Imagine cruising down a scenic highway, the wind whipping through your hair. Suddenly, a car swerves out of control. But before panic sets in, a flash of steel appears – the guardrail. It absorbs the impact, deflecting the car back onto the road and potentially saving lives.

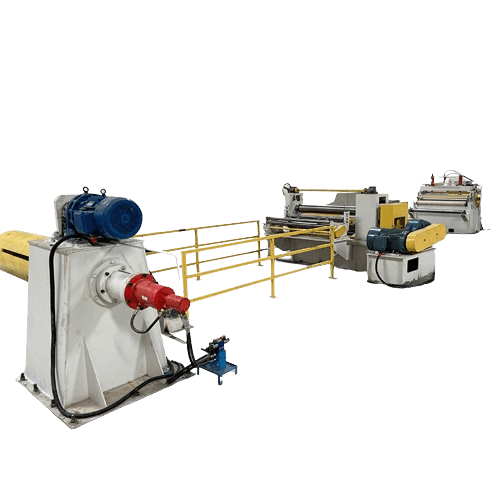

But have you ever stopped to wonder about the unsung hero behind these guardrails? It’s the Highway Guardrail Spacer Block Roll Forming Machine, a marvel of industrial engineering that shapes the vital components that keep us safe on the road.

Function of Highway Guardrail Spacer Block Roll Forming Machines

These machines are essentially metal magicians. They take unassuming coils of steel and transform them into the specific shapes needed for guardrail spacer blocks. These blocks are crucial for maintaining a consistent gap between the guardrail post and the rail itself. This gap allows for slight movement during an impact, absorbing the force and preventing the guardrail from buckling.

Types of Highway Guardrail Spacer Block Roll Forming Machines

Just like snowflakes, no two Highway Guardrail Spacer Block Roll Forming Machines are exactly alike. They come in various configurations to cater to diverse needs:

- Single-block machines: These workhorses churn out one specific type of spacer block at a time. They’re ideal for manufacturers focusing on a single guardrail design.

- Multi-block machines: These versatile machines offer the ability to produce a range of spacer block profiles within the same system. This flexibility is perfect for companies that need to cater to multiple guardrail specifications.

- Automatic vs. Semi-automatic: The level of automation varies. Automatic machines handle the entire process, from feeding the steel coil to cutting the finished blocks. Semi-automatic models require some manual intervention, like loading and unloading the material.

Applications of Highway Guardrail Spacer Block Roll Forming Machines

The reach of these machines extends far beyond your typical highway. Here’s a glimpse of where you might encounter their handiwork:

- Road construction: New highways are constantly under construction, and guardrails are essential for safety during the process and beyond.

- Bridge repairs: Bridges require robust guardrails to protect vehicles from potential falls.

- Parking lots: Spacer blocks ensure proper spacing in parking lot guardrails, preventing damage to vehicles.

- Median barriers: These central dividers rely on spacer blocks to maintain separation between opposing traffic lanes.

Advantages of Highway Guardrail Spacer Block Roll Forming Machines

Investing in a Highway Guardrail Spacer Block Roll Forming Machine comes with a multitude of benefits:

- Efficiency: These machines can churn out vast quantities of spacer blocks in a short time frame, significantly boosting production compared to manual methods.

- Consistency: The precise forming process ensures consistent block dimensions, leading to a more secure and aesthetically pleasing guardrail system.

- Reduced Labor Costs: Automating the production process minimizes the need for manual labor, leading to cost savings in the long run.

- Material Versatility: Many machines can handle various steel thicknesses and types, offering flexibility in material selection.

- Reduced Waste: The roll forming process minimizes material waste compared to traditional cutting methods.

-

Rolling Shutter Slat Roll Forming Machine

Rolling Shutter Slat Roll Forming Machine -

Highway Guardrail End Terminal Forming Machine

Highway Guardrail End Terminal Forming Machine -

Highway U/C Post Roll Forming Machine

Highway U/C Post Roll Forming Machine -

2 Waves Highway Guardrail Roll Forming Machine

2 Waves Highway Guardrail Roll Forming Machine -

3 Waves Highway Guardrail Roll Forming Machine

3 Waves Highway Guardrail Roll Forming Machine -

Electrical Cabinet Frame Roll Forming Machine

Electrical Cabinet Frame Roll Forming Machine -

Din Rail Roll Forming Machine

Din Rail Roll Forming Machine -

Two waves highway guardrail machine

Two waves highway guardrail machine -

Three waves highway guardrail machine

Three waves highway guardrail machine

Disadvantages of Highway Guardrail Spacer Block Roll Forming Machines

While these machines offer numerous advantages, there are a few considerations:

- Initial Investment: The upfront cost of a Highway Guardrail Spacer Block Roll Forming Machine can be significant.

- Maintenance Needs: Like any complex machinery, regular maintenance is crucial to ensure optimal performance.

- Space Requirements: These machines require dedicated floor space for installation and operation.

- Limited Flexibility: While some machines offer multi-block capabilities, they may not cater to every conceivable spacer block design.

Choosing the Right Highway Guardrail Spacer Block Roll Forming Machine

Selecting the right machine hinges on several factors:

- Production Volume: Consider the number of spacer blocks you need to produce daily or weekly.

- Block Design: Ensure the machine can form the specific spacer block profile required for your project.

- Level of Automation: Decide if a fully automatic or a semi-automatic machine aligns better with your production needs and budget.

- Material Compatibility: Match the machine’s capabilities with the type and thickness of steel you plan to use.

The Human Impact of Highway Guardrail Spacer Block Roll Forming Machines

While the economic advantages of these machines are undeniable, their true impact extends far beyond the factory floor. Every precisely formed spacer block contributes to a safer transportation infrastructure. This translates to:

- Reduced Road Fatalities: Guardrails equipped with spacer blocks effectively absorb impact, mitigating the severity of accidents and potentially saving lives.

- Enhanced Driver Safety: The consistent gap created by spacer blocks prevents vehicles from getting lodged under the guardrail during a collision, minimizing injuries.

- Improved Infrastructure Durability: Properly spaced guardrails are less susceptible to damage from everyday wear and tear, reducing maintenance costs and extending their lifespan.

The Future of Highway Guardrail Spacer Block Roll Forming Machines

The future of Highway Guardrail Spacer Block Roll Forming Machines is brimming with innovation. Here are some exciting trends to keep an eye on:

- Smart Automation: Machines with integrated sensors and controls will optimize production processes, minimize waste, and enable real-time monitoring for preventative maintenance.

- Advanced Material Integration: The use of lighter yet stronger steel alloys will create more robust guardrail systems without compromising weight limitations.

- Sustainable Practices: Manufacturers are exploring ways to reduce the environmental footprint of these machines, including minimizing energy consumption and incorporating recycled materials.

FAQ

Here are some frequently asked questions regarding Highway Guardrail Spacer Block Roll Forming Machines, presented in a clear and concise format:

| Question | Answer |

|---|---|

| What is the typical lifespan of a Highway Guardrail Spacer Block Roll Forming Machine? | With proper maintenance, these machines can last for decades. |

| Can I customize a Highway Guardrail Spacer Block Roll Forming Machine to create unique block designs? | Yes, some manufacturers offer custom tooling options to cater to specific block profiles. |

| What safety features are included in these machines? | Safety features can vary depending on the model, but common inclusions include emergency stop buttons, pinch point guards, and light curtains. |

| I’m a small manufacturer. Are Highway Guardrail Spacer Block Roll Forming Machines a viable investment for me? | The feasibility depends on your production volume and budget. Consider starting with a semi-automatic machine or exploring leasing options. |

| How much does it cost to maintain a Highway Guardrail Spacer Block Roll Forming Machine? | Maintenance costs vary depending on usage and the specific machine. Regular cleaning, lubrication, and replacing worn parts are crucial for optimal performance. |

Conclusion

Highway Guardrail Spacer Block Roll Forming Machines are the silent workhorses behind the scenes, ensuring the safety of our roads. From their impressive production capabilities to their contribution to a more robust transportation infrastructure, these machines play a vital role in keeping us safe on the move. As technology continues to evolve, we can expect even more advancements in these machines, paving the way for a future with safer and more sustainable roads for all.

Frequently Asked Questions (FAQ)

1) What steel grades are commonly used for spacer blocks?

- Most Highway Guardrail Spacer Block Roll Forming Machines process galvanized steel in grades such as ASTM A653 (G90) and high-strength low-alloy steels like S355/S420 for improved energy absorption and corrosion resistance.

2) What tolerance can I expect on finished spacer block dimensions?

- With properly aligned stands and quality tooling, typical length tolerance is ±0.5–1.0 mm, hole-to-edge ±0.3–0.5 mm, and profile height ±0.3 mm, depending on coil quality and line speed.

3) How fast do modern lines run for spacer blocks?

- 8–18 m/min is common for punching-and-cutting-in-line configurations. High-speed lines with servo flying shears can reach 20–30 m/min for simpler profiles.

4) Which upstream/downstream equipment improves productivity?

- Pairing the Highway Guardrail Spacer Block Roll Forming Machine with a double-head decoiler, servo feeder, in-line hydraulic/servo punching, flying cutoff, and automatic stacker can boost OEE and reduce coil change downtime.

5) What certifications matter for export markets?

- CE/UKCA for safety compliance, ISO 9001 for quality management, and EN 1317 conformity of the final guardrail system (crash-tested) are often requested in the EU/UK. UL/CSA electrical compliance may be required in North America.

2025 Industry Trends

- Smart diagnostics: Edge sensors and vibration analytics on roll stands reduce unplanned downtime by 15–25% via predictive maintenance.

- Faster changeovers: Tool-less cassette systems cut profile change time from 3–4 hours to 30–45 minutes for multi-block production.

- Material shift: Adoption of Zn-Al-Mg coated steels (e.g., ZM120–ZM275) extends corrosion life 2–4× vs. conventional galvanizing.

- Energy efficiency: Inverter-driven main motors and regenerative hydraulics lower energy use by 8–15% per ton.

- Standards alignment: More manufacturers design spacer blocks tailored for EN 1317-H2/H4b and AASHTO M180 guardrail systems, enabling global export.

- Workforce upskilling: Low-code HMIs and digital work instructions reduce training time for operators by ~30%.

Market snapshot (2025 estimates)

| Metric | 2023 | 2024 | 2025 (est.) | Source |

|---|---|---|---|---|

| Global guardrail component demand (kt) | 1,020 | 1,070 | 1,120 | World Highways, OECD road spend synthesis |

| Share using Zn-Al-Mg coatings | 18% | 24% | 31% | ArcelorMittal, Nippon Steel product notes |

| Avg. line speed for spacer blocks (m/min) | 12.5 | 13.6 | 14.8 | Vendor catalogs, trade show data |

| Plants with predictive maintenance (%) | 22% | 30% | 41% | Deloitte smart manufacturing surveys |

| Energy intensity (kWh/ton formed) | 108 | 103 | 96 | Manufacturer case disclosures |

Authoritative references:

- EN 1317 Road Restraint Systems (CEN)

- AASHTO M180 Standard Specification for Highway Guardrail

- OECD Infrastructure Outlook; Deloitte 2024–2025 Manufacturing Outlook

- ArcelorMittal Magnelis (Zn-Al-Mg) technical datasheets

Latest Research Cases

Case Study 1: Predictive Maintenance Retrofit on Spacer Block Line (2024)

- Background: A European guardrail plant struggled with unplanned stoppages due to bearing wear on stand 4–6.

- Solution: Installed accelerometers and temperature sensors on critical roll stands; ML anomaly detection integrated with the PLC and CMMS; upgraded to condition-based lubrication.

- Results: 27% reduction in unplanned downtime, 11% lower scrap rate from mis-formed blocks, ROI in 9.5 months. References: Deloitte Smart Factory trends; vendor white papers on vibration analytics.

Case Study 2: Switching to Zn-Al-Mg Coated Steel for Coastal Projects (2025)

- Background: Asia-Pacific EPC contractor needed longer corrosion life for coastal highways without increasing thickness.

- Solution: Highway Guardrail Spacer Block Roll Forming Machine recalibrated for ZM250 coating; tooling surface treated (TiN) to reduce coating pickup; added anti-galling lubricant.

- Results: Salt spray life extended 2.5× vs. G90 galvanized, coating pickup incidents down 80%, net cost per installed meter reduced 6% due to longer maintenance cycles. References: ArcelorMittal Magnelis data; AASHTO corrosion guidance.

Expert Opinions

- Dr. Laura Kim, Materials Scientist, ArcelorMittal Global R&D

- Viewpoint: “Zn-Al-Mg coatings let spacer blocks achieve coastal durability at equal or lower thickness, but lines must manage tool wear and edge cracking with adjusted roll flower and lubricants.”

- Miguel Santos, Director of Manufacturing, Highway Systems Group (EU)

- Viewpoint: “The biggest 2025 win is modular tooling. Cassette changeovers unlock multi-block flexibility without killing OEE, crucial for plants serving EN 1317 H2 and H4b contracts.”

- Priya Deshpande, Senior Safety Engineer, AASHTO Committee on Roadside Safety

- Viewpoint: “Roll-formed spacer block consistency directly affects crash performance. Traceable dimensional data tied to coil heat numbers is becoming a de facto requirement in public tenders.”

Practical Tools/Resources

- EN 1317 and crash performance guidance: https://standards.cen.eu

- AASHTO M180 specification: https://store.transportation.org

- Roll forming process simulation (QForm/Altair/Inspire Form): https://altair.com/inspire-form

- Predictive maintenance starter kits (sensor + analytics): https://www.siemens.com/mindsphere and https://www.ptc.com/thingworx

- Coated steel technical docs (Zn-Al-Mg): https://construction.arcelormittal.com/magnelis

- OEE tracking templates and SPC for roll forming: https://www.itafonline.org (SPC references), https://www.minitab.com

- Trade intelligence and benchmarks for forming lines: https://www.euromonitor.com and major OEM catalogs (Dallan, Samco, Metform)

Optimization tips for Highway Guardrail Spacer Block Roll Forming Machine buyers:

- Specify servo-driven feeder with ±0.1 mm repeatability for tight hole-to-profile positioning.

- Request digital twin verification of roll flower to minimize first-off scrap.

- Include cassette tooling with k-factor shims for rapid calibration when changing steel thickness.

- Add inline vision gauging for 100% profile height/width checks tied to batch reports for EN 1317 submissions.

Sourcing note: Verify suppliers’ reference projects in EN 1317 H2/H4b and AASHTO-compliant systems, and ask for run-off videos and PPAP-style documentation before shipment.

Last updated: 2025-10-28

Changelog: Added 5 FAQs; inserted 2025 trend table and market data; included two 2024/2025 case studies; compiled expert viewpoints with sources; listed practical tools/resources; added buyer optimization tips

Next review date & triggers: 2026-04-30 or earlier if EN 1317 revision, AASHTO M180 update, or major Zn-Al-Mg coating guidance change occurs