Trapezoidal panel roll forming machine is mainly used to produce roof panels. Normally the panel thickness is 0.3-0.8mm with normal galvanized steel or colored coil.

Roofing system roll forming machine has a big range of metal sheet profiles. It includes trapezoidal panel, corrugated panel, roof tile, glazed tile, metal deck, wall panel, standing seam, K span and ridge cap. Its products are widely used in roof and wall system in workshop construction and housing construction.

In Construction Industries, we are able to manufacture more machines like main channel roll forming machine, purlin roll forming machine, drywall roll forming machine, stud roll forming machine, track roll forming machine, top hat roll forming machine, clip roll forming machine, metal deck (floor deck) roll forming machine, roof/wall panel roll forming machine, roof tile roll forming machine, corrugated roll forming machine, ridge cap roll forming machine, downspout roll forming machine, etc.

We make different solutions according to customers’ drawing, tolerance and budget, offering professional one-to-one service, adaptable for your all requirements. Whichever line you choose, the quality of SUNWAY Machinery will ensure you obtain perfectly functional profiles.

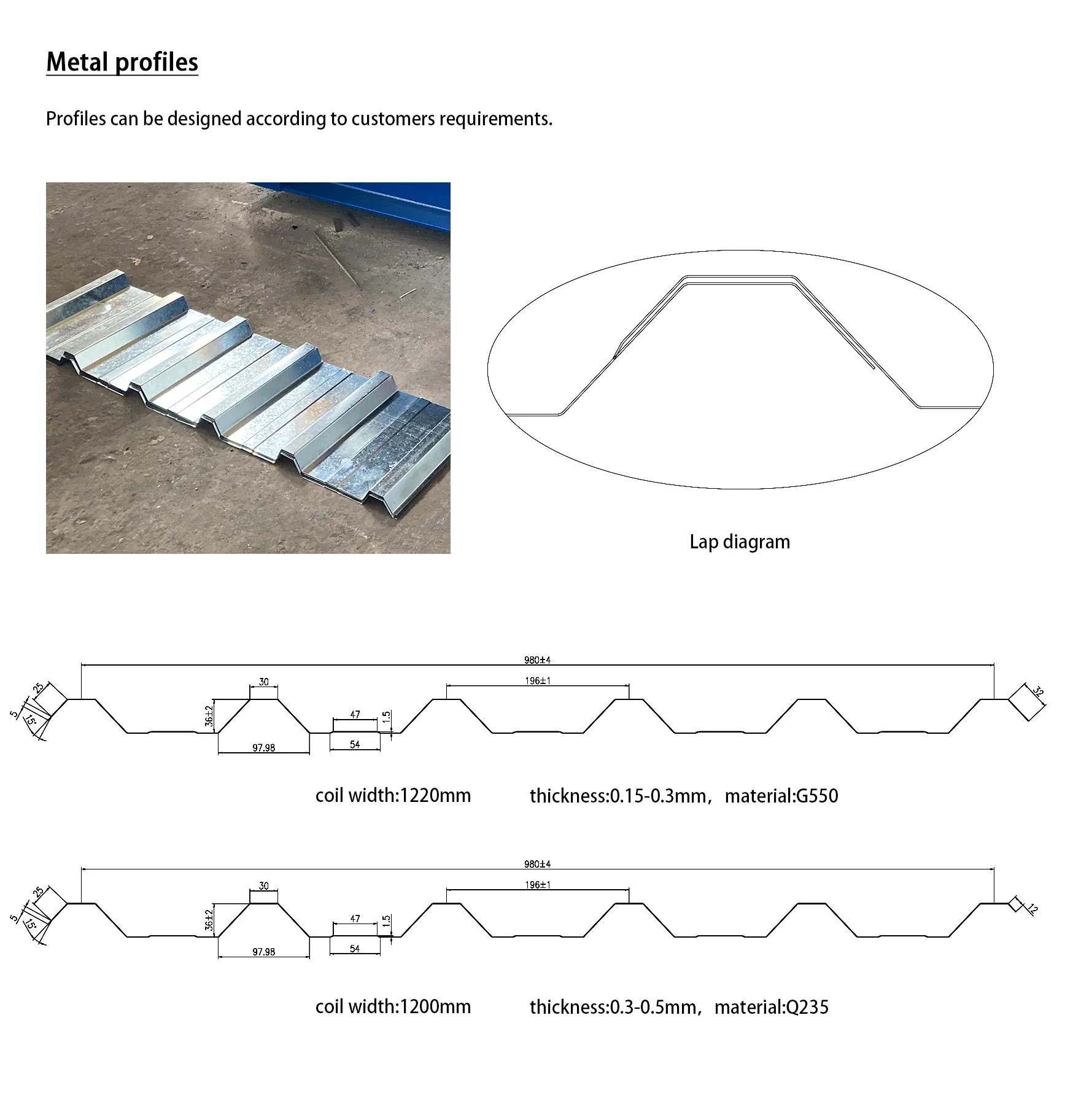

Profile Drawings

Production Line

Product Details

Product Parameters

| Trapezoidal Panel Roll Forming Machine | ||

|

Machinable Material

|

A) Galvanized Coil |

Thickness(MM): 0.3-0.8 According To Your Requirement

|

| B) PPGI, PPGL | ||

| Yield Strength | 250 – 350 Mpa / 350-550Mpa | |

| Tensil Stress | 350 Mpa-550 Mpa | |

| Coil Width | 914mm, 1000mm, 1200mm, 1220mm, 1250mm etc | |

| Forming Speed | 10-35 (m/min) | * Or According To Your Requirement |

| Forming Station | 16-24 Stations | * According To Your Profile Drawings |

| Decoiler | Manual Decoiler | * Hydraulic Decoiler (Optional) |

| Driving System | Chain Drive | * Gearbox Drive (Optional) |

| Machine Structure | Steel Plates Welded | * Cast Iron Stands (Optional) |

| Rollers’ Material | 45# | |

| Cutting System | Hydraulic Post Cut | * Hydraulic Servo Tracking Cutter (Optional) |

| Output Way | Roller Table | * Auto Stacker (Optional) |

| Frequency Changer Brand | Yaskawa | * Siemens (Optional) |

| Power Supply | 380V 50Hz 3ph | * Or According To Your Requirement |

| Machine Color | Industrial Blue | * Or According To Your Requirement |

Application

what is trapezoidal roll forming machine?

A trapezoidal roll forming machine is a type of industrial equipment used for the continuous shaping of metal sheets into trapezoidal profiles. It is commonly employed in the manufacturing of roofing and wall cladding systems, particularly in the construction industry.

The roll forming process involves feeding a flat metal strip or coil into the machine, which then passes through a series of roller dies. These rollers gradually shape the metal into the desired trapezoidal profile by bending it along specific contours and forming the necessary flanges and ribs. The rollers are typically adjustable to achieve different profile dimensions and shapes.

The trapezoidal profile produced by the roll forming machine is characterized by its trapezoid-shaped cross-section, which provides strength, structural integrity, and efficient water drainage for roofing and cladding applications. The machine may incorporate additional stations for cutting, punching, and other operations to produce finished components or panels.

Trapezoidal roll forming machines are often automated and capable of high-speed production, allowing for large-scale manufacturing with consistent quality and precision. They are widely used in the construction industry to create metal roof panels, wall cladding systems, and other applications where trapezoidal profiles are required.

application of trapezoidal sheet roll forming machine

Trapezoidal sheet roll forming machines are extensively used in various applications, primarily in the construction industry. Here are some common applications of trapezoidal sheet roll forming machines:

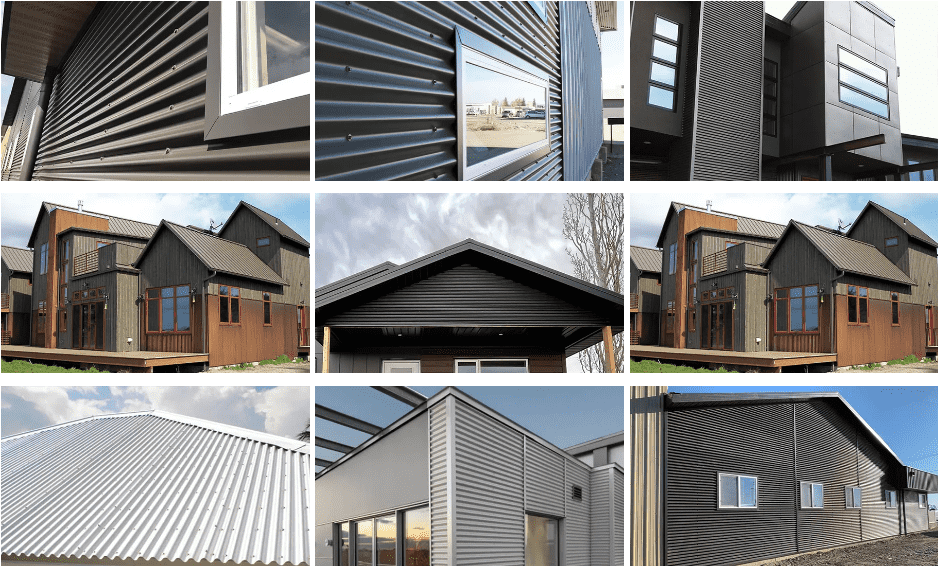

- Roofing Systems: Trapezoidal sheets produced by the roll forming machine are widely used as roofing materials for commercial, industrial, and residential buildings. The trapezoidal profile provides excellent water shedding capabilities, structural strength, and durability. These sheets are often made from materials such as galvanized steel, aluminum, or coated steel.

- Wall Cladding: Trapezoidal sheets are also used as wall cladding panels to enhance the aesthetic appeal and weather resistance of buildings. The roll forming machine can produce trapezoidal sheets with different surface finishes and coatings, allowing for a wide range of design options.

- Fencing and Enclosures: Trapezoidal profiles can be used for fencing systems and enclosures, providing security and privacy for various applications, including residential, commercial, and industrial properties.

- Agricultural Buildings: Trapezoidal sheet roll forming machines are employed in the manufacturing of agricultural building components such as barns, sheds, and storage facilities. These sheets offer excellent protection against weather conditions and are often used for roofing and siding applications.

- Industrial Applications: Trapezoidal sheets find use in various industrial applications, including factories, warehouses, and industrial facilities. They can be used as roofing and cladding materials due to their durability, ease of installation, and low maintenance requirements.

- Transportation Industry: Trapezoidal sheets are utilized in the manufacturing of trailers, containers, and other transportation-related applications. They provide lightweight yet strong solutions for protecting goods during transit.

- Energy Sector: Trapezoidal sheets are commonly used for solar panel mounting systems, offering a robust and reliable base for solar installations on roofs or ground-mounted structures.

These are just a few examples of the applications of trapezoidal sheet roll forming machines. The versatility, efficiency, and customization capabilities of these machines make them a valuable asset in the construction and manufacturing industries.

Application Fields of Corrugated Steel Panel Roll Forming Machine

A corrugated steel panel roll forming machine is a specialized piece of equipment used to produce corrugated steel panels. These panels feature a wavy or corrugated pattern, which provides strength, rigidity, and aesthetic appeal. Here are some of the application fields where corrugated steel panels produced by roll forming machines are commonly used:

- Roofing Systems: Corrugated steel panels are extensively used as roofing materials in residential, commercial, and industrial buildings. The unique corrugated pattern adds strength to the panels, allowing them to withstand heavy loads, wind, and other weather elements. These panels provide excellent water shedding capabilities and are available in a variety of sizes, profiles, and finishes.

- Wall Cladding: Corrugated steel panels are used for exterior wall cladding in various types of buildings. They offer durability, corrosion resistance, and a modern aesthetic appearance. The panels can be installed vertically or horizontally, enhancing the architectural design of the structure.

- Agricultural Structures: Corrugated steel panels find application in agricultural buildings such as barns, stables, and storage sheds. These panels are ideal for protecting agricultural equipment, livestock, and crops from the elements. They are easy to install and require minimal maintenance.

- Industrial Buildings: Corrugated steel panels are commonly used for roofing and cladding in industrial facilities, including factories, warehouses, and manufacturing plants. They provide strength, durability, and long-lasting performance in demanding industrial environments.

- Fencing and Enclosures: Corrugated steel panels are utilized for fencing systems and enclosures, providing security and privacy for residential, commercial, and industrial properties. The strength and rigidity of the panels make them an effective barrier for perimeter protection.

- Infrastructure and Construction: Corrugated steel panels are employed in various infrastructure projects such as bridges, tunnels, and railway stations. They are used for cladding, roofing, and structural purposes due to their strength, durability, and resistance to harsh environmental conditions.

- Interior Applications: Corrugated steel panels can also be used for interior applications such as wall partitions, ceilings, and decorative accents. They add an industrial and modern look to spaces, making them popular in contemporary architectural designs.

- Temporary Structures: Corrugated steel panels are often used in temporary structures such as portable cabins, temporary housing, and construction site offices. These panels are lightweight, easy to transport, and can be quickly assembled and disassembled.

These are some of the primary application fields for corrugated steel panels produced by roll forming machines. The versatility, durability, and cost-effectiveness of these panels make them a popular choice in various industries and construction projects.