Overview of Corrugated Metal Panels

Corrugated metal panels are a staple in modern construction, offering a unique blend of durability, flexibility, and aesthetic appeal. These versatile materials have become a go-to solution for various applications, ranging from roofing and siding to industrial and agricultural projects. But what makes corrugated metal panels so popular? Is it their strength? Their longevity? Or perhaps the rustic charm they bring to any structure? This comprehensive guide will dive deep into the world of corrugated metal panels, exploring their types, working processes, applications, and much more.

A Comprehensive Guide to Corrugated Metal Panels

Corrugated metal panels, often referred to as corrugated iron, are sheets of metal that have been roll-formed into a series of alternating ridges and grooves. This unique design increases their strength, making them resistant to bending and buckling, which is crucial for load-bearing applications like roofing. Available in various metals, such as steel, aluminum, and copper, these panels can be tailored to fit the specific needs of different projects.

Types of Corrugated Metal Panels

Different types of corrugated metal panels are available on the market, each offering unique properties that make them suitable for specific applications. Below is a table summarizing the most common types of corrugated metal panels and their characteristics.

| Type | Material | Thickness | Common Uses | Key Features |

|---|---|---|---|---|

| Galvanized Steel | Steel | 24-26 gauge | Roofing, Siding | Rust-resistant, economical |

| Aluminum Panels | Aluminum | 0.032-0.040″ | Coastal Buildings, Siding | Lightweight, corrosion-resistant |

| Stainless Steel | Stainless Steel | 24-26 gauge | Industrial Roofing, High-End Siding | High corrosion resistance, sleek appearance |

| Copper Panels | Copper | 16-20 oz | Decorative Roofing, High-End Siding | Aesthetic appeal, patinas over time |

| Corten Steel Panels | Corten Steel | 22-24 gauge | Architectural Features, Siding | Weathering steel, develops a rust-like appearance |

| Zinc Panels | Zinc | 0.7-1.0mm | Siding, Roofing | Self-healing, long-lasting |

| Polycarbonate Panels | Polycarbonate | Varies | Skylights, Greenhouses | UV-resistant, lightweight |

| Fiberglass Panels | Fiberglass | Varies | Skylights, Canopies | Lightweight, translucent |

| Powder-Coated Steel | Steel | 24-26 gauge | Residential Roofing, Siding | Enhanced durability, various color options |

| Tin Panels | Tin | 24-26 gauge | Historical Renovations, Siding | Vintage look, lightweight |

The Working Process of Corrugated Metal Panels

Creating corrugated metal panels involves several precise steps to ensure the material’s strength and durability. Here’s a breakdown of the process:

- Metal Selection: The process begins with choosing the appropriate metal, based on the intended use of the panels. For instance, galvanized steel is often selected for its rust-resistant properties, while aluminum might be chosen for its lightweight and corrosion resistance.

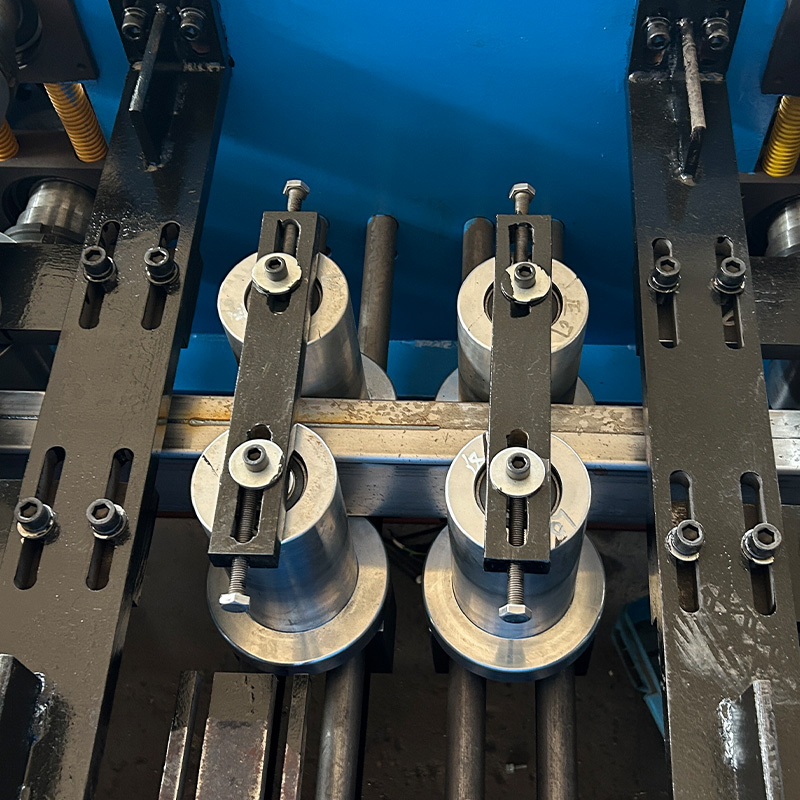

- Roll Forming: The selected metal is fed through a roll-forming machine, which bends the metal into the desired corrugated shape. This step is crucial as it gives the metal its strength and rigidity.

- Cutting to Size: After corrugating, the metal sheets are cut to the required size. Precision in this step ensures that the panels will fit perfectly during installation.

- Finishing: Depending on the intended application, the metal panels might be galvanized, powder-coated, or otherwise finished to enhance their durability and aesthetic appeal.

- Quality Inspection: Finally, the panels undergo a thorough quality inspection to ensure they meet industry standards and customer expectations.

Key Components and Their Functions in Corrugated Metal Panels

Every corrugated metal panel system consists of several critical components, each playing a specific role in ensuring the system’s overall functionality and durability.

| Component | Function |

|---|---|

| Panels | Provide the structural surface for roofing or siding. |

| Fasteners | Secure the panels to the underlying structure. |

| Sealants | Prevent water ingress at joints and seams. |

| Trim | Covers edges and corners for aesthetic finish and protection. |

| Underlayment | Acts as a moisture barrier beneath the panels. |

| Flashing | Directs water away from vulnerable areas like chimneys or valleys. |

-

Storage Rack Shelf Box Panel Making Machine Steel Storage Rack System Box Beam Roll Forming Line

Storage Rack Shelf Box Panel Making Machine Steel Storage Rack System Box Beam Roll Forming Line -

Highway Guardrail End Terminal Forming Machine

Highway Guardrail End Terminal Forming Machine -

Highway U/C Post Roll Forming Machine

Highway U/C Post Roll Forming Machine -

2 Waves Highway Guardrail Roll Forming Machine

2 Waves Highway Guardrail Roll Forming Machine -

3 Waves Highway Guardrail Roll Forming Machine

3 Waves Highway Guardrail Roll Forming Machine -

Corrugated Panel Roll Forming Machine

Corrugated Panel Roll Forming Machine -

Light Gauge Steel Roll Forming Machine

Light Gauge Steel Roll Forming Machine -

C Section Bracing Omega Storage Rack Upright Post Roll Forming Machine

C Section Bracing Omega Storage Rack Upright Post Roll Forming Machine -

Steel Box Plate Making Roll Forming Machine

Steel Box Plate Making Roll Forming Machine

Machine Speed and Efficiency in Corrugated Metal Panel Production

The production of corrugated metal panels involves machines with varying speeds and efficiencies. Here’s an overview:

| Machine Type | Average Speed | Efficiency |

|---|---|---|

| Roll Forming Machine | 30-100 feet per minute | High efficiency, minimal waste |

| Cutting Machine | 20-60 cuts per minute | High precision, low error rate |

| Powder Coating Line | Varies | High quality, uniform coverage |

Customized Mechanical Parameters for Corrugated Metal Panels

Customization in corrugated metal panels allows for a tailored approach to meet specific project requirements. Below are common parameters that can be customized:

| Parameter | Range | Customization Impact |

|---|---|---|

| Panel Thickness | 0.5mm – 1.5mm | Affects strength and load-bearing capacity. |

| Ridge Height | 18mm – 50mm | Influences water runoff and aesthetic appeal. |

| Panel Length | Up to 40 feet | Custom lengths reduce waste and simplify installation. |

| Finish Type | Galvanized, Powder-coated, Painted | Affects durability, corrosion resistance, and appearance. |

Applications and Uses of Corrugated Metal Panels

Corrugated metal panels are highly versatile and can be used in a wide range of applications:

| Application | Description |

|---|---|

| Residential Roofing | Provides durable, weather-resistant roofing solutions. |

| Commercial Siding | Used for both aesthetic and functional purposes in commercial buildings. |

| Agricultural Structures | Ideal for barns, sheds, and other agricultural buildings due to their durability and low maintenance. |

| Industrial Roofing | Offers protection for industrial facilities, resistant to harsh conditions. |

| Architectural Features | Enhances the visual appeal of buildings with unique, corrugated textures. |

| Skylights and Canopies | Transparent or translucent options like polycarbonate or fiberglass panels provide light while protecting from the elements. |

Installation, Operation, and Maintenance of Corrugated Metal Panels

The installation and maintenance of corrugated metal panels require careful attention to detail to ensure longevity and performance.

| Process | Details |

|---|---|

| Installation | Panels are installed with appropriate fasteners, ensuring overlaps and correct alignment. |

| Operation | Once installed, the panels should function without the need for further adjustments. |

| Maintenance | Regular inspection for rust, sealant integrity, and fastener security is recommended. |

| Cleaning | Periodic cleaning with water and a mild detergent can help maintain the panels’ appearance and longevity. |

Suppliers and Price Range for Corrugated Metal Panels

When it comes to purchasing corrugated metal panels, choosing the right supplier and understanding the price range is crucial.

| Supplier | Price Range (per sq. ft.) | Key Features |

|---|---|---|

| ABC Metal Roofing | $2.50 – $4.00 | Wide range of metal types and finishes. |

| Metal Sales Manufacturing | $3.00 – $5.00 | High-quality materials with extensive warranty options. |

| MBCI | $2.75 – $4.50 | Customization options and quick delivery. |

| Fabral | $2.50 – $4.20 | Known for its color options and durability. |

| ASC Building Products | $3.00 – $5.25 | Offers both standard and custom panel profiles. |

| McElroy Metal | $2.60 – $4.30 | High-strength panels, ideal for industrial use. |

| Roofing Superstore | $2.70 – $4.40 | Economical options with reliable quality. |

| BlueScope Steel | $3.20 – $5.50 | High-end panels with advanced corrosion resistance. |

| Klauer Manufacturing | $2.80 – $4.70 | Family-owned business with a reputation for quality. |

| Berridge Manufacturing | $3.50 – $5.75 | Premium materials with extensive color and finish options. |

How to Choose a Corrugated Metal Panel Supplier

Choosing the right supplier is as important as selecting the right type of panel. Here’s what to consider:

- Quality Assurance: Ensure the supplier provides high-quality materials with certifications and warranties.

- Customization Options: Look for suppliers who offer customization to meet your specific project needs.

- Pricing: Compare prices but remember that the cheapest option might not always be the best in terms of quality.

- Delivery Time: Consider the supplier’s ability to meet your project timeline.

- Customer Support: Opt for suppliers with responsive and helpful customer service teams.

Advantages and Disadvantages of Corrugated Metal Panels

Like any material, corrugated metal panels come with their own set of pros and cons.

| Aspect | Advantages | Disadvantages |

|---|---|---|

| Durability | Long-lasting, resistant to extreme weather conditions. | Can be prone to denting if not properly installed or maintained. |

| Cost | Generally more affordable compared to other roofing and siding materials. | Initial installation costs can be higher due to labor. |

| Aesthetic Appeal | Provides a rustic, industrial look that is highly sought after. | Limited design options compared to other materials like shingles or tiles. |

| Maintenance | Low maintenance, requires minimal upkeep over the years. | Can rust if not properly coated or maintained, especially in coastal areas. |

| Environmental Impact | Often made from recycled materials and is recyclable itself. | Production and transportation can have a significant carbon footprint. |

FAQs

Below is a table with some of the most common questions about corrugated metal panels, along with detailed answers to help you better understand these versatile materials.

| Question | Answer |

|---|---|

| What are corrugated metal panels? | Corrugated metal panels are sheets of metal roll-formed into ridges and grooves, used in roofing, siding, and more. |

| How long do corrugated metal panels last? | Depending on the material and environment, they can last anywhere from 20 to 70 years. |

| Are corrugated metal panels expensive? | They are generally affordable, with prices ranging from $2.50 to $5.75 per square foot. |

| Can corrugated metal panels be painted? | Yes, they can be painted or powder-coated in a variety of colors. |

| Do corrugated metal panels rust? | Galvanized and coated panels are rust-resistant, but bare steel panels can rust if not maintained. |

| How do you clean corrugated metal panels? | Clean with water and a mild detergent, avoiding harsh chemicals that could damage the coating. |

| Are corrugated metal panels eco-friendly? | Yes, they are often made from recycled materials and can be recycled at the end of their life cycle. |

| What is the best metal for coastal areas? | Aluminum and stainless steel are best for coastal areas due to their corrosion resistance. |

| Can I install corrugated metal panels myself? | While possible, professional installation is recommended for best results and to avoid potential issues. |

| What maintenance do corrugated metal panels require? | Regular inspection for damage, rust, and loose fasteners is recommended, along with occasional cleaning. |

Conclusion

Corrugated metal panels offer a versatile, durable, and aesthetically pleasing option for a wide range of construction projects. From residential roofing to industrial applications, these panels provide an excellent balance of strength, cost-effectiveness, and visual appeal. With the right type of metal and finish, corrugated panels can be tailored to suit nearly any environment, ensuring a long-lasting and low-maintenance solution.

When choosing corrugated metal panels for your project, it’s crucial to consider the specific requirements of your application, the quality of materials, and the reputation of your supplier. With proper care and installation, corrugated metal panels can serve as a reliable and attractive component of your building for decades to come.