There’s a new corrugated roll forming machine on the market that can save you time and money. This machine is perfect for producing smaller quantities of corrugated products, such as boxes and bags. In this article, we’ll show you 5 ways to use this machine to your advantage.

What is a Corrugated Roll Forming Machine?

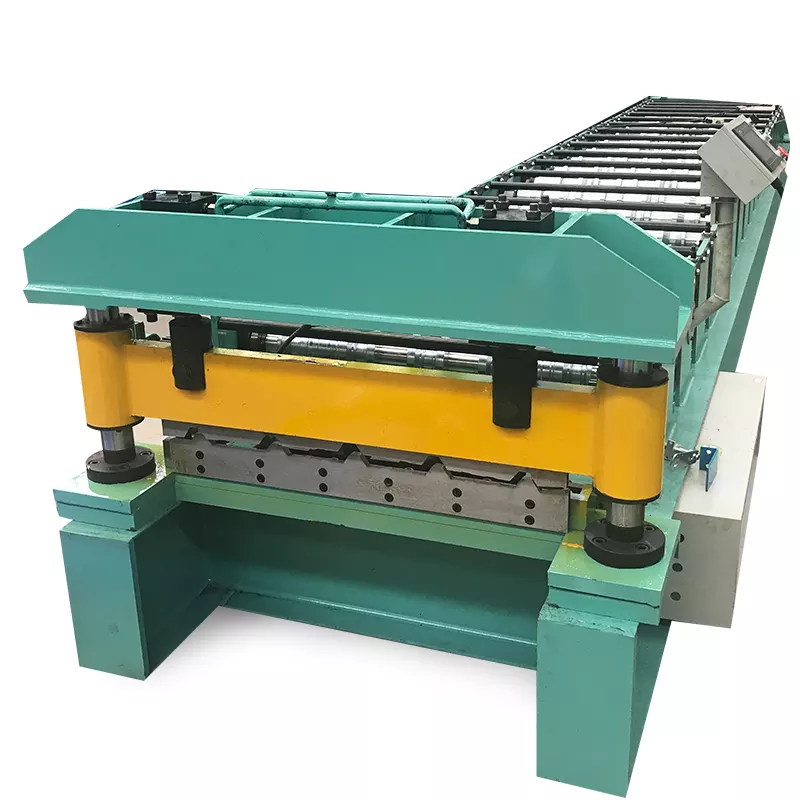

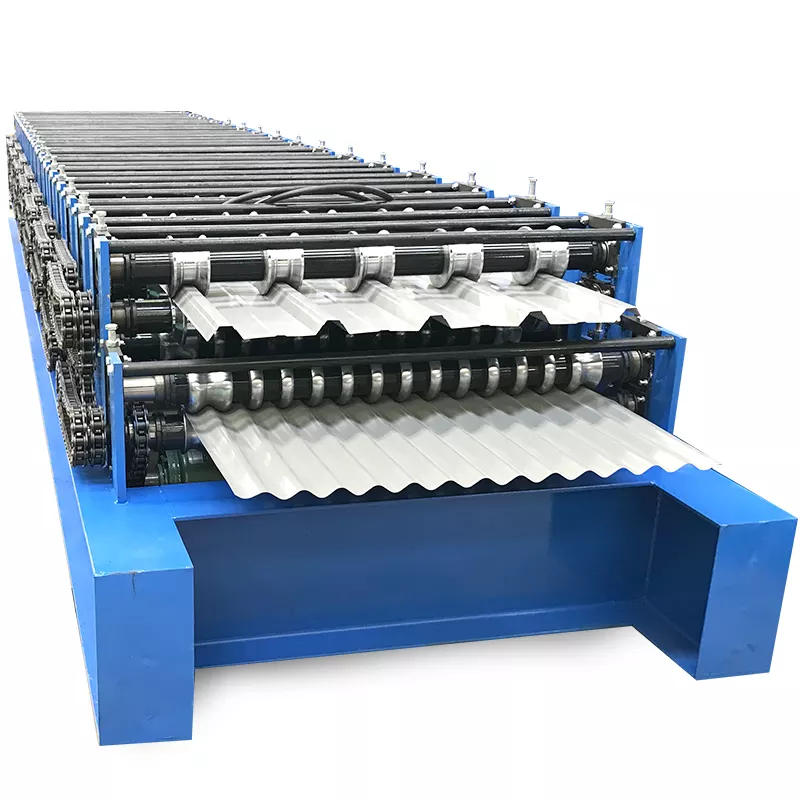

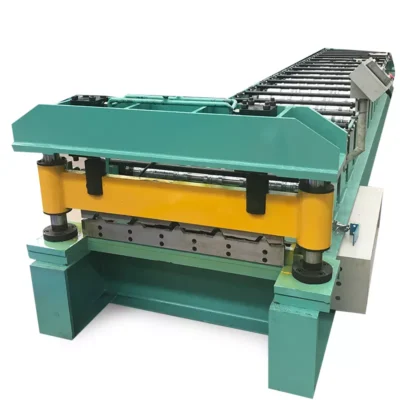

A corrugated roll forming machine is a type of industrial machinery used to produce a wide variety of products, including boxes, cartons, and cases. These machines are typically driven by a motor, and use a variety of cutting and shaping tools to produce the final product.

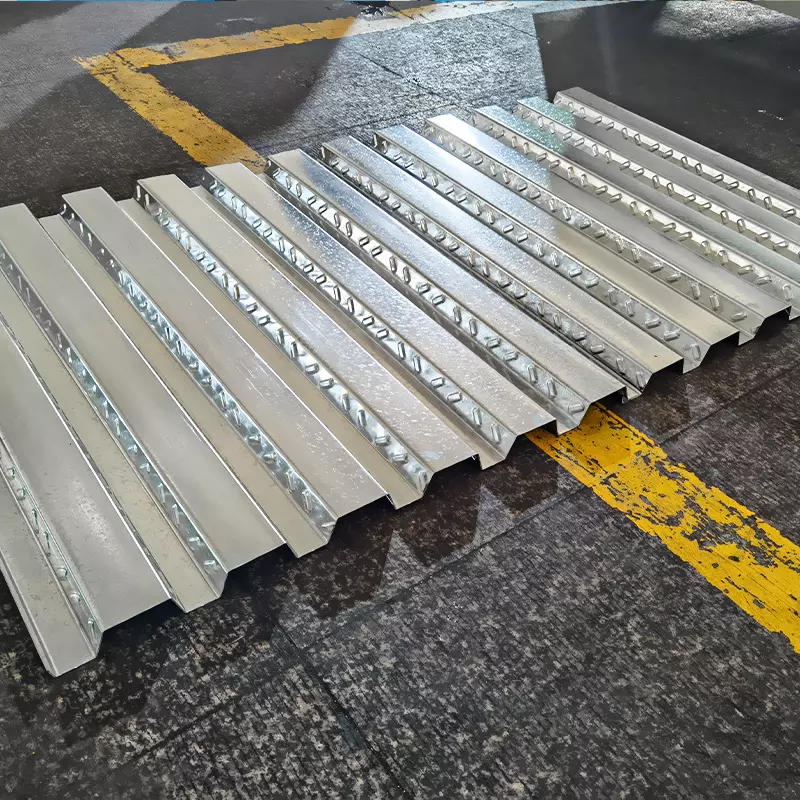

It is a critical piece of equipment in the manufacturing process for corrugated packaging. It’s used to create the distinctive and popular box-like shape that we see on products like cereal and beer cans. The machine uses a series of heated dies to form the folds in the paper, which gives the final product its characteristic fluting.

How does a Corrugated Roll Forming Machine Work?

Corrugated roll forming machines are simple to operate and can be used for a variety of applications. The machines use a continuous strip of paper or fabric to create the desired corrugated shape. The strip is fed through the machine one at a time, and the pressure from the rollers causes the paper or fabric to curl up into the desired pattern.

There are several different types of Corrugated Roll Forming Machines on the market, each with its own unique features and benefits. Some machines use an automated system to process the strips, while others require manual input. Regardless of how it is operated, all Corrugated Roll Forming Machines produce high-quality corrugated products.

-

Barrel Corrugated Roll Forming Machine

Barrel Corrugated Roll Forming Machine -

Corrugated Panel Roll Forming Machine

Corrugated Panel Roll Forming Machine -

Corrugated Roll Forming Machine

Corrugated Roll Forming Machine -

Barrel Corrugated Roll Forming Machine

Barrel Corrugated Roll Forming Machine -

PV Mounting Bracket C Shape Profile Roll Forming Machine

PV Mounting Bracket C Shape Profile Roll Forming Machine -

Roofing Sheet Roll Forming Machine Color Steel Corrugated Iron Sheet Roofing Tile Making Machine

Roofing Sheet Roll Forming Machine Color Steel Corrugated Iron Sheet Roofing Tile Making Machine -

PV Mounting Bracket Roll Forming Machine (HAT / Omega Profile)

PV Mounting Bracket Roll Forming Machine (HAT / Omega Profile) -

PV Mounting Bracket Z Shape Profile Roll Forming Machine

PV Mounting Bracket Z Shape Profile Roll Forming Machine

Benefits of Owning a Corrugated Roll Forming Machine

Owning a corrugated roll forming machine can be a huge benefit to your business. These machines are used to create various items, such as boxes, wrappers, and other packaging products. They can be used for a variety of applications, including food production, manufacturing, and more. Here are some of the benefits you can expect from owning a corrugated roll forming machine:

saved time and effort – With a corrugated roll forming machine in your arsenal, you’ll no longer need to manually form these products by hand. This will save you time and energy while ensuring high-quality results.

improved accuracy – With automated capabilities, your corrugated roll forming machine will ensure greater accuracy when creating products. This will result in fewer mistakes and better quality products overall.

faster production times – A well-equipped corrugated roll forming machine will help speed up the production process for your business. This will allow you to meet market demands more quickly and achieve maximum profits.

5 Ways to Use a New Corrugated Roll Forming Machine

If you have just purchased a new corrugated roll forming machine, there are plenty of ways to get started using it. Here are five tips:

- Orient the machine correctly the first time. The roll formers can be quite heavy and if they are not placed correctly on the machines, they can cause damage or even be stuck in the machine.

- Determine your goals. What do you want to create? Boxes? Sheets? Signs? Once you determine your goal, start designing your shapes based off that information.

- Use templates or designs to help guide your cuts. There are many free or inexpensive templates available online or at your local hardware store that will make cutting out your shapes much easier.

- Pay attention to the speed settings and adjust them accordingly for the type of material you are forming. Too fast of a speed can cause excessive heat and distortion, while too slow a speed can cause errors in shape and increased Production Time (Pt).

- Check the machine regularly for wear and tear, error messages, and malfunctioning parts before operating it in production mode. This will help ensure optimal efficiency and safety during use .

Tips for Keeping Your Machine in Good Condition

- Keep your machine clean: Make sure to keep your machine clean by using a vacuum cleaner to remove any dust or debris. Additionally, regularly wash the rollers and cutting tools with soap and water.

- Replace worn parts: When necessary, replace worn parts such as the drive belt, sprockets, and knives. Doing so will prolong the life of your machine and ensure accurate results.

- Check for compatibility: Be sure to check your machine’s compatibility before purchasing any new parts or accessories. This will help ensure that the additions fit properly and do not affect the performance of your machine.

- Adjusting settings: If there is an issue with your machine’s performance, be sure to adjust the settings accordingly in order to get optimal results. This includes adjusting the speed, temperature, and pressure levels.

Conclusion

Using a new corrugated roll forming machine can be a great way to increase production and improve efficiency in your business. By learning how to use this device, you can create custom products quickly and with minimal headache. In addition, this machine is versatile enough that it can be used for a variety of manufacturing tasks. So if you are looking to improve your business operation or just want to get creative, take the time to learn about corrugated roll forming machines. They could make a big difference in your bottom line!