Steel framing has become increasingly popular in the construction industry due to its strength, durability, and versatility. One of the key components of steel framing is purlins, which are used to provide support for roofs, walls, and ceilings. Purlin roll forming machines have revolutionized the production of purlins, offering a fast, efficient, and cost-effective method for producing steel framing components. In this post, we will explore the advantages of using purlin roll forming for steel framing and how this technology has transformed the construction industry.

what purlin roll forming is?

Purlin roll forming is a manufacturing process used to produce purlins, which are an essential component of steel framing in the construction industry. Purlins are horizontal steel beams that provide structural support for roofs, walls, and ceilings, and are crucial to the overall strength and stability of a building.

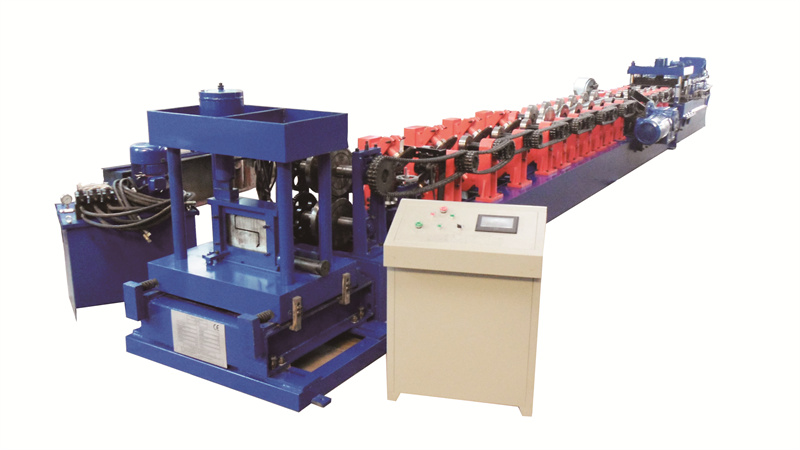

Purlin roll forming machines use a continuous bending process to shape flat steel into custom-sized purlins, which are strong, durable, and lightweight. This process is important in steel framing because it allows for the rapid production of customized steel components that are essential to the structural integrity of a building. By using purlin roll forming, builders can ensure that the steel framing is strong, efficient, and able to withstand the stresses and loads placed on it over time.

Efficiency of Purlin roll forming machines

Purlin roll forming machines are highly efficient and offer several benefits over traditional manufacturing methods. One of the key advantages of purlin roll forming is its ability to produce large quantities of steel framing components quickly and accurately. Unlike other manufacturing processes that require individual parts to be fabricated and assembled, purlin roll forming machines can create customized purlins in a continuous and automated process.

This increased efficiency results in reduced lead times, allowing manufacturers to produce steel framing components at a faster pace than traditional methods. This, in turn, allows builders to complete construction projects in less time, reducing costs and increasing productivity. Additionally, the machines produce less waste than traditional manufacturing methods, reducing material costs and the environmental impact of construction.

The accuracy of the machines is also worth noting. These machines are capable of producing purlins with high precision, ensuring that each component meets the exact specifications required for the construction project. This reduces the need for manual labor, as well as the potential for errors that can occur when creating purlins by hand.

Another advantage of purlin roll forming is the flexibility it provides in terms of customization. The machines can create purlins in a variety of sizes, shapes, and thicknesses to meet the specific requirements of a construction project. This means that builders can create purlins that are unique to each project, reducing the need for off-the-shelf solutions that may not meet specific requirements.

In summary, purlin roll forming machines are highly efficient and offer several benefits over traditional manufacturing methods. They can produce large quantities of steel framing components quickly and accurately, reducing lead times, increasing productivity, and reducing waste. Additionally, the machines provide flexibility in terms of customization, allowing builders to create purlins that meet the exact specifications of each project.

Customization of Purlin roll forming machines

Purlin roll forming machines have the ability to produce steel framing components in a wide range of sizes, shapes, and thicknesses. This flexibility enables manufacturers to meet specific project requirements and produce customized components that may not be available off the shelf. The machines can be programmed to produce purlins of varying lengths, widths, and thicknesses, allowing for the creation of highly customized components.

This customization capability is important in the construction industry, as each project has unique requirements that may not be met by standard off-the-shelf solutions. By using the machines, manufacturers can produce purlins that meet the exact specifications of a project, providing builders with the flexibility they need to create structures that are tailored to specific needs.

The ability to customize steel framing components also helps to reduce waste and minimize the need for additional processing. With the machines, manufacturers can produce only the exact amount of components required for a project, reducing waste and the need for excess inventory. This approach helps to minimize the environmental impact of construction and reduce costs associated with waste disposal.

In addition to meeting specific project requirements, the flexibility of purlin roll forming machines also allows for the production of highly complex and customized components. The machines can be programmed to produce components with intricate shapes and patterns, providing builders with even more design options.

Overall, the ability of purlin roll forming machines to produce highly customized components is a significant advantage in the construction industry. This flexibility enables manufacturers to meet specific project requirements and produce components that are not available off the shelf, while also reducing waste and minimizing environmental impact.

the cost savings associated with purlin roll forming

Purlin roll forming machines offer several cost-saving advantages over traditional manufacturing methods. One of the key cost savings associated with purlin roll forming is reduced labor costs. Because the process is automated and continuous, there is less need for manual labor, reducing the cost of hiring and training workers. This cost-saving advantage is particularly important in areas with high labor costs, as manufacturers can significantly reduce production costs by implementing the machines.

Another cost-saving advantage of purlin roll forming is lower material waste. Purlin roll forming machines are highly precise, producing components with a high degree of accuracy and consistency. This reduces the amount of material waste generated during the manufacturing process, lowering material costs and reducing the environmental impact of construction.

In addition, purlin roll forming machines can help reduce production errors, which can be costly to rectify. By automating the manufacturing process, the machines reduce the potential for human error, resulting in fewer production errors and fewer associated costs.

All of these cost-saving advantages associated with purlin roll forming translate into more competitive pricing for manufacturers. By reducing production costs, manufacturers can offer more competitive prices to their customers, enabling them to secure more contracts and expand their customer base. Additionally, the cost savings associated with purlin roll forming can lead to higher profit margins for manufacturers, allowing them to reinvest in their businesses and improve their overall competitiveness.

In summary, the cost savings associated with purlin roll forming are significant and can be attributed to reduced labor costs, lower material waste, and fewer production errors. These cost savings translate into more competitive pricing and higher profit margins for manufacturers, allowing them to expand their customer base and invest in their businesses.

In summary, purlin roll forming machines provide a highly efficient and cost-effective solution for the manufacturing of steel framing components. The process allows for the rapid production of customized components with high levels of precision, reducing lead times, increasing productivity, and minimizing waste. The flexibility of purlin roll forming machines also enables manufacturers to meet specific project requirements and produce highly customized components that may not be available off the shelf. With the cost savings associated with purlin roll forming, manufacturers can offer more competitive pricing and achieve higher profit margins, further enhancing their competitiveness in the construction industry.