The metal roof roll forming machine is best for those who want to produce large roofs. Buying a metal roof roll forming machine doesn’t have to be hard, though. In this article, we’ll talk about five things you need to know before buying one.

What is a Metal Roof Roll Forming Machine?

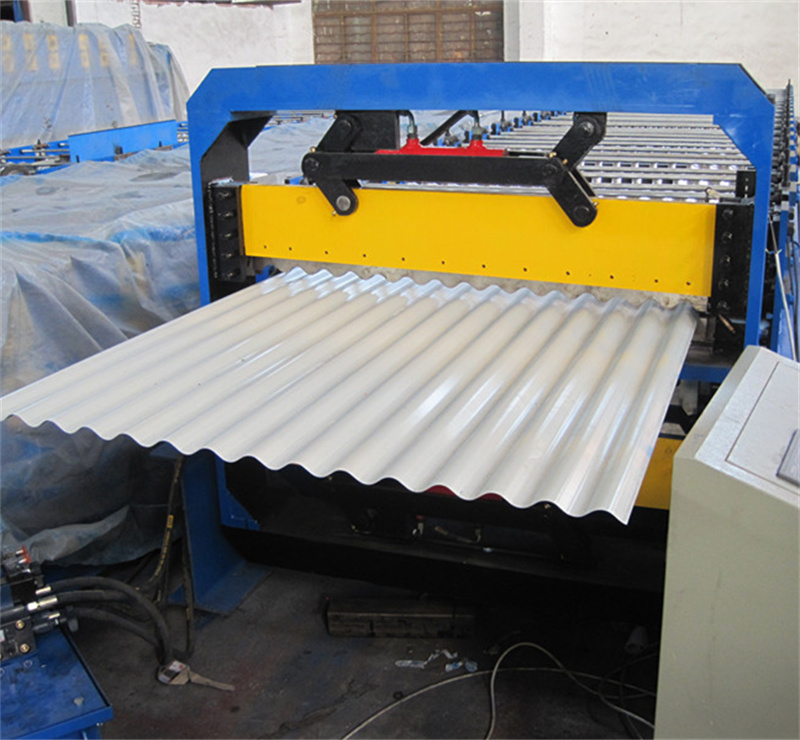

A metal roof roll forming machine is a device that is used to create metal roofs. These roofs are made by taking a large sheet of metal and rolling it into the desired shape. The machine then cuts the metal to the correct size and forms it into the desired shape.

If you are looking for a metal roof roll forming machine, it is important to consider your needs before making a purchase. You will need to decide what type of machine you need, as well as what size and shape you need your roof to be. Once you have these factors figured out, you can begin shopping around for the perfect machine for your needs.

Types of Roll Forming Machines

There are three main types of roll forming machines: standing seam, corrugated, and batten.

Standing seam roll forming machines are the most popular type of machine. They are used to create a standing seam roof, which is a type of metal roof that has seams that run vertically up the roof. These roofs are very strong and durable, and they are also energy efficient.

Corrugated roll forming machines are used to create a corrugated metal roof. These roofs have waves or ridges running across them, and they are very popular in industrial and commercial applications.

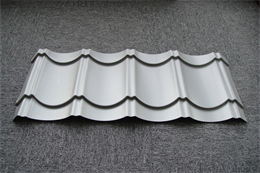

Batten roll forming machines are used to create a batten roof. Batten roofs have horizontal strips of wood or metal running across them. They are often used in residential applications.

-

Standing Seam Roof Panel Curving Machine

Standing Seam Roof Panel Curving Machine -

Barrel Corrugated Roll Forming Machine

Barrel Corrugated Roll Forming Machine -

Hydraulic Roof Sheet Curving Machine

Hydraulic Roof Sheet Curving Machine -

Stand Seaming Roof Panel Roll Forming Machine

Stand Seaming Roof Panel Roll Forming Machine -

Downspout Pipe Roll Forming Machine

Downspout Pipe Roll Forming Machine -

Gutter Roll Forming Machine

Gutter Roll Forming Machine -

Trapezoidal Panel Roll Forming Machine

Trapezoidal Panel Roll Forming Machine -

Ridge Cap Roll Forming Machine

Ridge Cap Roll Forming Machine -

Double Layer Panel Roll Forming Machine

Double Layer Panel Roll Forming Machine

Benefits of a Metal Roof Roll Forming Machine

A metal roof roll forming machine can offer many benefits for your business. Here are some of the key benefits:

- Increased production capacity – A metal roof roll forming machine can help to increase your production capacity, as it can produce large quantities of Roofing sheets in a short space of time. This can help you to keep up with demand and meet customer deadlines.

- Reduced costs – A metal roof roll forming machine can help to reduce your costs, as it is a highly efficient way of producing Roofing sheets. This means that you can save money on labour and materials costs, as well as on energy bills.

- Improved quality – A metal roof roll forming machine can produce high-quality Roofing sheets that are strong and durable. This means that your customers will be happy with the finished product, and they are less likely to experience problems or defects.

- Flexibility – A metal roof roll forming machine offers you flexibility when it comes to the design of your Roofing sheets. You can choose from a range of designs and specifications, meaning that you can create the perfect product for your needs.

- Easy to use – A metal roof roll forming machine is easy to use, meaning that you will be able to get started straight away without any prior experience. The machine is also easy to maintain, meaning that you won’t have to spend valuable time and money on repairs or maintenance.

4 Things to consider Before Buying A Metal Roof Roll Forming Machine

If you’re thinking about purchasing a metal roof roll forming machine, there are a few things you need to know before making your purchase. Here are four things to keep in mind when shopping for a metal roof roll forming machine:

- Know the different types of machines.

There are three main types of metal roof roll forming machines: panel machines, standing seam machines, and purlin machines. Each type of machine has its own unique benefits and drawbacks, so it’s important to know which type of machine is right for your needs before making a purchase.

- Consider the size of the machine.

Metal roof roll forming machines come in a variety of sizes, so it’s important to consider the size of the machine when making your purchase. If you’re only going to be using the machine for small projects, then a smaller machine may be all you need. However, if you plan on using the machine for larger projects, then you’ll need to purchase a larger machine.

- Determine the power source.

Most metal roof roll forming machines are either electric or hydraulic. If you have an existing power source, then you’ll need to purchase an electric metal roof roll forming machine. However, if you don’t have an existing power source, then you’ll need to purchase a hydraulic metal roof roll forming machine.

- Consider the warranty.

When purchasing any type of machinery, it’s important to consider the warranty that ‘s offered. Metal roof roll forming machines are no different. Make sure to find out what type of warranty is offered on the machine before making your purchase.

Conclusion

If you are in the market for a metal roof roll forming machine, there are several things you should take into consideration before making your purchase. In this article, we have outlined 4 of the most important factors to keep in mind when shopping for a metal roof roll forming machine. We hope that this information will help you make an informed decision and find the best machine for your needs.

FAQ

What is the standard size of metal roofing sheets?

The standard galvanized sheet would come in a standard 26″ wide sheet, with lengths of 8′, 10′, & 12′ long.

Frequently Asked Questions (FAQ)

1) What coil specs should a Metal Roof Roll Forming Machine support?

- For most roofing profiles: 0.3–0.8 mm thickness (0.012–0.032 in), 240–550 MPa yield strength, galvanized or galvalume per EN 10346 or ASTM A653/A792. Confirm max coil width (typically 914–1250 mm) and decoiler capacity (3–10 tons).

2) How fast can modern roofing lines run without losing cut-to-length accuracy?

- Typical production speed is 20–60 m/min. With servo flying shear and encoder feedback, expect ±0.5–1.0 mm over 6 m length when coil flatness and lubrication are controlled.

3) What features reduce changeover time between roofing profiles?

- Quick-change cassettes/rafts, servo-positioned stands, digital recipe storage (pass gaps, shear compensation, guide positions), and toolless side guides can cut changeovers to 10–20 minutes on best-in-class machines.

4) Which standards and coatings matter for metal roofing durability?

- Material standards: ASTM A653 (GI), ASTM A792 (AZ/Al-Zn), EN 10346 (Z/AZ). Coating mass examples: Z275 (EN) ≈ G90 (ASTM). For painted sheets, verify coil coating to ASTM A755/EN 10169.

5) What maintenance has the biggest impact on panel quality?

- Weekly roll alignment checks, blade/punch sharpening schedule, decoiler brake inspection, correct lubrication, and encoder calibration. Maintain hydraulic oil cleanliness at ISO 4406 17/15/12 or better and track SPC for panel width and length.

2025 Industry Trends

- Faster, smarter lines: Servo cassettes and absolute encoders push <15 minute profile changeovers for trapezoidal, corrugated, and standing seam.

- AI-assisted forming: Vision systems detect edge wave/oil canning and auto-tune pass gaps, reducing startup scrap by 30–50%.

- Energy efficiency: IE4 motors and regenerative VFDs cut kWh/ton by 15–25%; smart standby lowers idle consumption.

- HSLA and down-gauging: Wider use of 500–600 MPa steels with optimized profiles to maintain span capacity while reducing mass.

- Connected factories: OPC UA/MQTT connectivity links the Metal Roof Roll Forming Machine to MES/ERP for OEE and predictive maintenance.

- Safety and compliance: ISO 13849-1 PL d/e safety circuits and interlocked guarding for CE/UKCA export readiness.

2025 Benchmarks for Metal Roof Roll Forming Machines

| KPI | 2023 Typical | 2025 Best-in-Class | Notes |

|---|---|---|---|

| Changeover (profile A↔B) | 30–60 min | 10–20 min | Servo cassettes, digital recipes |

| Line speed (0.4–0.7 mm) | 20–45 m/min | 40–70 m/min | Stiffer frames, precision shear |

| Length accuracy @ 6 m | ±2.0–3.0 mm | ±0.5–1.0 mm | Dual encoders, thermal comp |

| Startup scrap (%) | 3–6% | 1–2% | AI pass tuning, coil analytics |

| Energy use (kWh/ton) | 90–130 | 70–100 | IE4 motors, regen drives |

| Punch/slot position tol. | ±1.0 mm | ±0.3–0.5 mm | Servo indexing, better strip feed |

Authoritative sources:

- ASTM A653/A792/A755: https://www.astm.org

- EN 10346 and EN 10169: https://standards.iteh.ai

- ISO 13849-1 safety: https://www.iso.org/standard/69883.html

- U.S. DOE Advanced Manufacturing (motors/drives): https://www.energy.gov/eere/amo

- CFSEI (AISI S100 cold-formed design): https://www.cfseionline.org

Latest Research Cases

Case Study 1: AI Vision Reduces Oil Canning on Trapezoidal Panels (2025)

Background: A roofing manufacturer experienced cosmetic oil canning and variable panel widths on 0.5 mm AZ150 coils at 50 m/min.

Solution: Installed camera-based flatness/edge-wave monitoring, integrated with servo stand micro-adjustments and recipe-based pass gaps; upgraded to a regenerative VFD main drive.

Results: Visible oil canning complaints down 48%; width CpK improved from 1.1 to 1.8; startup scrap reduced from 4.0% to 1.7%; energy per ton cut by 16%.

Case Study 2: Down-Gauging with HSLA for Standing Seam Roofs (2024)

Background: Contractor sought lighter panels for long-span standing seam roofs without compromising wind uplift performance.

Solution: Switched from G90, 0.6 mm mild steel to 0.5 mm 550 MPa HSLA with AZ coating; added two forming passes for corner strain control; optimized seam-lock geometry; validated per ASTM E1592.

Results: Mass reduced ≈15%; passed uplift tests with margin; throughput +10% due to lower forming force; payback in 9 months.

Expert Opinions

- Dr. Laura Kim, Professor of Manufacturing Systems, University of Michigan

- “On roofing lines, geometric stability hinges on strip flatness and pass symmetry. Servo-managed recipes minimize human variability during rapid changeovers.”

- Ahmed El-Sayed, Automation Director, DREISTERN GmbH & Co. KG

- “The biggest ROI in 2025 comes from data. Linking coil certificates to recipe parameters drives first-piece acceptance and slashes startup scrap.”

- Priya Natarajan, Senior Materials Engineer, BlueScope Steel

- “When adopting HSLA with Al-Zn coatings, pay attention to roll surface finish and lubrication. Minor surface defects can translate to visible panel waviness.”

Practical Tools/Resources

- CFSEI technical notes and AISI S100 references: https://www.cfseionline.org

- Eurocodes EN 1993 and execution EN 1090 overview: https://eurocodes.jrc.ec.europa.eu

- ASTM standards for coated steel and coil coating: https://www.astm.org

- EN 10346 (GI/AZ) and EN 10169 (organic coatings): https://standards.iteh.ai

- NIST Engineering Statistics Handbook (SPC templates): https://www.itl.nist.gov/div898/handbook

- OPC Foundation (OPC UA for machinery connectivity): https://opcfoundation.org

- Roll design software: COPRA RF by data M https://www.datam.de and UBECO PROFIL https://www.ubeco.com

- DOE AMO Motor/Drive efficiency tools: https://www.energy.gov/eere/amo

Optimization tip: Build a profile-specific digital recipe library for each Metal Roof Roll Forming Machine (pass gaps, guide offsets, seam-lock clearances, shear lead/lag, punch coordinates) and link it to coil metadata (grade, thickness, crown, coating). This consistently keeps panel width/length within tolerance across coil lots.

Last updated: 2025-10-21

Changelog: Added 5 FAQs, 2025 trends with benchmark table, two recent case studies, expert viewpoints, and curated tools/resources focused on Metal Roof Roll Forming Machine buyers/operators

Next review date & triggers: 2026-04-21 or earlier if ASTM/EN standards update, major OEMs release new servo/AI changeover packages, or HSLA/coating specifications shift impacting forming parameters