Overview of Corrugated Iron Roof Sheets

When it comes to roofing solutions, corrugated iron roof sheets are a staple. Known for their durability, affordability, and versatility, these sheets have been a preferred choice for many types of buildings, from residential homes to industrial complexes. But what makes corrugated iron so special? Let’s dive into the details.

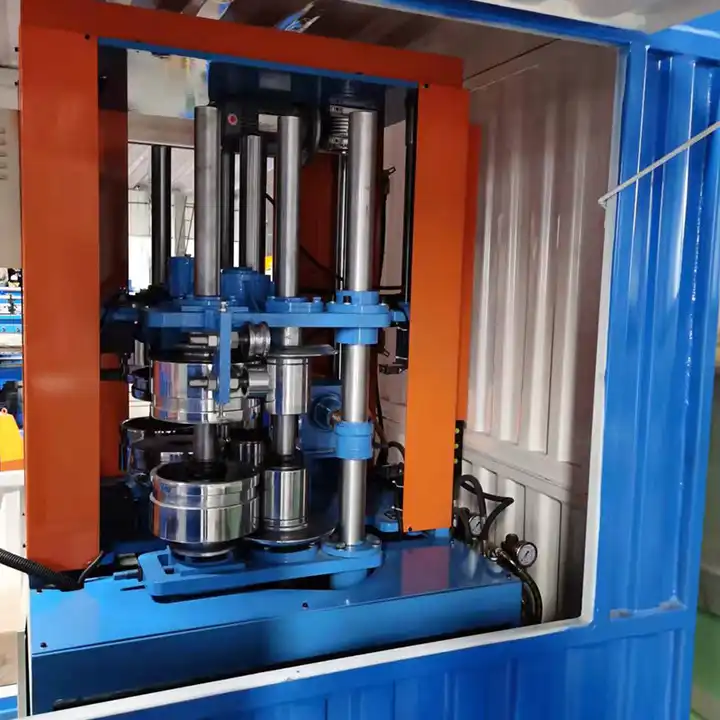

Present Roll Forming Machine Guide

The roll forming machine is essential for manufacturing corrugated iron sheets. This machine shapes the metal into its distinctive corrugated pattern, which enhances its strength and durability. Understanding how these machines work can provide insight into the overall production process.

Types of Corrugated Iron Roof Sheets

There are various types of corrugated iron roof sheets, each with its own unique characteristics and benefits. Here’s a comprehensive table to help you understand the differences:

| Type of Sheet | Description | Best Use | Durability | Cost |

|---|---|---|---|---|

| Galvanized Iron Sheets | Coated with a layer of zinc for rust resistance | Residential and commercial buildings | High | Moderate |

| Colorbond Sheets | Pre-painted and treated for added protection and aesthetic appeal | Residential homes, aesthetic structures | Very High | High |

| Polyester Painted Sheets | Coated with a polyester paint for added durability and color variety | Industrial buildings, warehouses | High | Moderate |

| Aluzinc Sheets | Coated with an alloy of aluminum and zinc for enhanced rust resistance | Coastal and industrial areas | Very High | High |

| Stainless Steel Sheets | Made from stainless steel for maximum rust resistance and durability | Industrial applications | Very High | Very High |

| Fiberglass Reinforced Sheets | Corrugated sheets reinforced with fiberglass for added strength and translucency | Greenhouses, skylights | Moderate | Moderate |

| Plastic Coated Iron Sheets | Iron sheets coated with plastic for enhanced weather resistance | Agricultural buildings | High | Low |

| Bitumen Corrugated Sheets | Bitumen coated for waterproofing and soundproofing | Residential roofing, sheds | Moderate | Low |

| Copper Corrugated Sheets | Made from copper for a premium finish and durability | Historical buildings, high-end homes | Very High | Very High |

| Aluminum Corrugated Sheets | Lightweight and corrosion-resistant aluminum sheets | Commercial buildings, lightweight structures | High | High |

Working Process of Corrugated Iron Roof Sheets

The production of corrugated iron roof sheets involves several key steps, all of which contribute to the final product’s quality and performance.

- Material Selection: High-quality metal coils are chosen based on the required properties like rust resistance, strength, and flexibility.

- Cleaning and Pre-Treatment: The metal is cleaned to remove any impurities that could affect the coating process.

- Roll Forming: The cleaned metal is passed through a roll forming machine, which shapes it into the characteristic corrugated pattern.

- Coating: Depending on the type of sheet being produced, the metal is coated with zinc, paint, or other protective materials.

- Cutting: The corrugated sheets are cut to the desired length.

- Quality Control: Each sheet is inspected to ensure it meets quality standards.

Key Components and Their Functions

Understanding the key components involved in the production of corrugated iron roof sheets can help in appreciating their quality and durability.

| Component | Function |

|---|---|

| Metal Coils | Provide the base material for the sheets |

| Cleaning Agents | Remove impurities from the metal surface |

| Roll Forming Machine | Shapes the metal into the corrugated pattern |

| Coating Materials | Provide rust resistance and aesthetic appeal |

| Cutting Tools | Trim the sheets to the required length |

| Quality Control Instruments | Ensure each sheet meets the required standards |

-

Storage Rack Shelf Box Panel Making Machine Steel Storage Rack System Box Beam Roll Forming Line

Storage Rack Shelf Box Panel Making Machine Steel Storage Rack System Box Beam Roll Forming Line -

Highway Guardrail End Terminal Forming Machine

Highway Guardrail End Terminal Forming Machine -

Highway U/C Post Roll Forming Machine

Highway U/C Post Roll Forming Machine -

2 Waves Highway Guardrail Roll Forming Machine

2 Waves Highway Guardrail Roll Forming Machine -

3 Waves Highway Guardrail Roll Forming Machine

3 Waves Highway Guardrail Roll Forming Machine -

C Section Bracing Omega Storage Rack Upright Post Roll Forming Machine

C Section Bracing Omega Storage Rack Upright Post Roll Forming Machine -

Steel Box Plate Making Roll Forming Machine

Steel Box Plate Making Roll Forming Machine -

Box Beam Steel Roll Forming Machine For Shelf Column

Box Beam Steel Roll Forming Machine For Shelf Column -

Pallet Racking Step Beam P Beam Roll Forming Machine

Pallet Racking Step Beam P Beam Roll Forming Machine

Machine Speed and Efficiency

The efficiency and speed of the roll forming machine are critical to the production process.

| Parameter | Details |

|---|---|

| Machine Speed | Up to 30 meters per minute |

| Production Capacity | 1,200 sheets per hour |

| Efficiency Rate | 95% operational uptime |

| Downtime | Minimal, scheduled for maintenance |

Customized Mechanical Parameters

For specific applications, the mechanical parameters of the corrugated iron sheets can be customized.

| Parameter | Range |

|---|---|

| Thickness | 0.4mm – 1.2mm |

| Width | 600mm – 1200mm |

| Length | Up to 12 meters |

| Coating Thickness | 20 microns – 275 microns |

| Wave Height | 15mm – 50mm |

| Wave Pitch | 75mm – 200mm |

Applications and Uses

Corrugated iron roof sheets are versatile and can be used in various applications.

| Application | Details |

|---|---|

| Residential Roofing | Durable and weather-resistant roofing solution for homes |

| Commercial Buildings | Cost-effective and long-lasting for offices and shops |

| Industrial Roofing | High strength and corrosion-resistant for factories |

| Agricultural Buildings | Protects barns, sheds, and storage facilities from the elements |

| Greenhouses | Fiberglass reinforced sheets provide translucency for plant growth |

| Skylights | Allows natural light into industrial and residential spaces |

| Sheds and Garages | Affordable and easy to install for personal use |

| Historical Buildings | Copper and aluminum sheets for aesthetic and durability |

| Temporary Structures | Quick installation for short-term use like events or shelters |

| Fencing | Provides a strong and durable barrier around properties |

Installation, Operation, and Maintenance

Proper installation and maintenance are crucial for the longevity of corrugated iron roof sheets.

| Aspect | Details |

|---|---|

| Installation | Ensure proper alignment and secure fastening to avoid leaks and wind damage. Use appropriate sealants and fasteners. |

| Operation | Minimal operational requirements. Regular inspections recommended. |

| Maintenance | Clean periodically to remove debris and prevent moss or algae growth. Inspect for rust or damage and repair promptly. |

Suppliers and Price Range

Finding the right supplier is key to getting high-quality corrugated iron roof sheets at a reasonable price.

| Supplier | Price Range (per square meter) | Contact Information |

|---|---|---|

| ABC Metals | $5 – $10 | www.abcmetals.com |

| Roofing Experts Ltd. | $6 – $12 | www.roofingexperts.com |

| MetalTech Industries | $7 – $15 | www.metaltech.com |

| Iron Roofs Co. | $5 – $11 | www.ironroofs.com |

| Durable Roof Supplies | $6 – $13 | www.durableroof.com |

| AllWeather Roofing | $8 – $14 | www.allweatherroofing.com |

| TopRoof Suppliers | $7 – $13 | www.toproofs.com |

| Prime Metal Sheets | $6 – $12 | www.primemetals.com |

| EcoRoof Solutions | $5 – $10 | www.ecoroofsolutions.com |

| Premium Roof Metals | $8 – $16 | www.premiumroofmetals.com |

Choosing the Right Supplier

When selecting a supplier for corrugated iron roof sheets, consider the following factors:

- Reputation: Look for reviews and testimonials from previous customers.

- Quality: Ensure the supplier provides high-quality materials that meet industry standards.

- Pricing: Compare prices to ensure you get the best deal without compromising on quality.

- Customer Service: Good customer support can help with installation and maintenance questions.

- Delivery Options: Check if the supplier offers convenient delivery options to your location.

Advantages and Limitations

Every roofing material has its pros and cons. Here’s how corrugated iron roof sheets stack up:

| Aspect | Advantages | Limitations |

|---|---|---|

| Durability | Long-lasting and resistant to harsh weather conditions | Can be prone to rust if not properly coated |

| Cost | Affordable compared to other roofing materials | Higher initial cost for premium coatings |

| Installation | Easy and quick to install | Requires precise alignment to avoid leaks |

| Maintenance | Low maintenance with occasional cleaning | Periodic inspections needed to check for rust or damage |

| Aesthetics | Available in various colors and finishes | May not suit all architectural styles |

| Weight | Lightweight and easy to handle | Less sturdy compared to heavier roofing materials |

FAQ

| Question | Answer |

|---|---|

| Are corrugated iron roof sheets environmentally friendly? | Yes, many corrugated iron sheets are made from recyclable materials. Additionally, coatings used can be eco-friendly, reducing environmental impact. |

| Can corrugated iron roof sheets be used in coastal areas? | Yes, but it’s important to choose a type with high corrosion resistance, such as Aluzinc or Stainless Steel sheets, due to the salt in coastal air. |

| What should I consider when choosing the thickness of corrugated iron roof sheets? | The thickness affects durability and insulation. Thicker sheets are generally more durable but may be heavier and more expensive. |

| How do I maintain corrugated iron roof sheets? | Regularly inspect for rust, clean off debris, and check for any damage. Re-coat or repaint if necessary to prolong the life of the sheets. |

| Can I install corrugated iron roof sheets myself? | Yes, but professional installation is recommended for best results. Proper alignment and securing are crucial to prevent leaks. |

| What are the benefits of using Colorbond sheets over galvanized iron sheets? | Colorbond sheets offer better color options, are more resistant to corrosion, and have a longer lifespan compared to standard galvanized sheets. |

| How do corrugated iron roof sheets compare to asphalt shingles? | Corrugated iron sheets are generally more durable and have a longer lifespan than asphalt shingles but can be noisier during rain. |

| Are there any warranties for corrugated iron roof sheets? | Many manufacturers offer warranties ranging from 10 to 50 years, depending on the type of sheet and coating. |

| What factors affect the cost of corrugated iron roof sheets? | Factors include the type of coating, thickness, size of the sheets, and the supplier’s pricing. Higher-quality materials and specialized coatings tend to be more expensive. |

| How can I find a reliable supplier for corrugated iron roof sheets? | Look for suppliers with good reviews, a strong reputation, and a track record of quality products. Compare prices and ensure they offer good customer support and delivery options. |

In summary, corrugated iron roof sheets are a versatile and durable roofing option suitable for various applications. Whether you are considering them for residential, commercial, or industrial use, understanding the different types, their applications, and how to maintain them can help you make an informed decision. By considering factors like material type, cost, and installation requirements, you can select the best option for your needs and ensure a long-lasting and effective roofing solution.