Roofing sheet roll forming machine can be used to make new roofs or roof repairs. These machines are often found in roofing companies or manufactured homes and they’re capable of producing bulk sheets of metal roofing in just minutes from start to finish. Find out the six ways that a roofing sheet roll forming machine could save your business time, money and labor by reading the article below!

What is a Roofing Sheet Roll Forming Machine?

A roofing sheet roll forming machine is a type of construction machinery used to create roofing sheets. These machines are designed to streamline the roofing sheet production process by reducing the need for manual labor. Roofing sheet roll forming machines can typically produce sheets faster and with less waste than traditional methods.

How Do Roofing Sheet Roll Forming Machines Work?

Roll forming machines are used to create long, continuous sheets of metal. The process begins with a large coil of metal that is fed into the roll forming machine. The machine has a series of rollers that shape the metal into the desired profile.

The speed and pressure at which the rollers operate can be adjusted to accommodate different types of metal and thicknesses. Once the sheet has been formed, it is cut to length and then discharged from the machine.

-

Standing Seam Roof Panel Curving Machine

Standing Seam Roof Panel Curving Machine -

Barrel Corrugated Roll Forming Machine

Barrel Corrugated Roll Forming Machine -

Hydraulic Roof Sheet Curving Machine

Hydraulic Roof Sheet Curving Machine -

Stand Seaming Roof Panel Roll Forming Machine

Stand Seaming Roof Panel Roll Forming Machine -

Downspout Pipe Roll Forming Machine

Downspout Pipe Roll Forming Machine -

Gutter Roll Forming Machine

Gutter Roll Forming Machine -

Trapezoidal Panel Roll Forming Machine

Trapezoidal Panel Roll Forming Machine -

Ridge Cap Roll Forming Machine

Ridge Cap Roll Forming Machine -

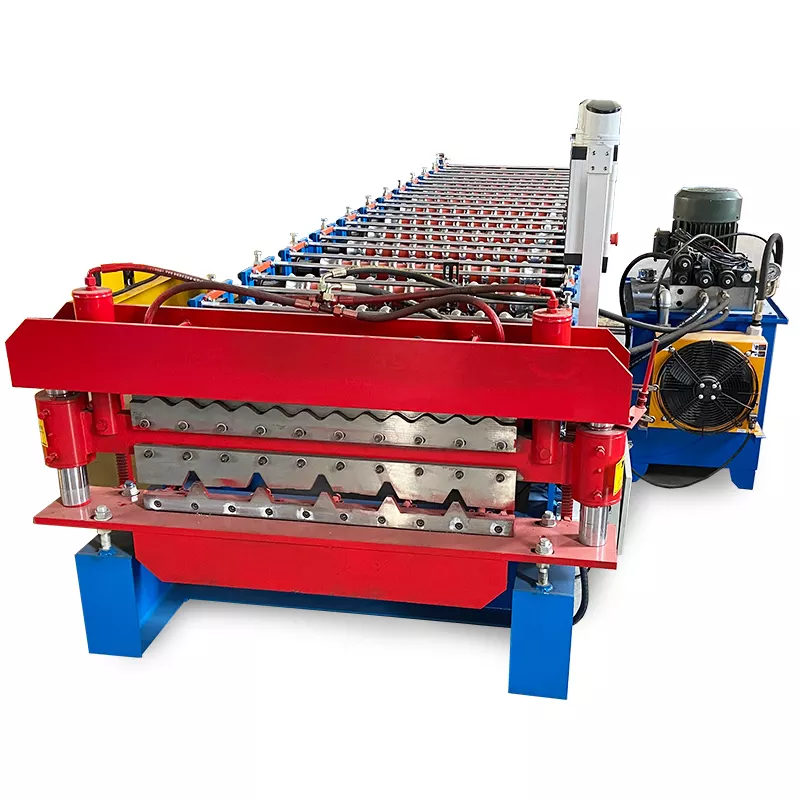

Double Layer Panel Roll Forming Machine

Double Layer Panel Roll Forming Machine

The Six Ways A Roofing Sheet Roll Forming Machine Can Save Your Business

A roofing sheet roll forming machine can save your business money in a number of ways. Here are six ways that a roofing sheet roll forming machine can save your business money:

- By increase production speed – A roofing sheet roll forming machine can significantly increase your production speed, allowing you to churn out more sheets in a shorter period of time. This is especially beneficial if you have large orders to fill or tight deadlines to meet.

- By reduce labor costs – Since a roofing sheet roll forming machine requires less manual labor, it can help you save on labor costs. This is an important factor to consider, as labor costs can make up a significant portion of your overall production costs.

- By reduce material waste – One of the main advantages of using a roofing sheet roll forming machine is that it helps to reduce material waste. Traditional methods of production often result in a lot of scrap material, but a good quality roll former will minimize waste and help you get the most out of your raw materials.

- By improve product quality – Another benefit of using a roofing sheet roll forming machine is that it can help improve the overall quality of your sheets. This is due to the fact that these machines help to ensure that sheets are produced with consistent dimensions and shapes.

- By enhance safety – When you use a roofing sheet roll forming machine, you can help to improve safety in your workplace. This is because these machines typically have built-in safety features that help to protect workers from potential injuries.

- By increase flexibility – A final benefit of using a roofing sheet roll forming machine is that it can help to increase your production flexibility. These machines can typically be easily customized to produce sheets of different sizes and shapes, which gives you the ability to better meet the needs of your customers.

Things to Consider Before Purchasing a Sheet Roll forming machine

When it comes to purchasing a roofing sheet roll forming machine, there are a few things you’ll need to take into consideration. Here are just a few:

-How much money are you willing to spend? Roofing sheet roll forming machines can range in price from a few hundred dollars to several thousand. It all depends on the features and capabilities that you need.

-What kind of sheets do you want to be able to create? There are machines that specialize in creating certain types of sheets, so if you have specific needs, make sure the machine you’re considering can accommodate them.

-How easy is the machine to operate? If you’re not mechanically inclined, you’ll want to make sure the machine is easy enough for you to use. Some machines are more complex than others, so it’s important to find one that’s within your skill set.

Conclusion

If you’ve been considering a roofing sheet roll forming machine for your business, we hope this article has helped show you how it can save you time and money. From reducing material waste to increasing production speed, a roofing sheet roll forming machine can provide a number of benefits for your business. With so many options on the market, it’s important to do your research to find the best possible machine for your needs. We hope this article has helped you in that process and that you’ll be able to find a roofing sheet roll forming machine that meets all of your requirements.