Highway U/C Post Roll Forming Machine is used to produce C barrier post or U post and thickness normally from 3-6mm.

The C barrier post or U post as a support for the beam guardrail and usually determines the performance of the guardrail during the collision. Proper installation of the guardrail post will maximize the performance of the guardrail. The barrier post has a long service life and the surface is usually hot-dip galvanized or spray-coated to provide rust and corrosion resistance.

The steel C post both with and without flanges, which are differentiated according to your intended application. Usually, the pillars without flanges are mostly fixed to the soft soil by the pillars. But if you want to fix it on a concrete pavement, the pillar with steel plate is the best choice for your installation: just use long bolts to secure the pillar to the position you want.

Highway guardrails provide a visual and physical barrier between traffic and work areas. It is used for protection against accidents due to lift trucks or other mobile equipment in dock areas, aisles, around special equipment. Reduce costly damage to equipment and inventory. Normally in Highway guardrails project, there would be such machines: two/three wave guardrail roll forming machine, U or C post roll forming machine, Connection punching line, End terminal punching line.

We make different solutions according to customers’ drawing, tolerance and budget, offering professional one-to-one service, adaptable for your all requirements. Whichever line you choose, the quality of SUNWAY Machinery will ensure you obtain perfectly functional profiles.

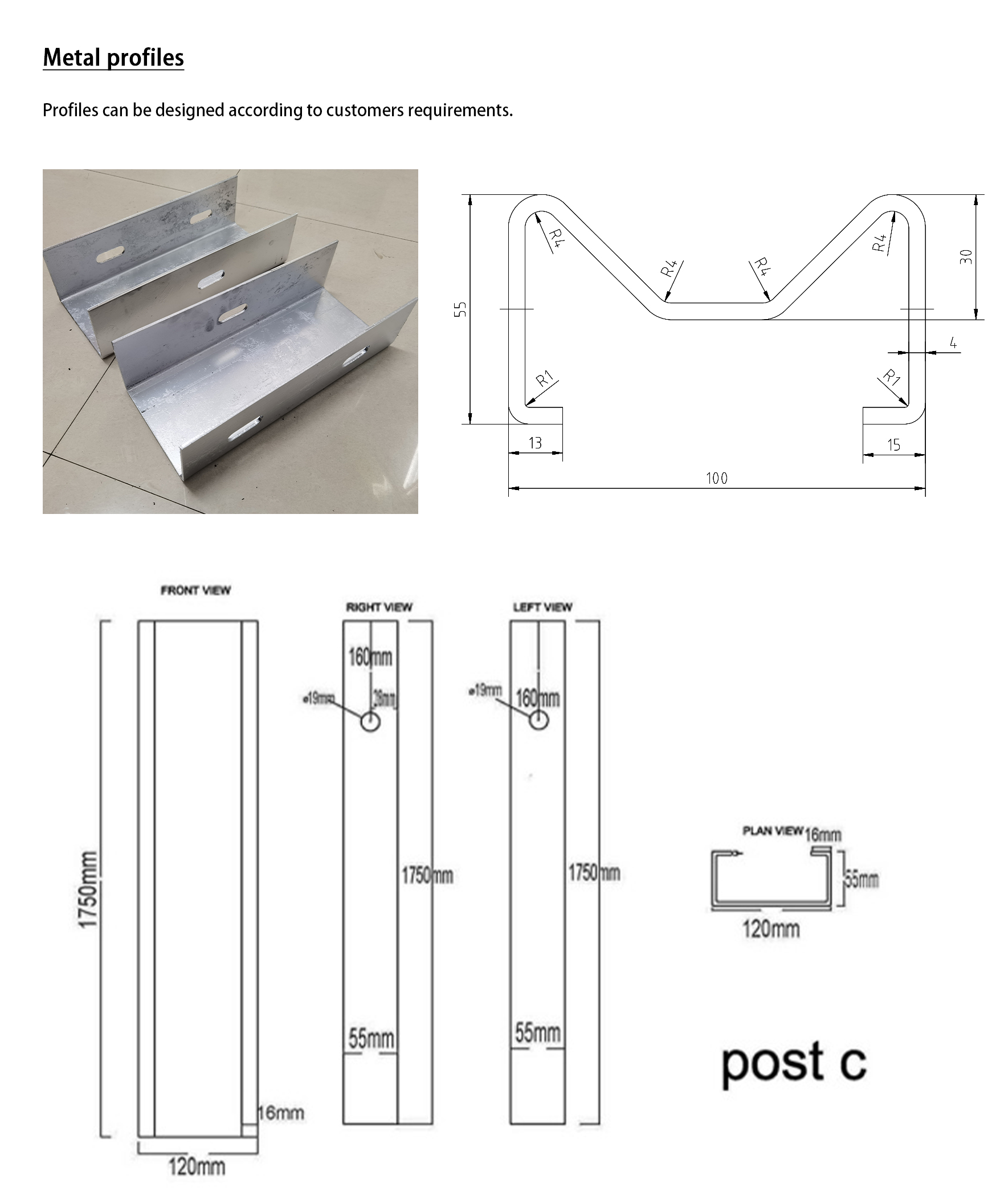

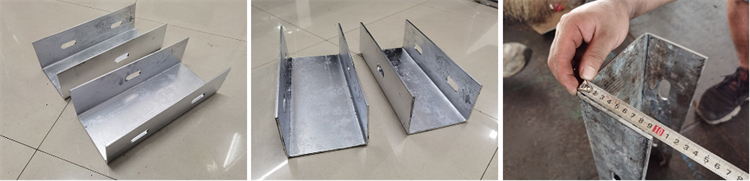

Profile Drawings

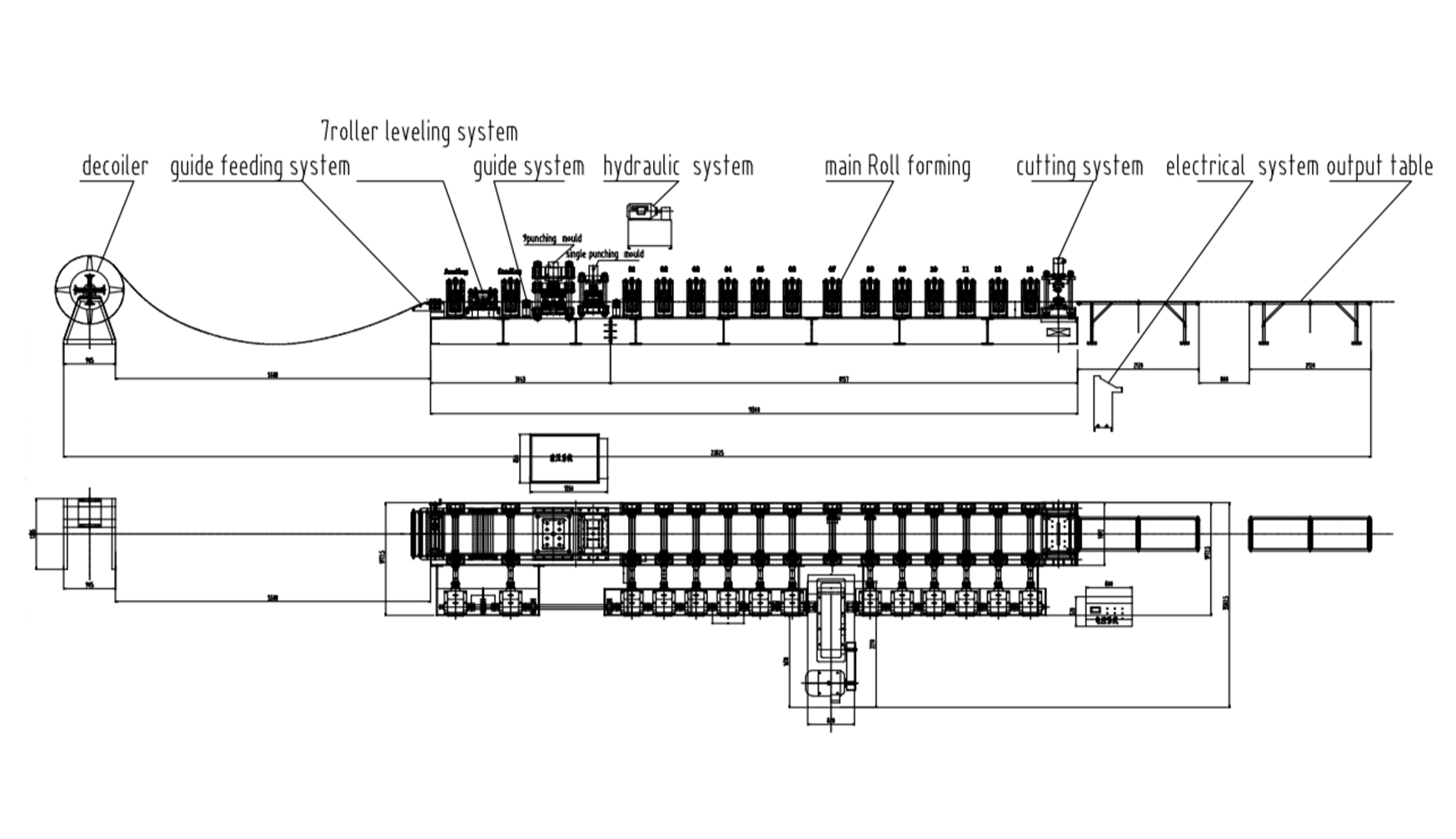

Production Line

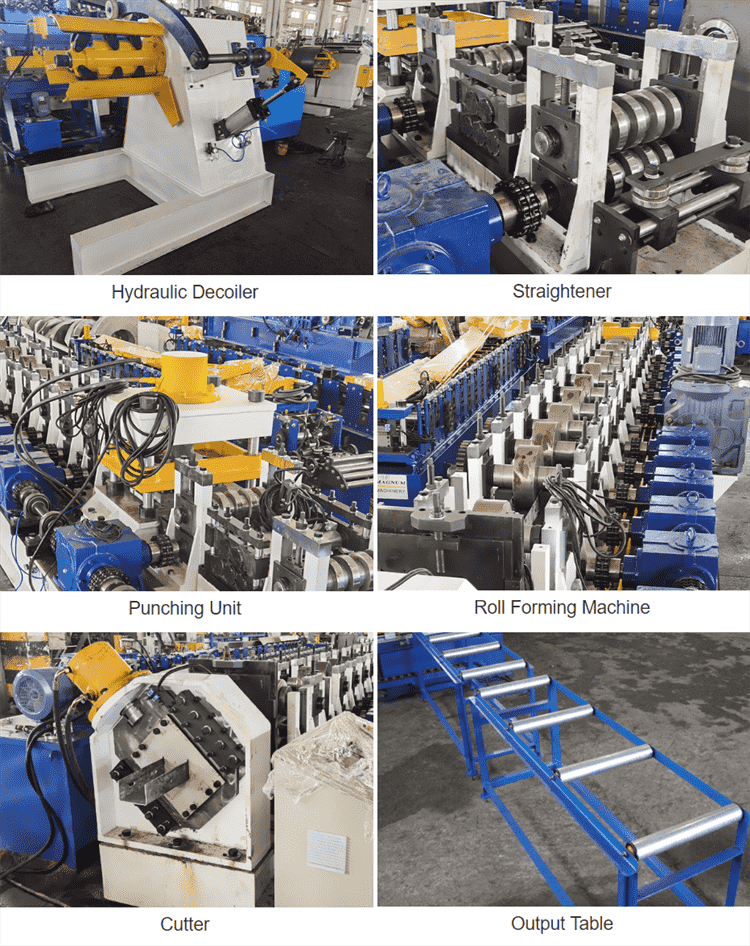

Product Details

Product Parameters

| Highway U/C Post Roll Forming Machine | ||

|

Machinable Material

|

A) Galvanized Steel |

Thickness(MM): 3.0-6.0 mm Or According To Customer

|

| B) PPGI | ||

| C) Carbon Steel | ||

| Yield Strength | 250 – 550 Mpa | |

| Tensil Stress | G250 Mpa-G550 Mpa | |

| Type | C Post, U post, M Post, Sigma Post, etc | |

| Decoiler | Hydraulilc Decoiler | |

| Punching System | Hydraulic Punching Station | |

| Forming Station | About 12 – 16 Stations | * According To Your Profile Drawings |

| Driving System | Gearbox Drive | |

| Machine Structure | Forged Iron Station | |

| Forming Speed | 0-20 (M/MIN) | Not Including Cutting And Punching |

| Rollers’ Material | GCr 15 | * Cr12Mov (Optional) |

| Cutting System | Post-cutting | |

| Frequency Changer Brand | Yaskawa | * Siemens (Optional) |

| PLC Brand | Panasonic | * Siemens (Optional) |

| Power Supply | 380V 50Hz 3ph | * Or According To Your Requirement |

| Machine Color | Industrial Blue | * Or According To Your Requirement |

Application