Introduction

Roller doors have become increasingly popular in various industries and residential settings due to their durability, security, and space-saving design. To meet the growing demand for roller doors, manufacturers rely on advanced machinery such as roller door roll forming machines. In this article, we will explore the significance of roller door roll forming machines, their benefits, and how they contribute to the manufacturing process.

Understanding Roller Doors

Definition of Roller Doors

Roller doors, also known as rolling doors or overhead doors, are a type of door commonly used in industrial, commercial, and residential applications. They consist of slats or panels that are hinged together and roll up into a compact coil when opened. Roller doors are known for their space-saving design, as they do not require a large swing-out area like traditional hinged doors.

Benefits of Roller Doors

Roller doors offer numerous advantages that make them a preferred choice in various settings. Firstly, they provide excellent security, as their sturdy construction and locking mechanisms make them highly resistant to unauthorized entry. Additionally, roller doors are durable and require minimal maintenance, saving both time and money. They are also space-efficient, allowing for maximum utilization of available floor area.

Applications of Roller Doors

Roller doors find applications in a wide range of industries and environments. In commercial and industrial settings, they are commonly used in warehouses, factories, garages, and storage facilities. Roller doors are also popular in residential properties, providing secure and convenient access to garages, sheds, and other storage areas. Furthermore, they are utilized in retail establishments, airports, and public buildings.

The Role of Roll Forming Machines

Definition of Roll Forming Machines

Roll forming machines are automated equipment designed to shape metal sheets or strips into desired profiles through a continuous bending process. These machines use a series of roll dies to gradually form the metal, ensuring precision and consistency. Roll forming machines are widely used in various industries, including construction, automotive, and appliance manufacturing.

Importance of Roll Forming Machines in Roller Door Manufacturing

Roll forming machines play a crucial role in the manufacturing of roller doors. They enable efficient and cost-effective production by automating the process of forming the metal slats or panels that compose the roller door. Roll forming machines ensure uniformity in the dimensions and shape of the profiles, resulting in high-quality and consistent roller doors.

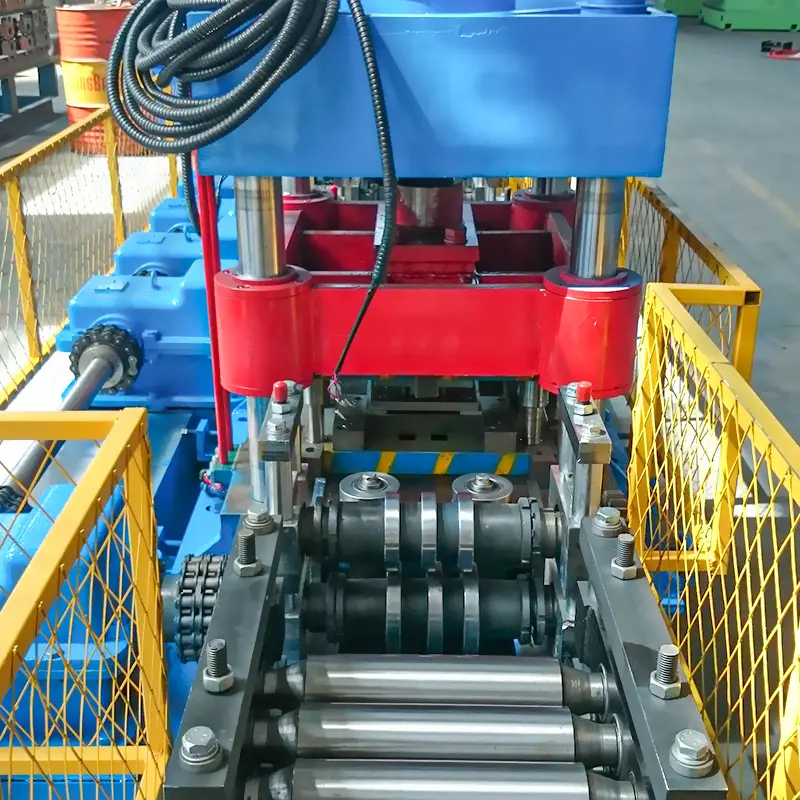

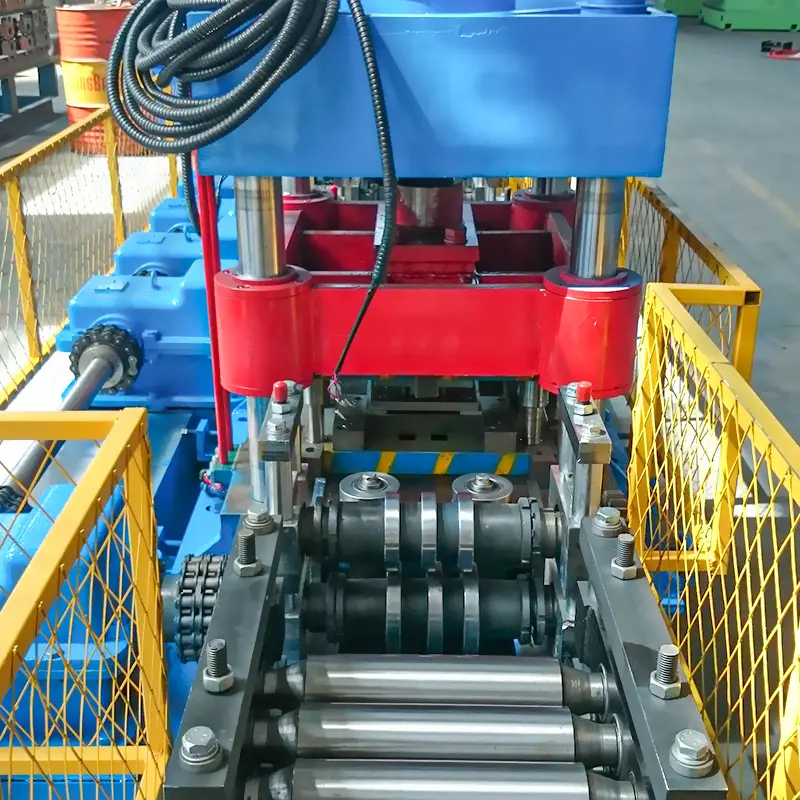

Key Features of Roller Door Roll Forming Machines

Roller door roll forming machines are specifically designed to meet the requirements of roller door manufacturing. These machines offer several key features that contribute to their effectiveness and efficiency. They incorporate adjustable roll dies, allowing for easy

customization of the profile shape and size according to specific project needs. The roll forming machines are equipped with advanced control systems that enable precise control over the speed, pressure, and positioning of the rolls, ensuring accurate and consistent forming.

Moreover, roller door roll forming machines are designed for high-speed production, minimizing production time and maximizing output. They have robust construction and are built to withstand the demands of continuous operation in industrial environments. These machines are also equipped with safety features to protect operators and prevent accidents during the manufacturing process.

Choosing the Right Roller Door Roll Forming Machine

Selecting the appropriate roller door roll forming machine is essential to ensure optimal production and quality outcomes. Here are some factors to consider when choosing a roll forming machine for roller door manufacturing:

Factors to Consider

1. Production Capacity

Evaluate the required production capacity based on the anticipated demand for roller doors. Consider the machine’s speed, output, and efficiency to ensure it can meet your production requirements.

2. Material Compatibility

Check the compatibility of the roll forming machine with the materials used for roller doors. Whether it’s steel, aluminum, or other metals, ensure that the machine can handle the specific material thickness and characteristics.

3. Customization Options

Look for roll forming machines that offer flexibility in profile design and size customization. This allows you to cater to diverse customer needs and produce a wide range of roller door variations.

4. Ease of Operation and Maintenance

Consider the user-friendliness of the machine, including intuitive controls and clear instructions. Additionally, assess the maintenance requirements, availability of spare parts, and technical support to ensure smooth operation and minimize downtime.

Popular Brands and Models

In the market, several reputable brands offer roller door roll forming machines. Some popular options include:

- ABC Roll Forming Machine Co., Ltd. – Known for their advanced technology and customization capabilities.

- Bradbury Group – Offers a wide range of roll forming machines suitable for various applications, including roller door manufacturing.

- Samco Machinery – Provides innovative roll forming solutions with a focus on productivity and efficiency.

Research and compare different models from these brands, considering your specific needs and budget, to make an informed decision.

Installation and Operation of Roller Door Roll Forming Machines

Pre-Installation Considerations

Before installing a roller door roll forming machine, ensure that you have a suitable space with adequate ventilation, power supply, and infrastructure requirements. Prepare the area by clearing any obstacles and ensuring a safe working environment.

Installation Process

Follow the manufacturer’s instructions and guidelines for installing the roll forming machine. This typically involves assembling the components, connecting power and utilities, and calibrating the machine for optimal performance. It’s recommended to involve experienced technicians or seek professional installation services to ensure accuracy and efficiency.

Operation and Maintenance Guidelines

Once the roller door roll forming machine is installed, it’s crucial to operate and maintain it correctly for long-term performance. Follow these guidelines:

- Familiarize yourself with the machine’s operating manual and safety protocols. Train operators on proper usage and safety precautions.

- Regularly inspect the machine for any signs of wear, damage, or malfunction. Address issues promptly to prevent further damage or production interruptions.

- Implement a scheduled maintenance routine, including lubrication, cleaning, and inspection of critical components. Follow the manufacturer’s recommended maintenance procedures.

- Keep a record of maintenance activities, including dates, tasks performed, and any repairs or replacements conducted. This documentation helps track the machine’s performance and aids in troubleshooting if issues arise.

By following these guidelines, you can ensure the smooth operation and longevity of your roller door roll forming machine, maximizing its value and productivity.

Industry Trends and Innovations

The roller door manufacturing industry continues to evolve with technological advancements and innovative practices. Here are some notable trends and innovations shaping the industry:

1. Technological Advancements

Advancements in technology have greatly influenced roller door manufacturing. Computer-aided design (CAD) software allows for precise design and customization of roller door profiles, improving efficiency and accuracy. Additionally, the integration of automation and robotics in roll forming machines has enhanced productivity, speed, and quality control.

2. Automation and Robotics

Automation plays a significant role in roller door manufacturing, streamlining the production process and reducing human error. Automated roll forming machines can perform tasks such as material feeding, profiling, cutting, and stacking, minimizing manual intervention and increasing production efficiency. Robotics further enhance automation by enabling tasks such as material handling, assembly, and quality inspection.

3. Sustainability and Energy Efficiency

The industry is placing a growing emphasis on sustainability and energy efficiency. Manufacturers are adopting eco-friendly practices by using recyclable materials and reducing waste generation. Energy-efficient components and processes, such as energy recovery systems and optimized power consumption, are being incorporated into roll forming machines to minimize environmental impact and operating costs.

Conclusion

Roller door roll forming machines have revolutionized the manufacturing process of roller doors, enabling efficient production, customization, and consistent quality. By understanding the importance of roll forming machines, considering the factors when choosing one, and following proper installation, operation, and maintenance guidelines, manufacturers can optimize their roller door production and meet the diverse demands of various industries. Embracing industry trends and innovations ensures competitiveness and sustainability in an evolving market.

FAQs (Frequently Asked Questions)

1. What materials can be used with roller door roll forming machines? Roller door roll forming machines are compatible with various materials, including steel, aluminum, and other metals commonly used in roller door manufacturing.

2. How long does it take to install a roller door roll forming machine? The installation time may vary depending on the specific machine and the complexity of the installation process. It is recommended to consult the manufacturer’s guidelines for accurate installation time estimation.

3. Can roller door roll forming machines be customized for specific profile designs? Yes, roller door roll forming machines can be customized to accommodate specific profile designs. They offer flexibility in adjusting the shape and size of the profiles according to customer requirements.

4. Are roller door roll forming machines safe to operate? Roller door roll forming machines are designed with safety features to ensure operator safety. It is important to follow the provided safety guidelines and train operators on proper usage and precautions.

5. How often should maintenance be performed on a roller door roll forming machine? Regular maintenance should be conducted according to the manufacturer’s recommendations. This typically includes routine inspections, cleaning, lubrication, and addressing any signs of wear or damage. Keeping a maintenance schedule helps ensure the machine’s optimal performance and longevity.