Box profile roofing sheets have emerged as one of the most popular choices for modern roofing projects, whether residential, commercial, or industrial. Combining strength, durability, and aesthetics, these sheets offer an ideal solution for those seeking a robust yet visually appealing roofing option. In this comprehensive guide, we’ll dive deep into everything you need to know about box profile roofing sheets, from the types available to their installation, maintenance, and beyond. Whether you’re a DIY enthusiast, a professional roofer, or simply exploring your options, this guide is tailored to meet your needs.

Overview of Box Profile Roofing Sheets

Box profile roofing sheets, commonly known as trapezoidal roofing sheets, are made from materials such as steel, aluminum, or other metal alloys. These sheets are characterized by their square or rectangular wave-like patterns, offering superior rigidity compared to traditional corrugated sheets. The design allows for better load distribution, making them suitable for areas prone to heavy rainfall, snow, or high winds.

These roofing sheets are versatile and can be used for a wide range of applications, from covering agricultural buildings to modern commercial structures. Their popularity stems not only from their functional benefits but also from their sleek, industrial aesthetic.

Key Benefits of Box Profile Roofing Sheets

- Durability: Made from high-strength materials, these sheets can withstand extreme weather conditions.

- Aesthetic Appeal: The clean lines of box profile sheets add a modern touch to any building.

- Cost-Effective: Compared to some other roofing materials, box profile sheets offer excellent value for money.

- Easy Installation: Their lightweight nature and uniform profile make installation quicker and more straightforward.

- Low Maintenance: These sheets require minimal upkeep, making them a hassle-free option for building owners.

Understanding Corrugated Iron Sheets vs. Box Profile Roofing Sheets

Before diving into the specifics of box profile roofing sheets, it’s essential to understand how they differ from traditional corrugated iron sheets. Both options are commonly used in roofing projects, but they serve different purposes based on their design and functionality.

Comparison: Corrugated Iron Sheets vs. Box Profile Roofing Sheets

| Feature | Corrugated Iron Sheets | Box Profile Roofing Sheets |

|---|---|---|

| Design | Wavy, sinusoidal patterns | Rectangular or square-shaped patterns |

| Strength | Less rigid due to the wave-like structure | More rigid and durable, offering better load distribution |

| Aesthetic | Traditional, rustic appearance | Modern, industrial appearance |

| Installation | Can be more challenging due to the wavy pattern | Easier to install, with sheets aligning perfectly |

| Usage | Suitable for agricultural buildings and rural settings | Ideal for commercial, industrial, and contemporary residential buildings |

| Cost | Typically lower in cost | Slightly higher cost but offers more benefits |

| Maintenance | Can require more maintenance due to dirt accumulation in the waves | Lower maintenance, easier to clean and maintain |

| Weather Resistance | Provides good weather resistance but can struggle under heavy loads | Excellent weather resistance, particularly in areas with heavy rainfall or snow |

As you can see, while both types of roofing sheets have their advantages, box profile roofing sheets tend to offer more benefits, especially for modern buildings where strength and aesthetics are crucial.

Types of Box Profile Roofing Sheets

Box profile roofing sheets come in various types, each designed to meet specific needs. Understanding the differences between these types can help you choose the right product for your project.

1. Galvanized Steel Box Profile Sheets

Overview:

Galvanized steel sheets are coated with a layer of zinc, which provides excellent corrosion resistance. These sheets are highly durable and are ideal for environments where rust and corrosion could be a concern, such as coastal areas.

Key Features:

- Corrosion Resistance: The zinc coating prevents rust, ensuring a longer lifespan.

- High Strength: Steel’s inherent strength makes these sheets suitable for areas with heavy loads.

- Cost-Effective: Offers excellent value for money, considering its durability.

2. Polyester-Coated Steel Box Profile Sheets

Overview:

These sheets are coated with a layer of polyester paint, adding an extra layer of protection and enhancing the aesthetic appeal. They are available in various colors, making them ideal for projects where visual appeal is important.

Key Features:

- Aesthetic Versatility: Available in a wide range of colors and finishes.

- Enhanced Durability: The polyester coating provides additional protection against the elements.

- UV Resistance: Resists fading and degradation from sunlight exposure.

3. PVC Plastisol-Coated Steel Box Profile Sheets

Overview:

Plastisol-coated sheets are steel sheets that have been treated with a thick layer of PVC, offering superior protection against harsh weather conditions. These sheets are particularly popular in industrial and commercial applications.

Key Features:

- Weather Resistance: The PVC coating provides exceptional protection against UV rays, rain, and snow.

- Long Lifespan: Can last up to 30 years or more with minimal maintenance.

- Impact Resistance: The coating adds a layer of impact resistance, protecting against dents and scratches.

4. Aluminum Box Profile Sheets

Overview:

Aluminum sheets are lightweight yet strong, making them ideal for projects where weight is a consideration. They also offer excellent corrosion resistance without the need for additional coatings.

Key Features:

- Lightweight: Easier to handle and install compared to steel sheets.

- Natural Corrosion Resistance: Aluminum naturally resists corrosion, even in harsh environments.

- Recyclable: Aluminum is 100% recyclable, making it an environmentally friendly choice.

5. Color-Coated Box Profile Sheets

Overview:

These sheets are coated with color using various techniques, offering both aesthetic appeal and additional protection. They are popular in residential projects where the roof’s appearance is as important as its function.

Key Features:

- Wide Range of Colors: Available in various colors to match different architectural styles.

- Protective Coating: The color coating also adds a layer of protection against the elements.

- Customizable: Can be customized in terms of color, thickness, and profile to suit specific needs.

6. Stainless Steel Box Profile Sheets

Overview:

Stainless steel sheets are the pinnacle of durability and resistance to corrosion. They are often used in highly corrosive environments, such as chemical plants or coastal buildings.

Key Features:

- Exceptional Durability: Offers the highest level of resistance to corrosion and wear.

- Low Maintenance: Requires minimal upkeep, even in harsh environments.

- Premium Appearance: The polished finish of stainless steel adds a touch of luxury to any building.

7. Bitumen-Coated Box Profile Sheets

Overview:

These sheets are coated with bitumen, a type of asphalt, providing excellent waterproofing. They are often used in applications where water resistance is critical, such as in damp climates.

Key Features:

- Waterproofing: The bitumen coating ensures complete waterproofing, protecting the building structure.

- Sound Insulation: Bitumen also provides sound insulation, reducing noise from rain or hail.

- Temperature Regulation: Helps in maintaining a stable temperature within the building by reflecting heat.

8. Fibre Cement Box Profile Sheets

Overview:

Fibre cement sheets combine cement with fibrous materials to create a strong, durable roofing solution. These sheets are ideal for agricultural buildings due to their resistance to chemicals and fire.

Key Features:

- Chemical Resistance: Resists degradation from chemicals, making it ideal for agricultural use.

- Fire Resistance: Offers excellent fire resistance, enhancing building safety.

- Durability: Can last for decades with minimal maintenance.

9. Zincalume Box Profile Sheets

Overview:

Zincalume sheets are coated with a blend of zinc and aluminum, providing superior corrosion resistance. These sheets are often used in areas with extreme weather conditions.

Key Features:

- Corrosion Resistance: The zinc-aluminum alloy offers enhanced protection against rust and corrosion.

- High Reflectivity: Reflects heat, making it energy-efficient and ideal for warm climates.

- Long Lifespan: Can last up to four times longer than standard galvanized sheets.

10. Hybrid Box Profile Sheets

Overview:

Hybrid sheets combine different materials, such as steel and aluminum, to leverage the benefits of each. These sheets are customized to meet specific project needs.

Key Features:

- Customized Solutions: Can be tailored to meet specific requirements, such as enhanced strength or reduced weight.

- Multi-Layer Protection: Combines the strengths of various materials for superior durability and resistance.

- Versatile Applications: Suitable for a wide range of environments and building types.

-

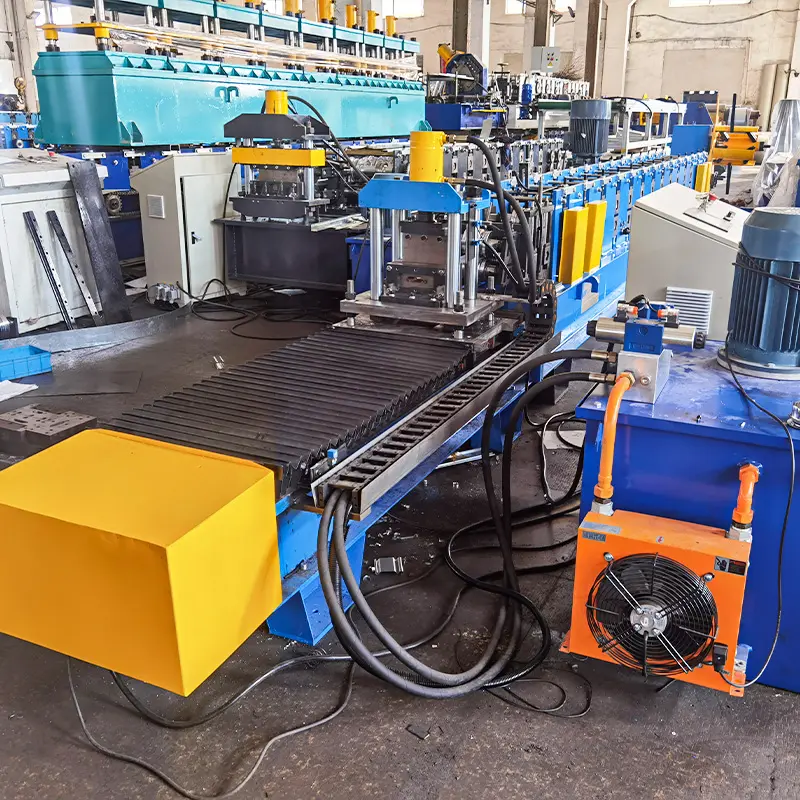

Storage Rack Shelf Box Panel Making Machine Steel Storage Rack System Box Beam Roll Forming Line

Storage Rack Shelf Box Panel Making Machine Steel Storage Rack System Box Beam Roll Forming Line -

Highway Guardrail End Terminal Forming Machine

Highway Guardrail End Terminal Forming Machine -

Highway U/C Post Roll Forming Machine

Highway U/C Post Roll Forming Machine -

2 Waves Highway Guardrail Roll Forming Machine

2 Waves Highway Guardrail Roll Forming Machine -

3 Waves Highway Guardrail Roll Forming Machine

3 Waves Highway Guardrail Roll Forming Machine -

C Section Bracing Omega Storage Rack Upright Post Roll Forming Machine

C Section Bracing Omega Storage Rack Upright Post Roll Forming Machine -

Steel Box Plate Making Roll Forming Machine

Steel Box Plate Making Roll Forming Machine -

Box Beam Steel Roll Forming Machine For Shelf Column

Box Beam Steel Roll Forming Machine For Shelf Column -

Pallet Racking Step Beam P Beam Roll Forming Machine

Pallet Racking Step Beam P Beam Roll Forming Machine

Working Process of Box Profile Roofing Sheets

Understanding how box profile roofing sheets are manufactured and installed is crucial for selecting the right product and ensuring a successful installation.

Manufacturing Process

The manufacturing process of box profile roofing sheets typically involves the following steps:

- Material Selection: High-quality steel, aluminum, or other metal alloys are selected based on the desired properties, such as strength, weight, and corrosion resistance.

- Cold Rolling: The selected material is passed through a series of rollers to create the desired profile. This process is done at room temperature, hence the term “cold rolling.”

- Coating: Depending on the type of sheet being produced, a protective coating (such as zinc, polyester, or PVC) is applied to enhance durability and resistance to environmental factors.

- Cutting: The sheets are then cut to the required lengths using precision cutting machines

.

- Quality Control: Each sheet undergoes rigorous quality checks to ensure it meets industry standards in terms of strength, durability, and finish.

- Packaging: Finally, the sheets are carefully packaged to prevent damage during transportation and are ready for shipment.

Installation Process

Installing box profile roofing sheets is a relatively straightforward process, but it requires attention to detail to ensure a secure and durable roof. Here’s a step-by-step guide to the installation process:

- Preparation: Ensure the roof structure is sound and capable of supporting the weight of the roofing sheets. Clear any debris from the roof area.

- Laying the Sheets: Start by laying the first sheet at one end of the roof, aligning it with the edge. Ensure the sheet is positioned correctly before fixing it in place.

- Fixing the Sheets: Use self-tapping screws with neoprene washers to secure the sheets to the roof structure. The screws should be placed in the valleys of the profile, not on the peaks, to prevent leaks.

- Overlapping Sheets: When laying subsequent sheets, overlap them by one or two profiles to ensure a watertight seal. The overlap distance will depend on the pitch of the roof.

- Ridge and Eave Flashings: Install ridge and eave flashings to protect the roof edges and prevent water ingress.

- Final Checks: Once all the sheets are installed, check for any loose screws or gaps. Make any necessary adjustments to ensure a secure and weatherproof roof.

Components and Functions in Box Profile Roofing Sheets

Box profile roofing sheets consist of various components, each playing a vital role in the overall performance of the roof. Understanding these components can help in choosing the right product and ensuring proper installation.

Key Components and Their Functions

| Component | Function |

|---|---|

| Sheet Profile | The shaped profile of the sheet provides structural strength and rigidity. |

| Coating | Protective layer (e.g., zinc, polyester) that prevents corrosion and extends the sheet’s lifespan. |

| Self-Tapping Screws | Fasteners used to secure the sheets to the roof structure, ensuring they stay in place during extreme weather. |

| Neoprene Washers | Placed under the screw heads to create a watertight seal and prevent leaks. |

| Ridge Flashing | Protects the ridge of the roof, preventing water from seeping in. |

| Eave Flashing | Installed at the eaves to protect the roof edge and direct water away from the structure. |

| End Lap Tape | Used between overlapping sheets to create a waterproof seal. |

| Barge Board | Installed along the gable ends to protect the roof edges and enhance the roof’s appearance. |

Machine Speed and Efficiency in Production

The production of box profile roofing sheets involves various machines, each operating at different speeds and efficiencies. Understanding these metrics can help optimize the production process.

Production Machine Speeds and Efficiencies

| Machine | Speed (m/min) | Efficiency (%) | Function |

|---|---|---|---|

| Roll Forming Machine | 10-30 | 95 | Shapes the metal into the desired box profile. |

| Cutting Machine | 5-15 | 90 | Precision cuts the sheets to the required lengths. |

| Coating Line | 20-50 | 85 | Applies protective coatings to the sheets. |

| Packaging Machine | 10-20 | 98 | Packages the finished sheets for transport. |

Customized Mechanical Parameters

When choosing box profile roofing sheets, it’s essential to consider customized mechanical parameters to ensure the product meets specific project requirements.

Customized Mechanical Parameters for Box Profile Sheets

| Parameter | Standard Value | Customizable Range | Significance |

|---|---|---|---|

| Thickness | 0.5-1.0 mm | 0.3-2.0 mm | Determines the sheet’s strength and durability. |

| Width | 800-1200 mm | 600-1500 mm | Affects coverage and installation time. |

| Length | 2-6 meters | 1-12 meters | Can be customized to fit specific roof dimensions. |

| Coating Thickness | 20-40 microns | 10-60 microns | Impacts corrosion resistance and longevity. |

| Yield Strength | 250-350 MPa | 200-500 MPa | Indicates the sheet’s ability to withstand stress. |

Applications and Uses of Box Profile Roofing Sheets

Box profile roofing sheets are versatile and can be used in various applications across different industries. Below are some of the common uses of these sheets.

Applications of Box Profile Roofing Sheets

| Application | Description |

|---|---|

| Residential Roofing | Provides a modern and durable roofing solution for homes. |

| Commercial Buildings | Ideal for offices, retail stores, and other commercial properties. |

| Industrial Warehouses | Strong enough to withstand heavy loads and harsh industrial environments. |

| Agricultural Buildings | Resistant to chemicals and suitable for barns, silos, and other farm structures. |

| School and Educational Institutions | Offers a safe and long-lasting roofing option for schools and universities. |

| Retail Outlets | Provides an attractive and durable roof for shops and stores. |

| Carports and Garages | Lightweight and easy to install, making them perfect for carports and garages. |

| Sports Halls and Arenas | Offers large span coverage and can be customized for aesthetic appeal. |

| Public Buildings | Suitable for libraries, museums, and other public structures. |

| Temporary Structures | Easy to install and remove, making them ideal for temporary buildings. |

Installation, Operation, and Maintenance

Proper installation, operation, and maintenance of box profile roofing sheets are crucial to ensuring their longevity and performance. Here’s a detailed guide on these aspects.

Installation, Operation, and Maintenance Guidelines

| Aspect | Details |

|---|---|

| Installation | Follow the manufacturer’s guidelines for laying, overlapping, and securing the sheets. Ensure proper alignment and use the recommended fasteners to prevent leaks and damage. |

| Operation | Once installed, ensure that the roof is inspected regularly for any signs of wear, such as loose screws or damaged coatings. Immediate repairs should be made to prevent further damage. |

| Maintenance | Clean the roof periodically to remove debris and dirt that could lead to corrosion. Check the seals and flashings regularly to ensure they remain watertight. Reapply coatings as needed to maintain protection against the elements. |

Suppliers and Price Range for Box Profile Roofing Sheets

When purchasing box profile roofing sheets, it’s essential to choose a reliable supplier who offers quality products at competitive prices. Here’s a guide to help you find the right supplier and understand the price range for these products.

Suppliers and Price Range of Box Profile Roofing Sheets

| Supplier | Price Range (per sqm) | Location | Specialties |

|---|---|---|---|

| ABC Roofing Supplies | $20 – $30 | United States | Specializes in galvanized and color-coated box profile sheets. |

| RoofTech Distributors | $18 – $28 | United Kingdom | Offers a wide range of coated steel and aluminum roofing sheets. |

| Global Metal Roofing Solutions | $25 – $35 | Australia | Known for high-quality stainless steel and zincalume box profile sheets. |

| MetalRoofDirect | $22 – $32 | Canada | Provides customized roofing solutions with various coating options. |

| Durable Roofing Materials | $19 – $29 | South Africa | Specializes in durable, weather-resistant roofing sheets for harsh climates. |

| EcoRoof Suppliers | $20 – $30 | India | Focuses on eco-friendly and energy-efficient box profile roofing materials. |

| EuroMetal Roofing Supplies | $21 – $31 | Germany | Offers a range of high-strength, customizable box profile sheets. |

| ProBuild Roof Systems | $18 – $28 | New Zealand | Known for competitively priced, high-quality roofing sheets. |

| Asian Roofing Enterprises | $17 – $27 | China | Provides affordable yet durable roofing solutions for large-scale projects. |

| RoofMaster Distributors | $19 – $29 | Brazil | Specializes in PVC plastisol-coated and polyester-coated box profile sheets. |

How to Choose the Right Supplier

Selecting the right supplier is crucial for ensuring you get high-quality box profile roofing sheets at the best possible price. Here are some tips to help you make the right choice.

Guide to Choosing a Supplier for Box Profile Roofing Sheets

| Criteria | Considerations |

|---|---|

| Reputation | Look for suppliers with positive customer reviews and a strong reputation in the industry. |

| Product Range | Ensure the supplier offers a variety of products to meet your specific needs, including customization options. |

| Price | Compare prices from different suppliers, but don’t sacrifice quality for cost. |

| Customer Service | Choose a supplier known for excellent customer service, including pre-sale consultation and post-sale support. |

| Delivery Options | Check if the supplier offers reliable delivery services, especially if you’re in a remote location. |

| Warranty and Guarantees | Opt for suppliers who provide warranties or guarantees on their products, ensuring peace of mind. |

Advantages and Disadvantages of Box Profile Roofing Sheets

While box profile roofing sheets offer numerous benefits, it’s important to weigh the pros and cons to determine if they’re the right choice for your project.

Pros and Cons of Box Profile Roofing Sheets

| Advantages | Disadvantages |

|---|---|

| Durability: Highly resistant to weather, corrosion, and mechanical damage. | Cost: Generally more expensive than traditional roofing options like corrugated sheets. |

| Aesthetic Appeal: Offers a modern, industrial look suitable for various applications. | Installation Complexity: Although easier than corrugated sheets, professional installation is recommended. |

| Versatility: Can be used in residential, commercial, and industrial settings. | Thermal Conductivity: Metal sheets can conduct heat, potentially leading to increased temperatures inside the building. |

| Low Maintenance: Requires minimal upkeep, reducing long-term costs. | Noise: Metal roofs can be noisy during rain or hail unless soundproofing measures are taken. |

| Energy Efficiency: Reflective coatings can improve energy efficiency by reducing heat absorption. | Weight: Heavier than some other roofing materials, which may require a stronger supporting structure. |

FAQ

| Question | Answer |

|---|---|

| What is a box profile roofing sheet? | A box profile roofing sheet is a type of metal sheet with a square or rectangular pattern, offering superior strength and durability compared to traditional corrugated sheets. |

| How do box profile roofing sheets compare to corrugated sheets? | Box profile sheets are more rigid and provide better load distribution, making them more suitable for modern buildings, whereas corrugated sheets have a more traditional appearance. |

| What materials are box profile roofing sheets made from? | They are typically made from steel, aluminum, or other metal alloys and may have additional coatings such as zinc, polyester, or PVC for added protection. |

| Can box profile roofing sheets be used for residential buildings? | Yes, they are suitable for residential buildings and offer a modern aesthetic, especially when coated with color or other finishes. |

| How long do box profile roofing sheets last? | Depending on the material and coating, they can last anywhere from 20 to 50 years with proper maintenance. |

| Are box profile roofing sheets energy efficient? | Yes, especially when coated with reflective materials that reduce heat absorption, improving energy efficiency in buildings. |

| How do I maintain box profile roofing sheets? | Regular cleaning to remove debris, checking for loose screws, and reapplying coatings as needed will help maintain their appearance and durability. |

| What are the typical costs of box profile roofing sheets? | Prices vary depending on the material, coating, and supplier but typically range from $18 to $35 per square meter. |

| Can box profile roofing sheets be customized? | Yes, many suppliers offer customization in terms of thickness, length, width, and coating to meet specific project requirements. |

| Is professional installation required for box profile roofing sheets? | While DIY installation is possible, professional installation is recommended to ensure proper alignment, sealing, and longevity. |

Conclusion

Box profile roofing sheets are an excellent choice for those seeking a durable, aesthetically pleasing, and versatile roofing solution. With a wide range of materials and coatings available, these sheets can be tailored to meet the specific needs of any project, whether residential, commercial, or industrial. By understanding the various types, components, and installation processes, you can make an informed decision and select the right product for your roofing needs.

Remember, the key to a successful roofing project lies not only in choosing the right materials but also in proper installation and maintenance. With the information provided in this guide, you’re well-equipped to take on your next roofing project with confidence.