When you’re looking to protect your home or building from the elements, one of the first things that comes to mind is the roof. It’s your first line of defense against rain, wind, and the sun’s harsh rays. And when it comes to roofing materials, iron sheets have been a popular choice for decades, thanks to their durability, affordability, and versatility.

In this detailed guide, we’re diving deep into the world of iron sheets for roofing, covering everything you need to know — from types of iron sheets to their benefits, installation process, and more. We’ll also present key data in tables, helping you compare different models, suppliers, and more. Let’s get started!

Overview of Iron Sheets for Roofing

Iron sheets for roofing, often referred to as corrugated metal sheets, are an excellent roofing material due to their longevity, resistance to weather conditions, and cost-effectiveness. These sheets are generally made of iron or steel and are often coated with zinc (galvanized) or painted to prevent rusting.

Iron roofing sheets are available in a variety of designs, profiles, and finishes, making them suitable for different types of buildings, from residential homes to industrial structures. One of the standout features is their ability to withstand extreme weather conditions without warping, cracking, or becoming damaged. Moreover, with proper installation, they can last for decades, providing a solid return on investment.

Types of Iron Sheets for Roofing

There are multiple types of iron sheets available for roofing, each offering unique advantages. From corrugated sheets to ribbed and tile profile designs, there’s something for every project. Below, we’ll go over ten specific iron sheet models, breaking down their features and benefits.

| Type | Description | Benefits |

|---|---|---|

| Corrugated Iron Sheets | Traditional design featuring a wavy pattern. Ideal for both residential and commercial roofing. | Offers excellent water drainage and is highly resistant to rust when galvanized. Cost-effective and easy to install. |

| Galvanized Iron Sheets | Iron sheets coated with zinc to prevent rusting. Often used in harsh environments. | Resistant to corrosion, making them ideal for areas with heavy rainfall or near the coast. Affordable and long-lasting. |

| Colorbond Roofing Sheets | Pre-painted steel roofing sheets available in a wide range of colors. Highly durable and designed for extreme weather conditions. | Aesthetic appeal with a variety of colors to choose from. Superior resistance to corrosion and UV rays. Energy-efficient in hot climates. |

| Tile Profile Iron Sheets | Iron sheets shaped to resemble traditional roofing tiles. Used primarily for residential homes where aesthetics are key. | Combines the strength of metal with the aesthetic appeal of traditional tiles. Lightweight and easier to install than actual tiles. |

| Aluzinc Roofing Sheets | A type of iron sheet with a coating of aluminum, zinc, and silicon. Designed for superior performance in terms of rust resistance. | Excellent rust resistance, up to 4x better than galvanized sheets. Reflective surface helps reduce heat absorption, making it energy-efficient. |

| Ribbed Iron Sheets | These sheets have raised ribs running along their surface, offering additional strength and rigidity. | Highly durable and resistant to bending. Ideal for large commercial or industrial buildings. Better water runoff due to its raised ridges. |

| Polyester Coated Iron Sheets | Coated with a polyester resin, these iron sheets are designed for durability and weather resistance. Available in multiple colors. | Affordable option with good resistance to weathering. Easy to clean and maintain. Color options make it suitable for both homes and businesses. |

| Standing Seam Iron Sheets | Featuring long, flat panels with interlocking seams, this type of roofing offers a modern, sleek look. | Provides a watertight seal with interlocking seams. Excellent for areas with heavy snowfall or rain. Stylish and contemporary in appearance. |

| Galvalume Iron Sheets | An iron sheet coated with an alloy of aluminum and zinc for enhanced durability and resistance to corrosion. | Outperforms galvanized iron in terms of durability. Highly resistant to rust and oxidation, even in coastal environments. |

| Zincalume Roofing Sheets | A product of steel coated with aluminum and zinc alloy. Known for its excellent resistance to corrosion and long-lasting performance. | Long-lasting with high resistance to harsh weather conditions. Often used in areas with extreme climates or near the ocean. |

Iron Sheets for Roofing Guide

When choosing the right iron sheets for your roofing project, it’s essential to consider factors such as your environment, the type of structure, and aesthetic preferences. Here’s a handy guide to help you make an informed decision:

Corrugated Iron Sheets

Corrugated iron sheets are easily the most recognizable. With their wavy design, they provide superior strength and excellent water drainage. But what sets them apart? Their design allows water to run off quickly, preventing leaks and water damage. These sheets are lightweight, easy to install, and great for both residential and industrial applications.

Tile Profile Iron Sheets

If you’re after something that combines durability with a traditional look, tile profile iron sheets are a fantastic option. These sheets mimic the appearance of ceramic tiles but come with the added benefits of being lightweight and more affordable. Compared to heavy clay or concrete tiles, iron tile profiles offer a quicker installation process, saving both time and labor costs.

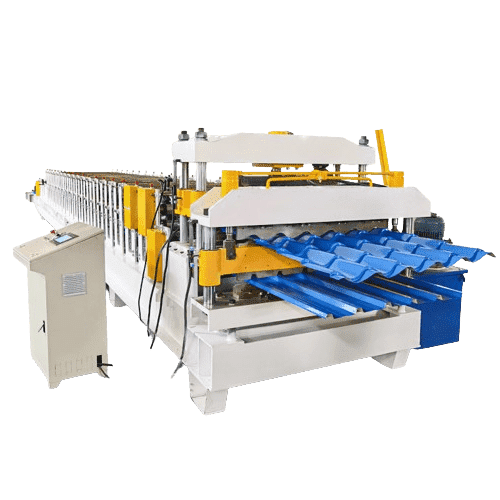

How Iron Sheets for Roofing Are Made

Iron sheets undergo a detailed process before they are ready to be installed on your roof. Here’s a step-by-step explanation of how they are made:

- Raw Material Preparation: High-quality iron ore is sourced, smelted, and refined into steel. This serves as the base material for the roofing sheets.

- Rolling and Shaping: The steel is rolled into flat sheets and then passed through corrugating machines to create different profiles like wavy, ribbed, or tile-like patterns.

- Coating: To prevent rust and ensure longevity, the sheets are often coated with zinc (galvanization) or aluminum-zinc alloys (galvalume).

- Painting: For aesthetic purposes and extra protection, the sheets can be painted or coated with polyester or other types of weather-resistant paint.

- Cutting: The sheets are cut into specific lengths and widths, depending on the requirements of the customer.

Once manufactured, the sheets are ready for transportation and installation. It’s a highly automated process, ensuring uniformity and quality across every sheet produced.

Key Components of Iron Roofing Sheets and Their Functions

| Component | Function |

|---|---|

| Base Material (Steel/Iron) | Provides strength and durability to the roofing sheet. |

| Coating (Zinc/Aluminum) | Protects the iron sheet from rust, corrosion, and environmental wear and tear. |

| Paint Finish | Adds an additional layer of protection and enhances the aesthetic appeal of the roof. |

| Ribbing or Corrugation | Improves structural strength and provides better water drainage. |

| Interlocking Seam | In standing seam designs, the interlocking feature helps create a watertight seal between sheets. |

| Fasteners and Fixings | Used to secure the sheets to the roof frame. These are typically made of stainless steel to prevent rust. |

-

Carriage Board Roll Forming Machine

Carriage Board Roll Forming Machine -

Highway Guardrail End Terminal Forming Machine

Highway Guardrail End Terminal Forming Machine -

Highway U/C Post Roll Forming Machine

Highway U/C Post Roll Forming Machine -

2 Waves Highway Guardrail Roll Forming Machine

2 Waves Highway Guardrail Roll Forming Machine -

3 Waves Highway Guardrail Roll Forming Machine

3 Waves Highway Guardrail Roll Forming Machine -

Electrical Cabinet Frame Roll Forming Machine

Electrical Cabinet Frame Roll Forming Machine -

Din Rail Roll Forming Machine

Din Rail Roll Forming Machine -

Two waves highway guardrail machine

Two waves highway guardrail machine -

Three waves highway guardrail machine

Three waves highway guardrail machine

Machine Speed and Efficiency in Iron Sheet Production

The efficiency of machines in the production of roofing sheets depends on their speed, quality, and consistency. Below is a typical representation of machine speed and efficiency in the production of iron roofing sheets:

| Machine Type | Average Speed | Efficiency |

|---|---|---|

| Corrugating Machine | 25-30 meters per minute | High accuracy in creating uniform waves/ribs. |

| Galvanizing Line | 40-60 meters per minute | Ensures high-quality corrosion protection. |

| Painting and Coating Line | 15-25 meters per minute | Uniform paint coating and long-lasting finish. |

Customizable Mechanical Parameters for Iron Sheets

Roofing projects may require custom solutions depending on the location, weather, and architectural design. Here’s a table showcasing customizable parameters:

| Customizable Parameter | Description |

|---|---|

| Sheet Thickness | Varies from 0.30mm to 0.50mm, with thicker sheets providing better durability and insulation. |

| Sheet Length | Can be cut to the required length, usually between 2 meters and 6 meters. |

| Profile Type | Corrugated, ribbed, or tile profiles, depending on the aesthetic and functional requirements. |

| Coating Thickness | Coatings can vary in thickness, with heavier coatings offering superior corrosion resistance. |

| Paint Color and Finish | Customers can choose from a wide variety of colors and finishes, including matte, glossy, or metallic. |

Applications and Uses of Iron Sheets for Roofing

Iron sheets are a versatile roofing material, suitable for a variety of structures and environments. Here’s a table highlighting their common applications:

| Application | Description |

|---|---|

| Residential Homes | Tile-profile or corrugated sheets are commonly used for homes, providing an affordable and durable solution. |

| Commercial Buildings | Ribbed and corrugated sheets are ideal for warehouses and factories due to their strength and durability. |

| Agricultural Structures | Used in barns, sheds, and storage units, thanks to their ability to withstand harsh weather conditions. |

| Coastal Buildings | Galvalume and zincalume sheets are preferred in coastal regions due to their superior resistance to salt corrosion. |

| Industrial Warehouses | Standing seam sheets provide a watertight, durable roofing solution for large industrial buildings. |

Installation, Operation, and Maintenance

Proper installation and maintenance are crucial to ensure that your iron roofing sheets last for decades. Here’s a breakdown of the installation, operation, and maintenance process:

| Stage | Description |

|---|---|

| Installation | Secure the sheets using proper fasteners. Ensure overlapping seams for a watertight installation. |

| Operation | Once installed, the roof requires minimal operation. Regular inspections are recommended. |

| Maintenance | Clean the roof regularly to prevent dirt build-up. Check for loose fasteners and re-tighten if necessary. |

How to Choose a Supplier for Iron Roofing Sheets

Choosing the right supplier can be overwhelming. Here are some key factors to consider:

| Factor | What to Look For |

|---|---|

| Quality Certifications | Ensure the supplier complies with international standards such as ISO or ASTM for quality assurance. |

| Product Range | A wide product range allows you to choose the best material for your project. |

| Customer Reviews | Check online reviews to gauge the supplier’s reliability and customer service. |

| Pricing | Compare prices from multiple suppliers to ensure you’re getting the best deal. |

| After-Sales Service | A good supplier should offer after-sales support, including guidance on installation and maintenance. |

Price Range and Suppliers for Iron Roofing Sheets

The price of iron sheets for roofing varies depending on the type of sheet, coating, and region. Here’s a table outlining typical price ranges:

| Supplier | Price Range per Sheet (USD) |

|---|---|

| ABC Iron Roofing Co. | $15 – $25 |

| SteelRoof Solutions | $18 – $30 |

| GalvaShield Metalworks | $12 – $22 |

| ColorTech Roofing Systems | $20 – $35 |

| ZincAlum Roofing Inc. | $25 – $40 |

Advantages and Disadvantages of Iron Sheets for Roofing

No material is perfect. While iron sheets have many advantages, they also come with some limitations. Here’s a comparison of their pros and cons:

| Aspect | Advantages | Disadvantages |

|---|---|---|

| Durability | Long-lasting and resistant to extreme weather. | Can be prone to rust if not properly coated or maintained. |

| Cost | Affordable compared to other roofing materials like tiles or shingles. | Higher initial cost compared to some cheaper roofing alternatives like asphalt. |

| Weight | Lightweight, making installation easier and less labor-intensive. | Lightweight nature might not be ideal for regions prone to hurricanes or high winds. |

| Maintenance | Requires minimal maintenance compared to other roofing materials. | Occasional repainting may be required, depending on the finish and exposure to the elements. |

| Aesthetic Appeal | Available in various colors and finishes, offering flexibility in design. | Metal roofs can sometimes look industrial or less warm compared to traditional tiles or shingles. |

FAQ

Below is a collection of frequently asked questions about iron sheets for roofing, along with answers.

| Question | Answer |

|---|---|

| What is the lifespan of iron roofing sheets? | With proper installation and maintenance, iron roofing sheets can last up to 50 years or more, especially when galvanized or coated with protective finishes. |

| Do iron roofing sheets rust? | Galvanized and coated iron sheets are resistant to rust. However, if the coating is damaged or wears off over time, rust can occur. |

| Can iron roofing sheets be painted? | Yes, many iron roofing sheets come pre-painted. However, you can also repaint them after installation to match your desired aesthetic or refresh the appearance. |

| Are iron sheets energy-efficient? | Coated iron sheets, like Colorbond or Aluzinc, have reflective properties that help reduce heat absorption, improving energy efficiency in hot climates. |

| Is it easy to install iron roofing sheets? | Yes, iron roofing sheets are lightweight and come in larger sizes, making installation faster and easier compared to materials like tiles or shingles. |

| How do I maintain my iron roof? | Regular inspections, cleaning debris, and re-tightening loose fasteners will help maintain the roof’s longevity. Repainting may be required after several years. |

| Are iron roofing sheets noisy during rain? | Without proper insulation, iron sheets can be noisy during heavy rain. Installing insulation or a sound-deadening underlayment can minimize noise. |

| Can iron sheets be recycled? | Yes, iron roofing sheets are highly recyclable, making them an environmentally friendly roofing option. |

Conclusion

Iron sheets for roofing offer a range of benefits, from durability and cost-effectiveness to versatility in design and resistance to extreme weather. Whether you’re considering corrugated iron sheets for a commercial building or a tile-profile iron sheet for your home, the options are abundant. By understanding the different types of iron sheets, the installation process, and how to maintain them, you’ll be well-equipped to make the best choice for your roofing project.

With a variety of models, customizable features, and suppliers to choose from, iron roofing sheets stand out as one of the most reliable and efficient roofing materials available.