Introduction

The roll forming industry is evolving rapidly, driven by technological advancements, automation, and demand for lightweight, high-strength materials. As we move into 2025, manufacturers must stay ahead of emerging trends to remain competitive.

But what’s changing in the roll forming industry? What are the most significant trends shaping the future of metal forming?

In this guide, we’ll explore:

✅ The latest advancements in roll forming technology

✅ Automation and AI-driven roll forming

✅ Sustainability and eco-friendly manufacturing

✅ New material trends in metal forming

✅ Market growth and future outlook for roll forming

Let’s dive into the roll forming industry trends for 2025 and beyond!

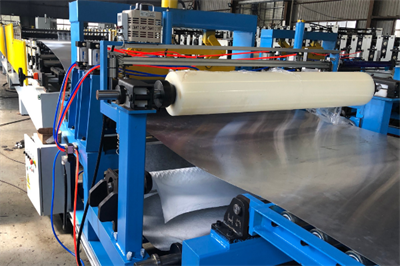

1. Automation & Smart Roll Forming Machines

Automation is revolutionizing the roll forming industry, allowing manufacturers to increase productivity while reducing labor costs.

Key Advancements in Automated Roll Forming

✅ CNC & PLC-controlled machines – Improve precision and repeatability.

✅ AI-powered quality control – Detects defects in real-time, reducing waste.

✅ IoT-enabled machines – Remote monitoring and predictive maintenance.

✅ Fully automated roll forming lines – Minimize human intervention, increasing efficiency.

Benefits of Automation in Roll Forming

✅ Higher production speeds – Automated lines run 24/7 with minimal supervision.

✅ Lower labor costs – Reduces dependence on skilled operators.

✅ Improved product consistency – Eliminates human error in forming and cutting.

Pro Tip: By 2025, over 60% of roll forming manufacturers are expected to adopt AI-powered automation!

2. Sustainability & Eco-Friendly Manufacturing

Sustainability is becoming a major focus in metal forming, with manufacturers investing in energy-efficient roll forming machines and recyclable materials.

Green Innovations in Roll Forming

✅ Energy-efficient servo motors – Reduce power consumption.

✅ Solar-powered roll forming lines – Lower carbon footprint.

✅ Recyclable steel and aluminum – Support circular economy initiatives.

✅ Water-based lubricants – Replace harmful chemical-based lubricants.

Why Sustainability Matters

✅ Governments are introducing stricter environmental regulations.

✅ Consumers demand eco-friendly building materials and metal products.

✅ Companies adopting green manufacturing gain a competitive edge.

Pro Tip: Sustainable roll forming can reduce production costs by 20% while improving brand reputation!

3. High-Strength & Lightweight Materials in Roll Forming

The demand for stronger, lighter materials is growing in industries like automotive, aerospace, and construction.

Trending Materials in Roll Forming

✅ Advanced High-Strength Steel (AHSS) – Used in automotive chassis & structural components.

✅ Aluminum Alloys – Lightweight, corrosion-resistant, ideal for solar panel frames & aerospace.

✅ Galvanized & Coated Metals – Enhance durability and weather resistance.

✅ Composite Metal Panels – Combining metals with polymers for improved strength-to-weight ratio.

Why Lighter & Stronger Materials Matter

✅ Automotive manufacturers aim to reduce vehicle weight for better fuel efficiency.

✅ Solar and construction industries demand lightweight yet durable components.

✅ Reduced transportation costs due to lighter materials.

Pro Tip: By 2025, over 70% of roll-formed parts in the automotive industry will use Advanced High-Strength Steel (AHSS).

4. Growth of Custom Roll Forming & On-Demand Manufacturing

Customization is becoming a key factor in the roll forming industry, with manufacturers offering tailored solutions for different industries.

Why Custom Roll Forming is Growing

✅ Demand for specialized profiles in solar energy, racking & shelving, and HVAC.

✅ 3D modeling & CAD integration allow for rapid prototyping.

✅ On-demand manufacturing reduces inventory costs and improves flexibility.

Industries Driving Custom Roll Forming Growth

✅ Solar Energy – Custom profiles for solar panel mounting structures.

✅ Automotive – Precision-formed body panels & reinforcements.

✅ Construction – Unique architectural metal panels & roofing components.

Pro Tip: Custom roll forming allows businesses to charge premium prices while reducing material waste!

5. Market Growth & Future Outlook for Roll Forming

The global roll forming market is expected to grow significantly, driven by demand from construction, infrastructure, and automotive sectors.

Roll Forming Market Growth Projections (2025-2030)

| Region | Market Growth Rate | Key Industries Driving Growth |

|---|---|---|

| North America | 6% CAGR | Construction, steel framing, solar energy |

| Europe | 5.5% CAGR | Automotive, aerospace, renewable energy |

| Asia-Pacific | 7.2% CAGR | Infrastructure, industrial shelving, railway |

| Middle East & Africa | 4.8% CAGR | Roofing, pipelines, oil & gas |

Factors Driving Market Growth

✅ Rapid urbanization & infrastructure development.

✅ Increasing adoption of roll forming in renewable energy projects.

✅ Technological advancements in high-speed, automated roll forming machines.

Pro Tip: Asia-Pacific is the fastest-growing market for roll forming, with demand increasing for construction and transportation projects!

6. Digital Integration & Industry 4.0 in Roll Forming

The future of roll forming lies in smart manufacturing and digital integration.

Industry 4.0 Technologies in Roll Forming

✅ IoT Sensors – Real-time machine performance tracking.

✅ Cloud-Based Production Management – Remote monitoring & predictive maintenance.

✅ AI-Driven Process Optimization – Reduces material waste and improves efficiency.

✅ 3D Printing & Hybrid Manufacturing – Faster prototyping and tooling.

Benefits of Digital Roll Forming

✅ Faster production times with data-driven automation.

✅ Lower maintenance costs with predictive analytics.

✅ Higher accuracy and less waste due to AI-powered process optimization.

Pro Tip: By 2030, over 80% of roll forming manufacturers will adopt Industry 4.0 technologies!

Where to Buy the Latest Roll Forming Machines for 2025?

For state-of-the-art roll forming machines that meet future industry demands, visit WUXI SUNWAY MACHINERY CO., LTD.

Why Choose WUXI SUNWAY MACHINERY?

✅ 15+ Years of Industry Experience – A trusted global supplier.

✅ Advanced Automation & Custom Roll Forming Solutions.

✅ Energy-Efficient & High-Speed Machines for maximum productivity.

✅ Reliable After-Sales Support & Spare Parts Availability.

Looking to upgrade your roll forming technology? Contact us today!

7. The Role of AI and Robotics in the Future of Roll Forming

Artificial Intelligence (AI) and robotics are transforming the roll forming industry by improving efficiency, precision, and predictive maintenance.

How AI & Robotics Are Changing Roll Forming

✅ AI-Powered Quality Control – Detects defects in real-time, reducing waste.

✅ Robotic Material Handling – Automates coil feeding, stacking, and packaging.

✅ Predictive Maintenance – AI predicts machine failures before they happen, minimizing downtime.

✅ Automated Tool Change Systems – Reduce setup time for multi-profile roll forming machines.

Benefits of AI & Robotics in Roll Forming

✅ Minimizes human error, leading to higher precision.

✅ Reduces labor costs by automating repetitive tasks.

✅ Increases production speed while maintaining quality.

✅ Extends machine lifespan by preventing premature failures.

Pro Tip: By 2030, nearly all high-end roll forming machines will integrate AI-driven automation!

8. The Growing Demand for Roll Formed Solar Mounting Structures

The solar energy industry is booming, and roll forming plays a critical role in producing solar panel mounting structures.

Why Roll Forming is Ideal for Solar Industry?

✅ High Precision & Strength – Ensures durable and stable solar panel frames.

✅ Lightweight yet Strong – Aluminum and galvanized steel profiles reduce weight.

✅ Corrosion Resistance – Essential for outdoor solar installations.

✅ High Production Speed – Meets the growing demand for solar infrastructure.

Global Solar Market Growth & Impact on Roll Forming

| Year | Global Solar Market Value | Impact on Roll Forming |

|---|---|---|

| 2023 | $180 Billion | Growing demand for customized solar panel frames |

| 2025 | $250 Billion | Increased production of steel and aluminum solar structures |

| 2030 | $400 Billion | Fully automated roll forming lines for solar energy applications |

Pro Tip: Companies investing in solar mounting roll forming machines will see strong demand growth in the coming years!

9. The Shift Towards Modular & Flexible Roll Forming Machines

Manufacturers are moving towards modular roll forming machines, allowing for quick profile changes and flexible production.

Why Modular Roll Forming is the Future?

✅ Quick Tool Change Systems – Reduce downtime during profile switching.

✅ Multi-Profile Capability – Produce different shapes on the same machine.

✅ Scalable Design – Easily expand production by adding new forming stations.

✅ Better ROI – Invest in one machine for multiple applications.

Industries Benefiting from Modular Roll Forming

✅ Automotive – Producing multiple body components on a single line.

✅ Construction – Flexible machines for roofing, wall panels, and framing.

✅ Industrial Storage – Adaptable designs for racking and shelving.

Pro Tip: Modular roll forming machines reduce costs by eliminating the need for multiple dedicated lines!

10. The Rise of 3D Printing in Roll Forming Tooling

3D printing is revolutionizing roll forming tooling, offering faster and more cost-effective solutions.

How 3D Printing is Changing Roll Forming?

✅ Rapid Prototyping – Design and test new roll forming profiles quickly.

✅ Lower Tooling Costs – Traditional dies are expensive—3D-printed dies are cheaper.

✅ Custom Tooling for Small Batches – Ideal for low-volume, high-precision applications.

✅ Complex Geometries – Create intricate roll-formed profiles that were previously impossible.

Industries Using 3D-Printed Roll Forming Tooling

✅ Aerospace – Lightweight, high-strength roll-formed components.

✅ Medical Equipment – Precision-formed metal parts for medical devices.

✅ Automotive – Custom roll-formed parts for electric vehicle (EV) manufacturing.

Pro Tip: 3D printing reduces tooling costs by up to 50%, making it a game-changer in roll forming!

11. Global Competition & The Future of Roll Forming Manufacturing

As global competition increases, manufacturers must focus on efficiency, automation, and sustainability to stay ahead.

Key Competitive Factors in the Roll Forming Industry

✅ Cost-Effective Production – Lower material waste, energy consumption, and labor costs.

✅ High-Speed Automation – Faster production cycles with minimal downtime.

✅ Customization & Flexibility – Ability to produce unique, high-margin products.

✅ Sustainability Initiatives – Compliance with green manufacturing standards.

Which Countries Lead the Roll Forming Industry?

| Country | Industry Strength | Competitive Advantage |

|---|---|---|

| China | Largest producer | Cost-efficient mass production |

| Germany | Precision engineering | High-tech automation & AI integration |

| USA | Innovation leader | Advanced material forming & sustainability focus |

| India | Fast-growing market | Affordable labor & increasing infrastructure demand |

Pro Tip: Manufacturers investing in automation and sustainability will lead the global roll forming market!

12. Where to Buy the Most Advanced Roll Forming Machines in 2025?

For next-generation roll forming machines designed for automation, efficiency, and sustainability, visit WUXI SUNWAY MACHINERY CO., LTD.

Why Choose WUXI SUNWAY MACHINERY?

✅ 15+ Years of Expertise – A global leader in roll forming machine manufacturing.

✅ AI-Powered & High-Speed Machines – Cutting-edge automation for maximum ROI.

✅ Custom Roll Forming Solutions – Machines tailored for roofing, shelving, automotive, and solar applications.

✅ Competitive Pricing & Global Shipping – Affordable and delivered worldwide.

✅ Reliable After-Sales Support – Spare parts, technical assistance, and installation services.

Looking to upgrade your roll forming technology? Contact us today!

FAQ: Roll Forming Industry Trends 2025

1. What are the biggest technological advancements in roll forming?

- AI, robotics, IoT, and predictive maintenance are transforming the industry.

2. How is sustainability affecting roll forming?

- Manufacturers are adopting energy-efficient machines, recyclable materials, and solar-powered production lines.

3. What industries will drive growth in roll forming?

- Construction, solar energy, automotive, aerospace, and industrial storage will see the highest demand.

4. Are modular roll forming machines better than traditional machines?

- Yes! They allow quick profile changes, multi-product capability, and better scalability.

5. Where can I find the most advanced roll forming machines?

- WUXI SUNWAY MACHINERY provides state-of-the-art roll forming solutions with automation, AI, and energy-efficient designs.

Final Thoughts

The roll forming industry is undergoing massive transformations with automation, sustainability, and AI-driven manufacturing leading the way. To stay competitive, manufacturers must invest in the latest roll forming technology and adapt to market trends.

✅ Need smart, high-speed roll forming machines?

✅ Looking for customized roll forming solutions?