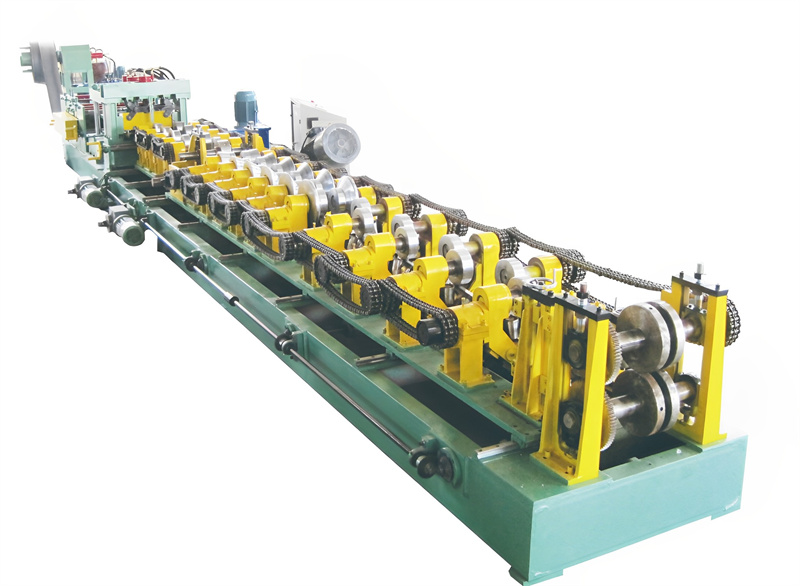

Features

CZ Purlin Roll forming machine can produce C, Z profiles. Produce the C and Z purlin by exchange one side of the roller up and down, only need about half hour. This machine also can adjust roller horizontal distance to achieve C or Z purlins of the width with high precision automatic. And also save time and increase production.

CZ Purlin Roll forming machine Applications

The finished products are widely used as the supporter of roof and wall in large-scale and mid-scale construction, such as factory, warehouse, garage, exhibition center, cinema, theatre, garden and so on.

CZ Purlin Roll forming machine Process Flow

Uncoiler — Feeding — Straightening — Pre-punching — Pre-cutting — Roll Forming — Exit Rack

Machine Configurations

| 1. Hydraulic Uncoiler |

2. Feeding Device

|

| 3. Straightening |

4. Roll Forming Machine

|

| 5. Post Punching | 6. Post Cutting |

| 7. PLC Control System | 8. Exit Rack |

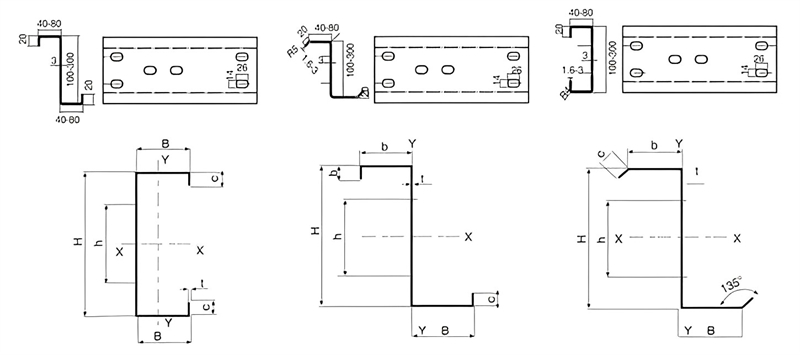

Profile Drawings for Reference

| C Purlin Section Size | |||||||

|

Model

|

Section Size (mm) | Hole Distance |

Remark

|

||||

| H | B | B | C | t | h | ||

| C100 | 100 | 40 | 40 | 15 | 2.0-3.0 | No Punching |

We Can Design the Machine According to Customer’s Requests

(with Middle Hole Punching).

|

| C120 | 120 | 50 | 50 | 20 | 2.0-3.0 | 40 | |

| C140 | 140 | 50 | 50 | 20 | 2.0-3.0 |

Adjustable Hole Distance

|

|

| C160 | 160 | 60 | 60 | 20 | 2.0-3.0 | ||

| C180 | 180 | 60 | 60 | 20 | 2.0-3.0 | ||

| C200 | 200 | 60 | 60 | 20 | 2.0-3.0 | ||

| C220 | 220 | 70 | 70 | 20 | 2.0-3.0 | ||

| C250 | 250 | 70 | 70 | 20 | 2.0-3.0 | ||

| C300 | 300 | 80 | 80 | 20 | 2.0-3.0 | ||

| Z Purlin Section Size | |||||||

|

Model

|

Section Size (mm) | Hole Distance |

Remark

|

||||

| H | B | b | C | t | h | ||

| Z100 | 100 | 55 | 50 | 20 | 2.0-3.0 | 40 |

We Can Design the Machine According to Customer’s Requests

(with Middle Hole Punching or Flange Punching).

|

| Z120 | 120 | 55 | 50 | 20 | 2.0-3.0 |

Adjustable Hole Distance

|

|

| Z140 | 140 | 55 | 50 | 20 | 2.0-3.0 | ||

| 2150 | 160 | 67 | 61 | 20 | 2.0-3.0 | ||

| Z160 | 180 | 67 | 61 | 20 | 2.0-3.0 | ||

| 2180 | 200 | 67 | 61 | 20 | 2.0-3.0 | ||

| 2200 | 220 | 67 | 61 | 20 | 2.0-3.0 | ||

| Z250 | 250 | 78 | 72 | 20 | 2.0.3.0 | ||

| Z280 | 280 | 78 | 72 | 20 | 2.0-3.0 | ||

| 2300 | 300 | 78 | 72 | 20 | 2.0-3.0 | ||

3 Reasons Why You Need To Get A CZ Purlin Roll Forming Machine

Photos for Reference

what is c z purlin roll forming machine?

C Z purlin roll forming machine is a specialized industrial machine used for the continuous production of C-shaped and Z-shaped steel purlins. Purlins are structural components commonly used in the construction of buildings, particularly in the roofing and wall framing systems.

The roll forming machine consists of a series of rolls and tooling that progressively shape a flat strip of metal into the desired purlin profile. The machine takes in a coil of steel, usually galvanized or cold-rolled, and feeds it through the roll forming process. The rolls and tooling are designed to bend and form the metal strip into the precise shape of a C or Z purlin.

The machine operates in a continuous manner, meaning that the purlins are produced in a continuous length with cut-off mechanisms integrated into the system. The process typically involves several steps, including decoiling the steel coil, leveling the strip, punching holes or slots for fastening purposes, and finally, shaping the purlin profile. The machine can be computer-controlled and automated, ensuring accurate and consistent production.

C purlins have a C-shaped cross-section, resembling a rectangular beam with flanges on both sides. They are commonly used as structural supports for roofs, walls, and floor joists. Z purlins, on the other hand, have a Z-shaped cross-section, resembling the letter “Z.” They are typically used in situations where more load-carrying capacity is required, such as larger buildings or structures with heavier roof loads.

By using a C Z purlin roll forming machine, manufacturers can efficiently produce purlins in large quantities and with consistent quality. The machine offers high productivity, precise shaping capabilities, and flexibility to produce different sizes and profiles of purlins. It plays a crucial role in the construction industry, providing the necessary components for efficient and durable building structures.

advantage of China cz purlin roll forming machine

- Cost-effectiveness: China is known for its competitive manufacturing industry, and CZ purlin roll forming machines from China often offer a cost-effective solution compared to machines from other countries. The lower production costs in China can translate into more affordable prices for the machines, making them an attractive option for buyers.

- High-quality manufacturing: Chinese manufacturing companies have made significant advancements in terms of technology and production standards. Many Chinese CZ purlin roll forming machine manufacturers use modern machinery, advanced automation, and stringent quality control processes to ensure high-quality products. This means that buyers can expect reliable and durable machines.

- Wide range of options: China has a vast market of CZ purlin roll forming machine manufacturers, offering a wide range of options to choose from. Buyers can find machines with different specifications, sizes, and features to meet their specific production requirements. The competitive market in China encourages manufacturers to innovate and provide various options to cater to different customer needs.

- Customization capabilities: Chinese CZ purlin roll forming machine manufacturers often offer customization services. This means that buyers can request modifications or additional features to suit their unique production needs. Customization can include adjustments in roll design, punching patterns, and other specifications, allowing buyers to optimize the machine’s performance for their specific applications.

- Export experience: China has extensive experience in exporting machinery and equipment to various countries around the world. Chinese manufacturers have established efficient logistics and shipping networks, making it relatively easy to import CZ purlin roll forming machines from China to different locations globally. This experience can simplify the buying process and ensure smooth delivery of the machines.

advantage of China cz purlin roll forming machine

There are several advantages of China CZ purlin roll forming machines. Here are some of the key benefits:

- Cost-effectiveness: China is known for its competitive manufacturing industry, and CZ purlin roll forming machines from China often offer a cost-effective solution compared to machines from other countries. The lower production costs in China can translate into more affordable prices for the machines, making them an attractive option for buyers.

- High-quality manufacturing: Chinese manufacturing companies have made significant advancements in terms of technology and production standards. Many Chinese CZ purlin roll forming machine manufacturers use modern machinery, advanced automation, and stringent quality control processes to ensure high-quality products. This means that buyers can expect reliable and durable machines.

- Wide range of options: China has a vast market of CZ purlin roll forming machine manufacturers, offering a wide range of options to choose from. Buyers can find machines with different specifications, sizes, and features to meet their specific production requirements. The competitive market in China encourages manufacturers to innovate and provide various options to cater to different customer needs.

- Customization capabilities: Chinese CZ purlin roll forming machine manufacturers often offer customization services. This means that buyers can request modifications or additional features to suit their unique production needs. Customization can include adjustments in roll design, punching patterns, and other specifications, allowing buyers to optimize the machine’s performance for their specific applications.

- Export experience: China has extensive experience in exporting machinery and equipment to various countries around the world. Chinese manufacturers have established efficient logistics and shipping networks, making it relatively easy to import CZ purlin roll forming machines from China to different locations globally. This experience can simplify the buying process and ensure smooth delivery of the machines.

It’s important to note that while there are advantages to purchasing CZ purlin roll forming machines from China, it is always recommended to conduct thorough research and due diligence before making a purchase. This includes evaluating the reputation, reliability, and after-sales support of the specific manufacturer or supplier to ensure a satisfactory buying experience.

Reviews

There are no reviews yet.