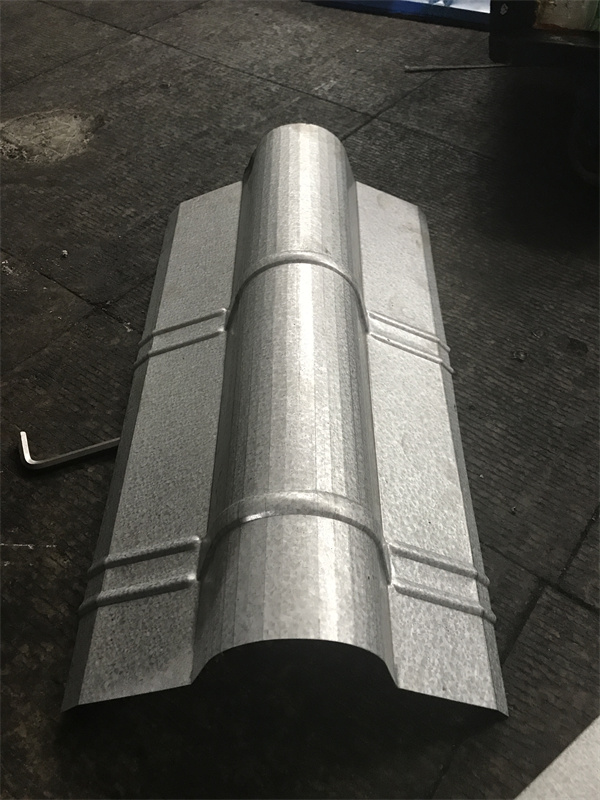

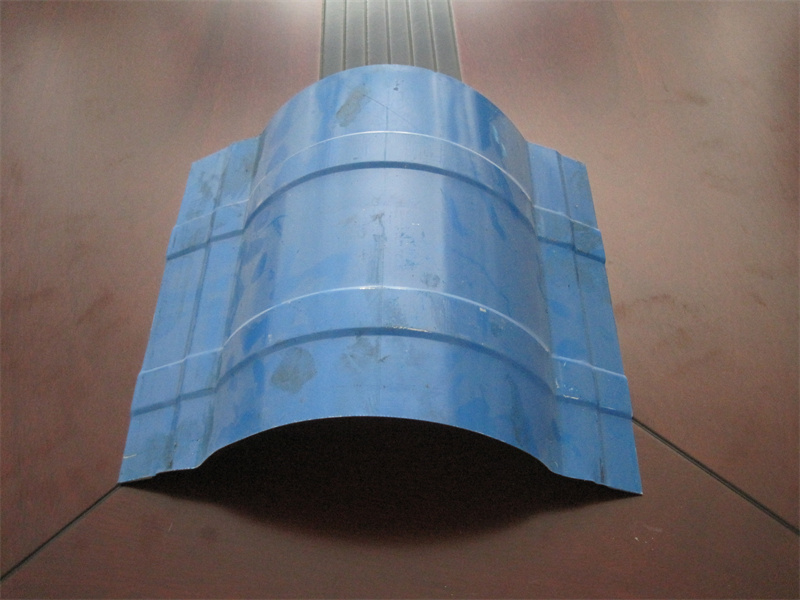

Panel profile

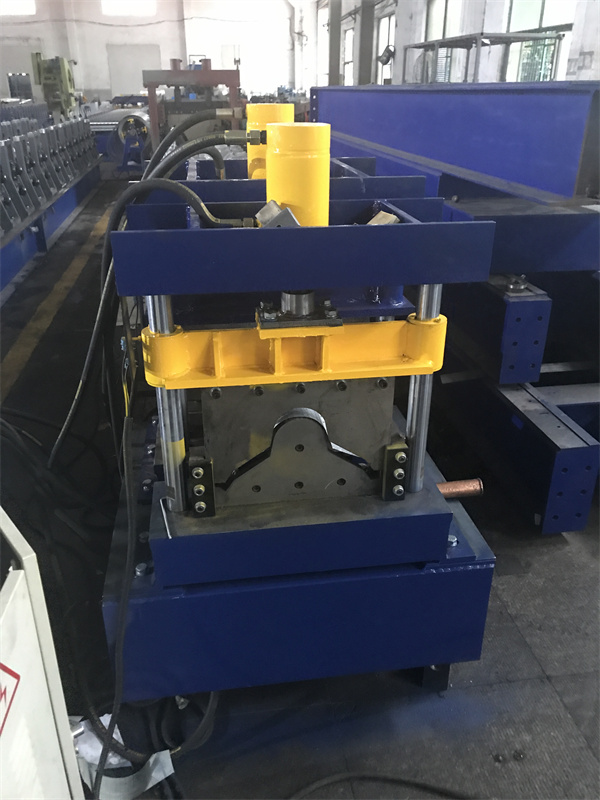

Main technical parameter

- Metaldecoiler:manual expanding,passive uncoil, inner Dia. 508mm

- weight capacity of decoiler:3T

- machine stand: welded “工” shape steel

- type of forming machine:wallboard type with chain transmission

- diameter of shaft: ¢75㎜

- chain:16A

- motor power of forming machine:5 KW

- motor of hydraulic station:3KW

- forming speed:10-15 m/min

- roll station:13stations

- material of roller: high-grade 45# steel

- surface of roller coated with chrome 0.05mm thickness

- type of cutting:hydraulic cutting

- material of cutting blade:Cr12mould steel

- heat treatment of cutting blade:HRC58°-60°

- thickness of steel coil:3-0.8mm

- tolerance of length:10±2mm

- transducer: Japan YASKAWA

- computer adopts Panasonic PLC

- computer operating board adopts Touch screen

- Voltage: 380V 3 phase 50HZ or at buyer’s requirement

Technical process

Manual decoiler→ feed with guide→ roll forming→ cutting with fixed length→ output with table

Flow chart

Equipment

Manual decoiler、main forming machine、hydraulic cutting device、hydraulic station、PLC computer control、output table

The time of producing: 30-35days after deposit

What is capping roll forming machine?

A capping roll forming machine is a type of roll forming equipment used to produce capping profiles or caps. Capping refers to the process of applying a protective cover or finishing element to the edges or ends of various materials, such as walls, panels, or roof sheets. The capping profiles produced by the machine are typically made from metal, such as aluminum or steel, and are designed to provide a durable and aesthetically pleasing finish.

The main function of a capping roll forming machine is to shape and form the metal strip into the desired capping profile. Here’s a general overview of how a capping roll forming machine works:

- Uncoiling: The machine starts by unwinding the metal coil, known as the uncoiling process. The coil serves as the raw material for the roll forming machine.

- Feeding and leveling: The uncoiled metal strip is then fed into the roll forming machine, where it passes through a leveling system. This system straightens and prepares the strip for the subsequent roll forming process.

- Roll forming: The heart of the machine is the roll forming station, which consists of a series of rollers. These rollers progressively shape the metal strip into the desired capping profile. The strip is guided through the rollers, which bend and form it into the specific shape and dimensions of the capping profile.

- Cutting: Once the capping profile has been formed to the desired length, a cutting mechanism is employed to separate the profile from the remaining strip. This can be done using a shear or a flying cutoff method.

- Additional features: Depending on the specific design and requirements of the capping profile, the machine may include additional features such as embossing, hole punching, or notching capabilities. These features can create patterns, perforations, or specialized features on the capping profile.

- Control system: The machine is typically equipped with a control panel that allows operators to adjust various parameters, including speed, length measurement, and other settings to ensure accurate production.

- Stacking or packaging: Once the capping profiles are cut to the desired length, they may be collected, stacked, or packaged for easy handling, transportation, and storage.

Capping roll forming machines are widely used in industries such as construction, architecture, and manufacturing, where a protective and decorative finish is required for edges or ends of various materials.

What is ridge capping roll forming machine?

A ridge capping roll forming machine is a specific type of roll forming equipment used to manufacture ridge caps. Ridge caps are roofing components that are installed at the peak of a sloped roof to provide weatherproofing and protection against water penetration.

The ridge capping roll forming machine is designed to produce ridge caps with precise dimensions and consistent quality. Here’s an overview of how a typical ridge capping roll forming machine works:

- Uncoiling: The machine begins by unwinding the metal coil, which serves as the raw material for the ridge caps. The coil is placed on an uncoiler, and the strip is fed into the machine.

- Feeding and leveling: The metal strip is guided through a feeding system, which ensures a continuous and even feed into the roll forming machine. A leveling system may be used to straighten and prepare the strip for the roll forming process.

- Roll forming: The strip passes through a series of roll forming stations, each equipped with rollers that gradually shape the metal strip into the desired ridge cap profile. The rollers bend and form the metal strip according to the specific dimensions and shape required for the ridge cap.

- Cutting: Once the ridge cap profile is formed to the desired length, a cutting mechanism is employed to separate the profile from the remaining strip. This can be done using a shear or a flying cutoff method.

- Additional features: Depending on the design and requirements of the ridge cap, the roll forming machine may incorporate additional features such as embossing, punching, or notching capabilities. These features can create patterns, perforations, or specialized features on the ridge cap.

- Control system: The machine is typically equipped with a control panel that allows operators to adjust various parameters, such as speed, length measurement, and other settings to ensure accurate production.

- Stacking or packaging: Once the ridge caps are cut to the desired length, they may be collected, stacked, or packaged for easy handling, transportation, and installation on roofs.

Ridge capping roll forming machines are widely used in the roofing industry to manufacture ridge caps efficiently and precisely. These machines help ensure consistent quality, dimensional accuracy, and high productivity in the production of ridge caps for various types of roofs.

applicationg of metal roof ridge cap roll forming machine

The metal roof ridge cap roll forming machine is specifically designed for the production of ridge caps used in metal roofing systems. Ridge caps are essential components that are installed at the peak of a sloped roof to provide a weatherproof and aesthetically pleasing finish. The roll forming machine allows for efficient and precise manufacturing of metal ridge caps, offering numerous benefits and applications. Here are some of the key applications of the metal roof ridge cap roll forming machine:

- Roofing Construction: The primary application of the ridge cap roll forming machine is in the roofing industry. It is used to produce ridge caps for various types of metal roofs, including steel roofs, aluminum roofs, and other metal roofing systems. The machine ensures the accurate and consistent production of ridge caps, which are crucial for sealing and protecting the roof’s highest point.

- Residential Buildings: Metal roof ridge caps are commonly used in residential buildings with sloped roofs. The roll forming machine enables the production of ridge caps that not only provide weatherproofing but also enhance the visual appeal of the roof. These ridge caps contribute to the overall aesthetics and functionality of the roofing system, ensuring a durable and attractive finish.

- Commercial and Industrial Buildings: Metal roofs are widely used in commercial and industrial buildings due to their durability and cost-effectiveness. The ridge cap roll forming machine is utilized to manufacture ridge caps for these structures, offering reliable protection against water infiltration and maintaining the structural integrity of the roof. The machine enables the production of ridge caps that meet the specific requirements and dimensions of commercial and industrial roofing systems.

- Architectural Projects: Metal roofs are increasingly favored in architectural projects for their versatility and modern appearance. The ridge cap roll forming machine plays a crucial role in fabricating ridge caps for architecturally unique and complex roof designs. It allows for the customization of ridge caps with different profiles, dimensions, and finishes to meet the specific aesthetic and functional demands of architectural projects.

- Roofing Material Suppliers: Manufacturers and suppliers of metal roofing materials utilize the ridge cap roll forming machine to produce ridge caps as part of their product offerings. The machine enables efficient production and ensures consistent quality, enabling roofing material suppliers to meet the demands of the market and provide comprehensive roofing solutions to their customers.

Overall, the metal roof ridge cap roll forming machine is indispensable in the production of ridge caps for metal roofs, contributing to the durability, functionality, and visual appeal of various types of buildings and roofing systems.