If you’re considering galvanized metal roofing sheets, you’re probably looking for a durable, corrosion-resistant solution that can withstand the elements. Galvanized metal roofs have been a staple in the building industry for decades, thanks to their robustness and long lifespan. In this article, we’ll dive into the nitty-gritty of galvanized roofing sheets, from types and specifications to installation, maintenance, and everything in between. Let’s make sure you have all the information to decide if galvanized roofing sheets are right for you.

Overview: Why Choose Galvanized Metal Roofing Sheets?

Galvanized metal roofing sheets offer a blend of strength, durability, and affordability that’s hard to beat. These roofing sheets are steel sheets coated with a layer of zinc to enhance their resistance to rust and corrosion. This zinc layer acts as a barrier, preventing the steel from rusting, even when exposed to moisture and harsh weather conditions. Plus, galvanized roofing sheets are low-maintenance and can last upwards of 50 years with the right care.

Why is zinc so essential? Think of it as a shield—it keeps the elements from attacking the steel beneath. Whether you’re in a region with heavy rainfall, snow, or intense heat, galvanized metal sheets are built to endure.

Types of Galvanized Metal Roofing Sheets

Understanding the different types of galvanized roofing sheets can help you select the best fit for your project. From corrugated sheets to profiled panels, each type offers unique benefits based on design, application, and structural demands.

| Type of Galvanized Metal Roofing Sheet | Description |

|---|---|

| Corrugated Sheets | Classic wave-like pattern; known for strength and water runoff capabilities, ideal for both residential and industrial roofing. |

| Standing Seam Panels | Feature raised seams that lock together; known for durability and clean, modern aesthetics, often used in commercial buildings. |

| Ribbed or Trapezoidal Panels | Provide high load-bearing capacity, thanks to deep ridges, often found in agricultural or storage buildings where durability is key. |

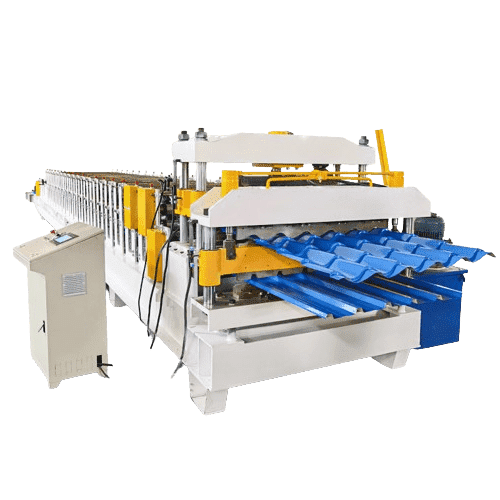

| Tile-Look Sheets | Mimic the appearance of classic roof tiles; used in residential areas for aesthetic appeal alongside the benefits of galvanized steel. |

| Flat Sheets | Simple, flat sheets often used in DIY projects or for custom-shaped installations. |

| Pre-painted Galvanized Sheets | Coated with an additional layer of paint for added aesthetics and enhanced corrosion resistance, often in residential or commercial properties. |

| Galvalume Sheets | Combine zinc and aluminum coatings; offer greater corrosion resistance compared to standard galvanized sheets, especially in coastal environments. |

| Embossed Galvanized Sheets | Feature a textured surface for unique aesthetics; commonly used for decorative roofing or wall cladding. |

| Perforated Galvanized Sheets | Contain holes for better airflow; often used in agricultural buildings or applications where ventilation is essential. |

| Zinc-Aluminum-Magnesium Coated Sheets | Advanced coating mix providing exceptional durability; used in extreme weather conditions and highly industrial areas. |

How Galvanized Metal Roofing Sheets Are Made

The galvanization process is where steel sheets get their protective edge. Think of it like a high-tech armor-plating session—each sheet is bathed in molten zinc to ensure a strong, durable layer. This process, called “hot-dip galvanizing,” allows the zinc coating to bond with the steel, creating a permanent protective layer.

- Preparation: The steel is cleaned thoroughly to ensure there’s no residue that could interfere with the bonding.

- Dipping: The clean steel sheets are submerged in molten zinc, allowing the zinc to coat the surface evenly.

- Cooling: Once coated, the sheets are quickly cooled to harden the zinc layer.

- Finishing: Depending on the type, sheets may undergo additional treatments like painting or embossing.

Components and Functions of Galvanized Metal Roofing Sheets

Each component of a galvanized roofing sheet has a specific function. Understanding these functions can help when selecting materials or assessing product quality.

| Component | Function |

|---|---|

| Zinc Coating | Protects the steel base from corrosion; acts as a sacrificial layer to prolong the sheet’s life. |

| Steel Core | Provides strength and structural integrity to the roofing sheet. |

| Optional Paint Layer | Enhances aesthetics and provides an additional barrier against weather exposure. |

| Seams (for Panels) | Lock together to prevent water infiltration and increase wind resistance. |

| Embossing (if applicable) | Adds texture for visual appeal and potentially reduces solar reflectivity, lowering heat retention. |

-

Carriage Board Roll Forming Machine

Carriage Board Roll Forming Machine -

Highway Guardrail End Terminal Forming Machine

Highway Guardrail End Terminal Forming Machine -

Highway U/C Post Roll Forming Machine

Highway U/C Post Roll Forming Machine -

2 Waves Highway Guardrail Roll Forming Machine

2 Waves Highway Guardrail Roll Forming Machine -

3 Waves Highway Guardrail Roll Forming Machine

3 Waves Highway Guardrail Roll Forming Machine -

Vineyard Post Roll Forming Machine

Vineyard Post Roll Forming Machine -

Auto Size Changeable Sigma Purlin Roll Forming Machine

Auto Size Changeable Sigma Purlin Roll Forming Machine -

Electrical Cabinet Frame Roll Forming Machine

Electrical Cabinet Frame Roll Forming Machine -

Din Rail Roll Forming Machine

Din Rail Roll Forming Machine

Efficiency and Machine Speed for Manufacturing Galvanized Roofing Sheets

When producing galvanized metal roofing sheets, machines are used at specific speeds to ensure quality and efficiency. Here’s a quick look at how manufacturing processes vary:

| Machine Type | Speed (m/min) | Efficiency |

|---|---|---|

| Corrugation Machine | 10-15 | High; optimized for quick, uniform corrugation |

| Roll Forming Machine | 5-10 | Medium; adjusts based on sheet thickness |

| Embossing Machine | 3-8 | Moderate; additional time needed for texture |

| Cut-to-Length Machine | 10-20 | High; automated for precise cuts |

| Coating Line Machine | 8-12 | Consistent; maintains a uniform coating layer |

Customized Mechanical Parameters for Specific Project Requirements

Whether you’re working on a warehouse, barn, or residential home, you might need specific mechanical parameters in your roofing sheets.

| Parameter | Specification Range | Best Use Cases |

|---|---|---|

| Thickness | 0.12mm – 1.2mm | Residential (lighter), Industrial (heavier) |

| Zinc Coating Weight | 50g/m² – 275g/m² | Coastal areas (higher), inland (standard) |

| Width | 600mm – 1250mm | Narrow profiles for homes; wide for warehouses |

| Coating Types | Zinc, Zinc-Aluminum, Pre-Painted | Industrial (basic zinc), Residential (pre-painted) |

| Seam Height (Standing Seam) | 25mm – 50mm | Taller seams for areas with high rainfall |

Applications for Galvanized Metal Roofing Sheets

Galvanized metal roofing sheets are versatile, and their applications are nearly endless.

| Application Area | Details |

|---|---|

| Residential Buildings | Lightweight, aesthetically versatile options, often pre-painted or in tile-mimicking patterns. |

| Industrial Warehouses | Highly durable, ribbed or trapezoidal for strength and load-bearing capabilities. |

| Agricultural Buildings | Perforated or ribbed designs for enhanced ventilation and protection from weather elements. |

| Commercial Buildings | Modern standing seam panels for durability and sleek appearance. |

| Temporary Structures | Lightweight corrugated sheets; cost-effective for short-term usage. |

| Coastal Construction | Zinc-Aluminum sheets preferred for superior corrosion resistance in salty environments. |

Installation, Operation, and Maintenance of Galvanized Metal Roofing Sheets

Proper installation and maintenance ensure that galvanized roofing sheets last for decades without losing their integrity.

| Phase | Instructions |

|---|---|

| Installation | Ensure sheets are properly aligned and fixed with corrosion-resistant fasteners. |

| Operation | Regular inspections to check for any signs of wear, especially in high-stress areas. |

| Maintenance | Clean twice a year to prevent dirt build-up; re-coat any areas showing signs of rust. |

Choosing a Supplier for Galvanized Metal Roofing Sheets

Selecting a reliable supplier is crucial, as it impacts not only the quality of the roofing sheets but also the installation process, maintenance needs, and overall longevity. Here’s a breakdown of factors to consider when choosing a supplier and how these impact your decision.

| Factor | Description |

|---|---|

| Reputation and Reviews | Check customer reviews and testimonials to gauge the supplier’s reliability and product quality. A well-reviewed supplier likely offers consistent quality and good customer service. |

| Certifications | Look for certifications like ISO or CE marking, as these indicate quality standards in manufacturing. |

| Product Range | A supplier with a broad range of products (e.g., corrugated, standing seam, pre-painted) offers more flexibility in meeting specific project requirements. |

| Customization Options | Some projects may require specific customizations, such as thickness, coating weight, or color. Ensure the supplier can accommodate these needs without compromising quality. |

| Delivery and Logistics | For large orders, consider whether the supplier offers reliable logistics, as delays in delivery can impact project timelines. Some suppliers offer “just-in-time” delivery to avoid storage issues on site. |

| Warranty and After-Sales | Reliable suppliers often provide warranties and after-sales support. A good warranty covers any defects in the zinc coating or premature wear. |

| Pricing and Transparency | Pricing is essential, but also consider price transparency—some suppliers provide detailed cost breakdowns that make it easier to compare value. Beware of very low prices, as these might indicate inferior materials or hidden fees. |

Comparing Galvanized Metal Roofing Sheet Types: Pros and Cons

To help you make an informed decision, here’s a comparison of popular galvanized metal roofing sheet types. Each option has its own strengths and limitations, so consider your project’s specific requirements.

| Roofing Type | Advantages | Disadvantages |

|---|---|---|

| Corrugated Sheets | High durability, excellent water runoff, affordable for large areas | Traditional appearance may not suit modern aesthetics; requires skilled installation for best results |

| Standing Seam Panels | Sleek, modern look; superior waterproofing and wind resistance | Higher cost compared to corrugated; requires skilled labor for installation |

| Ribbed or Trapezoidal Panels | Great load-bearing capability; ideal for industrial and agricultural use | Less visually appealing for residential areas; installation can be more labor-intensive |

| Tile-Look Sheets | Combines aesthetic appeal of tiles with durability of metal roofing | More expensive than standard corrugated; limited style options depending on the supplier |

| Flat Sheets | Simple, versatile for custom applications | Minimal aesthetic appeal; not ideal for direct roofing applications unless further processed |

| Pre-Painted Galvanized Sheets | Enhanced aesthetic with added corrosion resistance; wide color options | Higher cost due to additional paint layer; paint may fade over time in extreme sunlight conditions |

| Galvalume Sheets | Excellent corrosion resistance, especially in coastal areas | Higher cost due to added aluminum content; may be limited in color options |

| Embossed Sheets | Unique textured surface for aesthetics and reduced reflectivity | Higher cost due to embossing; may require custom installation methods |

| Perforated Galvanized Sheets | Provides ventilation; suitable for agricultural buildings | Not suitable for weatherproof roofing; mainly used in partial roofing applications for ventilation purposes |

| Zinc-Aluminum-Magnesium Sheets | Exceptional durability and corrosion resistance in extreme conditions | Higher cost; relatively new on the market, so limited availability |

Installation, Operation, and Maintenance Guidelines

Proper care from installation to regular maintenance ensures that galvanized metal roofing sheets maintain their integrity for decades. Here are some best practices for each stage.

| Phase | Best Practices |

|---|---|

| Installation | Always use corrosion-resistant fasteners, like stainless steel, to prevent rust around screws and bolts. Ensure proper alignment and secure sheet overlaps to prevent leaks. Hire experienced installers for complex types like standing seam or embossed sheets. |

| Operation | Regularly inspect the roof for any signs of damage or wear, especially after extreme weather. Address issues early to prevent small problems from escalating, especially in areas prone to high winds, hail, or heavy snow. |

| Maintenance | Wash the roof twice a year using water and mild soap to remove dirt, debris, and potential contaminants. For regions near industrial zones, additional cleaning may be necessary to remove pollutants. For any areas showing minor rust, reapply zinc paint or anti-corrosion coatings as needed. |

Applications of Galvanized Metal Roofing Sheets

Galvanized metal roofing sheets find applications in a wide range of sectors. Here’s a quick look at some common uses:

| Application | Description |

|---|---|

| Residential Homes | Commonly used in modern and traditional designs; pre-painted or tile-look sheets are popular. |

| Commercial Buildings | Standing seam or ribbed sheets provide a sleek look and reliable protection for offices, malls, etc. |

| Agricultural Structures | Perforated or ribbed sheets allow ventilation and durability for barns, greenhouses, and sheds. |

| Industrial Warehouses | Durable corrugated or ribbed sheets offer high load-bearing capability, ideal for large structures. |

| Temporary Shelters | Lightweight corrugated sheets provide affordable, temporary roofing solutions for construction sites. |

| Recreational Facilities | Used in recreational buildings like sports halls due to durability and aesthetic flexibility. |

Supplier Price Range and Cost Factors

The cost of galvanized metal roofing sheets can vary widely depending on factors like sheet type, thickness, coating, and additional customization. Here’s an overview of typical price ranges and cost considerations.

| Type of Galvanized Sheet | Approximate Price Range (per square foot) | Factors Affecting Price |

|---|---|---|

| Basic Corrugated Sheets | $1.00 – $2.50 | Thickness, zinc coating weight, sheet size |

| Standing Seam Panels | $3.00 – $6.00 | Seam height, finish options (e.g., pre-painted or raw finish) |

| Ribbed/Trapezoidal Sheets | $2.00 – $4.50 | Ridges, sheet thickness, surface finish options |

| Tile-Look Sheets | $3.00 – $5.50 | Design complexity, color coating, material availability |

| Flat Sheets | $0.80 – $1.50 | Basic sheet thickness, typically lower cost as they require no profiling |

| Pre-Painted Sheets | $2.50 – $4.50 | Color choice, coating quality, customization options |

| Galvalume Sheets | $2.50 – $5.00 | Aluminum content, coating thickness, additional treatments |

| Embossed Sheets | $3.50 – $6.50 | Pattern complexity, embossing depth, overall thickness |

| Perforated Sheets | $2.50 – $4.00 | Hole pattern, sheet thickness, perforation density |

| Zinc-Aluminum-Magnesium Sheets | $5.00 – $8.00 | Advanced coating material, durability, limited supply in some areas |

Advantages and Disadvantages of Galvanized Metal Roofing Sheets

Each type of galvanized metal roofing sheet has its pros and cons. Let’s look at some general advantages and limitations of galvanized metal roofing in general to help you weigh your options.

| Advantages | Disadvantages |

|---|---|

| Long-lasting durability due to zinc coating protection. | Zinc layer can wear over time, especially in extreme climates. |

| Corrosion resistance against rust in standard conditions. | May still rust in areas with constant exposure to salty air. |

| Affordable compared to other roofing materials. | Customizations and additional coatings can increase cost. |

| Low maintenance with periodic cleaning required. | Installation costs can be high for complex types like standing seam. |

| Versatile designs suitable for residential, industrial, and agricultural use. | Limited color options unless pre-painted. |

| Eco-friendly as metal can be recycled after use. | May be noisy in heavy rain without sound insulation. |

FAQ

Here’s a quick FAQ section covering some of the most common questions on galvanized metal roofing.

| Question | Answer |

|---|---|

| How long does galvanized roofing last? | With proper maintenance, galvanized roofing sheets can last anywhere from 40 to 70 years, depending on environmental conditions and coating quality. |

| Are galvanized roofing sheets environmentally friendly? | Yes, galvanized steel is recyclable and generally considered eco-friendly. The zinc coating does not affect recyclability, making it a sustainable choice for roofing materials. |

| Can galvanized sheets withstand extreme weather? | Yes, galvanized sheets are designed to withstand rain, snow, and heat. However, in highly salty or humid environments, higher zinc or additional aluminum coatings like Galvalume are recommended for increased durability. |

| What is the best thickness for galvanized roofing? | It depends on the project; however, for residential use, a thickness of 0.4mm to 0.6mm is common, while industrial buildings may require thicker sheets for added strength. |

| Can I paint galvanized roofing sheets? | Yes, galvanized sheets can be painted, but it’s recommended to use specially formulated paint for metal roofs to ensure adhesion and long-lasting results. Pre-painted options are also available from most suppliers for added convenience and durability. |

| How does galvanized roofing compare to aluminum? | Galvanized roofing is typically stronger and more affordable, while aluminum is lighter and more resistant to salt corrosion. Aluminum may be preferable in coastal areas, but galvanized is often chosen for its cost-effectiveness and strength in general applications. |