Automobile Profile Roll Forming Machine

Imagine a car – any car you love, a sleek sports coupe or a sturdy SUV. Now, peel back the shiny exterior and the comfortable interior. Beneath the glamour lies

Imagine a car – any car you love, a sleek sports coupe or a sturdy SUV. Now, peel back the shiny exterior and the comfortable interior. Beneath the glamour lies

Imagine your storefront. A wave of customers floods in each morning, eager to explore your wares. But what secures your shop at night, keeping your inventory safe and your mind

Imagine cruising down the highway, the wind whipping through your hair (or sunroof, if you’re fancy). Suddenly, a deer darts out onto the road! You slam on the brakes, the

Ever driven down a highway and admired the smooth guardrails lining the sides? Those seemingly simple metal barriers play a crucial role in road safety, preventing countless accidents and saving

Imagine a machine that can transform a flat sheet of metal into the octagonal heart of a roller shutter door – the very structure that allows your home or business

Imagine a security guard that unfurls itself from a compact canister at your command, ready to shield your storefront or garage. That’s the magic of rolling shutter machines – versatile

Imagine driving down a highway, the wind whipping through your hair as you cruise along the open road. Suddenly, a car swerves out of control. Your heart jumps into your

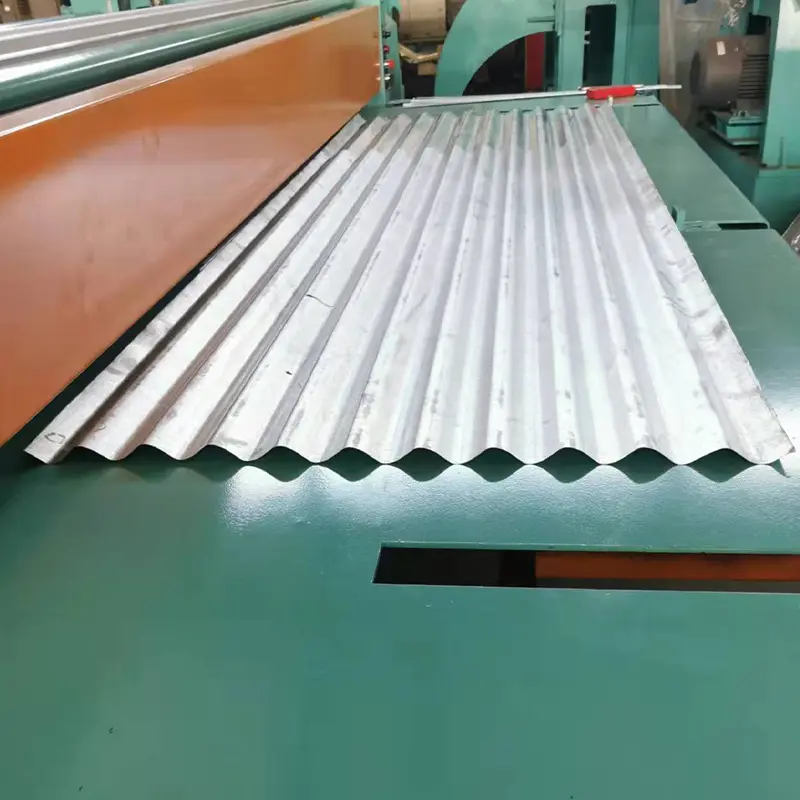

Imagine a machine that can take a flat sheet of metal and transform it into a symphony of curves and ridges. That’s the magic of a barrel corrugated roll forming

Imagine a warehouse – a vast, cavernous space humming with activity. Forklifts dance between towering structures, their metallic arms retrieving and depositing pallets laden with goods. These silent giants rely

Ever looked up at a neatly finished roof and admired the sharp line capping it off? That my friend, is the handiwork of a ridge cap, the crucial element shielding

Imagine the countless structures that shape our world – bridges spanning rivers, warehouses storing goods, and even the humble playground swing set. These seemingly ordinary creations often rely on a

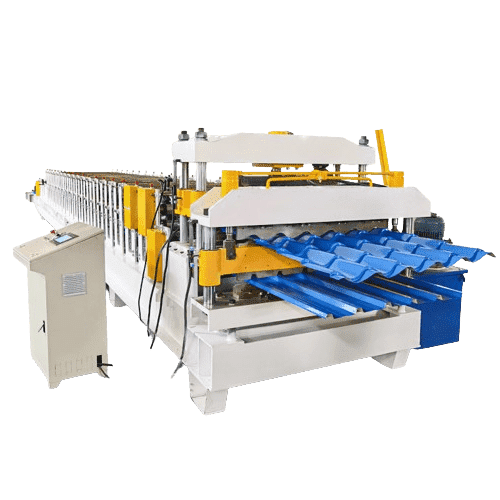

Imagine a machine that can transform long sheets of metal into intricate interlocking panels, ready to create a sleek, modern roof. That’s the magic of a Bemo Roof Panel Roll

Ever driven past a house during a downpour and noticed a steady stream cascading from the gutters? That’s rainwater efficiently directed away from the foundation thanks to a network of

Imagine a factory floor abuzz with activity. Sheets of metal are being transformed into the sturdy frames that house vital electrical components – control panels, distribution boxes, and instrument enclosures.

Imagine a towering skyscraper piercing the clouds, or a sprawling bridge gracefully arching over a river. These marvels of modern construction wouldn’t be possible without the silent heroes behind the

Introduction Choosing the right roll forming machine is a big decision, but what better way to understand its impact than

Introduction Choosing the right roll forming machine can be challenging—especially with so many options available in the market. Whether you’re

Introduction Automation is revolutionizing the roll forming industry, making production faster, more precise, and less dependent on manual labor. As

Introduction The roll forming industry is undergoing a technological revolution, driven by automation, AI, sustainability, and advanced materials. As we