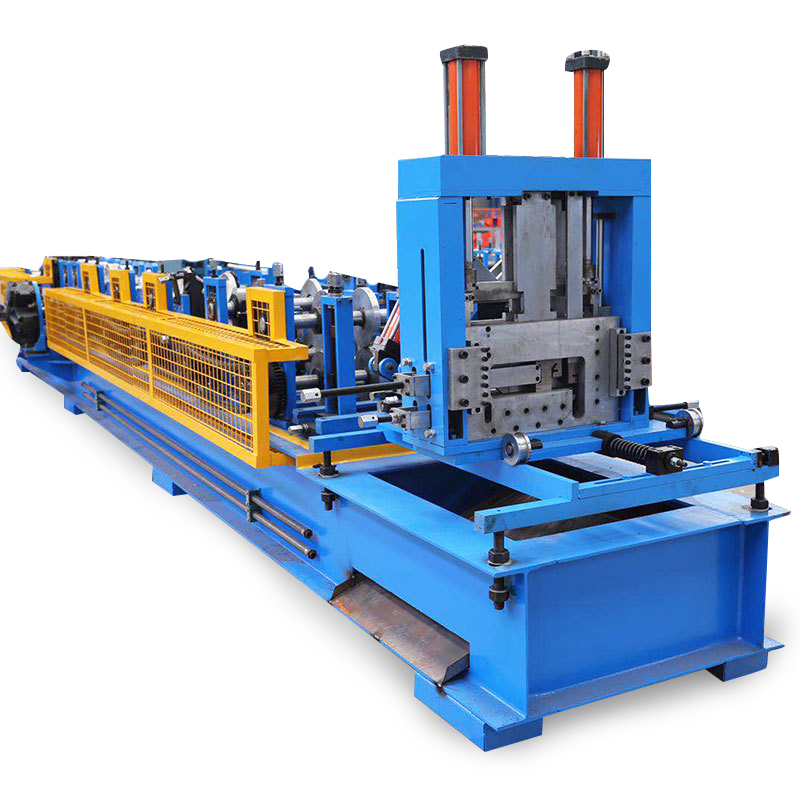

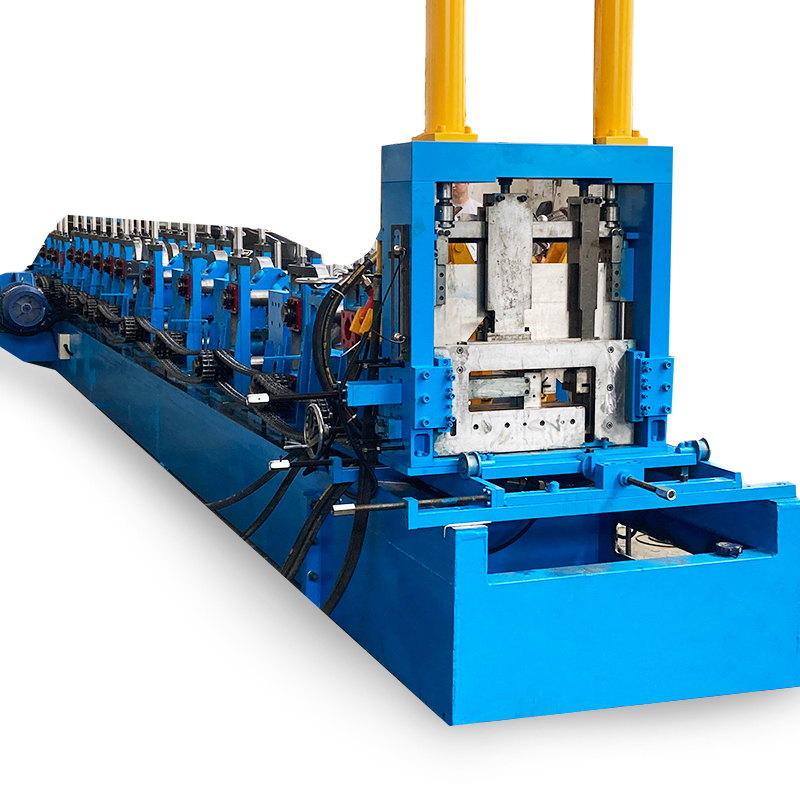

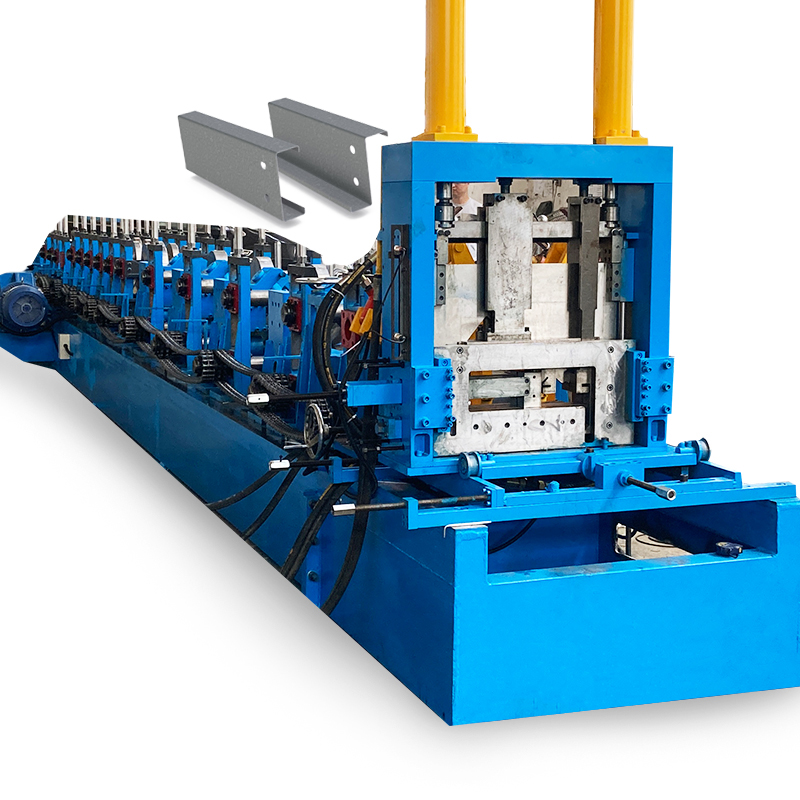

Fully automatic C&Z purlin machine quick Interchangeable Roll Forming Machine, adopts a special structure for both C and Z purlin making. The rollers for C & Z are changed very quickly without dismantle any parts. Cutter adopts universal hydraulic cutting device, no need to change cutter blade while producing different profiles with different sizes which save labor costs and improve production efficiency.

Full Automatic C Z Purlin Machine Details

Stand Base

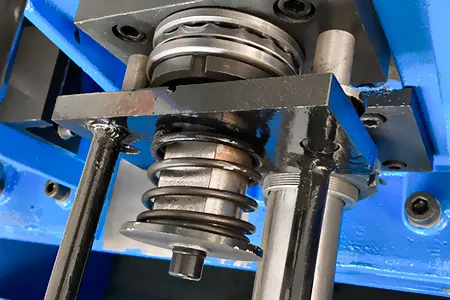

Roll stands adopt cast iron single station which is most heavy and strong.

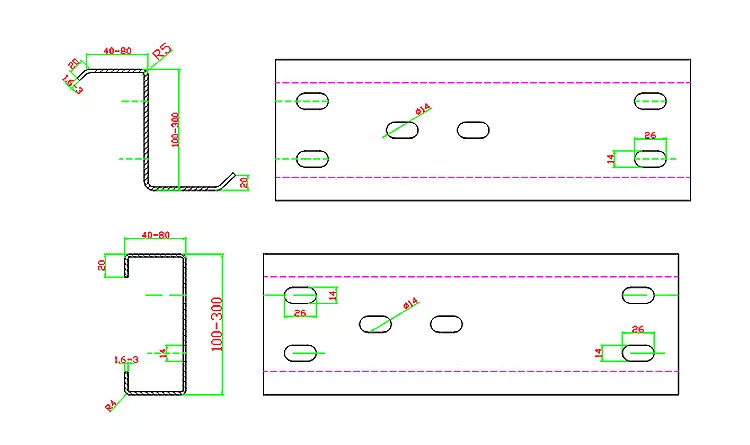

Interchangeable

Produce different purlin sizes without changing rollers or spacers.

Only need to overturn the rollers 180 degree, Save cost and time.

Universal Cut

Universal post cutter. No need change cutter blades for different sizes.

Customization

Senior and experienced engineer control the whole process for your customize.

Full Automatic C Z Purlin Machine Parameters

| Product |

C&Z purlin Quick Interchangeable Roll Forming Machine

|

| Model |

C Channel Profile / Z Shape Profile (Customizable )

|

| Base Material |

Galvanized Steel Hot And Cold Rolled Steel

|

| Thickness |

1.5-3.0mm (Customizable)

|

| Effective Width |

According To Profile Size

|

| Roller Station |

About 16 Stations

|

| Roller Material |

Bearing Steel / Cr12Mov

|

| Roller Driven Type |

By Chain/ Gearbox

|

| Color |

According To Customer Requirements / Customizable

|

| Brand | SUNWAY |

| Control System |

Worldwide Famous Brand PLC (Panasonic, Siemens, Delta, etc.)

|

| Power | 15KW-18KW |

| Frame |

350 H Steel / 400 H Steel

|

| Cutting Drive | Hydraulic Drive |

| Cutting & Hydraulic Type |

Type:Post Universal Cutter

Hydraulic Pump Station :11kw Blade: Cr12mov HRC: 58-62 |

advantage of china c/z purlin roll forming machine

- Cost-effectiveness: Chinese manufacturing offers cost advantages due to lower labor and production costs compared to many other countries. This translates into more affordable prices for C/Z purlin roll forming machines, making them accessible to a wider range of customers.

- High-quality production: Chinese manufacturers have invested heavily in advanced technology and modern machinery to ensure high-quality production. Many Chinese manufacturers follow strict quality control processes to meet international standards and customer expectations.

- Wide range of options: China has a vast market for machinery production, resulting in a wide range of options for C/Z purlin roll forming machines. Whether you need standard machines or customized solutions, Chinese manufacturers can often provide a variety of models, sizes, and configurations to suit your specific requirements.

- Customization capabilities: Chinese manufacturers are known for their ability to offer customized solutions. They can tailor C/Z purlin roll forming machines to meet specific design and production needs, such as different sizes, profiles, and material thicknesses.

- Technical expertise: China has a large pool of skilled engineers and technicians specializing in machinery manufacturing. Many Chinese manufacturers have accumulated extensive experience in roll forming technology, enabling them to design and produce efficient and reliable C/Z purlin roll forming machines.

- After-sales support: Chinese manufacturers generally offer comprehensive after-sales support, including installation, training, and technical assistance. They understand the importance of providing ongoing service to ensure customer satisfaction and maintain long-term relationships.

- Global reach: Chinese machinery manufacturers have a strong presence in the global market. They have established distribution networks and partnerships worldwide, making it easier to access their products and services from different countries.

What is steel frame roll forming machine mainly used for?

- Construction industry: Steel frames are widely used in the construction of buildings, such as residential houses, commercial complexes, industrial facilities, and warehouses. Steel frame roll forming machines can produce various profiles and sections that form the structural framework of these buildings.

- Infrastructure projects: Steel frames are also used in infrastructure projects like bridges, flyovers, stadiums, and airports. Steel frame roll forming machines can manufacture the required components with precision and efficiency.

- Prefabricated housing: Steel frames are commonly used in the production of prefabricated or modular houses. The roll forming machine can create the necessary sections and profiles that form the skeleton of these structures, enabling faster and efficient construction.

- Partition walls and interior systems: Steel frames are utilized for constructing partition walls and interior systems in both residential and commercial buildings. These frames provide structural support and enable the installation of various finishes, such as drywall, insulation, and cladding.

- Solar panel mounting systems: Steel frames are used to create mounting structures for solar panels. These frames are designed to securely hold the panels in place and withstand the environmental conditions they will be exposed to.

- Automotive industry: Steel frames are used in the manufacturing of automobile components, such as car frames, chassis, and reinforcements. Roll forming machines can produce the required profiles and shapes with high precision and repeatability.

- Storage systems: Steel frames are utilized in the construction of storage systems like racks, shelves, and pallets. These frames provide the necessary strength and stability to support heavy loads and organize storage spaces effectively.

Price advantage of china door frame roll forming machine

- Competitive manufacturing costs: China has long been known for its competitive manufacturing costs due to factors such as lower labor costs and economies of scale. This often translates into more affordable prices for machinery, including door frame roll forming machines.

- Extensive manufacturing infrastructure: China has a well-developed manufacturing infrastructure with a vast network of suppliers and components manufacturers. This allows for efficient production processes and cost savings through economies of scale.

- Technological expertise: Chinese manufacturers have invested heavily in advanced technology and machinery, including roll forming machines. They have developed expertise in the design, development, and production of these machines, enabling them to offer cost-effective solutions without compromising on quality.

- Access to raw materials: China is a major global supplier of raw materials, including steel and other metals used in the production of door frames. This proximity to raw material sources can help reduce transportation costs and lead to more competitive pricing.

- Supply chain efficiency: Chinese manufacturers often have well-established and efficient supply chains, which contribute to cost savings. They can source components, parts, and materials locally, reducing logistics costs and streamlining the production process.

- Customization options: China offers a wide range of customization options for door frame roll forming machines. Manufacturers can tailor the machines to meet specific requirements, such as different door frame profiles, sizes, and material thicknesses. This flexibility allows customers to choose the features they need at a competitive price.

- Global market presence: Chinese manufacturers have a significant presence in the global market for roll forming machines, including door frame roll forming machines. This market competitiveness drives manufacturers to offer attractive pricing to remain competitive and attract customers from around the world.

Reviews

There are no reviews yet.