The roof wall panel roll forming machine is a type of metal forming machine, which has been widely used in the manufacturing process of building materials. These machines are generally equipped with roll and press tools to form metal coils or sheets. In this article, we’ll cover what such a machine is for what it does and how it works as well as some helpful tips on what features you should consider when buying one for your home or business!

What Is A Roof Wall Panel Roll Forming Machine?

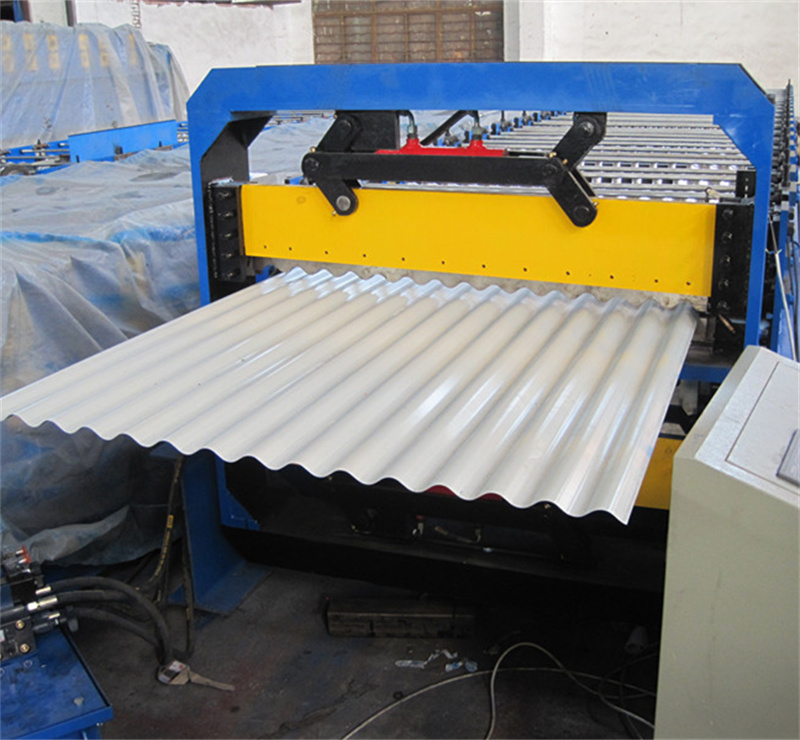

A roof wall panel roll forming machine is a specialized industrial machine that forms roof panels from sheets of metal. The machine uses a series of rolls to create the roof panels, which are then cut to size and assembled into a roof.

The roof wall panel roll forming machine is typically powered by an engine, and it requires a lot of space to operate. The machines are also expensive to buy and maintain, so they are usually only used in large manufacturing plants.

How Does a Roof Wall Panel Roll Forming Machine Work?

The roof wall panel roll forming machine is a specialized device that will help you manufacture roof wall panels quickly and easily. This machine requires minimal setup time, and you can start rolling roof wall panels as soon as the machine is operational. You will need to provide the machine with the appropriate materials, and then it will do the rest.

The first step in using this machine is to assemble the roll formers. These are large cylinders that hold the roof wall panel sheets while they are being formed. You will need at least two roll formers, and you can add more if necessary. The second step is to load the sheet of Roof Wall Panel into one of the roll formers. Make sure that the sheet is fully rolled up so that it forms a tight cylinder.

Once the Roof Wall Panel has been loaded into one of the roll formers, use the controls on the machine to begin forming the panel. The roll formers will move along the sheet, pressing down on it and forcing it into a shape that you specify. The process should take around 45 minutes, but if there are any errors or problems with the formation of the panel, you can stop and correct them before continuing.

Once your Roof Wall Panel has been formed, it needs to be cut to size. This can be done using a saw or a series of cutting machines that are specifically designed for this purpose.

-

Standing Seam Roof Panel Curving Machine

Standing Seam Roof Panel Curving Machine -

Barrel Corrugated Roll Forming Machine

Barrel Corrugated Roll Forming Machine -

Hydraulic Roof Sheet Curving Machine

Hydraulic Roof Sheet Curving Machine -

Stand Seaming Roof Panel Roll Forming Machine

Stand Seaming Roof Panel Roll Forming Machine -

Downspout Pipe Roll Forming Machine

Downspout Pipe Roll Forming Machine -

Gutter Roll Forming Machine

Gutter Roll Forming Machine -

Trapezoidal Panel Roll Forming Machine

Trapezoidal Panel Roll Forming Machine -

Ridge Cap Roll Forming Machine

Ridge Cap Roll Forming Machine -

Double Layer Panel Roll Forming Machine

Double Layer Panel Roll Forming Machine

components of a roof wall panel roll forming machine

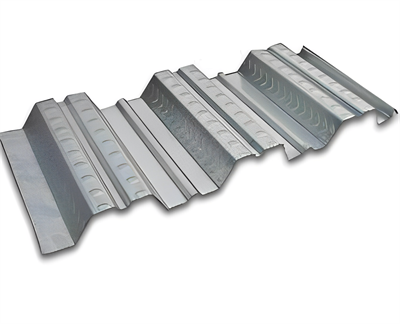

The roof wall panel forming machine is mainly composed of the following:

- The cutting device which can cut the panels into different sizes and shapes according to the customer’s requirements.

- The roll forming device which will form the roof wall panels by compressing and bonding them together.

- The coating device which will coat the roof wall panels with a strong adhesive to make them waterproof and heat-resistant.

types of a Roof Wall Panel Roll Forming Machine

There are basically three types of roof wall panel roll forming machines: the belt type, the blade type and the screw type.

Belt Type Roof Wall Panel Roll Forming Machine: The belt type roof wall panel roll forming machine is mainly composed of a motor, a driving system, a conveyor belt, and a mold. The motor rotates the driving system, which moves the conveyor belt forward at a consistent speed. As the conveyor belt moves forward, it contacts the mold on one side and pushes it downward. This causes the metal sheet to be pressed into a desired shape.

Blade Type Roof Wall Panel Roll Forming Machine: The blade type roof wall panel roll forming machine is similar to the belt type in that it also contains a motor, a driving system, and a mold. However, instead of using a conveyor belt to move the metal sheet around, the blade types uses blades on either side of the metal sheet to cut it into desired shapes.

Screw Type Roof Wall Panel Roll Forming Machine: The screw type roof wall panel roll forming machine is unique in that it does not use blades or a conveyor belt to move the metal sheet around; instead, it uses screws to create its desired shapes.

Conclusion

A roof wall panel forming machine works by feeding the panels into a die that forms them into their desired shape. The machine is able to do this with great accuracy, which means that you can be sure that your panels will look exactly how you want them to. If you’re looking for a way to improve the aesthetics of your property without having to spend a lot of money, then consider investing in a roof wall panel forming machine.