The metal roof roll forming machine is best for those who want to produce large roofs. Buying a metal roof roll forming machine doesn’t have to be hard, though. In this article, we’ll talk about five things you need to know before buying one.

What is a Metal Roof Roll Forming Machine?

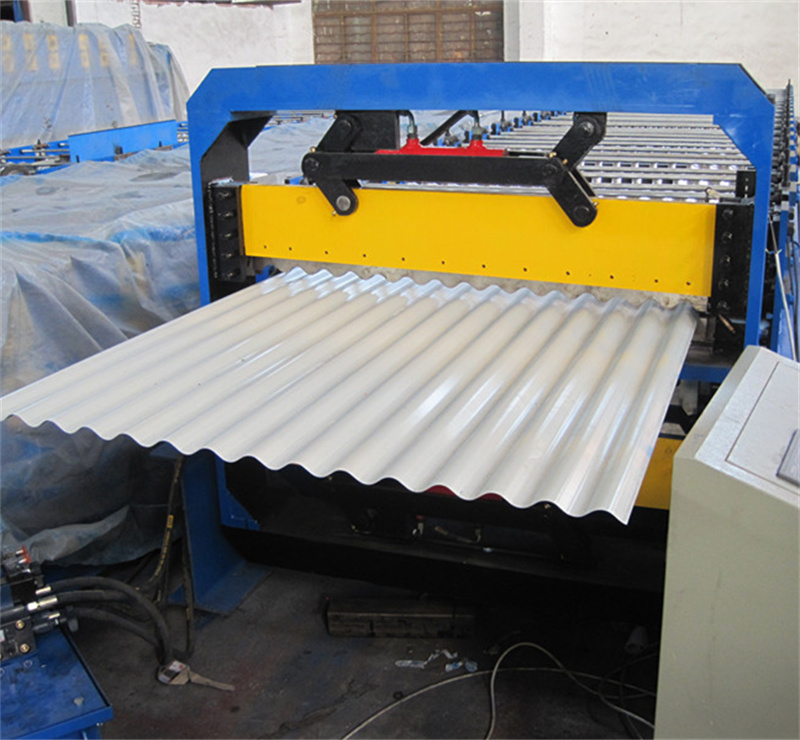

A metal roof roll forming machine is a device that is used to create metal roofs. These roofs are made by taking a large sheet of metal and rolling it into the desired shape. The machine then cuts the metal to the correct size and forms it into the desired shape.

If you are looking for a metal roof roll forming machine, it is important to consider your needs before making a purchase. You will need to decide what type of machine you need, as well as what size and shape you need your roof to be. Once you have these factors figured out, you can begin shopping around for the perfect machine for your needs.

Types of Roll Forming Machines

There are three main types of roll forming machines: standing seam, corrugated, and batten.

Standing seam roll forming machines are the most popular type of machine. They are used to create a standing seam roof, which is a type of metal roof that has seams that run vertically up the roof. These roofs are very strong and durable, and they are also energy efficient.

Corrugated roll forming machines are used to create a corrugated metal roof. These roofs have waves or ridges running across them, and they are very popular in industrial and commercial applications.

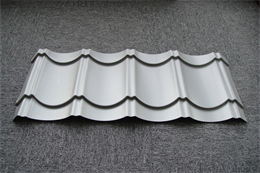

Batten roll forming machines are used to create a batten roof. Batten roofs have horizontal strips of wood or metal running across them. They are often used in residential applications.

-

Standing Seam Roof Panel Curving Machine

Standing Seam Roof Panel Curving Machine -

Barrel Corrugated Roll Forming Machine

Barrel Corrugated Roll Forming Machine -

Hydraulic Roof Sheet Curving Machine

Hydraulic Roof Sheet Curving Machine -

Stand Seaming Roof Panel Roll Forming Machine

Stand Seaming Roof Panel Roll Forming Machine -

Downspout Pipe Roll Forming Machine

Downspout Pipe Roll Forming Machine -

Gutter Roll Forming Machine

Gutter Roll Forming Machine -

Trapezoidal Panel Roll Forming Machine

Trapezoidal Panel Roll Forming Machine -

Ridge Cap Roll Forming Machine

Ridge Cap Roll Forming Machine -

Double Layer Panel Roll Forming Machine

Double Layer Panel Roll Forming Machine

Benefits of a Metal Roof Roll Forming Machine

A metal roof roll forming machine can offer many benefits for your business. Here are some of the key benefits:

- Increased production capacity – A metal roof roll forming machine can help to increase your production capacity, as it can produce large quantities of Roofing sheets in a short space of time. This can help you to keep up with demand and meet customer deadlines.

- Reduced costs – A metal roof roll forming machine can help to reduce your costs, as it is a highly efficient way of producing Roofing sheets. This means that you can save money on labour and materials costs, as well as on energy bills.

- Improved quality – A metal roof roll forming machine can produce high-quality Roofing sheets that are strong and durable. This means that your customers will be happy with the finished product, and they are less likely to experience problems or defects.

- Flexibility – A metal roof roll forming machine offers you flexibility when it comes to the design of your Roofing sheets. You can choose from a range of designs and specifications, meaning that you can create the perfect product for your needs.

- Easy to use – A metal roof roll forming machine is easy to use, meaning that you will be able to get started straight away without any prior experience. The machine is also easy to maintain, meaning that you won’t have to spend valuable time and money on repairs or maintenance.

4 Things to consider Before Buying A Metal Roof Roll Forming Machine

If you’re thinking about purchasing a metal roof roll forming machine, there are a few things you need to know before making your purchase. Here are four things to keep in mind when shopping for a metal roof roll forming machine:

- Know the different types of machines.

There are three main types of metal roof roll forming machines: panel machines, standing seam machines, and purlin machines. Each type of machine has its own unique benefits and drawbacks, so it’s important to know which type of machine is right for your needs before making a purchase.

- Consider the size of the machine.

Metal roof roll forming machines come in a variety of sizes, so it’s important to consider the size of the machine when making your purchase. If you’re only going to be using the machine for small projects, then a smaller machine may be all you need. However, if you plan on using the machine for larger projects, then you’ll need to purchase a larger machine.

- Determine the power source.

Most metal roof roll forming machines are either electric or hydraulic. If you have an existing power source, then you’ll need to purchase an electric metal roof roll forming machine. However, if you don’t have an existing power source, then you’ll need to purchase a hydraulic metal roof roll forming machine.

- Consider the warranty.

When purchasing any type of machinery, it’s important to consider the warranty that ‘s offered. Metal roof roll forming machines are no different. Make sure to find out what type of warranty is offered on the machine before making your purchase.

Conclusion

If you are in the market for a metal roof roll forming machine, there are several things you should take into consideration before making your purchase. In this article, we have outlined 4 of the most important factors to keep in mind when shopping for a metal roof roll forming machine. We hope that this information will help you make an informed decision and find the best machine for your needs.

FAQ

What is the standard size of metal roofing sheets?

The standard galvanized sheet would come in a standard 26″ wide sheet, with lengths of 8′, 10′, & 12′ long.