With all the choices available, it’s hard to know where to start when you’re looking for sheet metal roll forming machines. With this blog post, you’ll find four tips that will help you decide which metal roll forming machine is right for your needs.

What is Sheet Metal Roll Forming Machines?

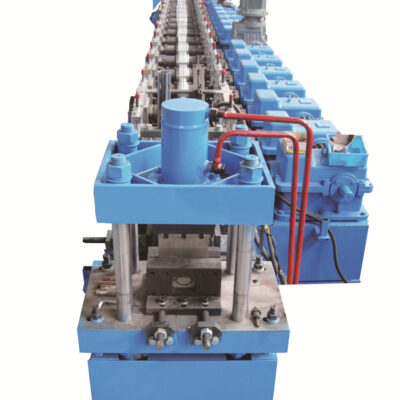

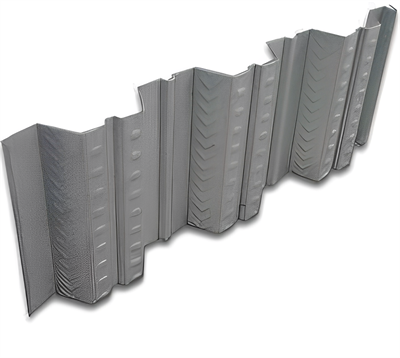

A roll forming machine is a type of machine that is used to create long, continuous metal sheets from coils of metal. These machines can be used to create a variety of shapes and sizes, and are often used in the construction industry to create roofing, siding, and other building materials.

Most machines are designed to work with either thin gauge or thick gauge material, but there are some that can accommodate both. Additionally, some machines are designed for specific metals, such as aluminum or steel, while others can work with multiple metals.

Benefits of Sheet Metal Roll Forming Machines

There are many benefits of owning a sheet metal roll forming machine. For starters, these machines can produce large quantities of parts very quickly and with great precision. Additionally, they are very versatile and can be used to create a variety of different shapes and sizes.

Another great benefit is that they require very little set-up time and can be easily operated by just about anyone. This makes them ideal for small businesses or those who do not have a lot of experience with manufacturing equipment.

Finally, sheet metal roll forming machines are relatively inexpensive to purchase and maintain, making them a great investment for any business.

-

Vineyard Post Roll Forming Machine

Vineyard Post Roll Forming Machine -

Light Gauge Steel Roll Forming Machine

Light Gauge Steel Roll Forming Machine -

Auto Size Changeable Sigma Purlin Roll Forming Machine

Auto Size Changeable Sigma Purlin Roll Forming Machine -

Auto Size Changeable Z Purlin Roll Forming Machine

Auto Size Changeable Z Purlin Roll Forming Machine -

Full automatic quick-change C Z purlin roll forming machine

Full automatic quick-change C Z purlin roll forming machine -

Vineyards Post Roll Forming Machine

Vineyards Post Roll Forming Machine -

Omega Purlin Roll Forming Machine

Omega Purlin Roll Forming Machine -

L Angle roll forming machine

L Angle roll forming machine -

Keel Steel Roll Forming Machine

Keel Steel Roll Forming Machine

4 Tips To Buy a Sheet Metal Roll Forming Machine

There are many options available when it comes to purchasing new sheet metal roll forming machines. Here are a few tips to help you choose the right one for your business:

- Determine Your Budget

The first step is to determine your budget. This will help you narrow down your options and find a machine that fits within your price range. Keep in mind that you may need to purchase additional equipment or accessories, so factor this into your budget as well.

- Consider Your Needs

Next, think about what you’ll be using the machine for. Do you need a simple machine for light-duty projects or something more robust for heavy-duty tasks? Consider your business’s needs to help guide your purchase decision.

- Compare Features and Benefits

Once you’ve determined your budget and needs, it’s time to start comparing different machines. Look at the features and benefits of each option to find the best fit for your business. Be sure to read online reviews as well to get an idea of how satisfied other customers are with their purchase.

- Get quotes from multiple suppliers

Finally, once you’ve decided on the perfect machine for your business, get quotes from multiple suppliers before making your final purchase decision. This will help ensure you’re getting the best possible price on the market.

types of sheet metal roll forming machines

There are three basic types of sheet metal roll forming machines:

- Manual machines – These are the least expensive and most versatile. They can be used for a variety of projects, but require more operator involvement than the other two types.

- CNC machines – These are computer controlled and can be programmed to do very specific tasks. They are faster and more precise than manual machines, but also more expensive.

- Hybrid machines – These combine features of both manual and CNC machines. They offer the best of both worlds, but come at a higher price tag than either type of machine alone.

important factors of Sheet Metal Roll Forming Machines

- Cost: The initial cost of the machine is a important consideration, as is the cost of maintenance and operation.

- Capacity: The machines ability to produce the required amount of product in the required time-frame is an important factor to consider.

- Quality: The machines ability to produce a high-quality product is an important consideration.

- Flexibility: The machines ability to produce a variety of products, or to be easily modified to produce new products, is an important consideration.

- Service and Support: The availability of service and support from the manufacturer or distributor is an important consideration .

Conclusion

If you’re looking for reliable and affordable sheet metal roll forming machines, then following these tips should help you find the perfect one for your needs. With so many different machines on the market, it can be tough to know which one is right for you. But by doing your research and considering your budget and specific needs, you’ll be able to find a machine that will help you get the job done right.

FAQ

What is a sheet metal roller called?

Metal rollers are an important part of every machine shop. Metal rollers, also called sheet metal rollers or metal roller benders, can create a wide array of arcs, bends, cylinders and circular objects. This equipment is also an important part of custom material fabrication.