Bemo Roof Panel Roll Forming Machine Features:

Bemo Roof Panel Roll Forming Machine is used to form the pre-painted sheet/GI/GA and aluminum material. It is composed of the uncoiler, guide feeder, roll forming machine, hydraulic cutting machine, PLC control system, hydraulic starion, output tables, auto seamer, and curving machine (Option)

Applications

The finished products are used as the roof and walls of gymnasiums, airports, theaters, factories, warehouses, garages, exhibition centers etc.

Process Flow

Uncoiling — feeding — roll forming — cutting — output — seaming — curving (option)

Machine Configurations

| 1. Uncoiler | 2. Guide feeder |

| 3. roll former |

4. Hydraulic cutting machine

|

| 5. PLC control system |

6. Hydraulic station

|

| 7. Output conveyor | 8. Auto seamer |

|

9. Curving machine (option)

|

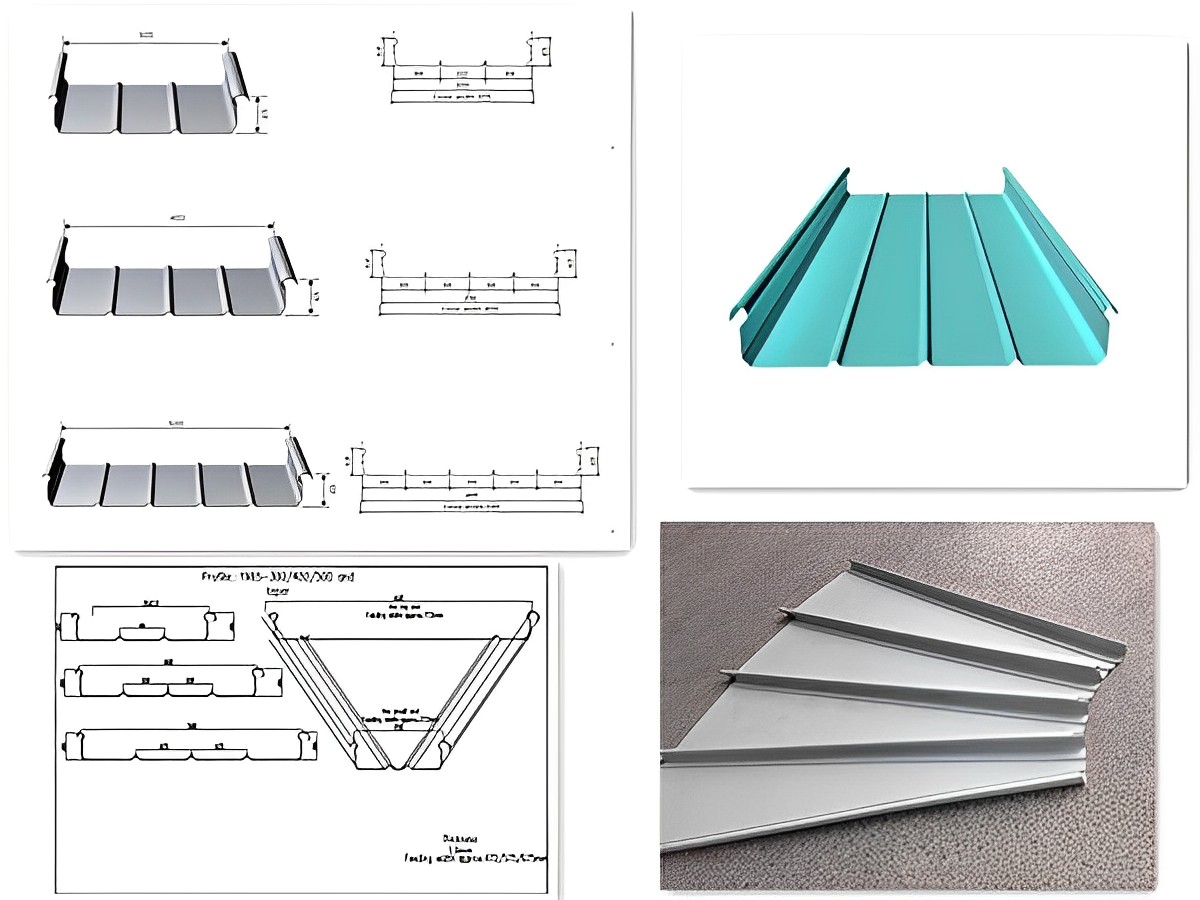

Profile Drawings for Reference

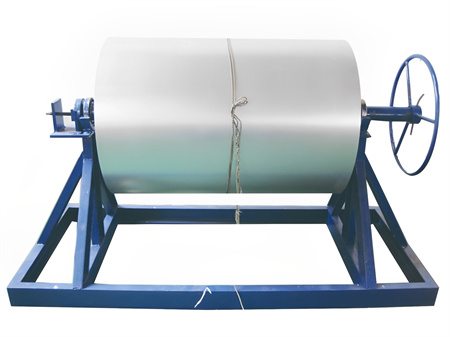

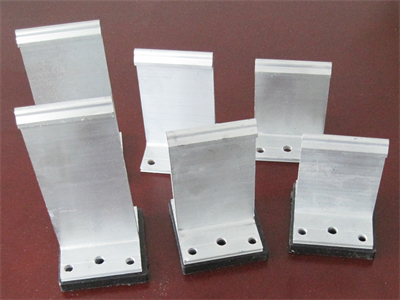

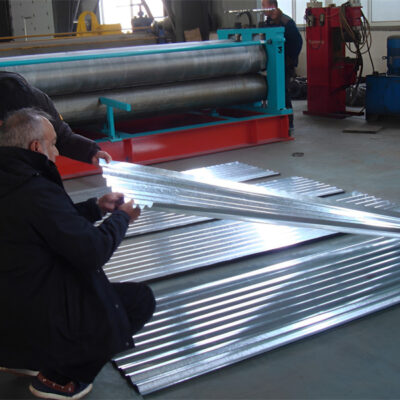

Photos for Reference

What is panel roll forming machine?

A panel roll forming machine is a type of industrial machinery used to fabricate metal panels with a consistent shape and profile. It is commonly employed in the construction industry to produce roofing panels, wall panels, and other similar components.

The roll forming process involves passing a continuous strip of metal through a series of rolling dies. These dies are designed to progressively shape the metal into the desired profile. The strip is typically fed into the machine from a coil, and various operations such as cutting, punching, and bending may be performed during the process.

The panel roll forming machine consists of several key components:

- Uncoiler: This part holds the metal coil and feeds the strip into the machine.

- Roll forming stations: These are sets of rollers arranged in a specific sequence. Each set of rollers gradually bends the metal strip to form a specific part of the panel’s profile.

- Drive system: The machine is equipped with a motor and gear system that drives the rollers, ensuring a continuous and precise feed of the metal strip.

- Cutting system: Depending on the design requirements, the machine may include a cutting mechanism to shear the panel to the desired length.

- Control system: The machine is controlled by a computerized system that regulates the speed, feed, and other parameters of the roll forming process.

Panel roll forming machines offer several advantages, including high production efficiency, precise shaping capabilities, and the ability to produce panels of different lengths and profiles. They are often used in large-scale manufacturing operations to create panels with consistent quality and dimensional accuracy.

What is ag panel roll forming machine?

An AG (Agricultural) panel roll forming machine is a type of industrial equipment used to manufacture AG panels, which are commonly used in the construction of agricultural buildings such as barns, sheds, and storage facilities.

Roll forming is a continuous bending process where a long strip of metal, typically steel or aluminum, is passed through a series of roller dies. Each roller die shapes the metal gradually, forming the desired profile. In the case of AG panels, the machine is specifically designed to produce the corrugated or ribbed profiles commonly used in agricultural construction.

The AG panel roll forming machine typically consists of a series of adjustable roller dies, which are set up to gradually form the desired corrugations or ribs in the metal. The machine can handle various widths and thicknesses of metal coils, allowing for flexibility in producing different panel sizes. The metal coil is fed into the machine, and as it passes through the roller dies, it is shaped into the corrugated or ribbed profile.

The roll forming process is highly efficient and allows for the continuous production of AG panels with consistent quality. The finished panels can be cut to the desired length and then used for various applications in agricultural construction.

AG panel roll forming machine plays a crucial role in the manufacturing process of AG panels, providing a cost-effective and efficient solution for producing high-quality panels used in agricultural buildings.

does metal roof panel roll forming machine belog to panel roll forming machine?

Yes, a metal roof panel roll forming machine is a specific type of panel roll forming machine. Panel roll forming machines are designed to produce a wide range of panels used in various applications, including roofing, wall cladding, flooring, and more.

A metal roof panel roll forming machine is specifically tailored to manufacture metal roof panels. These machines are equipped with specialized roller dies and other components that are optimized for producing roof panels with specific profiles, such as standing seam panels, corrugated panels, or other types of metal roofing profiles.

The metal roof panel roll forming machine operates on the same principle as other panel roll forming machines, with a continuous bending process that shapes the metal coil into the desired profile. However, the specific design and configuration of the machine are focused on meeting the requirements of metal roof panel production.

The metal roof panel roll forming machine is a subset of panel roll forming machines, specifically designed for manufacturing metal roof panels. It is a specialized equipment that caters to the specific needs and demands of the metal roofing industry.

Reviews

There are no reviews yet.