Corrugated steel sheets have been around for decades, but they’re more relevant now than ever. Whether you’re in construction, architecture, or DIY, corrugated steel offers numerous benefits, from cost-effectiveness to durability. This in-depth guide will cover everything from the various types of corrugated steel sheets to their applications, working processes, and how to choose the best supplier. Buckle up, because you’re about to dive into the world of corrugated steel sheets like never before!

Overview of Corrugated Steel Sheets

Corrugated steel sheets are a type of metal roofing material made from sheets of hot-dip galvanized steel that are rolled into a wave-like pattern. These ridges provide structural strength, making them ideal for roofing, siding, and decking applications. Known for their high durability, flexibility, and corrosion resistance, corrugated steel is a popular choice in residential, commercial, and industrial settings.

But why is corrugated steel so versatile? Well, it’s all about the corrugation (the “wavy” shape), which increases the material’s strength-to-weight ratio. This means that while it’s lightweight, it’s incredibly strong. It’s not just functional—it’s also aesthetically pleasing and highly customizable, thanks to various finishes, coatings, and colors.

Corrugated Iron Sheets Guide

When it comes to choosing the right corrugated steel sheet for your project, there’s no one-size-fits-all solution. There are various types of corrugated steel sheets available, each suited for specific purposes. Here’s a comprehensive guide on the types you might encounter and what makes each type unique.

Types of Corrugated Steel Sheets

| Type of Corrugated Steel Sheet | Description |

|---|---|

| Galvanized Corrugated Steel | Made from hot-dip galvanized steel, providing excellent corrosion resistance. Perfect for outdoor applications exposed to weather. |

| Aluminum Corrugated Sheets | Lightweight and rust-resistant, often used in coastal areas or where moisture levels are high. |

| Stainless Steel Corrugated Sheets | Offers superior corrosion resistance compared to galvanized steel. Used in environments prone to chemical exposure. |

| Copper Corrugated Sheets | An aesthetically pleasing option, copper develops a patina over time, making it ideal for decorative or architectural purposes. |

| Pre-Painted Corrugated Steel | Coated with a durable paint finish, available in a variety of colors, commonly used in residential or commercial roofing. |

| Fiberglass Reinforced Panels (FRP) | A hybrid solution that incorporates fiberglass with steel for enhanced strength, often used in industrial applications. |

| Polycarbonate Corrugated Sheets | While not steel, these are often grouped with steel sheets due to their corrugated form. They’re used in skylight applications for their transparency. |

| Cold-Rolled Corrugated Steel | Offers improved surface finish and tighter tolerances. Mostly used in applications requiring precision and aesthetic appeal. |

| Zinc-Aluminum Corrugated Sheets (Galvalume) | Combines the benefits of aluminum and zinc for a more corrosion-resistant and durable material. |

| Stone-Coated Steel Roofing | A premium option where the steel is coated with stone chips, providing additional durability and aesthetics. |

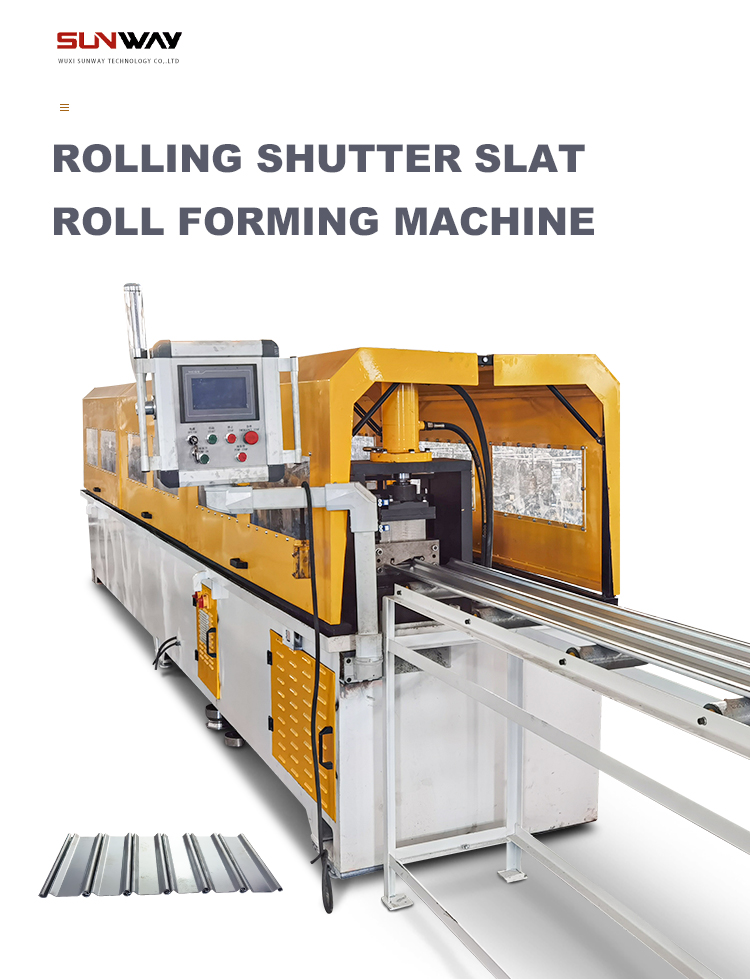

The Working Process of Corrugated Steel Sheets

So, how are these versatile sheets made? The manufacturing process is a fascinating blend of engineering and chemistry. Let’s walk through the steps:

- Raw Material Sourcing: Corrugated steel sheets typically start with galvanized steel or cold-rolled steel, depending on the type you’re producing.

- Cutting: Sheets are cut to the required width, typically from coils of steel.

- Corrugation: The most crucial step. The sheets are passed through a series of rollers that press them into the signature corrugated pattern. The height and spacing of the ridges can vary depending on the application.

- Surface Treatment: Depending on the type, sheets may undergo additional surface treatments, such as galvanization, painting, or coating with zinc-aluminum.

- Quality Control: After corrugation, the sheets are inspected for uniformity and integrity. Defective sheets are discarded or recycled.

- Finishing: Sheets are trimmed and cut to custom lengths before being packed and shipped.

Key Components of Corrugated Steel Sheets and Their Functions

| Component | Function |

|---|---|

| Steel Substrate | Provides the core structural integrity of the sheet, offering strength and flexibility. |

| Galvanized Coating | A zinc layer that protects against rust and corrosion. |

| Corrugation (Ridges) | Increases the sheet’s strength-to-weight ratio, making it more durable without adding excessive weight. |

| Paint or Powder Coating | Adds aesthetic appeal and an extra layer of protection against environmental elements. |

| Underlay (Optional) | Used in some applications for insulation or soundproofing purposes. |

-

Carriage Board Roll Forming Machine

Carriage Board Roll Forming Machine -

Highway Guardrail End Terminal Forming Machine

Highway Guardrail End Terminal Forming Machine -

Highway U/C Post Roll Forming Machine

Highway U/C Post Roll Forming Machine -

2 Waves Highway Guardrail Roll Forming Machine

2 Waves Highway Guardrail Roll Forming Machine -

3 Waves Highway Guardrail Roll Forming Machine

3 Waves Highway Guardrail Roll Forming Machine -

Electrical Cabinet Frame Roll Forming Machine

Electrical Cabinet Frame Roll Forming Machine -

Din Rail Roll Forming Machine

Din Rail Roll Forming Machine -

Two waves highway guardrail machine

Two waves highway guardrail machine -

Three waves highway guardrail machine

Three waves highway guardrail machine

Machine Speed and Efficiency in Corrugated Steel Sheet Production

The machines that produce corrugated steel sheets are highly efficient, operating at various speeds and efficiencies depending on the manufacturer.

| Parameter | Value |

|---|---|

| Machine Speed | 10-30 meters/minute |

| Efficiency | Up to 95% |

| Production Capacity | 1000-1500 tons/month |

| Power Requirement | 15-50 KW |

Customized Mechanical Parameters for Corrugated Steel Sheets

For those looking to customize their corrugated steel sheets, here are some of the mechanical parameters that can be tailored:

| Parameter | Range |

|---|---|

| Sheet Thickness | 0.12mm – 2mm |

| Sheet Length | Up to 12 meters |

| Ridge Height | 12mm – 75mm |

| Corrugation Spacing | 50mm – 250mm |

| Material Grades | ASTM A653, AISI 304, AISI 316, etc. |

| Surface Coating Thickness | 15µm – 45µm |

Applications and Uses of Corrugated Steel Sheets

Corrugated steel sheets are incredibly versatile and are used in a wide range of applications:

| Application | Use |

|---|---|

| Roofing | For residential, commercial, and industrial buildings. The lightweight, weather-resistant properties make it ideal. |

| Siding | Often used for exterior cladding, providing protection from weather while adding to the building’s aesthetics. |

| Decking | Used in composite floor systems in construction due to its high strength-to-weight ratio. |

| Fencing | Corrugated steel sheets provide a durable and rust-resistant fencing option. |

| Carports and Garages | Ideal for quick construction with a long lifespan. |

| Industrial Shelters | Used for warehouses, storage units, and other industrial spaces. |

| Architectural Features | Popular in modern and industrial design aesthetics, used in feature walls or accent facades. |

| Agricultural Buildings | Used in barns, silos, and greenhouses due to their durability and low cost. |

| Water Storage Tanks | Some corrugated sheets are specifically designed for use in water and grain storage tanks. |

Installation, Operation, and Maintenance of Corrugated Steel Sheets

Proper installation, operation, and maintenance are key to ensuring the longevity and performance of corrugated steel sheets. Here’s what you need to know:

| Aspect | Detail |

|---|---|

| Installation | Ensure sheets are installed with the ridges running vertically to allow for maximum strength. Use proper screws with rubber washers to prevent leaks. |

| Operation | The sheets are virtually maintenance-free during operation, but ensure they are free from excessive debris. |

| Maintenance | Periodically check for any rust spots, especially at joints and edges. Clean with a mild detergent to remove dirt or stains. |

| Lifespan | With proper installation and minimal maintenance, corrugated steel sheets can last up to 50 years. |

Suppliers and Price Range of Corrugated Steel Sheets

| Supplier | Location | Price Range (per sq meter) |

|---|---|---|

| BlueScope Steel | Global | $10 – $20 |

| Tata Steel | India | $8 – $18 |

| ArcelorMittal | Global | $9 – $22 |

| Nippon Steel | Japan | $12 – $25 |

| JFE Steel Corporation | Japan | $15 – $30 |

| POSCO | South Korea | $10 – $23 |

| United States Steel | USA | $11 – $26 |

How to Choose the Right Supplier for Corrugated Steel Sheets

Choosing the right supplier can be overwhelming. Here are some tips to help make your decision easier:

| Consideration | Details |

|---|---|

| Price | Compare prices between suppliers, but remember that cheaper isn’t always better. Consider value for money. |

| Quality | Look for suppliers who offer durable and high-quality steel with certifications. |

| Location | Local suppliers can save on shipping costs and lead times. |

| Reputation | Read reviews and get feedback from previous customers. |

| Customization | Choose a supplier who offers customization options, especially if you need sheets of non-standard sizes or finishes. |

| After-Sales Support | Opt for suppliers who offer warranties, maintenance, or installation support. |

Corrugated Steel Sheets: Advantages vs. Disadvantages

| Aspect | Advantages | Disadvantages |

|---|---|---|

| Durability | Can last 30-50 years with minimal maintenance. | Prone to rust without proper coating. |

| Cost | More affordable than traditional roofing materials. | Slightly more expensive than some alternative options like asphalt shingles. |

| Aesthetic Appeal | Modern, industrial look, available in various finishes. | Limited design flexibility due to its corrugated shape. |

| Ease of Installation | Lightweight and easy to transport and install. | Requires professional installation to ensure watertightness. |

| Weather Resistance | Highly resistant to extreme weather conditions. | May be noisy during heavy rain or hailstorms. |

FAQ

| Question | Answer |

|---|---|

| What is corrugated steel used for? | Corrugated steel is mainly used for roofing, siding, and decking applications. It’s durable, lightweight, and weather-resistant, making it perfect for a wide range of construction projects. |

| How long do corrugated steel sheets last? | With proper maintenance, corrugated steel sheets can last anywhere from 30 to 50 years. |

| What’s the difference between galvanized and stainless steel corrugated sheets? | Galvanized steel has a zinc coating that protects it from rust, whereas stainless steel is inherently corrosion-resistant due to its chromium content. |

| Are corrugated steel sheets expensive? | Corrugated steel sheets are generally affordable compared to other roofing materials, with prices ranging from $10 to $30 per square meter, depending on the type and finish. |

| How do you maintain corrugated steel sheets? | Regular maintenance involves checking for rust spots, ensuring that screws are tight, and occasionally washing the surface to remove debris. |

Conclusion

Corrugated steel sheets are a versatile, cost-effective, and durable option for a wide variety of applications. Whether you’re building a roof for your home, siding for a warehouse, or looking for an aesthetically pleasing architectural element, corrugated steel has you covered—literally. With this guide, you should now have a deeper understanding of the types of corrugated steel available, how they’re produced, and the key factors to consider when choosing a supplier. So, what’s stopping you from taking the plunge into the world of corrugated steel?