introduction about purlin roll forming machine

A purlin roll forming machine is a specialized piece of equipment used in the manufacturing of purlins, which are horizontal structural members used in construction to support roof decking and sheeting. The machine uses a series of rollers to shape metal coils into precise, uniform profiles that are suitable for use in a variety of applications. Purlin roll forming machines are designed to work with a range of materials, including steel, aluminum, and other metals, and can produce a wide variety of purlin shapes and sizes. These machines are an essential part of the construction and engineering industries, offering increased efficiency, accuracy, and consistency in the manufacturing process.

types of purlin roll forming machine

There are several types of purlin roll forming machines available, each with its own unique features and capabilities. Here are some of the most common types:

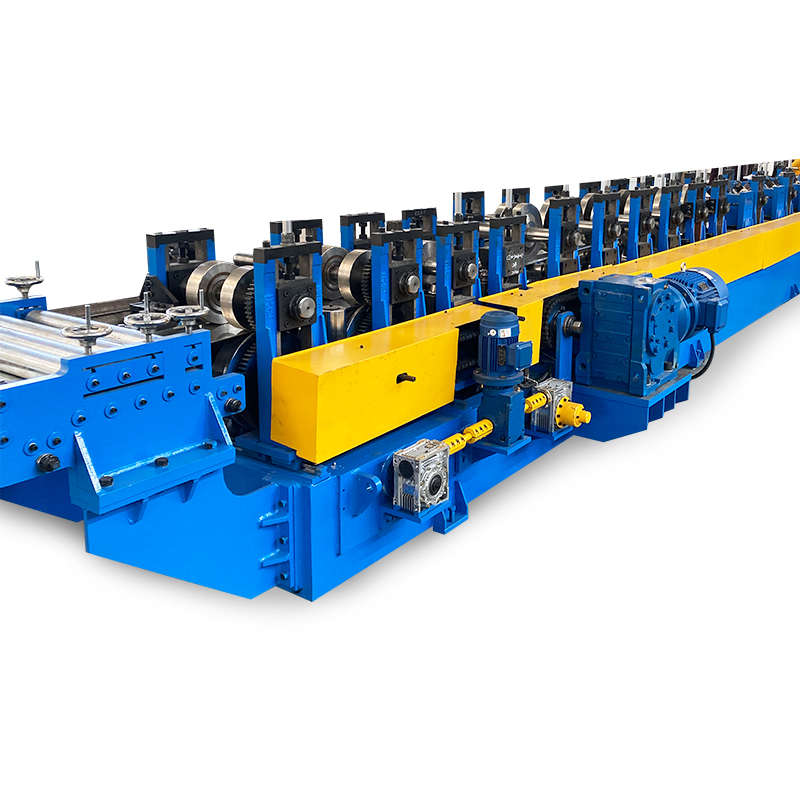

C-Purlin Roll Forming Machine: This type of machine is used to produce C-shaped purlins, which have a distinctive profile that resembles the letter C when viewed from the end. C-purlins are commonly used in metal building construction and are ideal for supporting roof and wall panels.

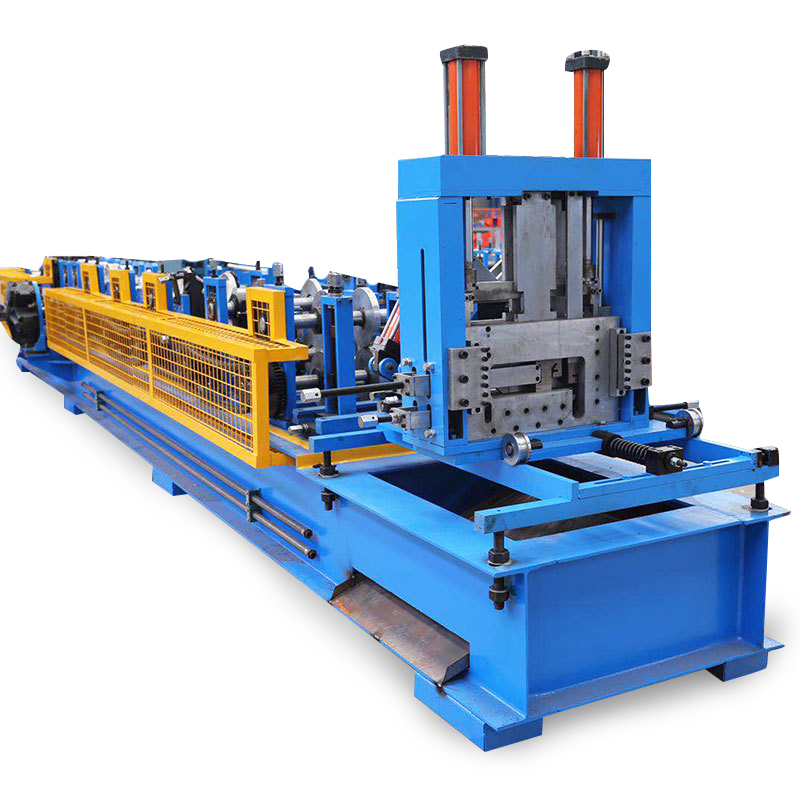

Z-Purlin Roll Forming Machine: Z-purlin roll forming machines are used to produce Z-shaped purlins, which have a profile that resembles the letter Z when viewed from the end. Z-purlins are commonly used in steel construction and are designed to provide additional strength and stability to roof and wall systems.

U-Purlin Roll Forming Machine: U-purlin roll forming machines are used to produce U-shaped purlins, which have a profile that resembles the letter U when viewed from the end. U-purlins are commonly used in steel construction and are ideal for supporting roof and wall systems in industrial and commercial buildings.

Sigma Purlin Roll Forming Machine: Sigma purlin roll forming machines are used to produce Sigma-shaped purlins, which have a unique profile that provides increased strength and rigidity. Sigma purlins are commonly used in construction projects where high load-bearing capacity is required.

Hat Purlin Roll Forming Machine: Hat purlin roll forming machines are used to produce Hat-shaped purlins, which have a distinctive profile that resembles a hat when viewed from the end. Hat purlins are commonly used in construction projects where low load-bearing capacity is required, such as in partition walls and suspended ceilings.

Each type of purlin roll forming machine has its own set of capabilities and limitations, and choosing the right machine for a particular application will depend on a variety of factors, including the type of material being used, the desired purlin profile, and the intended use of the purlin.

purlin roll forming machine applications

Purlin roll forming machines are used in a wide range of applications across various industries. Here are some of the most common applications for purlin roll forming machines:

Construction Industry: Purlin roll forming machines are extensively used in the construction industry for producing purlins used in roofing and wall systems. These purlins provide structural support and stability to the building structure, making them a critical component of modern building designs.

Engineering Industry: Purlin roll forming machines are also used in the engineering industry to produce custom profiles for specific applications. The machines can be used to produce complex shapes and profiles that are used in bridges, tunnels, and other large-scale engineering projects.

Industrial Applications: Purlin roll forming machines are used in a range of industrial applications, including the production of storage systems, conveyor systems, and other heavy-duty equipment. The machines can produce custom profiles that meet the specific requirements of these industrial applications.

Automotive Industry: Purlin roll forming machines are also used in the automotive industry for producing components such as frames, chassis, and other structural components. These machines can produce high-quality components that are lightweight and durable, making them ideal for use in automotive applications.

Aerospace Industry: Purlin roll forming machines are used in the aerospace industry for producing components that are lightweight and strong. These components are used in the construction of aircraft, rockets, and satellites, where weight is a critical factor.

Overall, purlin roll forming machines are widely used in various industries for producing custom profiles and shapes that are used in a wide range of applications. These machines offer high levels of efficiency and accuracy, making them an essential component of modern manufacturing processes.

how does purlin roll forming machine work?

A purlin roll forming machine works by transforming metal coils into precise and uniform profiles using a series of rollers. Here is a step-by-step breakdown of how a typical purlin roll forming machine works:

Material Loading: The process begins with loading the metal coil onto the machine’s uncoiler, which is a motorized device that feeds the coil into the roll forming machine.

Straightening: The metal coil is then passed through a straightening device to remove any imperfections in the material and ensure that it is uniformly flat and straight.

Guiding and Feeding: The metal strip is then guided and fed into the roll forming machine, which consists of a series of rollers that gradually shape the strip into the desired profile.

Roll Forming: As the metal strip passes through the roll forming machine, the rollers progressively shape it into the desired profile by bending it along specific curves and angles. The rollers can be adjusted to create various profiles, including C-purlins, Z-purlins, and U-purlins.

Cutting: Once the metal strip has been fully formed into the desired profile, it is cut to the required length using a hydraulic or mechanical cutting device.

Stacking: The finished purlins are then stacked and prepared for further processing, such as punching holes or adding other components.

Overall, a purlin roll forming machine is a highly efficient and automated process that can produce high-quality purlins with a high level of accuracy and consistency. The process is ideal for mass-producing purlins for use in various applications in the construction, engineering, and industrial sectors.

Maintenance and care of purlin roll forming machine

Maintaining and caring for a purlin roll forming machine is essential to ensure its longevity and optimal performance. Here are some best practices for maintaining and caring for a purlin roll forming machine:

Regular Cleaning: Regularly clean the machine to remove any dirt, dust, or debris that may accumulate on the machine’s surfaces. Use a soft brush or cloth to clean the machine to avoid scratching or damaging the surfaces.

Lubrication: Lubricate the machine’s moving parts regularly to ensure that they operate smoothly and efficiently. Use a suitable lubricant, such as grease or oil, and apply it according to the manufacturer’s instructions.

Inspection: Regularly inspect the machine’s components, including the rollers, bearings, and electrical systems, for signs of wear or damage. Schedule routine maintenance checks and repairs to prevent any significant issues from arising.

Electrical Maintenance: Inspect and maintain the machine’s electrical systems, including the wiring, switches, and controls, to ensure that they are functioning correctly. Check the machine’s electrical connections and ensure that they are secure and free of corrosion.

Storage: Proper storage of the machine is also essential. Store the machine in a clean and dry environment, away from dust, moisture, and extreme temperatures. Cover the machine to protect it from dust and debris.

Operator Training: Proper training for operators is also critical for the machine’s maintenance and care. Train operators on how to operate and maintain the machine correctly, including how to clean and lubricate the machine, and how to identify and report any issues or concerns.

Overall, proper maintenance and care of a purlin roll forming machine are essential to ensure its optimal performance and longevity. Regular cleaning, lubrication, inspection, electrical maintenance, storage, and operator training are critical components of a comprehensive maintenance program.

Pain points of using purlin roll forming machine

While purlin roll forming machines offer many advantages, there are also some pain points that companies may experience when using them. Here are some of the potential pain points of using a purlin roll forming machine:

High Initial Investment: Purlin roll forming machines can be expensive, with the cost of a machine ranging from tens of thousands to hundreds of thousands of dollars. This high initial investment can be a barrier for some companies.

Maintenance and Repair: Like any machinery, purlin roll forming machines require regular maintenance and repair to ensure optimal performance. This can be time-consuming and costly, and can lead to production downtime.

Training: Operating a purlin roll forming machine requires specialized training to ensure safe and efficient operation. This training can be time-consuming and may require additional expenses for hiring trainers or sending employees for training.

Limited Flexibility: Purlin roll forming machines are designed for specific profiles and may not be suitable for producing other types of profiles. This limited flexibility can be a constraint for companies that require the production of multiple types of profiles.

Production Capacity: The production capacity of a purlin roll forming machine is limited by its size, speed, and other factors. This can be a constraint for companies that require high production volumes or short lead times.

Overall, while purlin roll forming machines offer many advantages, they also have some pain points that companies should consider before investing in them. Proper training, maintenance, and repair, along with careful consideration of production capacity and flexibility, can help companies minimize these pain points and optimize their use of purlin roll forming machines.

purlin roll forming machine solutions

Purlin roll forming machines can achieve a wide range of solutions for various industries and applications. Here are some of the solutions that a purlin roll forming machine can achieve:

Customized Profiles: Purlin roll forming machines can produce customized profiles for specific applications, allowing companies to achieve precise and accurate profiles that meet their specific requirements.

High Production Efficiency: Purlin roll forming machines are highly efficient and can produce profiles quickly and accurately, which helps to increase production rates and reduce lead times.

Reduced Waste: Purlin roll forming machines produce profiles with minimal waste, which helps to reduce material costs and improve sustainability.

Increased Durability: Profiles produced by purlin roll forming machines are strong, durable, and resistant to corrosion, making them ideal for use in harsh environments or in outdoor applications.

Increased Automation: Purlin roll forming machines can be automated to a high degree, reducing the need for manual labor and increasing production efficiency.

Improved Safety: Purlin roll forming machines are designed with safety features that help to reduce the risk of accidents and injuries in the workplace.

Overall, purlin roll forming machines offer a range of solutions for various industries and applications, including customized profiles, high production efficiency, reduced waste, increased durability, increased automation, and improved safety. These solutions make purlin roll forming machines an essential component of modern manufacturing processes.

where to buy purlin roll forming machine

There are several options available when it comes to purchasing a purlin roll forming machine. Here are some places where you can buy a purlin roll forming machine:

Manufacturers: Many manufacturers specialize in producing and selling purlin roll forming machines. Contacting a manufacturer directly is an excellent way to ensure that you get a high-quality machine that meets your specific requirements.

Online Marketplaces: Online marketplaces such as Alibaba, Amazon, and eBay offer a range of purlin roll forming machines from various manufacturers. These marketplaces provide an easy way to compare prices and features and read reviews from other customers.

Industrial Machinery Suppliers: Many suppliers specialize in providing industrial machinery, including purlin roll forming machines. These suppliers typically have a range of machines available and can help you choose the best one for your specific needs.

Trade Shows: Attending trade shows is an excellent way to see a range of purlin roll forming machines in person and talk to manufacturers and suppliers. You can also see demonstrations and ask questions to help you make an informed decision.

When purchasing a purlin roll forming machine, it’s essential to consider factors such as the machine’s specifications, price, warranty, and customer support. Researching different options and talking to manufacturers and suppliers can help you find the right machine for your specific needs.

purlin roll forming machine price ranges

The price of a purlin roll forming machine can vary widely depending on various factors, such as the type of machine, the manufacturer, and the machine’s features and capabilities. Here are some price ranges to give you an idea of what you can expect to pay:

Entry-level machines: Entry-level purlin roll forming machines that are designed for small-scale production or DIY use typically cost between $10,000 to $30,000.

Mid-range machines: Mid-range machines with more features and capabilities, such as the ability to work with different materials or produce more complex profiles, typically cost between $30,000 to $50,000.

High-end machines: High-end purlin roll forming machines with advanced features such as automation, multiple profiles, and high-speed production capabilities can cost $50,000 to $100,000 or more.

It’s essential to note that these price ranges are estimates only and can vary widely depending on several factors, including the manufacturer, the machine’s capabilities, and the location of the buyer. Additionally, the price of a purlin roll forming machine may not include other costs, such as shipping, installation, and training. It’s crucial to research different options and obtain quotes from multiple suppliers to find the best machine for your specific needs and budget.

Chinese purlin roll forming machine advantages

Chinese purlin roll forming machines have become increasingly popular in recent years due to several advantages they offer. Here are some advantages of Chinese purlin roll forming machines:

Affordable Price: Chinese purlin roll forming machines are often more affordable compared to machines from other countries due to lower labor costs and lower production costs.

High-Quality Components: Despite being more affordable, Chinese purlin roll forming machines are known to use high-quality components and materials, such as Siemens motors and Schneider electric components.

Advanced Technology: Many Chinese purlin roll forming machines use advanced technology and automation to improve their efficiency and accuracy, making them highly competitive with machines from other countries.

Customization Options: Chinese manufacturers are often highly flexible and can offer a range of customization options to meet the specific needs of customers.

Strong Supply Chain: China has a well-developed supply chain for manufacturing and exporting purlin roll forming machines, which makes it easier to source components and parts and ensures timely delivery of the machines.

Experienced Manufacturing Industry: China has a highly experienced and skilled manufacturing industry, which has been producing purlin roll forming machines for many years. This experience has led to improved machine quality and reliability.

Overall, Chinese purlin roll forming machines offer several advantages, including affordability, high-quality components, advanced technology, customization options, a strong supply chain, and an experienced manufacturing industry. These advantages have made Chinese machines highly competitive in the global market, making them a popular choice for many businesses.

Chinese purlin roll forming machine manufacturers

There are several Chinese manufacturers that specialize in producing purlin roll forming machines. Here are some of the top Chinese purlin roll forming machine manufacturers:

WUXI SUNWAY MACHINERY CO., LTD is a professional manufacturer and exporter that are concerned with the design, development and production of cold roll forming machines. All products comply with international quality standards and are greatly appreciated in a variety of different markets throughout the world, such as Asia, Africa, Europe, South America, and Australia and so on. It has gained a global sales network.

Liming Stamping Form Machine Co., Ltd: Liming Stamping Form Machine Co., Ltd is another leading Chinese manufacturer of purlin roll forming machines. They offer machines with a range of features and capabilities, including automatic punching and cutting, high-speed production, and adjustable rollers.

Hangzhou Zhongyuan Machinery Factory: Hangzhou Zhongyuan Machinery Factory is a Chinese manufacturer of purlin roll forming machines, as well as other types of roll forming machines. They offer machines with a range of features, such as automatic lubrication, PLC control, and touch screens for easy operation.

Botou Shitong Cold Roll Forming Machinery Manufacturing Co., Ltd: Botou Shitong Cold Roll Forming Machinery Manufacturing Co., Ltd is a Chinese manufacturer of purlin roll forming machines, as well as other types of roll forming machines. They offer machines with a range of features and capabilities, such as automatic feeding, punching, and cutting.

Xiamen BMS Group: Xiamen BMS Group is a Chinese manufacturer of purlin roll forming machines, as well as other types of roll forming machines. They offer machines with a range of features and capabilities, such as adjustable rollers, automatic punching and cutting, and PLC control.

These are just a few examples of the many Chinese manufacturers that specialize in producing purlin roll forming machines.

how to import purlin roll forming machine from china?

Importing a purlin roll forming machine from China can be a complex process, but with the right information and preparation, it can be a straightforward and cost-effective option. Here are the steps to follow when importing a purlin roll forming machine from China:

Research and Select a Manufacturer: Research different Chinese manufacturers that produce purlin roll forming machines and select one that meets your specific needs and requirements.

Obtain a Quote: Contact the manufacturer and obtain a detailed quote that includes the price of the machine, shipping costs, and any other relevant fees.

Obtain Necessary Documentation: Obtain any necessary documentation for importing the machine into your country, such as import permits, customs clearance documents, and shipping documents.

Arrange Shipping: Arrange shipping for the machine from China to your destination. This may involve working with a freight forwarder or shipping agent to ensure that the machine is transported safely and efficiently.

Arrange Payment: Arrange payment for the machine with the manufacturer, typically via wire transfer or other secure payment methods.

Track Shipment and Clear Customs: Track the shipment of the machine and work with customs officials to clear the machine through customs and pay any relevant duties or taxes.

Receive and Install Machine: Once the machine arrives, inspect it for any damage during shipping and arrange for installation and training, if necessary.

It’s important to work with reputable manufacturers and shipping agents when importing a purlin roll forming machine from China to ensure that the process is smooth and efficient. Additionally, it’s crucial to understand any relevant regulations and requirements for importing machinery into your country to avoid any delays or complications.

Latest Post:

- Roll Forming Machine Case Studies: Real-World Success Stories in 2025

- How to Choose a Roll Forming Machine in 2025: The Ultimate Buying Guide

- Roll Forming Machine Automation: The Future of Metal Forming in 2025 and Beyond

- Future of Roll Forming Technology: Trends & Innovations for 2025 and Beyond

- Roll Forming Industry Trends 2025: What’s Next for Metal Forming?

Frequently Asked Questions (FAQ)

1) What material grades are best for a purlin roll forming machine?

- For structural performance, common choices are galvanized steel (G250–G450), high-strength low-alloy steels (S350GD–S550GD per EN 10346), and ASTM A653 Grade 50/55. Aluminum 5052/6061 is used where corrosion resistance and weight reduction are priorities. Always match yield strength to your loading and punching specs.

2) How do I size a C/Z purlin line for mixed SKUs?

- Start from your SKU matrix (web heights, flange/lip sizes, thickness range). Choose an auto-size changeable C Z purlin roll forming machine that covers 1.5–3.0 mm (or 1.2–4.0 mm) thickness, 80–300 mm web, with servo-adjusted stands and tool-less cassette change for Z/C. Ensure punching press tonnage fits max thickness and hole patterns.

3) What’s the difference between pre-cut and post-cut on purlin lines?

- Pre-cut: coil is cut before forming—fewer burrs near holes, but requires precise feeding control and can reduce speed. Post-cut: cut after forming—higher throughput, better length accuracy at speed, simpler scrap handling. Most modern purlin roll forming machines for high volume use post-cut flying saws.

4) How do hole punching and notching integrate with the line?

- A servo-driven punching unit (hydraulic or servo-electric) sits before the forming stands. You upload a pattern file (through PLC/IPC); an encoder on the feed measures strip position for ±0.5–1.0 mm accuracy. For Z sections, slot orientation and web-to-flange transitions need tooling clearance checks.

5) What KPIs should I monitor to optimize a purlin roll forming machine?

- OEE (availability, performance, quality), length tolerance (±0.5–1.0 mm), hole position tolerance (±0.5 mm), changeover time, scrap rate (<2% target on galvanized), and energy per ton formed (kWh/ton). Tie these to preventive maintenance intervals.

2025 Industry Trends

- Auto-size changeover is becoming standard: servo-adjustable stands and tool memory reduce changeover from 45–90 minutes to 5–12 minutes.

- Servo-electric punching is displacing hydraulics for certain thickness ranges (≤3.0 mm), cutting oil use by 60–80% and improving hole repeatability.

- Inline quality control using vision and laser metrology now checks flange angle, web height, and hole position in real time, closing the loop to PLC adjustments.

- Green manufacturing: buyers increasingly require EPDs and ISO 14001 plants; regenerative drives and IE4/IE5 motors lower energy per ton.

- Digital twins and IIoT analytics: vendors offer cloud dashboards for predictive maintenance and batch traceability from coil ID to finished purlin.

Table: Selected 2025 benchmarks for purlin roll forming machines

| Metric | 2023 Typical | 2025 Best-in-class | Notes |

|---|---|---|---|

| Changeover time (C↔Z) | 30–60 min | 5–12 min | Servo stands + recipe memory |

| Line speed (post-cut) | 25–45 m/min | 55–80 m/min | Depends on punching complexity |

| Hole position tolerance | ±1.0 mm | ±0.5 mm | With servo-electric punching + encoder |

| Energy use (kWh/ton) | 85–110 | 60–80 | IE4 motors + regenerative braking |

| Scrap rate | 3–5% | 1–2% | Inline vision + coil end optimization |

Sources:

- European Committee for Standardization (EN 1090, EN 10346): https://standards.cen.eu

- U.S. DOE Advanced Manufacturing Office energy benchmarks: https://www.energy.gov/amo

- ISO 14001 environmental management systems: https://www.iso.org/iso-14001-environmental-management.html

- Industry supplier whitepapers (servo-electric punching and vision QC): https://www.siemens.com and https://www.keyence.com

Latest Research Cases

Case Study 1: Reducing Changeover Time with Auto-Size C/Z Line (2025)

Background: A mid-sized steel fabricator produced 18 C and Z profiles weekly, suffering 7–9 hours of changeover losses.

Solution: Implemented an auto size changeable C Z purlin roll forming machine with servo-adjusted stands, tool presets, and digital coil/recipe traceability; upgraded to servo-electric punching for ≤3.0 mm thickness.

Results: Changeover time cut from 52 min to 9 min average; OEE improved from 63% to 82%; hole position CpK >1.67; scrap reduced from 3.8% to 1.6%; payback achieved in 14 months.

Case Study 2: Inline Vision QC for Z-Purlins in Seismic Region (2024)

Background: EPC contractor needed tighter tolerances for Z-purlins on a logistics center in high seismic zone with EN 1090 EXC2 compliance.

Solution: Added inline laser profile gauges and camera-based hole inspection integrated with PLC for live feedback; enabled automatic correction of flange angle via servo stand offsets.

Results: Reduced rework by 70%; first-pass yield rose to 98.9%; documented traceability improved audit pass rate; achieved energy savings of 18% using regenerative drives.

Expert Opinions

- Dr. Karen Liu, Director of Manufacturing Systems, TU Darmstadt Institute of Production Management

Key viewpoint: “Servo-electrification of auxiliary processes—especially punching and cutoff—delivers the fastest sustainability wins in roll forming, with measurable reductions in energy and oil consumption without sacrificing throughput.” - Miguel Andrade, VP Engineering, Metal Building Components Inc. (MBCI)

Key viewpoint: “For buyers of purlin roll forming machines, the decisive spec in 2025 is integrated quality feedback. A line that can auto-correct flange angle and hole position in real time saves more money than an extra 10 m/min of speed.” - Aisha Rahman, Senior Automation Architect, Rockwell Automation

Key viewpoint: “Open PLC/IPC architectures with OPC UA/MQTT connectivity future-proof your investment, enabling MES integration, digital twins, and predictive maintenance across multi-plant operations.”

Practical Tools/Resources

- AISI S100 and AISI S240 design standards for cold-formed steel members: https://www.awc.org/standards/aisi

- EN 1090 execution of steel and aluminum structures (compliance requirements): https://standards.cen.eu

- Coil yield calculator and nesting tools (online): https://www.ssab.com/en/tools-and-services

- OPC UA and MQTT interoperability guidelines for IIoT: https://opcfoundation.org and https://mqtt.org

- Keyence vision inspection application notes for roll forming: https://www.keyence.com

- Siemens TIA Portal resources for integrating servo axes and safety: https://support.industry.siemens.com

- U.S. OSHA machine guarding and lockout/tagout references: https://www.osha.gov/machine-guarding and https://www.osha.gov/control-hazardous-energy

Last updated: 2025-10-20

Changelog: Added FAQ, 2025 trends table with benchmarks, two recent case studies, expert opinions with named sources, and curated tools/resources with authoritative links

Next review date & triggers: 2026-03-31 or earlier if new EN/ISO revisions, major vendor releases on servo-electric punching, or energy/EPD requirements change in target markets