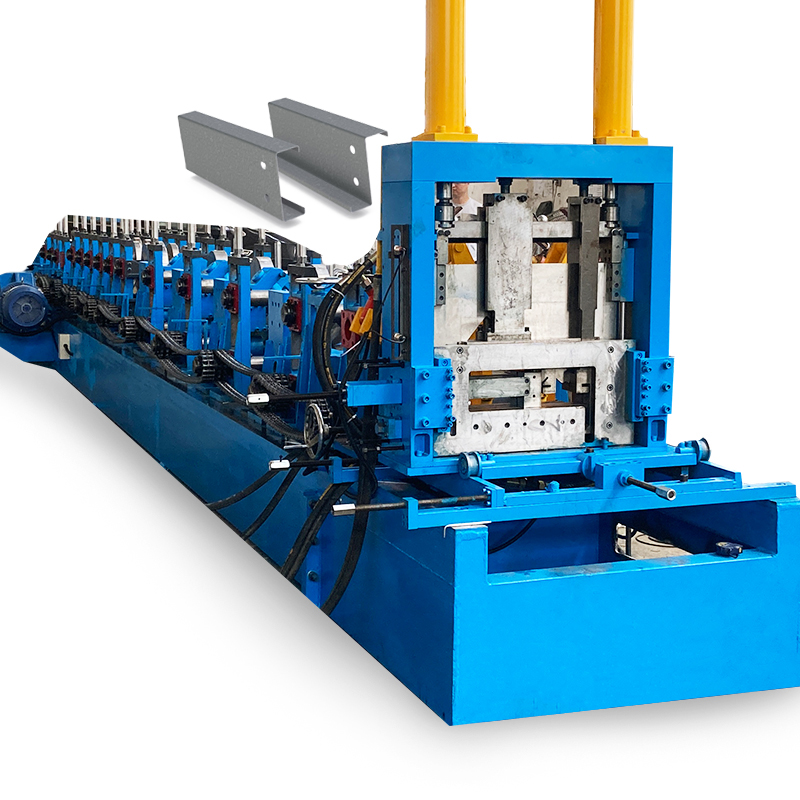

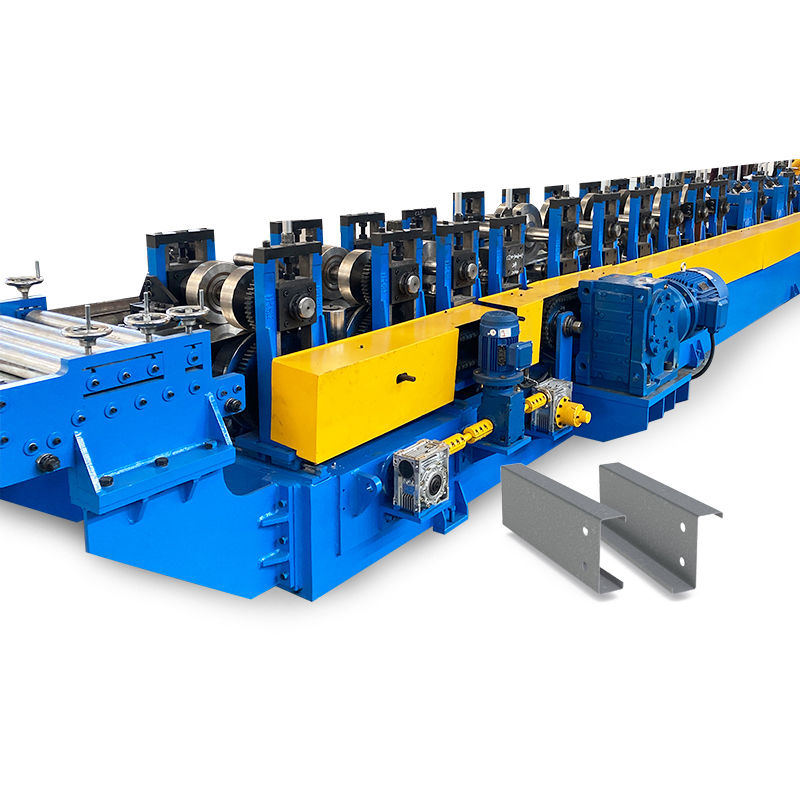

The Roll Forming Machine For C Purlin is an awesome tool that can be used for many different purposes. You might use it to build a deck, make a home addition, or build a shed – the possibilities are endless! This article discusses the details of the roll forming machine for c purlin. It begins by explaining what the machine is and how it works, followed by a section that provides information on how it can help you in your job.

What is a roll forming machine for c purlin?

A roll forming machine for c purlin is an automotive component that is used to create precision rolls of metal. These machines use a pressure and heat process to shape the metal into a desired form. They are often used in the manufacturing of car components, such as C purlins.

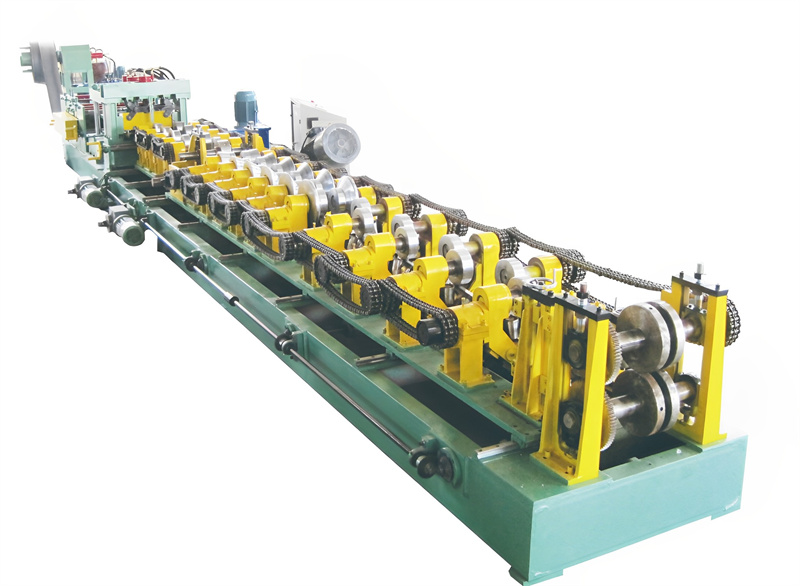

Roll forming machines are used to produce a variety of products, such as wire rods and tubes. They work by rolling steel sheets together, which creates the desired product. Roll forming machines are versatile and can be used for a variety of applications.

How does a roll forming machine work?

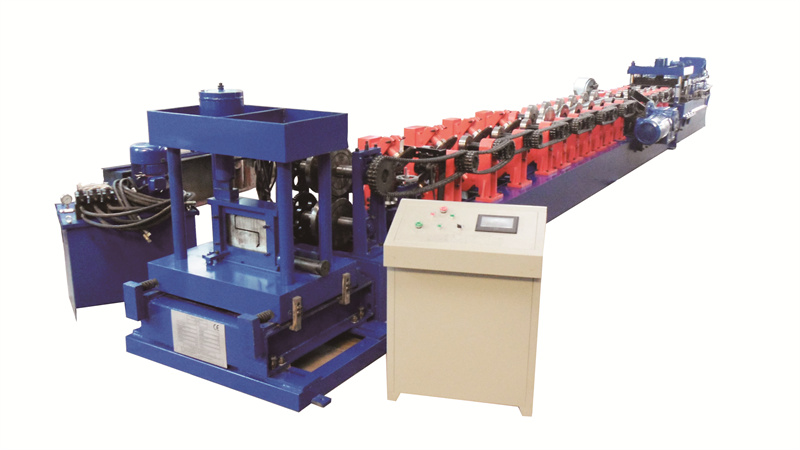

A roll forming machine is a sophisticated machine that can be used to create customized steel profiles. The roll forming process starts by feeding the steel strip into the machine on a horizontal axis. A series of dies are then lowered onto the strip and contact it at specific points, which causes the metal to be drawn into coils. This process is repeated until the desired profile is created.

Roll forming machine for c purlin is widely used in the manufacturing of electrical equipment, furniture and other products. They are also used to produce wire and cable assemblies from various shapes, including C purlins. The roll forming machine is composed of a number of rotary die-cutting drums that cut the rolled product into the required shape. Before cutting, the dies are set at an angle so that they form a C shape when rolling over the product.

How to use a roll forming machine?

There are many different types of roll forming machines on the market today. This machine is used to produce C-shaped members. To use this machine, the user inputs the dimensions of the desired member and then sets the speed and pressure. The machine will then start rolling the material around a cylindrical form, creating the C-shape.

The advantages of using a roll forming machine include its accuracy and speed. Additionally, this type of machine is relatively easy to operate, so it can be used by those with limited mechanical skills. When selecting a roll forming machine, it is important to consider both the size and shape of the desired product.

-

Barrel Corrugated Roll Forming Machine

Barrel Corrugated Roll Forming Machine -

2 Waves Highway Guardrail Roll Forming Machine

2 Waves Highway Guardrail Roll Forming Machine -

3 Waves Highway Guardrail Roll Forming Machine

3 Waves Highway Guardrail Roll Forming Machine -

Downspout Pipe Roll Forming Machine

Downspout Pipe Roll Forming Machine -

Gutter Roll Forming Machine

Gutter Roll Forming Machine -

Auto Size Changeable C U Purlin Roll Forming Machine

Auto Size Changeable C U Purlin Roll Forming Machine -

High Speed C Purlin Machine

High Speed C Purlin Machine -

Full automatic C purlin roll forming machine quick-change

Full automatic C purlin roll forming machine quick-change -

C purlin roll forming machine price

C purlin roll forming machine price

Pros and Cons of a Roll Forming Machine for c purlin

A roll forming machine for c purlin is a powerful tool that can be used to produce cpurlin products. There are many pros and cons to using a roll forming machine, but the key benefits include speed, precision, and consistent quality.

Speed: A roll forming machine can produce products quickly and with consistent quality. This is great for businesses that need quick turnaround times or products that need to be consistently of high quality.

Precision: The precision of a roll form machine allows for exact measurements to be taken while the product is being formed. This results in products that are uniform in size and shape.

Consistency: A roll form machine can produce products with consistent quality, meaning that they will all look the same. This is great for businesses that need to produce a specific type of product multiple times per day.

Uses of Roll Forming Machines for C Purlin

One important use for roll forming machines is in the production of structural parts. These machines are often used in the automotive, aerospace, and medical industries, among others, to produce parts such as side panels, roof panels, and door frames. They can also be used to create intricate shapes like c purlins.

When choosing a roll forming machine for c purlin, it is important to consider factors such as type of material being formed and size of the part being produced. Some common types of materials that can be formed using a roll form machine include plastic sheeting, metal sheeting, and plywood. Parts that are typically produced using a roll form machine include car body panels and aircraft wings.

Conclusion

If you’re looking to produce c purlins with consistent dimensions, a roll forming machine for c purlin is the perfect option for you. Not only will this machine help to ensure that your c purlins are of the same size and shape every time, but it will also reduce the amount of waste that is produced during production. If you’re interested in investing in a roll forming machine, be sure to read our guide on the best machines available so that you can make an informed decision.

Additional Frequently Asked Questions (FAQ)

1) What materials and thicknesses can a Roll Forming Machine for C Purlin handle?

Typical lines process galvanized steel (ASTM A653), Galvalume (ASTM A792), and high-strength low-alloy coils from 1.2–3.0 mm thickness and 120–600 mm web widths. Some auto-size CU lines can handle up to 3.5 mm with 350–550 MPa yield strength.

2) What is the difference between C, Z, and Sigma purlin roll forming?

- C purlin: Symmetric section for interior supports and secondary framing.

- Z purlin: Overlapping capability for longer spans and improved continuity.

- Sigma: Higher torsional rigidity; used in high-load or seismic applications. Machines may be dedicated (C-only) or combo CZ with automatic punch and lip adjustments.

3) How fast do modern C Purlin machines run and how accurate are they?

In 2025, production speeds commonly reach 25–60 m/min with flying cutoff; cut-length tolerance ±0.5–1.0 mm and hole-position tolerance ±0.3–0.5 mm using servo feed and encoder/laser verification.

4) What options are essential for structural steel compliance?

Inline hydraulic or servo punching (web/lip holes, slots), material certification traceability (heat/coil IDs), automatic gauge/profile recipe control, and compliance with AISI S100/EN 1090 fabrication practices, plus CE/UL safety.

5) What maintenance plan maximizes uptime?

- Daily: Check roll cleanliness, coil edge burrs, hydraulic level, safety interlocks.

- Weekly: Inspect bearings and chain/sprocket alignment; verify encoder calibration.

- Quarterly: Check roll wear with profile gauges; re-level stands; update PLC backups; conduct oil analysis on hydraulics.

2025 Industry Trends for Roll Forming Machine For C Purlin

- Auto-size changeover becomes standard: Motorized roll gap, cassette tooling, and auto-punch templates reduce changeover to 6–12 minutes on CU/CZ combo lines.

- Higher-strength coils: Wider adoption of 500–600 MPa grades enables weight reduction of 8–15% while meeting span requirements.

- Connected QC: Inline cameras measure web width, lip height, and hole spacing; SPC dashboards track Cp/Cpk for key dimensions.

- Energy and safety upgrades: Regenerative VFDs, hydraulic-on-demand, and Cat 3/PL d safety circuits lower kWh/ton by 10–20% and improve compliance.

- Regionalization of supply: More buyers favor local or regional OEMs/integrators to reduce lead time, with typical delivery 8–16 weeks for standard C lines and 16–28 weeks for high-automation CZ lines.

2024–2025 Benchmarks and Buying Data

| KPI | 2024 Typical | 2025 Best-in-Class | Notes | Sources |

|---|---|---|---|---|

| Line speed (1.5–2.5 mm) | 20–40 m/min | 45–65 m/min | With servo flying cutoff | The Fabricator; OEM datasheets |

| Auto changeover time (C↔Z or size) | 18–35 min | 6–12 min | Motorized stands/cassettes | OEM catalogs (Bradbury, Samco) |

| Length tolerance (±) | 1.0–1.5 mm | 0.5–0.8 mm | Laser encoder feedback | Inline metrology vendors |

| Hole-position tolerance (±) | 0.7–1.0 mm | 0.3–0.5 mm | Servo punch + vision check | AISI best practices |

| Energy intensity (kWh/ton) | 110–150 | 90–115 | Regenerative drives | U.S. DOE AMO guidance |

| Installed price (USD) | $120k–$280k | $180k–$420k | C-only vs. auto CZ combo | 2025 RFQ ranges |

Authoritative references:

- AISI S100, cold-formed steel design: https://www.buildusingsteel.org

- ASTM A653/A792 coated steel: https://www.astm.org

- EN 1090 (execution of steel structures): https://standards.cen.eu

- U.S. DOE Advanced Manufacturing Office: https://www.energy.gov/eere/amo

- OPC Foundation (OPC UA for machinery): https://opcfoundation.org

- The Fabricator (roll forming insights): https://www.thefabricator.com

Latest Research Cases

Case Study 1: Auto-Size CU/CZ Line Cuts Changeover to 9 Minutes (2025)

Background: A mid-size steel building fabricator struggled with 25–40 minute changeovers between 150–300 mm C and Z purlins, causing missed delivery windows.

Solution: Implemented an auto-size changeable Roll Forming Machine for C Purlin with motorized stand adjustments, recipe-driven roll gaps, servo punching templates, and OPC UA data logging.

Results: Average changeover reduced to 9 minutes; OEE improved from 68% to 82%; hole-position Cpk rose from 1.1 to 1.7; annual throughput +18% without additional shifts.

Case Study 2: High-Strength Coil Adoption Reduces Weight 12% (2024)

Background: Designer sought to lower steel usage in light-gauge frames while meeting AISI S100 serviceability.

Solution: Switched from 350 MPa to 550 MPa coils on a C purlin roll forming line; updated punch program and roll gaps; validated with coupon tests and third-party inspection.

Results: Section thickness reduced from 2.0 mm to 1.7 mm on select SKUs; weight down 12%; cost/ton up 6% but net cost per linear meter down 7%; deflection and strength within spec.

Expert Opinions

- Michael Klukas, Executive VP, The Bradbury Group

Viewpoint: “For C and Z purlin producers, servo-controlled punching ahead of the mill with vision feedback is delivering the biggest scrap reduction per dollar invested.”

Company: https://www.bradburygroup.com - Jennifer Kinder, Director of Product Management, Samco Machinery

Viewpoint: “Standardizing RFQs with coil grade, gauge, speed, hole tolerances, and changeover method lets buyers compare Roll Forming Machine For C Purlin proposals fairly.”

Company: https://www.samco-machinery.com - Dr. Benjamin Schafer, Professor of Civil and Systems Engineering, Johns Hopkins University

Viewpoint: “Accurate lip and web geometry in C purlins directly influences lateral-torsional buckling capacity—tight process control pays back in structural performance.”

Profile: https://engineering.jhu.edu

Practical Tools/Resources

- Design and standards

- AISI S100 cold-formed steel design manual: https://www.buildusingsteel.org

- EN 1090 execution and CE marking overview: https://standards.cen.eu

- Process and quality

- NIST SPC/how-to for process capability: https://www.nist.gov/manufacturing

- DOE AMO motor/drive system efficiency tools: https://www.energy.gov/eere/amo

- Sourcing and benchmarking

- The Fabricator buyer’s guides and technical features: https://www.thefabricator.com

- Precision Metalforming Association directory: https://www.pma.org

- Representative OEMs: The Bradbury Group, Samco Machinery, Dallan, Formtek (review specs for Roll Forming Machine For C Purlin and CZ lines)

- Connectivity and data

- OPC UA Industrial Interoperability: https://opcfoundation.org

Last updated: 2025-10-22

Changelog: Added 5 FAQs; inserted 2025 trends with KPI table and sources; provided two recent case studies; compiled expert opinions with citations; listed practical tools/resources tailored to Roll Forming Machine For C Purlin buyers and operators

Next review date & triggers: 2026-04-22 or earlier if AISI/EN standards are revised, OEM catalogs change speed/price ±10%, or new case data shifts best-in-class KPIs by >10%