C Z Purlin Roll Forming Machine

Product categories

- Profile roll forming machine (6)

- Purlin roll forming machine (4)

- Roll Former (15)

- Electric & Energy (9)

- Racking & Shelving (6)

- Steel Structure (26)

- Metal Wall & Roofing (28)

- Highway Engineering & Vehicle (7)

- Door & Windows (1)

- Cut To Length Line (3)

- Roll Forming Machine (4)

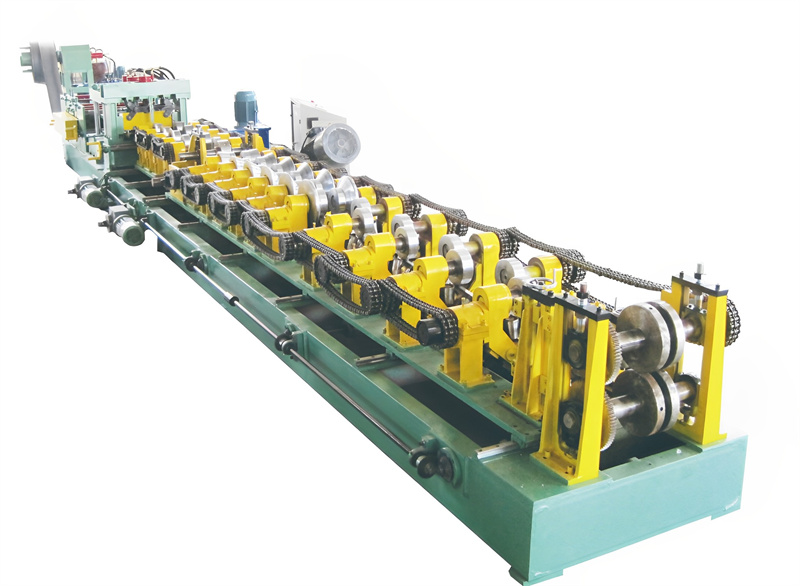

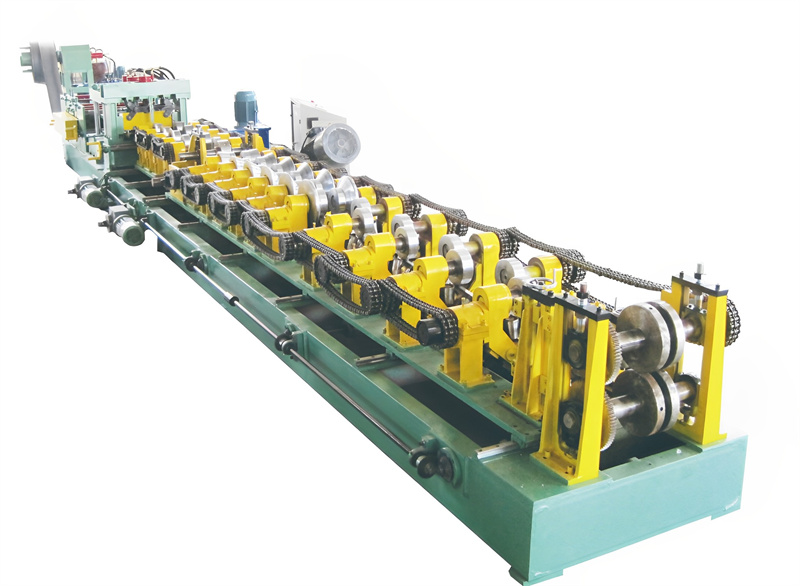

C Z Purlin Roll Forming Machine: A Versatile Solution for Your Purlin Production Needs

Discover the benefits and features of our state-of-the-art C Z Purlin Roll Forming Machine, designed to optimize your purlin production process.

Looking for a versatile, efficient, and reliable solution for your purlin production needs? Our C Z Purlin Roll Forming Machine is designed to produce both C and Z purlins quickly and accurately, making it the ideal choice for construction projects requiring a wide range of purlin sizes and shapes. With its advanced technology, customizable options, and user-friendly controls, our roll forming machine offers a comprehensive solution for all your purlin production requirements.

Key Features and Specifications of C Z purlin roll forming machine

Key Features and Specifications:

- Quick and Easy Profile Change: Our C Z Purlin Roll Forming Machine is designed with a user-friendly profile change system, allowing you to switch between C and Z purlin production with minimal downtime.

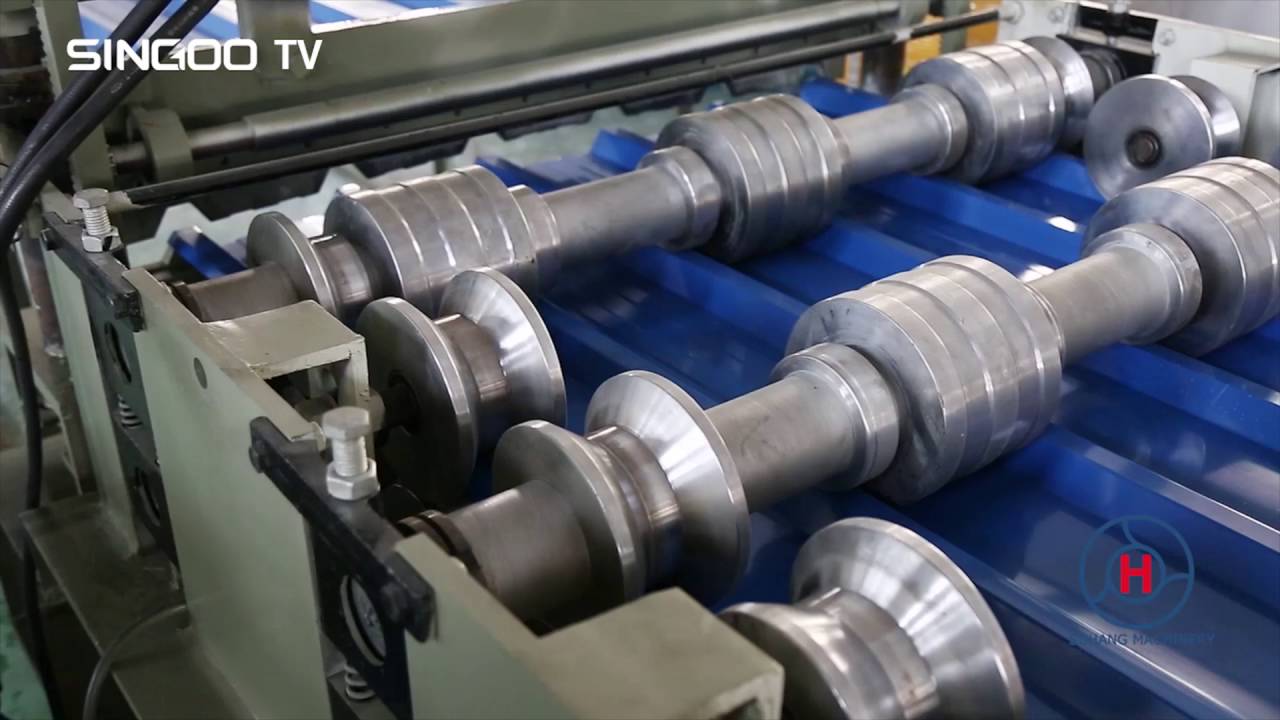

- Precision Roll Forming: Equipped with high-quality rollers and a robust frame, the machine ensures precise and consistent purlin dimensions for optimal structural performance.

- Adjustable Size and Thickness: The machine accommodates a wide range of purlin sizes and thicknesses, offering flexibility for various construction applications.

- High Production Speed: With its efficient design and powerful motor, our roll forming machine delivers impressive production speeds, maximizing output and reducing labor costs.

- PLC Control System: The machine features a user-friendly PLC control system, providing easy operation and real-time monitoring of the production process.

- Automatic Punching and Cutting: The integrated punching and cutting system allows for precise hole punching and accurate cutting to length, ensuring seamless installation of the finished purlins.

- Durable and Low-Maintenance: Constructed with high-quality components and materials, our C Z Purlin Roll Forming Machine offers long-lasting performance with minimal maintenance requirements.

Sunway C Z Roll forming machine Advantages and Benefits:

Advantages and Benefits:

- Versatility: Produce both C and Z purlins using a single machine, streamlining your production process and reducing equipment investment costs.

- Efficiency: Our roll forming machine’s high production speed and automated features save time and labor, resulting in increased efficiency and cost savings.

- Precision and Quality: With its advanced technology and precise roll forming capabilities, the machine delivers high-quality purlins that meet strict industry standards.

- Customization: Customize purlin sizes and thicknesses to suit your specific project requirements, ensuring optimal structural performance and cost-effectiveness.

- Ease of Use: The user-friendly PLC control system and simple profile change system make operating the machine easy and efficient, even for operators with limited experience.

C Z Purlin Roll Forming Machine applications:

The C Z Purlin Roll Forming Machine is a versatile piece of equipment that can be used in various construction applications. By producing both C and Z purlins with adjustable sizes and thicknesses, the machine can accommodate the needs of different projects. Some common applications of C Z Purlin Roll Forming Machine include:

Industrial and commercial buildings: C and Z purlins are frequently used as secondary structural components in the construction of factories, workshops, warehouses, and commercial facilities to support roofing and wall cladding systems.

Agricultural structures: Purlins produced by the C Z Purlin Roll Forming Machine are often used in the construction of barns, greenhouses, storage facilities, and other agricultural buildings, providing support for roofing and wall systems.

Residential buildings: C and Z purlins can be used in the construction of garages, sheds, and other residential structures, offering a cost-effective and durable solution for supporting roofing and wall materials.

Prefabricated buildings: The C Z Purlin Roll Forming Machine is ideal for producing purlins used in prefabricated steel building systems, where components are manufactured off-site and assembled on-site, ensuring quick construction and reduced labor costs.

Retrofit and renovation projects: C and Z purlins can also be used in retrofitting and renovation projects, providing additional structural support and reinforcement for existing buildings.

Solar panel mounting structures: C and Z purlins can be utilized as part of solar panel mounting systems, offering a strong and stable support structure for the installation of photovoltaic panels.

Mezzanine floors: Purlins produced by the C Z Purlin Roll Forming Machine can be used in the construction of mezzanine floors, providing support for elevated platforms within larger buildings.

These applications demonstrate the wide-ranging versatility of the C Z Purlin Roll Forming Machine and the diverse construction projects that can benefit from the use of C and Z purlins.

C Z Purlin Roll Forming Machine Industrials:

The C Z Purlin Roll Forming Machine is suitable for purchase by various individuals and organizations involved in the construction and manufacturing industries. Some target customers include:

Steel structure manufacturers: Companies that produce steel structures for commercial, industrial, and residential applications can benefit from using a C Z Purlin Roll Forming Machine to efficiently produce purlins for their projects.

Prefabricated building manufacturers: Those who manufacture prefabricated buildings can use the machine to produce customized C and Z purlins for their building systems, ensuring quick construction and reduced labor costs.

Metal roofing and cladding manufacturers: Companies specializing in metal roofing and cladding systems can benefit from producing their own purlins, providing a complete solution for their customers.

Construction contractors: Contractors involved in various construction projects, including commercial, industrial, and residential buildings, can use the machine to produce purlins on-site or in their workshop, reducing lead times and transportation costs.

Agricultural building manufacturers: Companies producing agricultural structures, such as barns and greenhouses, can benefit from using the C Z Purlin Roll Forming Machine to manufacture purlins tailored to their specific requirements.

Solar panel installation companies: Businesses that specialize in solar panel installations can use the machine to produce purlins for solar panel mounting structures, ensuring a strong and stable support system.

Metal fabrication workshops: Workshops that provide metal fabrication services can expand their product offerings by using the C Z Purlin Roll Forming Machine to produce custom purlins for various applications.

Entrepreneurs and small business owners: Individuals looking to start a business in the construction or manufacturing industries can invest in a C Z Purlin Roll Forming Machine as a key piece of equipment to produce purlins for various applications and projects.

By offering a versatile and efficient solution for purlin production, the C Z Purlin Roll Forming Machine is an ideal investment for a wide range of customers involved in the construction and manufacturing sectors.

How to choose a good C Z Purlin Roll Forming Machine ?

When choosing a good C Z Purlin Roll Forming Machine, consider the following factors to ensure you make an informed decision and select the best equipment for your needs:

Quality and durability: Look for a machine that is built with high-quality materials and components to ensure its durability and long-lasting performance. A well-built machine will require less maintenance and provide a higher return on investment.

Versatility: A good C Z Purlin Roll Forming Machine should be able to produce both C and Z purlins with adjustable sizes and thicknesses to suit various construction applications. This versatility allows you to cater to a wider range of projects and customer needs.

Production speed and efficiency: Evaluate the machine’s production speed and efficiency, as a faster and more efficient machine will help you maximize output, reduce labor costs, and increase profitability.

Precision and accuracy: Choose a machine that offers precise roll forming, accurate punching, and cutting capabilities to ensure the final purlins meet industry standards and provide optimal structural performance.

Ease of operation: Opt for a machine with a user-friendly control system, such as a PLC control system, which simplifies operation and allows for real-time monitoring of the production process.

Quick profile change: A good C Z Purlin Roll Forming Machine should have a quick and easy profile change system, minimizing downtime when switching between C and Z purlin production.

Customization options: Look for a machine that offers customization options, such as adjustable size and thickness settings, to cater to specific project requirements and ensure cost-effectiveness.

Technical support and after-sales service: Choose a manufacturer that provides exceptional technical support and after-sales service, including assistance with installation, training, troubleshooting, and spare parts supply.

Manufacturer reputation: Research the manufacturer’s reputation and track record to ensure they are known for producing high-quality, reliable equipment and providing excellent customer service.

Budget and return on investment: Consider your budget and the potential return on investment when selecting a C Z Purlin Roll Forming Machine. While it may be tempting to opt for a lower-priced machine, consider the long-term benefits of investing in a high-quality, durable machine that offers better performance, efficiency, and support.

By taking these factors into account, you can choose a good C Z Purlin Roll Forming Machine that meets your specific needs and provides a reliable, efficient solution for your purlin production requirements.

C Z Purlin Roll Forming Machine cost

The cost of a C Z Purlin Roll Forming Machine can vary significantly depending on several factors, such as the machine’s features, quality, production capacity, and the manufacturer’s reputation. It’s essential to consider these factors along with your budget and production requirements when evaluating the cost of a C Z Purlin Roll Forming Machine.

A basic C Z Purlin Roll Forming Machine can start at around $20,000, while more advanced machines with additional features and higher production capacities can range from $40,000 to over $100,000. Customizations, such as special tooling or unique size and thickness capabilities, may also add to the overall cost.

It’s important to remember that a lower-priced machine may not always be the best investment, as it could result in increased maintenance costs, lower efficiency, and a shorter lifespan. Investing in a high-quality, reliable machine with a solid reputation may have a higher upfront cost but can offer long-term benefits, such as better performance, efficiency, and a higher return on investment.

In addition to the cost of the machine itself, you should also consider other expenses, such as shipping, installation, training, and any necessary upgrades to your facility to accommodate the new equipment.

To get an accurate estimate of the cost of a C Z Purlin Roll Forming Machine that meets your specific needs, it’s best to contact several manufacturers and request quotes. This will allow you to compare prices, features, and support services to make an informed decision and select the machine that offers the best value for your investment.

Why choose to purchase a C Z Purlin Roll Forming Machine from China?

There are several reasons why you may choose to purchase a C Z Purlin Roll Forming Machine from China:

Cost-effectiveness: Chinese manufacturers often offer competitive prices for their products due to lower labor and production costs. This means you can potentially get a high-quality machine at a more affordable price compared to purchasing from manufacturers in other countries.

Manufacturing expertise: China has a well-established manufacturing industry with extensive experience in producing various types of machinery, including roll forming machines. Chinese manufacturers have the expertise and knowledge to produce reliable and efficient equipment.

Customization options: Many Chinese manufacturers are willing to work closely with customers to customize their machines according to specific requirements. This flexibility allows you to get a C Z Purlin Roll Forming Machine tailored to your exact needs, ensuring optimal performance and cost-effectiveness.

Large production capacity: Chinese manufacturers often have the capability to produce machines at a large scale, which can lead to shorter lead times and quicker delivery of your equipment.

Growing reputation for quality: While some buyers may have concerns about the quality of Chinese-made products, many reputable Chinese manufacturers are committed to producing high-quality machines that meet or exceed international standards. By conducting thorough research and selecting a reputable supplier, you can find a high-quality C Z Purlin Roll Forming Machine from China.

Global shipping and logistics: Chinese manufacturers typically have experience shipping their products worldwide, making it easier for you to receive your equipment regardless of your location.

However, it’s important to carefully research and select a reputable Chinese manufacturer to ensure you receive a high-quality machine with reliable performance and after-sales support. Always check the manufacturer’s reputation, customer reviews, and track record before making a decision. Communicate your specific requirements clearly and ensure the manufacturer can meet those needs to guarantee a satisfactory purchasing experience.

Auto Changeable C Z Purline Machine

SUNWAY design this auto changeable C Z purline machine to work with any size of the purlin, automatically adjustable sizes on PLC. Whats’ more, changing time from C to Z only need 5-10 minutes. Regarding the punching unit, we can

Auto Size Changeable C Z Purlin Roll Forming Machine

This auto size changeable C Z purlin roll forming machine is used to produce C&Z shape purlins from 100-300mm of width, normally its material thickness is 1.5-3mm, also Maximum thickness can be formed at 4.0-6.0mm according to customer requirement.

CZ Purlin Roll forming machine

Features CZ Purlin Roll forming machine can produce C, Z profiles. Produce the C and Z purlin by exchange one side of the roller up and down, only need about half hour. This machine also can adjust roller horizontal distance

C Z Purlin Channel Cold Roll Forming Machine Full Auto Galvanized Steel Profile

C Z Purlin Channel Cold Roll Forming Machine adopts a special structure for both C and Z purlin making. The rollers for C & Z are changed very quickly without dismantle any parts. Cutter adopts universal hydraulic cutting device, no

Auto Changeable C Z Purline Machine

SUNWAY design this auto changeable C Z purline machine to work with any size of the purlin, automatically adjustable sizes on PLC. Whats’ more, changing time from C to Z

Auto Size Changeable C Z Purlin Roll Forming Machine

This auto size changeable C Z purlin roll forming machine is used to produce C&Z shape purlins from 100-300mm of width, normally its material thickness is 1.5-3mm, also Maximum thickness

CZ Purlin Roll forming machine

Features CZ Purlin Roll forming machine can produce C, Z profiles. Produce the C and Z purlin by exchange one side of the roller up and down, only need about

C Z Purlin Channel Cold Roll Forming Machine Full Auto Galvanized Steel Profile

C Z Purlin Channel Cold Roll Forming Machine adopts a special structure for both C and Z purlin making. The rollers for C & Z are changed very quickly without

Recent Update

Roll Forming Machine Case Studies: Real-World Success Stories in 2025

Introduction Choosing the right roll forming machine is a big decision, but what better way to understand its impact than through real-world case studies? In this article, we’ll explore how

How to Choose a Roll Forming Machine in 2025: The Ultimate Buying Guide

Introduction Choosing the right roll forming machine can be challenging—especially with so many options available in the market. Whether you’re buying for roofing, shelving, automotive, or solar panel mounting, making

Roll Forming Machine Automation: The Future of Metal Forming in 2025 and Beyond

Introduction Automation is revolutionizing the roll forming industry, making production faster, more precise, and less dependent on manual labor. As manufacturers embrace smart automation, they can expect higher efficiency, reduced

Why Sunway

The Global Leader In Roll forming Industry

We pay meticulous attention to each detail from raw material to delivery. It is throughout our constantly effort that our customers get the consistently high level quality products they have to look for. We always make efforts to cut the cost at the same time improve the technological content of products in order to enhance the market competitiveness of the products. In the related diversification development, we increase investment and enhance development of key products and key projects continuously make breakthroughs in technology and product function, to rank at the advanced level in the market.

Providing Innovative Roll forming Machine Solution

- We Use Advance Manufacturing Process

- Provide Unique Technology

- Group Of Certified & Experienced Team

- The Best Services For Multiple Industries

100+

Destination Countries

500+

Finished Project

We are worth your trust

Some Of Our main Advantages

We Own Factory

We have our own factory since established, and with the development, our factory is getting bigger and bigger, and the production capacity of the factory is getting higher and higher. There is no trader between us, which means that we can achieve the most satisfactory level in terms of price, MOQ and product customization services.

Fair Price

We are a cold roll forming machine factory, not a trading company, which means there is no middleman between us. The relationship between you and us is direct, which saves you both money and hassle. The production process of Yupai factory reduces the burden of machinery costs, which minimizes the price on each individual unit. We can give you extremely competitive prices.

Flexible

You can tell us your budget & ideal profile drawing, and we can provide the most suitable solution for you. Sunway will cooperate to ensure you get the best bang for your buck. In accordance with High Quality Assurance and Valued Credibility, we provide customers high qualified and reliable products with complete after-sales service.

One-Stop

Here at Sunway, we have a multitude of cold roll forming machine products to choose from. Our machines feature beautiful appearance, long service life, good performance, and so on. We offer a truly one-stop shopping service. Sunway have years of knowledge in this industry, and are willing to guide you along your way, all while guaranteeing you the best quality goods.

Customer Support

Most factories primarily focus only on manufacturing, which leads to a lacking of sales and service awareness. Sunway have our own sales team, technicians and after-sales staff, which means that not only can we provide faster and better-quality service.

Serve All Customer

Whether it is a customer who has just stepped into the cold roll forming machine industry or a customer who has developed into a large scale, Sunway attach the same importance. We care about the experience of all customers.