Introduction

When it comes to efficient and precise metal roofing production, the R Panel Roll Forming Machine stands as a game-changer in the construction industry. This advanced piece of equipment is designed to streamline the manufacturing process of R panel roofing, a popular choice for various types of buildings due to its durability and cost-effectiveness.

How Does an R Panel Roll Forming Machine Work?

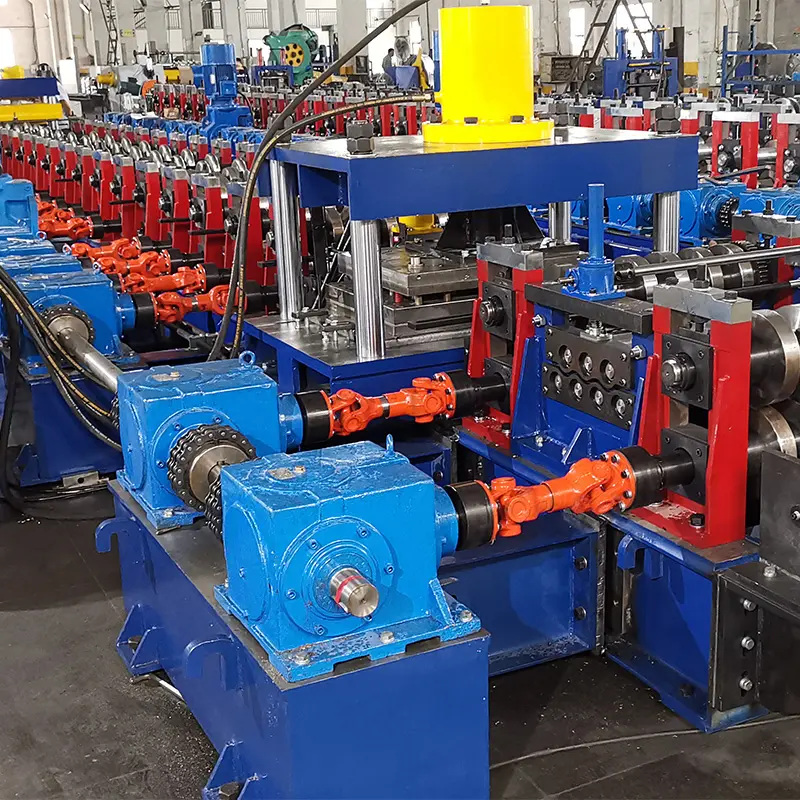

At its core, the R Panel Roll Forming Machine operates by transforming flat metal sheets into uniquely shaped R panel profiles. This is achieved through a series of precision roll forming stations. The metal sheets are fed into the machine, where they pass through several sets of rollers, each responsible for shaping a specific part of the panel. As the metal progresses through the rollers, it gradually takes on the distinctive R pattern, resulting in a uniform and seamless roofing panel.

Advantages of Using R Panel Roofing

R panel roofing offers a multitude of benefits that make it a preferred choice for builders and architects. Its high-strength design provides excellent resistance against weather elements, ensuring long-lasting protection for structures. The overlapping panel system enhances water drainage and prevents leaks, adding to its reliability. Additionally, R panel roofs come in a variety of finishes and colors, allowing for versatile aesthetic options.

Key Features of an R Panel Roll Forming Machine

An R Panel Roll Forming Machine is a complex piece of equipment with several essential features that contribute to its exceptional performance:

- High-Quality Material Feeding System: The machine is equipped with a reliable material feeding system that ensures consistent and accurate input of metal sheets. This precision feeding is crucial for maintaining the desired panel dimensions.

- Precision Roll Forming Stations: The heart of the machine lies in its roll forming stations. These stations are meticulously designed to shape the metal sheets into the R panel profile with utmost precision. Each station performs a specific bending or shaping operation, contributing to the final product’s quality.

- Automated Cutting Mechanism: Once the metal sheet has been transformed into a continuous R panel profile, the machine’s automated cutting mechanism comes into play. It precisely cuts the panel to the required length, ensuring uniformity across all panels produced.

- User-Friendly Control Panel: Modern R Panel Roll Forming Machines come with user-friendly control panels that allow operators to easily set machine parameters, monitor the production process, and make adjustments on the fly. This interface enhances operational efficiency and reduces downtime.

Step-by-Step Guide to Operating an R Panel Roll Forming Machine

Operating an R Panel Roll Forming Machine requires a systematic approach to ensure optimal results:

- Preparing the Raw Materials: Load the flat metal sheets onto the material feeding system, ensuring proper alignment and smooth flow into the machine.

- Setting Up the Machine Parameters: Use the control panel to input the desired panel dimensions, bending angles, and any other specifications.

- Initiating the Roll Forming Process: Start the machine, and watch as the metal sheets progress through the roll forming stations, gradually taking on the R panel profile.

- Cutting and Stacking the Finished Panels: As the continuous panel profile is formed, the automated cutting mechanism precisely cuts the panel to the predetermined length. The cut panels are then stacked for further processing.

Applications of R Panel Roofing

The versatility of R panel roofing extends across various building types, making it a popular choice for multiple applications:

- Residential Buildings: R panel roofs offer a clean and modern aesthetic that complements residential architecture. The durability of these roofs ensures protection for homeowners while requiring minimal maintenance.

- Commercial Structures: Many commercial establishments, from warehouses to retail spaces, benefit from the cost-effectiveness and durability of R panel roofing. Its ability to cover large areas efficiently makes it a practical solution for commercial projects.

- Agricultural Facilities: Farms and agricultural buildings often require roofing that can withstand harsh weather conditions. R panel roofing’s resistance to elements like rain, snow, and wind makes it an ideal choice for protecting valuable crops and equipment.

Factors to Consider When Choosing an R Panel Roll Forming Machine

Selecting the right R Panel Roll Forming Machine for your manufacturing needs involves careful consideration of several factors:

- Production Speed and Capacity: Assess the machine’s production speed and capacity to ensure it aligns with your required output. A machine that can meet or exceed your production goals is essential for efficiency.

- Customization Options: Look for a machine that allows flexibility in producing various panel sizes and profiles. Customization options enable you to cater to diverse client demands.

- Durability and Maintenance: Invest in a machine constructed from high-quality materials that can withstand the demands of continuous operation. Additionally, consider the ease of maintenance and availability of replacement parts.

- Technical Support and Training: A reliable manufacturer should provide adequate technical support and training for machine operators. Proper training ensures safe and efficient machine operation.

Ensuring Safety in Operating R Panel Roll Forming Machines

Safety should be a top priority when operating an R Panel Roll Forming Machine:

- Proper Training for Operators: Ensure that machine operators receive comprehensive training on how to operate the machine safely and efficiently.

- Implementing Safety Protocols: Establish strict safety protocols, including the use of personal protective equipment (PPE) and adherence to operational guidelines.

- Regular Maintenance Checks: Schedule routine maintenance checks to identify and address any potential issues before they escalate. Regular maintenance not only prolongs the machine’s lifespan but also enhances operator safety.

Future Trends in Roll Forming Technology

The roll forming industry is undergoing exciting advancements that will shape its future:

- Integration of Automation: Automation technologies are being integrated into roll forming machines, enhancing precision, efficiency, and reducing the need for manual intervention.

- Enhanced Material Compatibility: Future machines will likely accommodate a broader range of materials, including lightweight composites and environmentally friendly options.

- Sustainability Initiatives: As sustainability becomes more critical, roll forming machines may incorporate energy-efficient features and utilize recyclable materials.

Conclusion

In the realm of modern construction, the R Panel Roll Forming Machine holds a pivotal role in producing durable, efficient, and aesthetically pleasing roofing solutions. Its intricate process, coupled with innovative features, ensures that R panel roofs continue to be a popular choice for a diverse array of buildings. As technology evolves, these machines are poised to drive further advancements in the roll forming industry, ultimately reshaping the way we approach roofing solutions.

FAQs

Q1: What is the primary benefit of using R panel roofing?

A1: The main advantage of using R panel roofing lies in its exceptional durability and cost-effectiveness. R panel roofs are designed to withstand various weather conditions, making them a reliable choice for long-term protection. Additionally, their overlapping design promotes efficient water drainage, reducing the risk of leaks. The low maintenance requirements and versatile aesthetic options further contribute to their appeal.

Q2: Can R panel roofs be customized to fit specific design requirements?

A2: Absolutely. R panel roofing systems offer a degree of customization to meet specific design and architectural needs. Manufacturers often provide a range of colors, finishes, and panel profiles to choose from. This flexibility ensures that the roofing solution aligns with the overall aesthetics of the building, enhancing its visual appeal.

Q3: What safety precautions should be taken when operating roll forming machines?

A3: When operating roll forming machines, safety is paramount. Operators should receive thorough training on machine operation and safety protocols. The use of proper personal protective equipment (PPE), such as gloves and safety glasses, is crucial. Regular maintenance checks and adherence to operational guidelines are vital to prevent accidents and ensure a safe working environment.

Q4: Are R panel roofs suitable for extreme weather conditions?

A4: Yes, R panel roofs are well-suited for extreme weather conditions. Their sturdy design and overlapping panel system make them highly resistant to rain, snow, wind, and even hail. These roofs provide reliable protection for buildings located in areas prone to harsh weather, offering peace of mind to property owners.

Q5: How do I choose the right R Panel Roll Forming Machine for my business’s needs?

A5: Choosing the right R Panel Roll Forming Machine requires careful consideration. First, assess your production requirements in terms of speed and capacity. Look for machines that offer customization options to accommodate various panel sizes and profiles. Prioritize machines constructed from durable materials and inquire about maintenance needs. Additionally, seek out manufacturers that provide comprehensive technical support and operator training to ensure efficient and safe operation.

Additional Frequently Asked Questions (FAQ)

1) What materials and gauges do R Panel Roll Forming Machines typically run?

Most machines process PPGI/PPGL (pre-painted galvanized/galvalume), AZ50–AZ150 and G60–G90 coatings, 0.4–0.8 mm (26–22 ga) for architectural roofing, up to 1.0 mm (20 ga) for heavy-duty cladding, with aluminum options at 0.6–1.0 mm.

2) How fast can modern R panel lines produce and what accuracy can I expect?

2025 lines commonly run 35–70 m/min with servo flying cutoffs; length tolerance ±0.5–1.0 mm and rib pitch tolerance ±0.3–0.6 mm using encoder/laser verification and recipe control.

3) What features reduce oil-canning and waviness on R panels?

- Precision crowned rolls and stress-relief passes

- Coil flatness monitoring (inline shape meter)

- Tension stand/bridle to stabilize entry

- AI vision to flag edge wave, crossbow, and step variance in real time

4) Can one R Panel Roll Forming Machine handle multiple rib heights and cover widths?

Yes, with cassette tooling or motorized stand adjustments. Changeovers between 36-inch and 32-inch effective cover or different rib heights can be done in 10–30 minutes if profiles are designed for shared roll sets.

5) What standards/codes should finished R panels align with?

Material: ASTM A653/A792 or EN 10346; coatings to AAMA 2604/2605 or comparable PVDF specs; roof assembly wind-uplift and impact to UL 580/1897 and FM 4471 where applicable; fastener patterns per manufacturer testing.

2025 Industry Trends for R Panel Roll Forming Machines

- AI-driven inline QC: Vision + ML detects rib height variance and edge wave, cutting scrap 20–40%.

- Energy efficiency: Regenerative VFDs and hydraulic-on-demand reduce kWh/ton 10–18%.

- Faster, smarter changeovers: Auto stand positioning and cassette tooling bring profile change to 8–15 minutes on compatible R panel variants.

- High-reflectance cool roofs: Growth in SR/TE (solar reflectance/thermal emittance) coatings for energy codes (IECC/ASHRAE) boosts demand for premium coil coatings.

- Supply localization: More regional tooling and spare parts hubs; typical lead times 8–14 weeks (standard) and 16–26 weeks (high automation).

2024–2025 Benchmarks and Buying Data

| KPI | 2024 Typical | 2025 Best-in-Class | Relevance | Source Notes |

|---|---|---|---|---|

| Line speed (R panel, 0.5–0.7 mm) | 25–45 m/min | 50–70 m/min | Throughput | OEM datasheets; The Fabricator |

| Cut length tolerance (±) | 1.0–1.5 mm | 0.5–0.8 mm | Fit/trim savings | Inline laser encoder vendors |

| Rib height tolerance (±) | 0.8–1.2 mm | 0.3–0.6 mm | Panel flatness | AI vision QC |

| Energy intensity (kWh/ton) | 115–150 | 95–125 | Operating cost | U.S. DOE AMO guidance |

| Auto changeover time | 20–40 min | 8–15 min | Flexibility | OEM catalogs (Bradbury, Samco, Dallan) |

| Installed price (USD) | $120k–$260k | $180k–$420k | Budgeting | 2025 RFQ ranges |

References and resources:

- ASTM A653/A792: https://www.astm.org

- EN 10346: https://standards.cen.eu

- U.S. DOE AMO: https://www.energy.gov/eere/amo

- The Fabricator: https://www.thefabricator.com

- Cool Roof Rating Council (reflective coatings): https://coolroofs.org

Latest Research Cases

Case Study 1: AI Vision Slashes Scrap on R Panel Line (2025)

Background: A regional metal roofer faced 5.2% scrap from rib height variability and edge waviness on 0.6 mm PPGL coils.

Solution: Deployed inline AI vision measuring rib height, pitch, and edge wave; integrated to PLC for automatic roll gap micro-adjustments and reject diverter.

Results: Scrap reduced to 2.3% (−56%); rework down 41%; length/rib Cp rose from 1.1 to 1.6; payback achieved in 10 months.

Case Study 2: Energy Retrofit of Legacy R Panel Mill (2024)

Background: A 2017 line showed high kWh/ton and hydraulic overheating on summer shifts.

Solution: Added regenerative drives, hydraulic-on-demand, heat exchanger, and standby logic; implemented SPC dashboards for coil-to-coil energy tracking.

Results: Energy intensity fell from 146 to 112 kWh/ton (−23%); unplanned hydraulic downtime −68%; annual utility savings ≈ $44,000 at $0.11/kWh.

Expert Opinions

- Michael Klukas, Executive Vice President, The Bradbury Group

Viewpoint: “For R Panel Roll Forming Machines, pairing servo flying cutoff with inline metrology yields the fastest quality payback—painted coils leave little room for rework.”

Company: https://www.bradburygroup.com - Jennifer Kinder, Director of Product Management, Samco Machinery

Viewpoint: “Spec your RFQ with coil grade, coating system, cover width, rib geometry, tolerances, and changeover method so you can compare proposals apples-to-apples.”

Company: https://www.samco-machinery.com - Dr. Ben Schafer, Professor, Johns Hopkins University

Viewpoint: “Consistent rib geometry and fastener patterning improve panel stiffness and wind-uplift performance—manufacturing precision directly supports code compliance.”

Profile: https://engineering.jhu.edu

Practical Tools/Resources

- Standards and compliance

- ASTM A653/A792: https://www.astm.org

- EN 10346: https://standards.cen.eu

- UL 580/1897 wind uplift tests overview: https://www.ul.com

- Quality and energy optimization

- NIST SPC guidance: https://www.nist.gov/manufacturing

- DOE AMO Motor/Drive tools: https://www.energy.gov/eere/amo

- Cool Roof Rating Council directory (coatings): https://coolroofs.org

- Industry knowledge and sourcing

- The Fabricator technical articles: https://www.thefabricator.com

- Precision Metalforming Association supplier directory: https://www.pma.org

- Representative OEMs for R Panel Roll Forming Machines: The Bradbury Group, Samco Machinery, Dallan, Formtek (review specs, automation, support)

- Connectivity and data

- OPC UA for machinery interoperability: https://opcfoundation.org

Last updated: 2025-10-22

Changelog: Added focused FAQs; inserted 2025 trends with KPI table and sources; added two recent case studies; compiled expert opinions with citations; curated tools/resources tailored to R Panel Roll Forming Machines

Next review date & triggers: 2026-04-22 or earlier if OEM specs shift speed/price ±10%, energy guidance updates, or new AI QC benchmarks change tolerance best practices by >10%