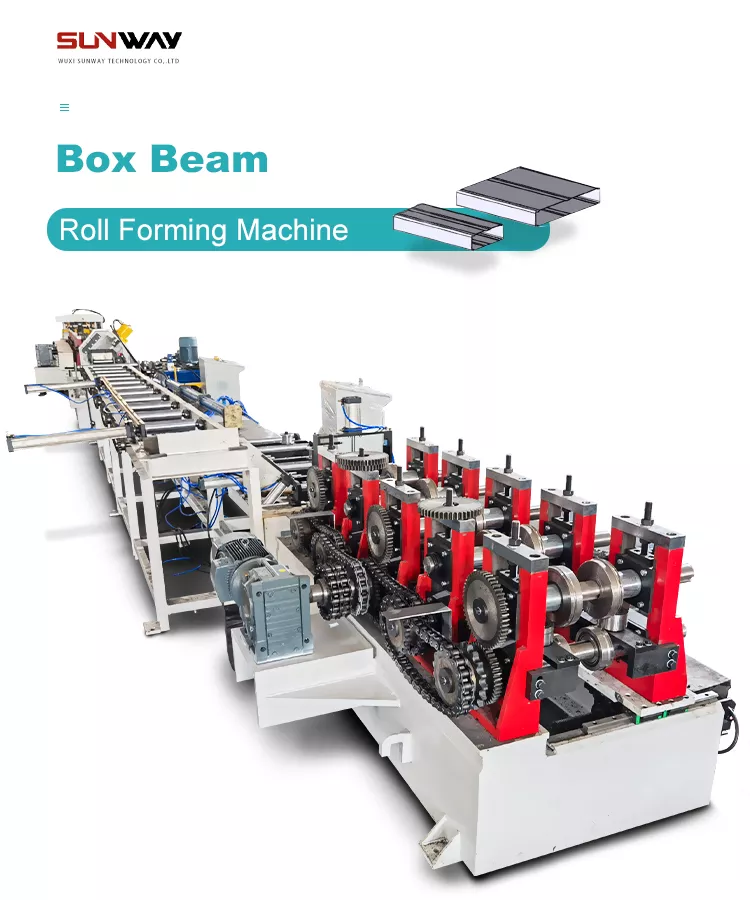

Box beam roll forming machine is developed to produce the beam which is fixed between the upright racks. It normally has two types: 1) both C beams are roll formed on a roll forming machine then seamed in a combined roll former to get a box beam; 2) one beam is formed on a roll forming machine directly to get a box beam.

Our intelligent roll forming machine could make various sizes of beam with thickness 1.5-3.0mm. Uncoiling, feeding, roll forming, welding, cutting etc process can be automatically realized on one line. Meantime, we have the roll forming machine to make step beam, upright rack and shelf panels. All these are components of Pallet racking system.

In warehouse pallet racking system, we are able to manufacture more machines like Step beam roll forming machine, Upright rack roll forming machine and shelf panel (box plate) roll forming machine etc.

We make different solutions according to customers’ drawing, tolerance and budget, offering professional one-to-one service, adaptable for your all requirements. Whichever line you choose, the quality of SUNWAY Machinery will ensure you obtain perfectly functional profiles.

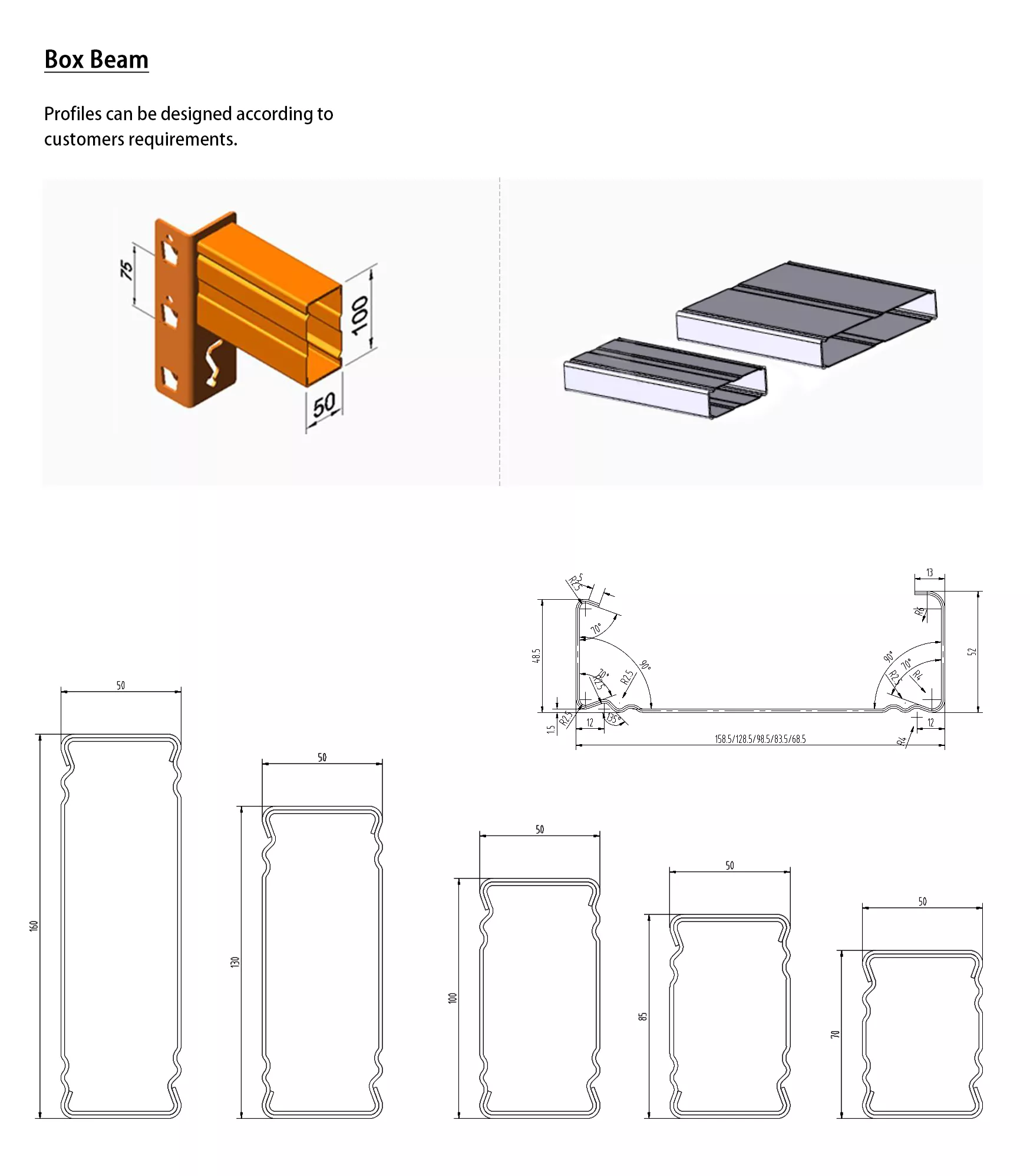

Profile Drawings

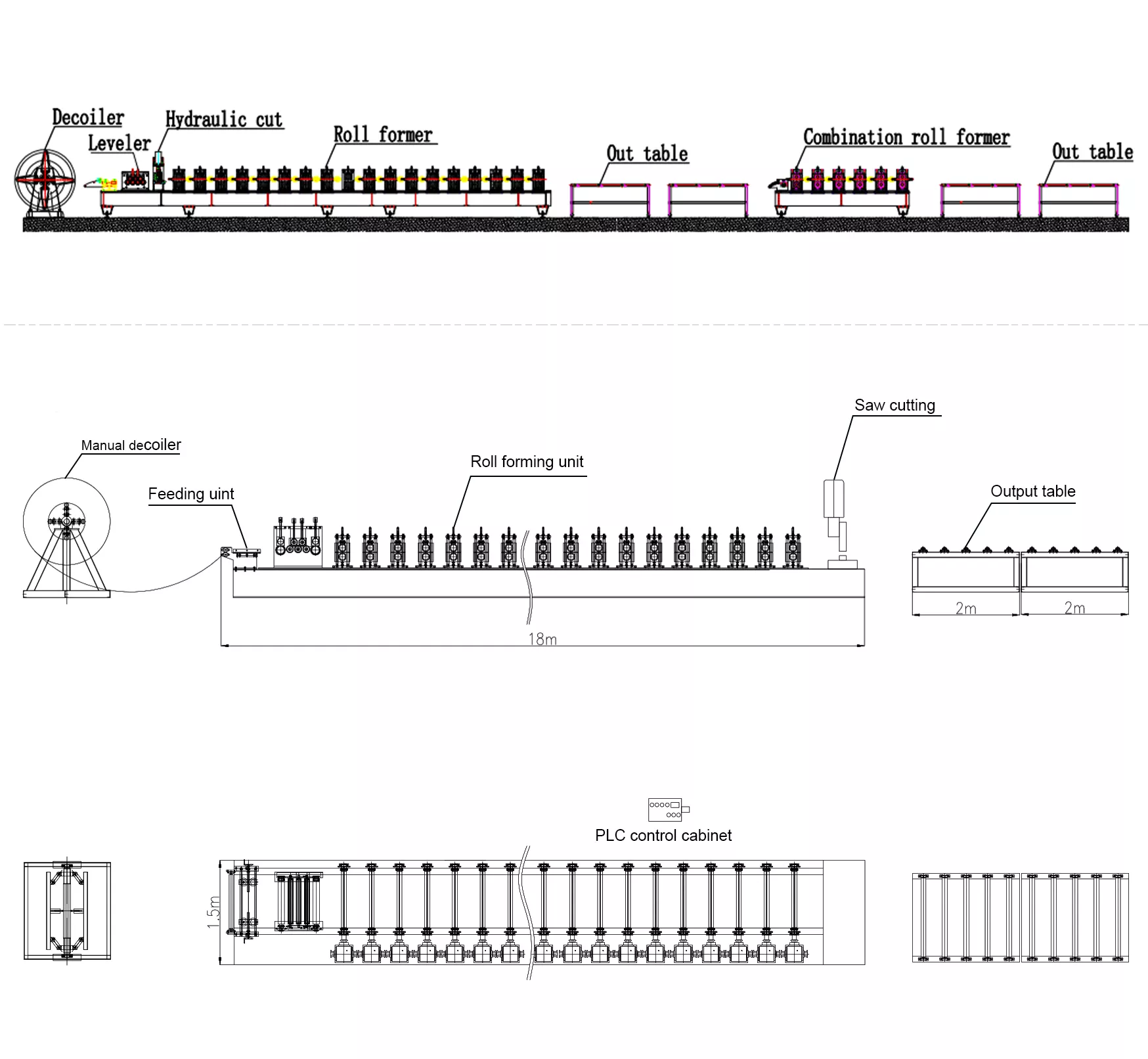

Production Line

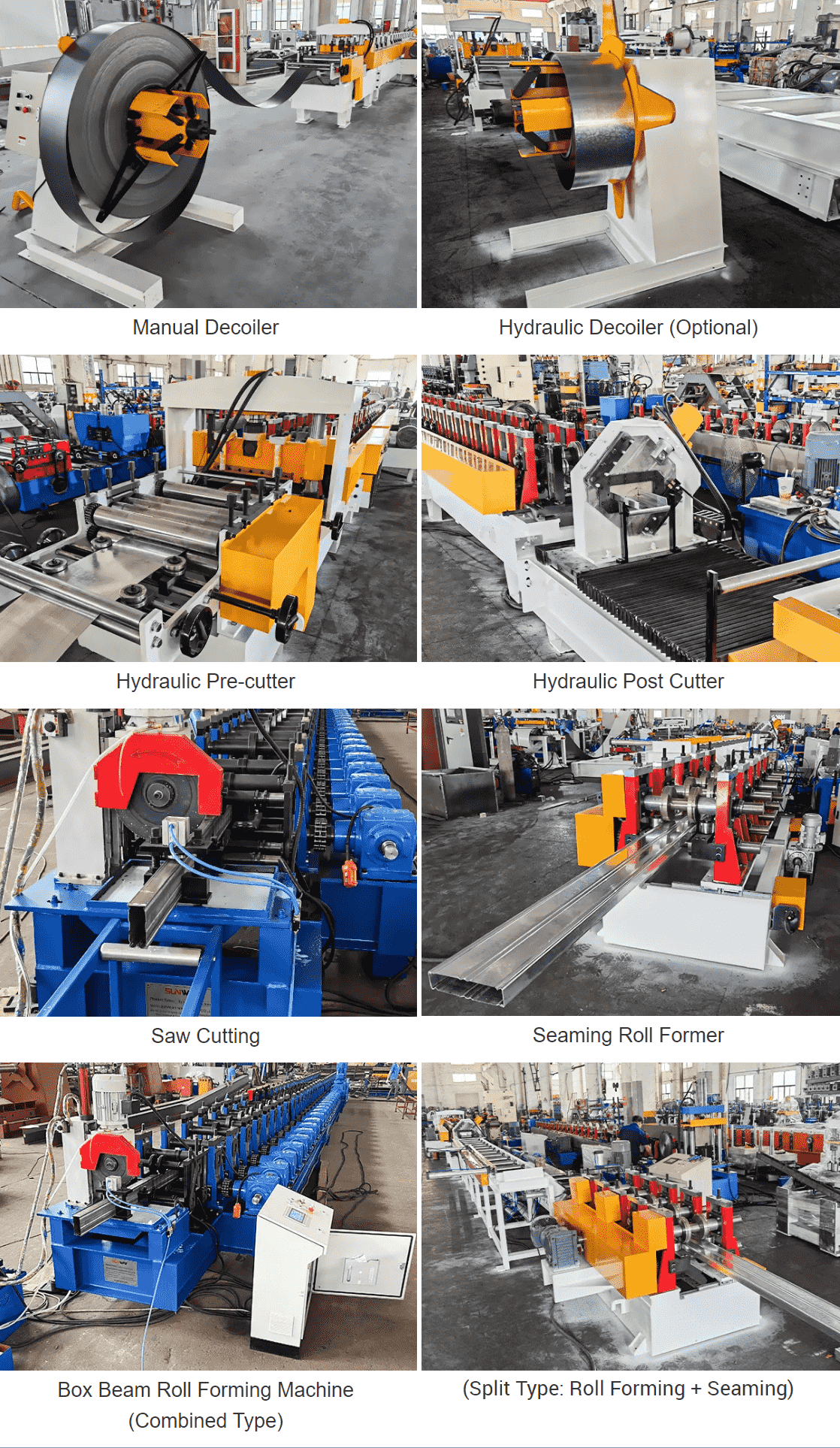

Product Details

Product Parameters

| Box Beam Roll Forming Machine | ||

|

Machinable Material

|

A) Galvanized Coil |

Thickness(MM): 1.5-3.0 as per customer

|

| B) PPGI | ||

| C) Cold-rolled Steel | ||

| D) Carbon Steel | ||

| Yield Strength | 250 – 350 Mpa | |

| Tensil Stress | 350 Mpa-500 Mpa | |

| Nominal Forming Speed(M/Min) | 10-20 | * Or According To Your Requirement |

| Forming Station | 18-20 | * According To Your Profile Drawings |

| Decoiler | Manual Decoiler | * Hydraulic Decoiler (Optional) |

| Driving System | Chain Drive | * Gearbox Drive (Optional) |

| Machine Structure | Steel Plates Welded | * Cast Iron Stands (Optional) |

| Rollers’ Material | GCr 15 | * Cr12Mov (Optional) |

| Cutting System | Hydraulic Cut | * Saw Cut (Optional) |

| Frequency Changer Brand | Yaskawa | * Siemens (Optional) |

| Power Supply | 380V 50Hz | * Or According To Your Requirement |

| Machine Color | Industrial Blue | * Or According To Your Requirement |

Application

What is shelf panel roll forming machine?

A shelf panel roll forming machine is an industrial machine used to produce shelf panels for various storage and shelving applications. The machine takes flat metal coils, typically steel or aluminum, and shapes them into the desired profile of the shelf panel.

The roll forming process involves feeding the metal coil into the machine, where it passes through a series of rollers and tooling. These rollers gradually bend and form the metal strip into the specific design and dimensions of the shelf panel. The machine includes various stations and components to perform tasks such as leveling, profiling, punching holes or slots, and cutting the panels to the desired length.

The shelf panel roll forming machine operates automatically, driven by motors and controlled by a computerized system. This ensures precise and efficient production of shelf panels with consistent quality.

Shelf panels produced by the machine are used in a wide range of applications, including commercial and industrial storage systems, retail displays, warehouse racks, and residential shelving solutions. They provide a sturdy and flat surface for storing items, maximizing space utilization, and organizing goods.

application of box beam roll forming machine

- Building and Structural Construction: Box beams are widely used in building and structural construction for various purposes. They can be used as primary load-bearing elements in building frames, bridges, and infrastructure projects. Box beams provide strength, rigidity, and stability to the structures, making them suitable for supporting heavy loads.

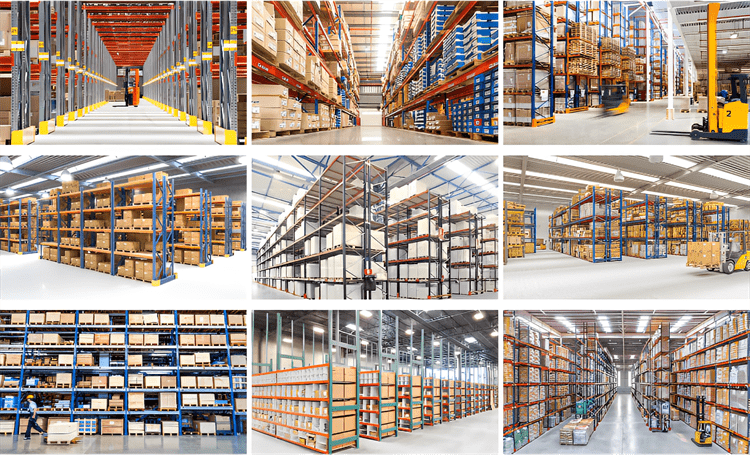

- Industrial Racking and Shelving Systems: Box beams are utilized in industrial racking and shelving systems for storage and organization purposes. They serve as horizontal support beams for holding shelves, pallets, and storage units. The robustness and durability of box beams make them suitable for heavy-duty storage applications in warehouses, distribution centers, and manufacturing facilities.

- Material Handling Equipment: Box beams find application in material handling equipment such as conveyors, cranes, and lifting mechanisms. They are used as structural components to support and guide the movement of materials and equipment. Box beams provide the necessary strength and stability for handling heavy loads and ensure safe and efficient material transfer.

- Automotive Industry: Box beams are utilized in the automotive industry for various applications. They are commonly used in vehicle frames, chassis, and structural components where strength, stiffness, and crashworthiness are required. Box beams provide the necessary structural integrity and contribute to the overall safety and performance of vehicles.

- Agricultural Equipment: In the agricultural sector, box beams are used in the construction of machinery and equipment such as tractors, trailers, and agricultural implements. They provide structural support, stability, and load-bearing capabilities required for heavy-duty agricultural operations.

These are just a few examples of the applications of box beams produced by the roll forming machine. The versatility and strength of box beams make them suitable for various industries where structural integrity, load-bearing capacity, and durability are crucial.

Price of beam roll forming machine

The price of a beam roll forming machine can vary significantly depending on various factors, including the machine’s specifications, size, complexity, brand, and the country of manufacture. Additionally, market conditions and fluctuations in raw material costs can also impact the price.

As a rough estimate, the price range for a basic beam roll forming machine typically starts at around $30,000 to $50,000 for smaller machines with simpler features. However, for larger and more advanced machines with specialized capabilities, the price can range from $100,000 to several hundred thousand dollars.

It’s important to note that these figures are general estimates and the actual price can vary based on individual circumstances. To get an accurate and specific price for a beam roll forming machine, it is recommended to contact manufacturers or suppliers directly. They can provide detailed quotations based on your specific requirements, including the desired beam profile, dimensions, material, and other customizations.

Additionally, it is advisable to consider factors such as after-sales service, warranty, technical support, and the reputation of the manufacturer when evaluating the price and making a purchasing decision.