Finding the best pipe for your machine can be a difficult task, especially if you’re a new business. If you’ve worked with pipe before, then you know how important it is to make sure that they’re of the right size and quality. In this blog article, we look into how a pipe rolling forming machine works and why it’s used.

What is a pipe roll forming machine?

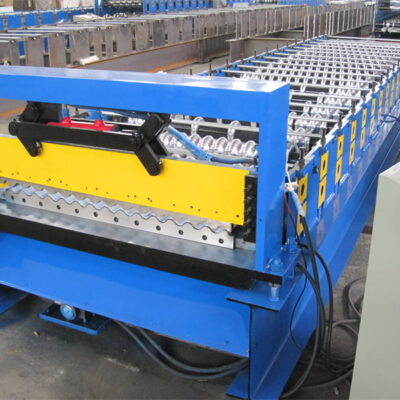

A pipe roll forming machine is a machine that forms pipe rolls. Pipe rolls are pieces of metal tubing that are used in various industries to transfer fluids and gases. The pipe roll forming machine uses a series of dies to create the required shape for the pipe roll.

Pipe roll forming machines are a great option for those looking to create custom or specific pipe shapes. They can be used to produce various items, like headers and header assemblies, flanges and other components, elbows and tees, and many others.

How does a pipe roll forming machine work?

A pipe roll forming machine is used to create pipe rolls. The machine has two rolls that are mounted on a rotating frame. The rolls are connected by a series of bars that extend between them. As the frame rotates, the bars cause the rolls to move around and form the desired shape. This process is used to produce pipes, tubes, and other small shapes from metal sheets.

The pipe roll forming machine is an important tool in the production of custom-made pipes and tubes. It’s often used to create pipes for water, gas, and oil pipelines. In addition, it’s also used to create other types of small round objects, such as caps and buttons.

The main reason why pipe roll forming machines are so popular is because they’re extremely versatile. They can be used to create a variety of different shapes and sizes. Additionally, they’re relatively easy to use and maintain.

-

Storage Rack Shelf Box Panel Making Machine Steel Storage Rack System Box Beam Roll Forming Line

Storage Rack Shelf Box Panel Making Machine Steel Storage Rack System Box Beam Roll Forming Line -

Downspout Pipe Roll Forming Machine

Downspout Pipe Roll Forming Machine -

Trapezoidal Panel Roll Forming Machine

Trapezoidal Panel Roll Forming Machine -

Roof Tile Panel Roll Forming Machine

Roof Tile Panel Roll Forming Machine -

Box Beam Steel Roll Forming Machine For Shelf Column

Box Beam Steel Roll Forming Machine For Shelf Column -

Trapezoidal panel roll forming machine

Trapezoidal panel roll forming machine -

Roof Panel Double Layer Machine丨Tile &

Roof Panel Double Layer Machine丨Tile & -

Roof Tile Roll Forming Machine

Roof Tile Roll Forming Machine -

Downpipe Roll Forming Machine

Downpipe Roll Forming Machine

Why is it used?

The pipe roll forming machine is a specialized piece of equipment used to form smooth, round pipes from metal sheet stock. The machine uses a set of rotating drums to deform the metal sheet into the desired shape, and then returns it to its original shape as it rolls along the drums.

The pipe roll forming machine has many benefits over other methods of pipe production. For one, the process is relatively easy and quick to execute. Additionally, the finished product is highly accurate and consistent, meaning that each pipe is identical in size and shape. Finally, due to the machine’s ability to produce multiple pieces simultaneously, it can be used for tasks such as fabricating large sections of piping or creating complex shapes that would be difficult or impossible to achieve using other methods.

Types of pipe roll forming machines

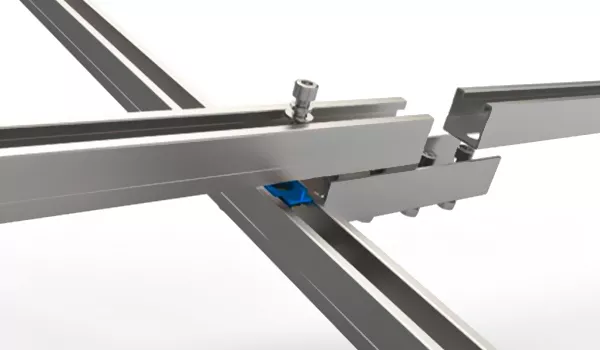

Pipe roll forming machines are used to form pipe, tubes and hoses. They use a rotating mandrel to create the desired shape. There are three main types of pipe roll forming machines: hydraulic, pneumatic and contact.

Hydraulic pipe roll forming machines use hydraulic pressure to form the pipe. They have a large pressurized chamber that forces the metal around the rotating mandrel. Pneumatic pipe roll forming machines use air pressure to form the pipe. They have a small air pressure chamber that forces the metal around the rotating mandrel. Contact pipe roll forming machines use metal-on-metal contact to form the pipe. The two pieces of metal move together as they rotate, creating the desired shape.

Why should you invest in a Roll Forming Machine?

Roll forming machines are incredibly versatile tools that can be used for a variety of different applications. They can be used to form virtually any type of pipe, from small diameter pipes to huge diameter pipes. Reasons you should invest in a roll forming machine include the following:

-They are fast and efficient: Roll forming machines are very fast and efficient machines. They can quickly form large quantities of pipe at a time, which is great for businesses that need to produce a lot of pipe quickly.

-They are versatile: Roll forming machines are versatile tools that can be used for a variety of different applications. This makes them perfect for businesses that need to produce a lot of different types of pipe.

-They are durable: Roll forming machines are durable tools. They can handle a lot of wear and tear, which means they will last long and be reliable over time.

Conclusion

As the manufacturing process continues to move towards automated systems, pipe roll forming machines could play a significant role in streamlining and improving the flow of production. By using these machines, manufacturers can reduce the time it takes to produce complex parts, or they can create custom parts that are not possible with traditional methods. If you’re interested in learning more about how pipe roll forming machines might impact your business, be sure to read on!

FAQ

What are the applications for roll forming?

Common Roll Forming Applications/Products, Door and window hardware, Metal fencing, Computer casings and components, Metal furniture components, Rain gutters and house siding, Desk drawer slides, Steel support framing, Metal tubing.