Three waves highway guardrail machine Features:

Three waves highway guardrail machines can produce different size of 3 waves guard rails which used for highway or other livestock farms.

Applications

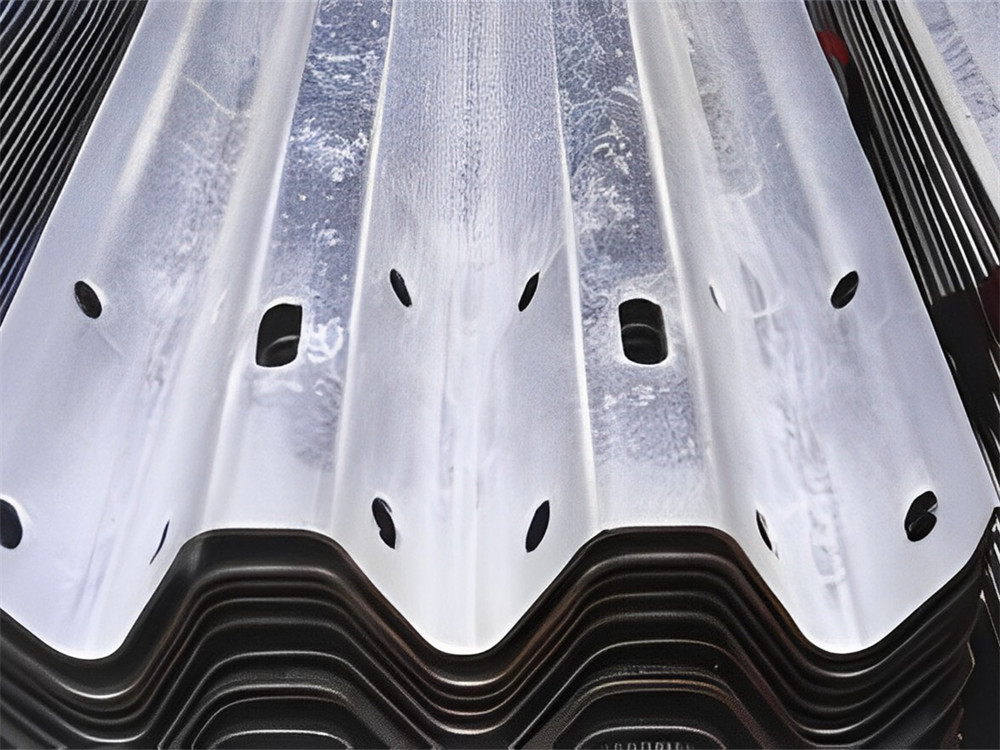

The finished products are used as a variety of guardrail, highway guardrail, fence and other livestock farms.

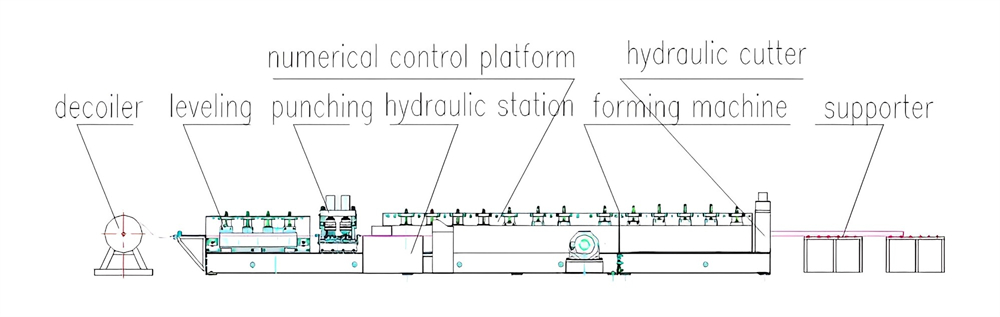

Process Flow

Uncoiler — feeding— leveling—punching—roll forming— cutting — output

Machine Configurations

| 1 | Uncoiler |

| 2 | Guide feeder |

| 3 | Leveling unit |

| 4 | Punching unit |

| 5 | Roll former |

| 6 |

Hydraulic cutting unit

|

| 7 |

PLC Control System

|

| 8 |

Hydraulic station

|

| 9 | Output table |

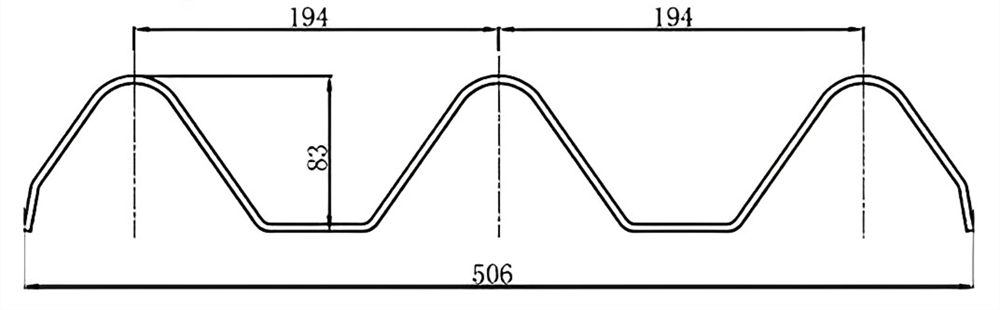

Profile Drawings

Photos for Reference

What is highway guardrail roll forming machine?

A highway guardrail roll forming machine is a specialized piece of equipment used in the manufacturing process of highway guardrails. Highway guardrails are installed along the sides of roads and highways to provide a barrier and prevent vehicles from leaving the roadway, reducing the risk of accidents and enhancing road safety.

The roll forming machine is designed to transform flat metal sheets into the desired shape and profile of highway guardrails. It typically consists of a series of rollers and tooling that gradually bends and forms the metal sheet into the required configuration. The machine can handle various types of metal, such as galvanized steel or stainless steel, which are commonly used for highway guardrail production.

The process starts with a coil of flat metal being fed into the roll forming machine. As the metal passes through the rollers, it undergoes a series of bending and shaping operations. The rollers have specific contours and designs that gradually shape the metal into the desired profile, which typically includes corrugations, flanges, and other structural features.

The highway guardrail roll forming machine is often automated and computer-controlled, ensuring precise and consistent production. It can also be equipped with cutting mechanisms to trim the formed guardrail sections to the required length.

Overall, the highway guardrail roll forming machine plays a crucial role in the efficient and cost-effective production of highway guardrails, enabling manufacturers to meet the demand for road safety infrastructure.

function of a highway guardrail forming machine

The function of a highway guardrail forming machine is to efficiently and accurately produce highway guardrails with the desired shape and specifications. Here are some key functions and features of a highway guardrail forming machine:

- Roll Forming: The machine uses a series of rollers and tooling to gradually bend and shape flat metal sheets into the desired profile of highway guardrails. It can create corrugations, flanges, and other structural features necessary for the guardrail design.

- Material Feeding: The machine is equipped with a material feeding system that accepts metal coils or sheets and feeds them into the roll forming process. This ensures a continuous and uninterrupted production flow.

- Precision and Consistency: Highway guardrail forming machines are designed to provide precise and consistent results. Computer-controlled automation ensures accurate measurements, angles, and dimensions, resulting in uniform guardrail sections.

- Speed and Efficiency: These machines are engineered to operate at high speeds, enabling efficient production rates. They can process a large volume of metal sheets within a relatively short time, enhancing productivity.

- Cutting Mechanisms: Some highway guardrail forming machines are equipped with cutting mechanisms that can trim the formed guardrail sections to the required length. This feature eliminates the need for manual cutting and improves overall production efficiency.

- Flexibility and Customization: The machines can be adjusted and configured to produce guardrails of different profiles, sizes, and specifications. This flexibility allows manufacturers to meet various project requirements and customer demands.

- Quality Control: Highway guardrails must meet specific quality standards and regulatory requirements. Guardrail forming machines incorporate quality control mechanisms to ensure the produced guardrails meet these standards, including dimensional accuracy, structural integrity, and surface finish.

Overall, the primary function of a highway guardrail forming machine is to streamline the manufacturing process, produce high-quality guardrails, and meet the demand for road safety infrastructure effectively.

TOP 5 highway guardrail roll forming machine manufacturers in China

- WUXI SUNWAY MACHINERY CO., LTD is a professional manufacturer and exporter that are concerned with the design, development and production of cold roll forming machines. All products comply with international quality standards and are greatly appreciated in a variety of different markets throughout the world, such as Asia, Africa, Europe, South America, and Australia and so on. It has gained a global sales network.

- Shanghai Metal Forming Machine Co., Ltd: Shanghai Metal Forming Machine is a leading manufacturer specializing in the design and production of roll forming machines. They offer a wide range of machinery, including highway guardrail roll forming machines, with a focus on quality and customer satisfaction.

- Jiangsu Guoqiang Zinc-Plating Industrial Co., Ltd: Guoqiang is a prominent manufacturer of highway guardrail systems, and they also produce highway guardrail roll forming machines. With years of experience in the industry, they provide reliable and efficient roll forming solutions.

- Cangzhou Zhongtuo International Trade Co., Ltd: Zhongtuo International Trade is a well-known supplier of roll forming machinery, including highway guardrail roll forming machines. They offer a comprehensive range of equipment and have a strong presence in the Chinese market.

- Tianjin Haixing Imp & Exp Co., Ltd: Haixing is a reputable manufacturer and exporter of roll forming machines, including highway guardrail roll forming machines. They have extensive experience in the industry and focus on delivering high-quality products to meet customer requirements.

About us

WUXI SUNWAY MACHINERY CO., LTD is a professional manufacturer and exporter that are concerned with the design, development and production of cold roll forming machines. All products comply with international quality standards and are greatly appreciated in a variety of different markets throughout the world, such as Asia, Africa, Europe, South America, and Australia and so on. It has gained a global sales network.

Our machines feature beautiful appearance, long service life, good performance, simple operation, reasonable price, good quality and so on. Strong technical resources are the most stable guarantee for our products’ quality. Our company is specialized in manufacturing different kinds of cold roll forming machines, such as color steel sheet forming machines for roof & wall, C and Z purling machines for steel structure, steel profiles forming machines for professional applications, slitting machines for processing raw material, especially in manufacturing Solar Mounting Bracket Machines which are widely used in Photovoltaic field.

Reviews

There are no reviews yet.