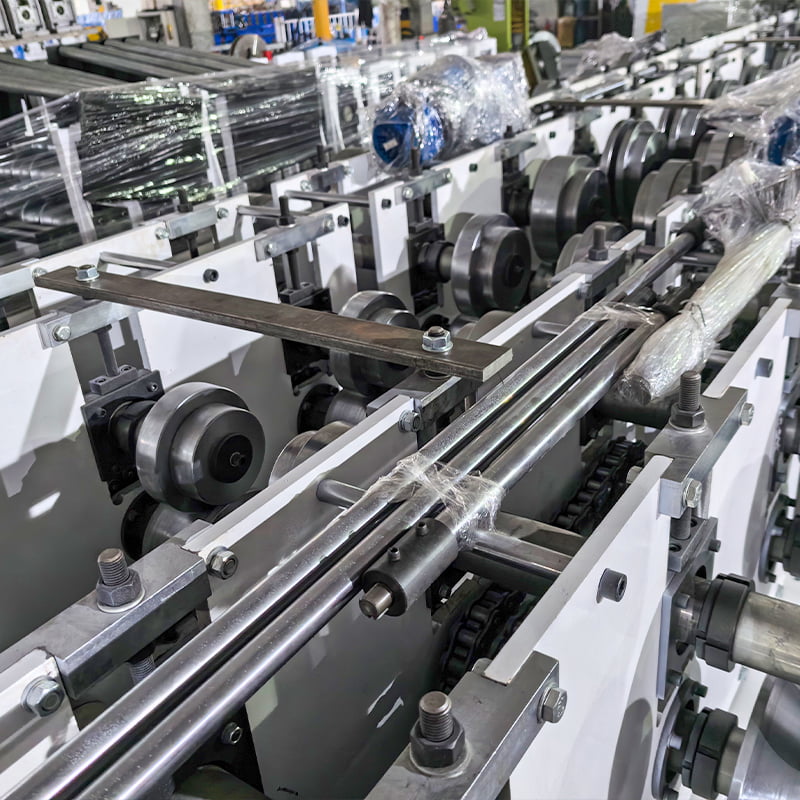

Machine Speed and Efficiency in the Production of Corrugated Metal

The manufacturing process for corrugated metal siding is highly automated and efficient. Sheets of metal are fed through rollers that shape them into the distinctive corrugated pattern. Depending on the type of metal and the desired profile, machines operate at different speeds and efficiency levels.

| Production Factor | Specification |

|---|---|

| Speed of Machine | Ranges from 15 meters per minute to 60 meters per minute, depending on the complexity of the corrugation. |

| Efficiency | The process can handle multiple sheet thicknesses and profiles in a single run, reducing production time. |

| Sheet Width | Machines can accommodate widths of up to 48 inches for some profiles. |

| Profile Variety | Some machines can switch between different profiles without significant downtime. |

Applications of Siding Corrugated Metal

Corrugated metal siding isn’t just for warehouses or industrial settings anymore. Its growing popularity in modern architecture has made it a go-to material for many building applications. Here’s where it shines:

| Application | Benefits |

|---|---|

| Residential Homes | Adds a modern, industrial look while offering durability and weather resistance. |

| Industrial Buildings | Ideal for large buildings that need to withstand harsh weather conditions and provide long-term protection. |

| Agricultural Structures | Perfect for barns and sheds due to its rust resistance and ability to withstand moisture. |

| Commercial Buildings | Provides a sleek, professional look for retail stores, office buildings, and restaurants. |

| Outbuildings | For garages, workshops, and storage units, corrugated metal offers an easy-to-maintain and durable exterior. |

Installation, Operation, and Maintenance of Corrugated Metal Siding

Ensuring that your corrugated metal siding performs well for years to come requires proper installation, operation, and regular maintenance. Here’s a quick guide to help you keep your siding in top condition:

| Stage | Recommendations |

|---|---|

| Installation | Follow the proper installation steps outlined above to ensure a tight and durable fit. Use the right fasteners and ensure proper overlap between sheets. |

| Operation | Corrugated metal siding requires minimal ongoing operation but regularly check for loose fasteners or signs of wear and tear. |

| Maintenance | Inspect the siding at least twice a year. Clean off any debris or dirt buildup using a soft brush and soapy water. Reapply sealant to seams and joints as needed. |

How to Choose the Right Corrugated Metal Siding Supplier

Choosing a reliable supplier is crucial to getting high-quality corrugated metal siding at the right price. Here’s a comparison of the most important factors to consider when selecting a supplier:

| Factor | Consideration |

|---|---|

| Price | Compare prices across multiple suppliers, but don’t sacrifice quality for cost. Lower-priced metals may corrode faster or have weaker profiles. |

| Customization Options | Some suppliers offer more options in terms of color, gauge, and profile customization. |

| Delivery Time | Make sure the supplier can meet your project timeline without causing delays. |

| Reputation | Look for suppliers with strong reviews and a proven track record of delivering durable, high-quality materials. |

| Customer Support | A supplier who offers strong customer support can help you make better decisions and solve any problems that arise. |

Suppliers and Price Range for Corrugated Metal Siding

Here’s a breakdown of some common suppliers and the price range for different types of corrugated metal siding:

| Supplier | Material | Price Range (per sq. foot) |

|---|---|---|

| ABC Metal Roofing | Galvanized Steel | $2.50 – $4.00 |

| Mueller Inc. | Galvalume | $1.80 – $3.50 |

| Metal Sales | Aluminum | $3.00 – $5.00 |

| Bridger Steel | Painted Steel | $3.50 – $6.00 |

| ASC Building Products | Corten Steel | $4.00 – $7.50 |

Pros and Cons of Siding Corrugated Metal

To help you make an informed decision, let’s compare the advantages and disadvantages of using corrugated metal siding:

| Advantages | Disadvantages |

|---|---|

| Durability: Corrugated metal is strong, weather-resistant, and long-lasting. | Cost: While affordable compared to some materials, high-end metals like copper can be expensive. |

| Aesthetic Appeal: Its modern, industrial look is perfect for contemporary designs. | Noise: Metal siding can amplify sound, especially during rainstorms. |

| Low Maintenance: Requires minimal upkeep compared to wood or vinyl siding. | Corrosion: If not properly coated or maintained, cheaper metals may rust over time. |

| Fire Resistant: Metal doesn’t burn, providing extra protection in fire-prone areas. | Thermal Conductivity: Metal can conduct heat, making buildings warmer in summer without proper insulation. |

| Eco-Friendly: Made from recyclable materials, making it an environmentally friendly choice. | Installation Difficulty: While not complex, improper installation can lead to water leakage or structural damage. |

FAQs

| Question | Answer |

|---|---|

| How long does corrugated metal siding last? | With proper care and maintenance, corrugated metal siding can last over 50 years. High-end materials like zinc or copper can last even longer. |

| Is corrugated metal siding energy efficient? | Metal conducts heat, so it’s not the most energy-efficient material. However, you can improve efficiency by adding insulation behind the siding. |

| Can corrugated metal be painted? | Yes, many types of corrugated metal come pre-painted, but you can also apply paint to match your desired color scheme. Just make sure to use metal-specific paints. |

| How do I clean corrugated metal siding? | Cleaning is easy—just use a soft brush and soapy water to remove dirt and debris. Avoid harsh chemicals that can damage the finish. |

| Can I install corrugated metal siding myself? | DIY installation is possible, but for best results, it’s recommended to hire a professional, especially if you’re unfamiliar with the material. |

| Does corrugated metal siding rust? | Most types are rust-resistant, especially if they are coated with a protective layer like zinc or aluminum. Regular maintenance and proper sealing also help prevent rust. |

Conclusion

Siding corrugated metal is an excellent choice for anyone looking for a durable, modern, and versatile siding option. Whether you’re drawn to its sleek industrial look or its long-lasting durability, it’s a material that can serve both functional and aesthetic purposes. Just remember to choose the right metal type for your project, follow proper installation guidelines, and maintain it regularly for the best results. With options ranging from galvanized steel to luxurious copper, there’s a perfect corrugated metal solution out there for every kind of build.

When it comes to durability, aesthetics, and affordability, siding corrugated metal stands tall. If you’re in the market for siding material that’ll make your property stand out while protecting it from the elements, look no further!