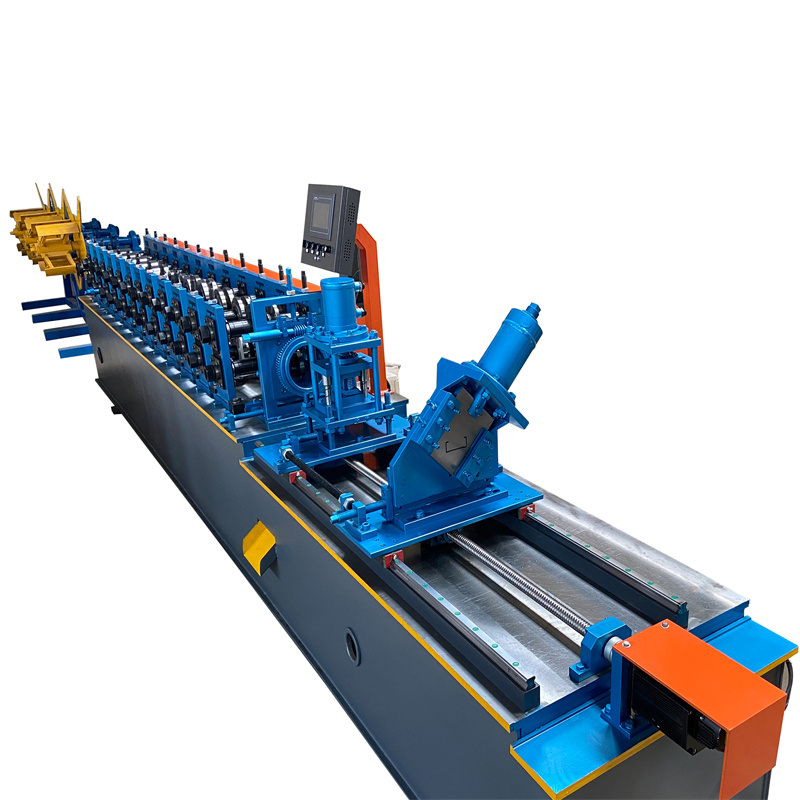

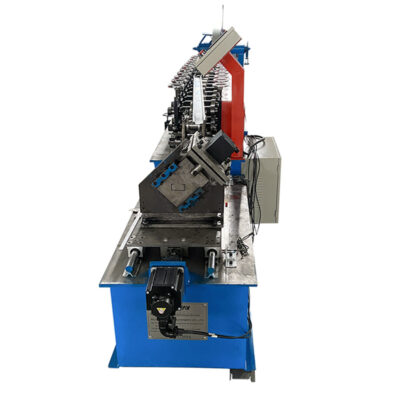

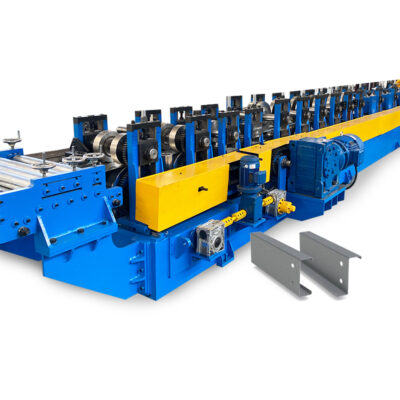

Keel/Truss/C/U/Omega/Stud Steel Roll Forming Machine with a small dimension, easy to transport. The speed can be up to 60m/min transmission, so the working will be more stable. We can also supply the customized machines.

Wall Angle Forming Machine Details

High Speed

Our high speed C/U/Omega stud roll forming machine speed can up to 60m/min. Normally, C//UOmega stud roll forming machine’s speed is around 45m/min

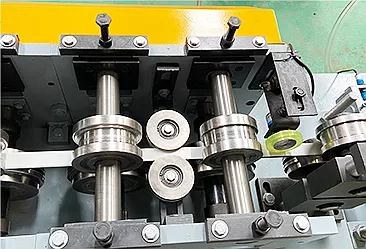

High speed C/U/Omega stud roll forming machine adopts cast steel roller fixer

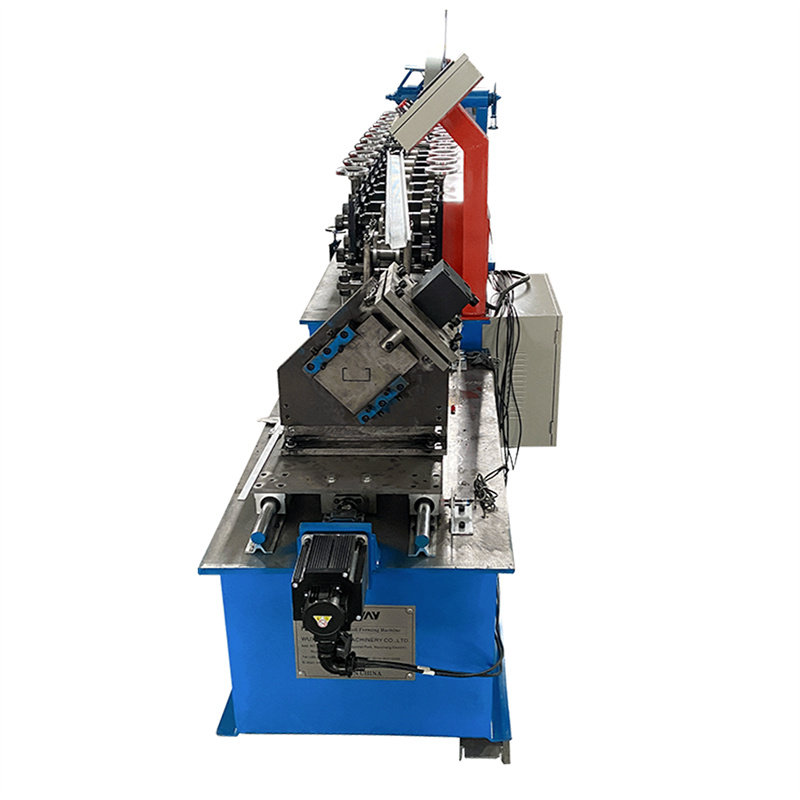

High speed C/U/Omega stud roll forming machine adopts PLC system. Customer can set production quantity, production speed on control cabinet.

Senior and experienced engineer control the whole process for your customize.

Wall Angle Forming Machine Parameters

| Raw Material | Galvanized Sheet Or PPGI, PPGL |

| Thickness Of Sheet (mm) | Customized |

| Operation | Fully Automatic |

| Transmission | By Chain/Gear |

| Roller Material | Cr12 |

| Shaft Diameter | 50mm Or As Per Profile |

| Roller Station | 10-16 Stations |

| Cutter | Hydraulic Servo Cutting With High Speed |

What equipment does the wall angle roll forming machine mainly produce?

The wall angle roll forming machine is primarily used to produce wall angles, which are structural components commonly used in the construction industry. Wall angles are L-shaped metal profiles that are installed at the corners or edges of walls to provide support and reinforcement. They are typically made from galvanized steel or other metals.

The equipment used in a wall angle roll forming machine generally includes:

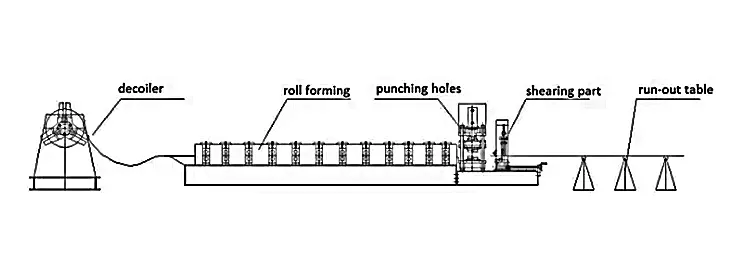

- Uncoiler: This device holds and uncoils the metal coil that serves as the raw material for the roll forming process.

- Feeding system: It transports the metal coil from the uncoiler into the roll forming machine, ensuring a continuous feed of material.

- Roll forming stations: These are sets of rollers that progressively shape the metal into the desired wall angle profile. Each station performs a specific bending or forming operation on the metal.

- Cutting system: Once the desired length of wall angle is formed, a cutting mechanism is employed to trim the profile to the required size. This can be done using a shear or a flying cutoff method.

- Control system: It consists of a computerized control panel that manages the machine’s operations, such as speed control, length measurement, and other parameters.

- Stacking or packaging system: After the wall angles are cut to length, they may be collected, stacked, or packaged for easy transportation and storage.

These components work together to shape the raw material into finished wall angle profiles of consistent size and shape. The exact configuration and specifications of a wall angle roll forming machine can vary depending on the manufacturer and specific requirements of the production process.

What is the function of the light keel roll forming machine?

The light keel roll forming machine is designed to produce light steel keels or studs, which are commonly used in construction for various purposes such as framing interior walls, ceilings, partitions, and suspended ceilings. The machine utilizes a roll forming process to transform raw materials, typically galvanized steel coils, into accurately shaped and sized light keel profiles.

The main function of a light keel roll forming machine is to perform the following tasks:

- Uncoiling: The machine starts by unwinding the metal coil, known as the uncoiling process. The coil serves as the raw material for the roll forming machine.

- Feeding and leveling: The uncoiled metal strip is then fed into the roll forming machine, where it passes through a leveling system. This system straightens and prepares the strip for the subsequent roll forming process.

- Roll forming: The heart of the machine is the roll forming station, which consists of a series of rollers. These rollers progressively shape the metal strip into the desired light keel profile. The strip is guided through the rollers, which bend and form it into the specific shape and size of the light keel. The number of roll forming stations can vary depending on the complexity of the keel profile.

- Cutting: Once the light keel profile has been formed to the desired length, a cutting mechanism is employed to separate the profile from the remaining strip. This can be done using a shear or a flying cutoff method.

- Hole punching (optional): Some light keel roll forming machines may also include a hole punching unit. This unit allows for the creation of holes or slots at specified locations along the length of the keel, which are necessary for connecting and fastening the keels during construction.

- Control system: The machine is typically equipped with a control panel that enables operators to adjust various parameters such as speed, length measurement, and other settings to ensure accurate production.

- Stacking or packaging: Once the light keels are cut to the desired length, they may be collected, stacked, or packaged for ease of handling, transportation, and storage.

The light keel roll forming machine provides a cost-effective and efficient solution for manufacturing light steel keels with consistent quality and precise dimensions, contributing to the construction industry’s needs for lightweight, durable, and easy-to-install framing components.

top light keel roll forming machine supplier in China

- WUXI SUNWAY MACHINERY CO., LTD is a professional manufacturer and exporter that are concerned with the design, development and production of cold roll forming machines. All products comply with international quality standards and are greatly appreciated in a variety of different markets throughout the world, such as Asia, Africa, Europe, South America, and Australia and so on. It has gained a global sales network.

- Hangzhou Roll Forming Machinery Co., Ltd. (HAIXING): HAIXING is a leading roll forming machine manufacturer in China, offering a wide range of roll forming machines, including light keel roll forming machines. They are known for their high-quality equipment and reliable customer service.

- Liming Stamping Forming Machine Co., Ltd.: Liming is a reputable supplier of roll forming machines, including light keel roll forming machines. They have been in the industry for many years and have established a strong presence in both domestic and international markets.

- Botou Kexinda Roll Forming Machine Co., Ltd.: Kexinda is a well-known manufacturer of roll forming machines, specializing in the production of light keel roll forming machines. They have a wide range of models and offer customized solutions to meet specific customer requirements.

- Tianjin Haixing Imp & Exp Co., Ltd.: Tianjin Haixing is a prominent supplier of roll forming machines, including light keel roll forming machines. They have a strong focus on technological innovation and provide reliable equipment to customers in China and abroad.

Reviews

There are no reviews yet.