Introduction

China has emerged as a global manufacturing powerhouse, continuously evolving its technologies to meet the ever-increasing demands of various industries. Among its impressive array of manufacturing equipment, China roll forming machines stand out as crucial tools that have revolutionized the way metal components and profiles are produced. This article explores the world of roll forming machines in China, shedding light on their features, applications, advantages, and the future they hold in the realm of manufacturing.

What is a Roll Forming Machine?

At its core, a China roll forming machine is a specialized piece of equipment used to shape metal sheets or strips into desired profiles by passing them through a series of roll stands. The process involves incremental bending of the metal, gradually forming it into the desired shape. Roll forming machines in China have become the go-to choice for mass-producing metal components due to their high efficiency, precision, and versatility.

The Evolution of Roll Forming Machines in China

The development of China roll forming machine has been a journey marked by significant advancements. Over the years, these machines have evolved from simple manual operations to highly automated and computer-controlled systems. Modern roll forming machines in China have integrated advanced technologies, enabling seamless production and quick changeovers between different profiles.

Advantages of China Roll Forming Machines

Cost-Effective Production

China roll forming machines in China offer a cost-effective solution for high-volume production, significantly reducing labor costs and material waste. The continuous and automated process ensures consistent quality, thereby minimizing the need for post-production inspections and rework.

Versatility in Design

With the ability to create a wide range of complex shapes and profiles, China roll forming machines in China cater to diverse manufacturing needs. From simple U-channels to intricate automotive components, these machines can adapt to various design requirements with ease.

High Production Speed

Roll forming machines boast impressive production speeds, allowing for swift fabrication of components. The seamless nature of the process reduces production time, enabling manufacturers to meet tight deadlines without compromising on quality.

Quality and Precision

Manufacturers rely on China roll forming machines for their exceptional precision and consistent quality. The automated nature of the process ensures that each product adheres to exact specifications, minimizing errors and variations in the final output.

Common Applications of Roll Forming Machines in China

Roll forming machines find applications across diverse industries, contributing to the efficient production of a wide range of products. Some common sectors where these machines are extensively used include:

Construction Industry

The construction sector utilizes roll forming machines to fabricate metal components like roofing panels, wall studs, and door frames. The machines’ ability to produce large quantities of standardized profiles makes them indispensable in the construction of buildings and structures.

Automotive Sector

In the automotive industry, China roll forming machines manufacture various automotive components like door sills, fenders, and chassis reinforcements. The machines’ capability to produce lightweight and durable parts aligns perfectly with the automotive industry’s requirements.

Manufacturing of Appliances

Roll forming machines play a vital role in producing components for household appliances like refrigerators, air conditioners, and washing machines. The ability to create precise and consistent parts ensures the appliances’ functionality and aesthetics.

Solar Energy Industry

In the renewable energy sector, roll forming machines are used to fabricate solar panel frames and mounting systems. The machines’ efficiency and speed make them ideal for the large-scale production required to support the growing solar energy market.

Furniture and Home Accessories

China roll forming machines contribute to the manufacturing of metal furniture components and various home accessories. From chair frames to decorative profiles, these machines play a significant role in enhancing the furniture industry’s efficiency.

Types of Roll Forming Machines in China

China offers a diverse range of China roll forming machines, each tailored to specific manufacturing needs. Some of the common types include:

Single Stand Roll Forming Machines

Single stand roll forming machines are ideal for producing simple profiles with a consistent cross-section. They are cost-effective and well-suited for applications requiring high-volume production of basic shapes.

Double Stand Roll Forming Machines

Double stand roll forming machines are equipped with two sets of roll stands, allowing for the simultaneous production of two different profiles. This setup increases productivity and reduces downtime during profile changes.

Multi-Station Roll Forming Machines

Multi-station roll forming machines incorporate multiple sets of roll stands, enabling the production of complex profiles in a single pass. These machines are highly efficient for manufacturing intricate shapes and can accommodate a wide variety of profiles.

Custom Roll Forming Machines

Custom China roll forming machines are tailored to meet specific production requirements. Manufacturers can work closely with suppliers to design machines that precisely match their needs, ensuring optimal efficiency and quality.

Key Components of Roll Forming Machines

Roll forming machines consist of several essential components that work together to ensure seamless production. These components include:

Material Handling System

The material handling system feeds metal sheets or strips into the roll forming machine, ensuring a continuous and smooth production process.

Roll Tooling

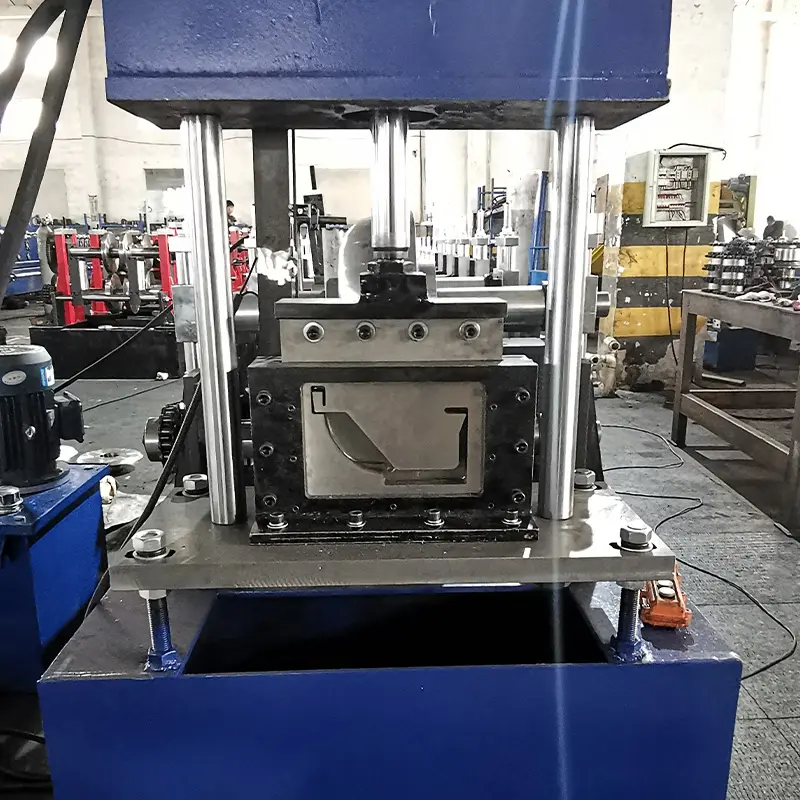

Roll tooling is a critical part of the machine, as it shapes the metal into the desired profile. The precision and design of the roll tooling directly impact the final product’s accuracy and quality.

Roll Forming Mill

The roll forming mill is the heart of the machine, containing a series of rolls that gradually bend the metal into the desired shape. The rolls’ configuration can be adjusted to produce different profiles.

Cutting and Punching Systems

After the metal is formed, cutting and punching systems trim and perforate the profile to the required length and shape. These systems contribute to the accuracy and consistency of the final product.

Control Systems

Modern China roll forming machines in China are equipped with advanced control systems that enable precise monitoring and adjustment of various parameters. These systems optimize production efficiency and quality.

Factors to Consider When Choosing a China Roll Forming Machine

Selecting the right roll forming machine is crucial for a smooth and successful manufacturing process. Some key factors to consider include:

Production Requirements

Manufacturers must assess their production volume and output goals to choose a machine that can meet their demand efficiently.

Material Compatibility

Different roll forming machines are designed to handle specific materials. Choosing a machine compatible with the intended material ensures optimal performance and product quality.

Customization Options

The ability to customize the machine for specific profiles and shapes offers greater flexibility in production and expands the range of products that can be manufactured.

Quality and Reputation of Manufacturer

Choosing a reputable and reliable manufacturer ensures the machine’s quality, durability, and after-sales support.

After-Sales Support and Warranty

A comprehensive after-sales support package and warranty provide peace of mind and prompt assistance in case of issues or maintenance requirements.

Maintenance and Safety Guidelines for Roll Forming Machines

To ensure the long-term performance and safety of roll forming machines, manufacturers and operators should follow these guidelines:

Regular Inspection and Cleaning

Frequent inspections and cleaning of the machine help identify any wear and tear, loose components, or material buildup that may affect its performance. Regular maintenance ensures the machine operates at its optimal efficiency.

Lubrication of Moving Parts

Proper lubrication of the machine’s moving parts reduces friction, minimizes wear, and extends the lifespan of critical components. Lubrication schedules should be strictly followed.

Safety Measures for Operators

Operators must be trained in safety protocols and provided with appropriate personal protective equipment (PPE) to prevent accidents and injuries during machine operation.

Training and Skill Development

Regular training sessions for machine operators improve their knowledge and expertise in handling roll forming machines, leading to improved productivity and safety.

Tips for Maximizing Efficiency and Productivity

To enhance the performance and productivity of roll forming machines, manufacturers can implement the following tips:

Optimal Machine Settings

Fine-tuning the machine settings, such as roll forming speed, roll gap, and material feed rate, ensures that the machine operates at peak efficiency for the specific profile being produced.

Proper Material Handling

Efficient material handling, including the use of coil cradles and uncoilers, minimizes material waste and improves overall production flow.

Minimizing Downtime

Swift changeovers between profiles and proactive maintenance practices help minimize downtime and maximize machine uptime.

Continuous Process Improvement

Constantly analyzing production data and identifying areas for improvement enables manufacturers to streamline processes and increase efficiency over time.

The Future of Roll Forming Machines in China

Technological Advancements

China roll forming machine industry continues to witness technological advancements. Integration of artificial intelligence, IoT-enabled systems, and advanced control algorithms promises to enhance machine performance, productivity, and adaptability.

Industry Trends and Innovations

As manufacturing demands evolve, roll forming machines will likely see innovations to cater to emerging industries, such as green technologies, electric vehicles, and advanced construction methods.

Conclusion

China roll forming machines have become indispensable assets in the manufacturing world, offering cost-effective, efficient, and precise solutions for producing metal profiles. With a wide array of applications and continuous technological advancements, these machines continue to shape the future of various industries.

FAQs

What is the working principle of a roll forming machine?

The working principle of a roll forming machine involves incrementally bending metal sheets or strips through a series of roll stands to gradually form them into desired profiles.

How long does it take to set up a roll forming machine?

The setup time for a roll forming machine depends on the complexity of the profile and the machine’s design. It can range from minutes to a few hours.

Can roll forming machines produce complex shapes?

Yes, roll forming machines can produce complex shapes by employing multi-station setups and precise roll tooling adjustments.

What are some popular roll forming machine brands in China?

China hosts several reputable roll forming machine manufacturers, including XYZ Rollformers, Innovate Rollforming, and Great Wall Machinery.

Are roll forming machines environmentally friendly?

Roll forming machines are relatively eco-friendly, as they generate minimal material waste and consume less energy compared to other metal forming methods.