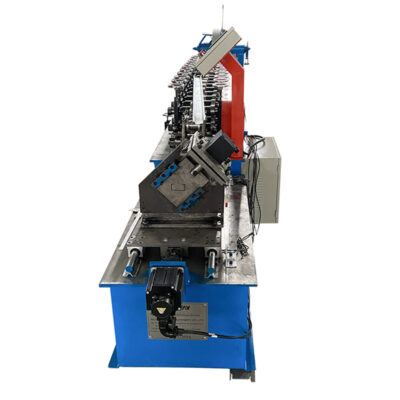

Stud And Track Roll Forming Machine

Stud And Track Roll Forming Machine

1. What is a Stud Roll Forming Machine?

A stud roll forming machine is a type of metal forming equipment used to create metal studs and tracks for use in construction projects. These machines typically consist of a series of rollers that shape and bend the metal into the desired shape. Stud roll forming machines can produce metal studs and tracks of various sizes, lengths, and thicknesses, depending on the specific needs of the project.

2. Types of Stud Roll Forming Machines

There are three main types of stud roll forming machines: single-sided machines, double-sided machines, and duplex machines. Each type has its own unique features and benefits.

Single-Sided Machines

Single-sided stud roll forming machines are designed to produce one side of the stud or track at a time. These machines are typically less expensive than double-sided and duplex machines and are ideal for small to medium-sized production runs.

Double-Sided Machines

Double-sided stud roll forming machines are capable of producing both sides of the stud or track simultaneously. These machines are more efficient than single-sided machines and are ideal for larger production runs.

Duplex Machines

Duplex stud roll forming machines are the most advanced type of stud roll forming machine. These machines are capable of producing multiple profiles simultaneously, making them ideal for high-volume production runs.

3. Key Components of a Stud Roll Forming Machine

A typical stud roll forming machine consists of several key components, including:

Uncoiler

The uncoiler is the first component of the stud roll forming machine. It is responsible for feeding the metal strip into the machine. The uncoiler can be either motorized or manual, depending on the specific needs of the project.

Feeding Section

The feeding section is responsible for guiding the metal strip into the machine and positioning it correctly for the roll forming section.

Roll Forming Section

The roll forming section is where the metal strip is shaped and bent into the desired shape. This section consists of a series of rollers, each of which performs a specific bending operation.

Cutting Section

The cutting section is responsible for cutting the metal strip into the desired length. This section typically uses a hydraulic or mechanical cutting system.

Control System

The control system is responsible for managing the operation of the stud roll forming machine. It includes a control panel that allows the operator to adjust the speed.

4. How Does a Stud Roll Forming Machine Work?

The stud roll forming machine works by passing a metal strip through a series of rollers that shape and bend it into the desired shape. The metal strip is first fed through the uncoiler, which unwinds the strip from the coil and feeds it into the machine. The feeding section then guides the metal strip into the roll forming section, where a series of rollers shape and bend the metal into the desired shape.

The cutting section then cuts the metal strip into the desired length, and the finished product is ejected from the machine. The control system manages the operation of the machine and allows the operator to adjust the speed and other parameters as needed.

5. Benefits of Using a Stud Roll Forming Machine

There are several benefits of using a stud roll forming machine for your construction or manufacturing needs:

Increased Production Efficiency

Stud roll forming machines are designed to produce metal studs and tracks quickly and efficiently, allowing you to increase your production output and meet tight deadlines.

Consistent Quality of Products

Stud roll forming machines are capable of producing metal studs and tracks with consistent quality and precision, ensuring that your products meet the required standards and specifications.

Cost-Effective

Stud roll forming machines are cost-effective compared to other metal forming methods, such as stamping and punching. They also require less labor and can reduce material waste, saving you money in the long run.

Versatility

Stud roll forming machines are versatile and can be used to produce metal studs and tracks of various sizes, lengths, and thicknesses. They can also produce other profiles and shapes, depending on the specific needs of the project.

6. Factors to Consider When Choosing a Stud Roll Forming Machine

When choosing a stud roll forming machine for your construction or manufacturing needs, there are several factors to consider:

Material Thickness and Width

The thickness and width of the metal strip will determine the size of the stud roll forming machine needed for the project.

Production Volume

The production volume required will determine the type of stud roll forming machine needed, whether single-sided, double-sided, or duplex.

Machine Dimensions

The available space and access to power and other utilities will determine the dimensions of the stud roll forming machine that can be accommodated.

Additional Features

Additional features such as automatic lubrication, digital readouts, and safety features can improve the efficiency and safety of the stud roll forming machine.

7. Maintenance and Troubleshooting Tips for Stud Roll Forming Machines

To ensure the optimal performance of your stud roll forming machine, regular maintenance is required. This includes cleaning, lubrication, and inspection of the key components of the machine. Troubleshooting tips include identifying and addressing issues with the uncoiler, feeding section, roll forming section, cutting section, and control system.

Why Sunway

The Global Leader In Roll forming Industry

We pay meticulous attention to each detail from raw material to delivery. It is throughout our constantly effort that our customers get the consistently high level quality products they have to look for. We always make efforts to cut the cost at the same time improve the technological content of products in order to enhance the market competitiveness of the products. In the related diversification development, we increase investment and enhance development of key products and key projects continuously make breakthroughs in technology and product function, to rank at the advanced level in the market.

Providing Innovative Roll forming Machine Solution

- We Use Advance Manufacturing Process

- Provide Unique Technology

- Group Of Certified & Experienced Team

- The Best Services For Multiple Industries

100+

Destination Countries

500+

Finished Project