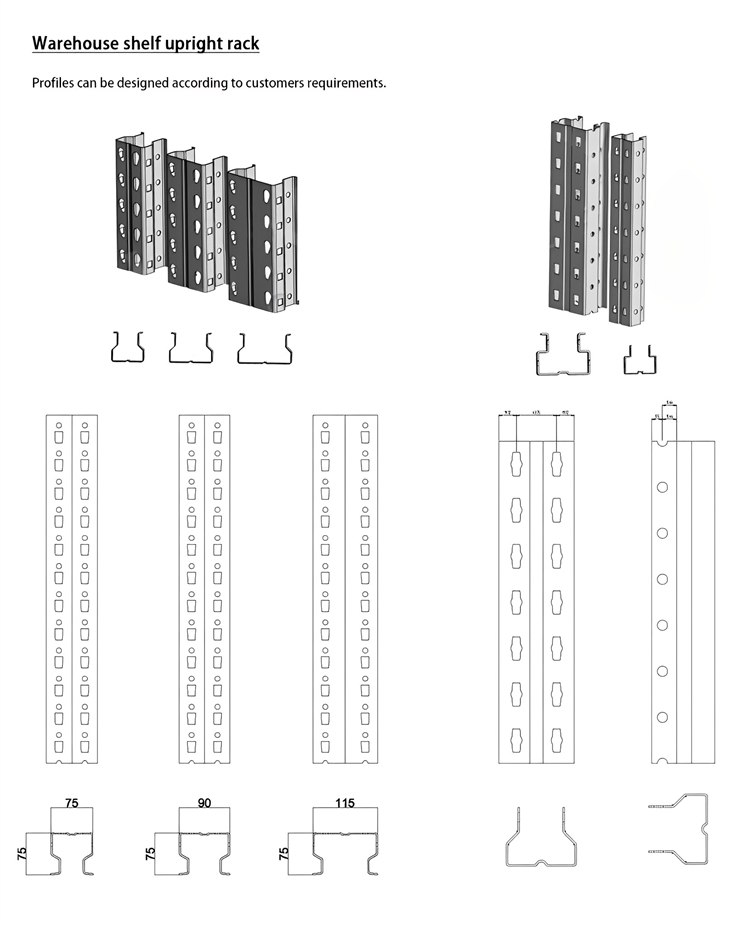

Profile Drawings

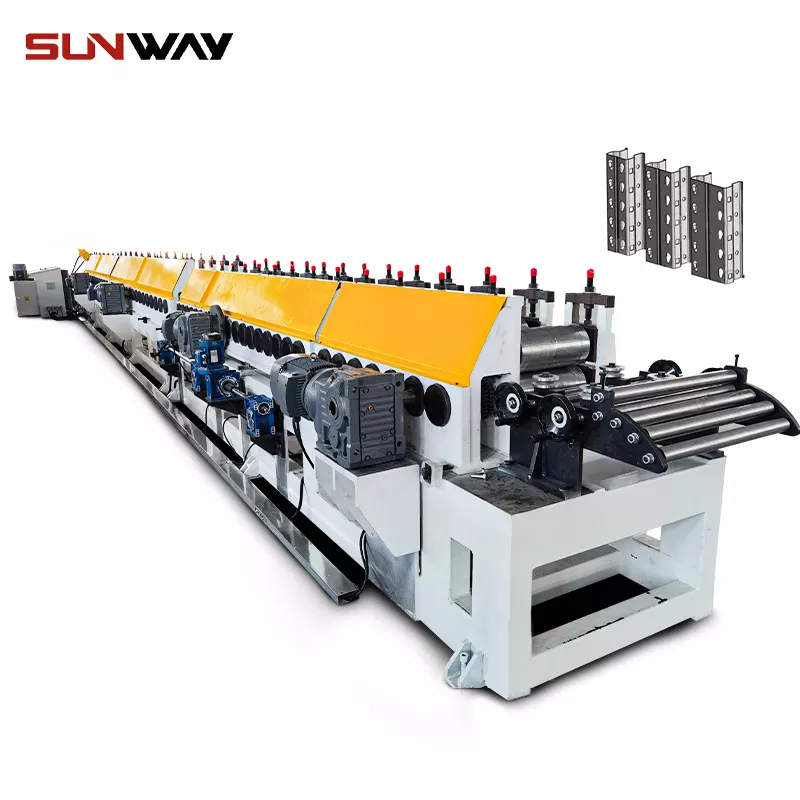

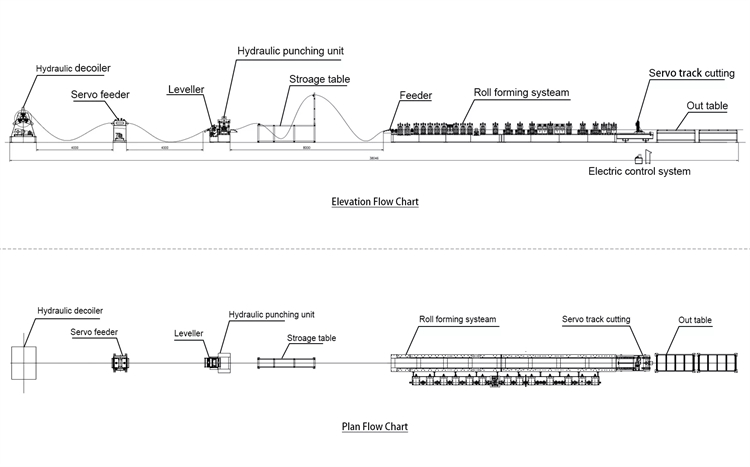

Production Line

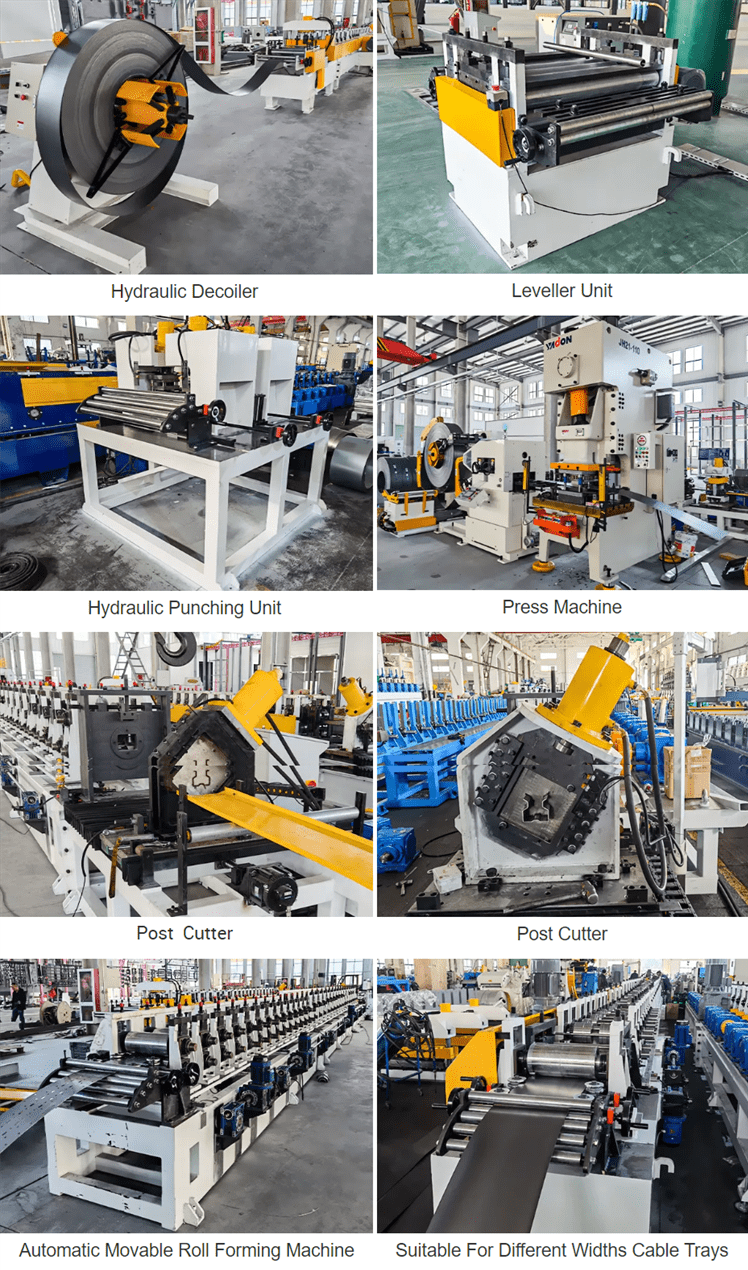

Product Details

Warehouse Shelf Upright Roll Forming Machine Parameters

| Warehouse Shelf Upright Roll Forming Machine | ||

|

Machinable Material

|

A) Galvanized Steel |

Thickness(MM): 1.5-3.0 as per customer

|

| B) Stainless Steel | ||

| Yield Strength | 250 – 550 Mpa | |

| Tensil Stress | G250 Mpa-G550 Mpa | |

| Decoiler | Manual Decoiler | * Hydraulic Decoiler (Optional) |

| Punching System | Hydraulic Punching Station | * Punching Press (Optional) |

| Forming Station | About 25 Stands | * According To Your Profile Drawings |

| Driving System | Chain Drive | * Gearbox Drive (Optional) |

| Machine Structure | Wall Panel Station | * Cast Iron Stands (Optional) |

| Forming Speed | 5-15 (M/MIN) | * Or According To Your Profile Drawings |

| Rollers’ Material | GCr 15 | * Cr12 (Optional) |

| Cutting System | Hydraulic Cutting | * Saw Cutting (Optional) |

| Frequency Changer Brand | Yaskawa | * Siemens (Optional) |

| PLC Brand | Panasonic | * Siemens (Optional) |

| Power Supply | 380V 50Hz 3ph | * Or According To Your Requirement |

| Machine Color | Industrial Blue | * Or According To Your Requirement |

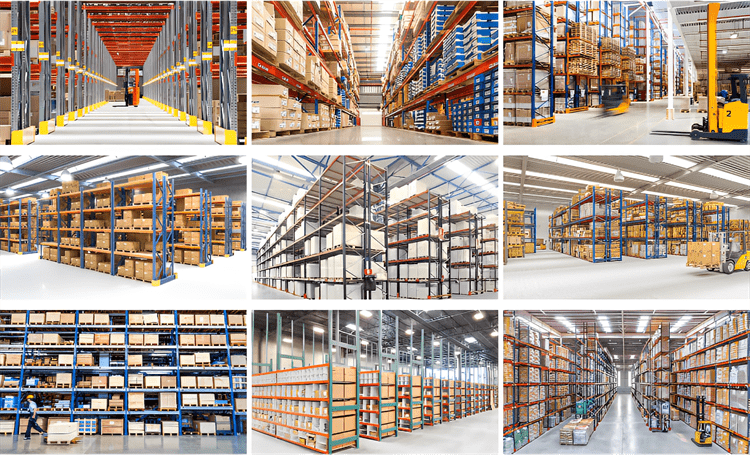

Application

what is upright roll forming machine?

An upright roll forming machine is a type of industrial machinery used in the metalworking industry for shaping and forming continuous metal strips into desired profiles. It is commonly used for producing structural components with a consistent cross-section, such as beams, channels, and panels.

The machine operates by passing the metal strip through a series of adjustable rollers arranged vertically. Each roller set is designed to gradually shape the strip by bending it to a specific contour. The rollers are positioned in a sequential order, with each set performing a specific bending or forming operation. As the metal strip passes through the machine, it undergoes a continuous shaping process until it reaches the desired profile.

Upright roll forming machines are known for their efficiency, accuracy, and high production rates. They are capable of handling various types of metals, including steel, aluminum, and stainless steel, with different thicknesses and widths. These machines are widely used in industries such as construction, automotive, aerospace, and manufacturing, where precise and consistent metal profiles are required for different applications.

how do rack shelf roll forming machine work?

A rack shelf roll forming machine is a specialized type of roll forming machine used to produce rack shelving systems, which are commonly used for storage purposes in warehouses, retail stores, and industrial settings. Here is an overview of how a rack shelf roll forming machine typically works:

- Material Loading: The process begins by loading a coil of sheet metal onto a decoiler, which holds the coil and feeds it into the machine. The sheet metal is usually steel or aluminum.

- Straightening and Feeding: The sheet metal is then fed through a straightening unit that removes any coil set or curvature, ensuring a flat and consistent strip. The straightened strip is then guided into the roll forming machine.

- Roll Forming: The roll forming machine consists of a series of roll tooling stations, typically arranged in a line. Each station has a set of rollers that gradually shape the metal strip into the desired profile. The rollers are precisely positioned and designed to bend and form the metal strip according to the rack shelf profile. The strip is guided through the machine, with each station contributing to the final shape of the profile.

- Cutting: Once the desired length of the rack shelf profile is formed, a cutting mechanism is activated. It can be a flying cutoff, hydraulic shear, or other cutting method, which cuts the formed profile to the desired length.

- Stacking and Output: The cut rack shelf profiles are then usually stacked or conveyed to an output area for further processing or packaging. The machine may include stacking or palletizing mechanisms to facilitate efficient handling of the finished profiles.

The entire process is typically automated, with the machine controlled by a computerized system that precisely controls the speed, positioning, and operation of the rollers and cutting mechanism. This automation allows for high production rates and consistent quality of the rack shelf profiles.

It’s important to note that the specific operation and features of a rack shelf roll forming machine can vary depending on the manufacturer and the requirements of the application.