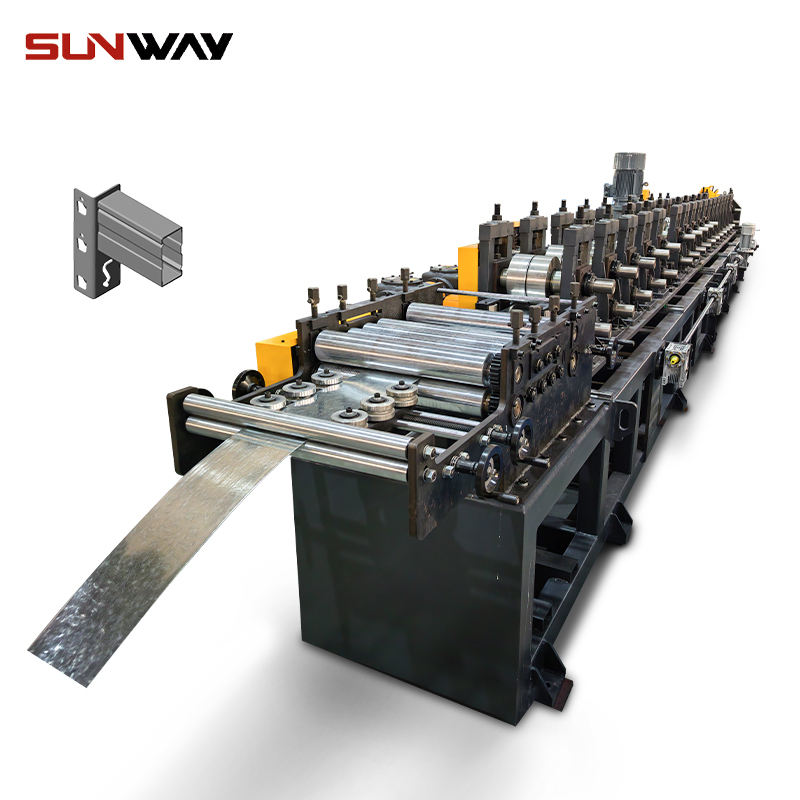

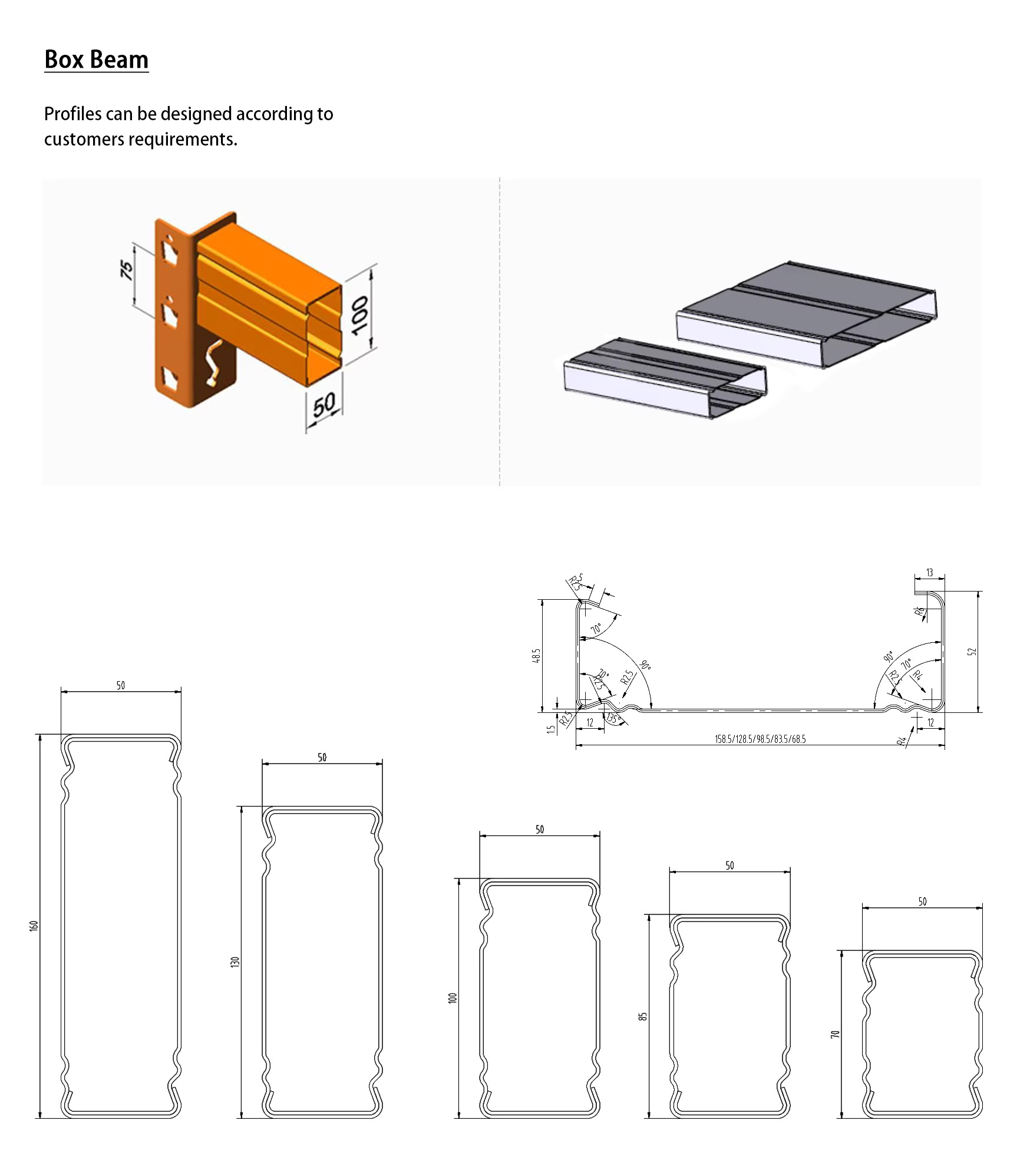

Box beam roll forming machine is developed to produce the beam which is fixed between the upright racks. It normally have two types: 1) both C beams are roll formed on a roll forming machine then seamed in a combined roll former to get a box beam; 2) one beam is formed on a roll forming machine directly to get a box beam.

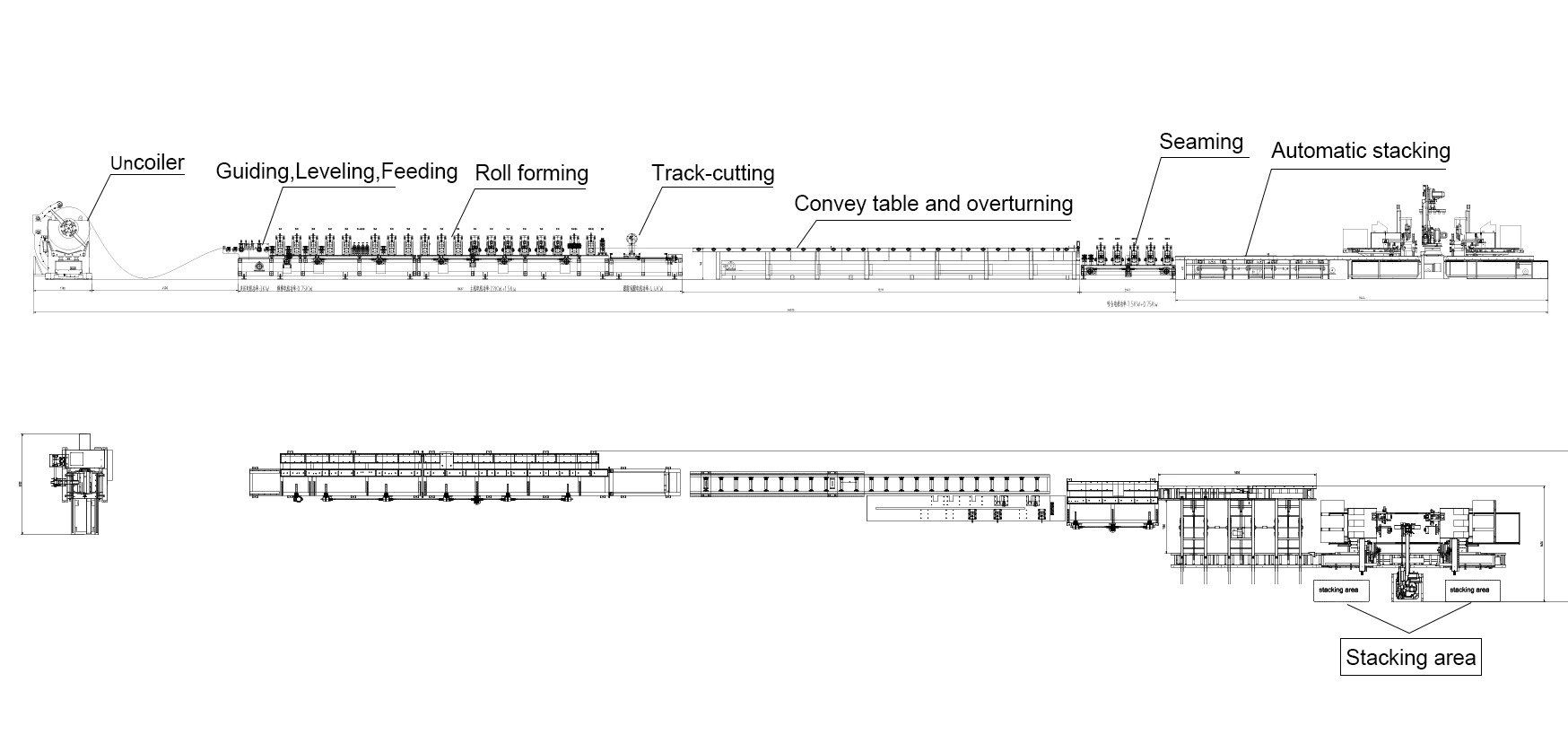

This full automatic box beam roll forming line is specially designed and equipped with auto welding, stacking which can reduce labor and increase production efficiency. Whole line flow chart is

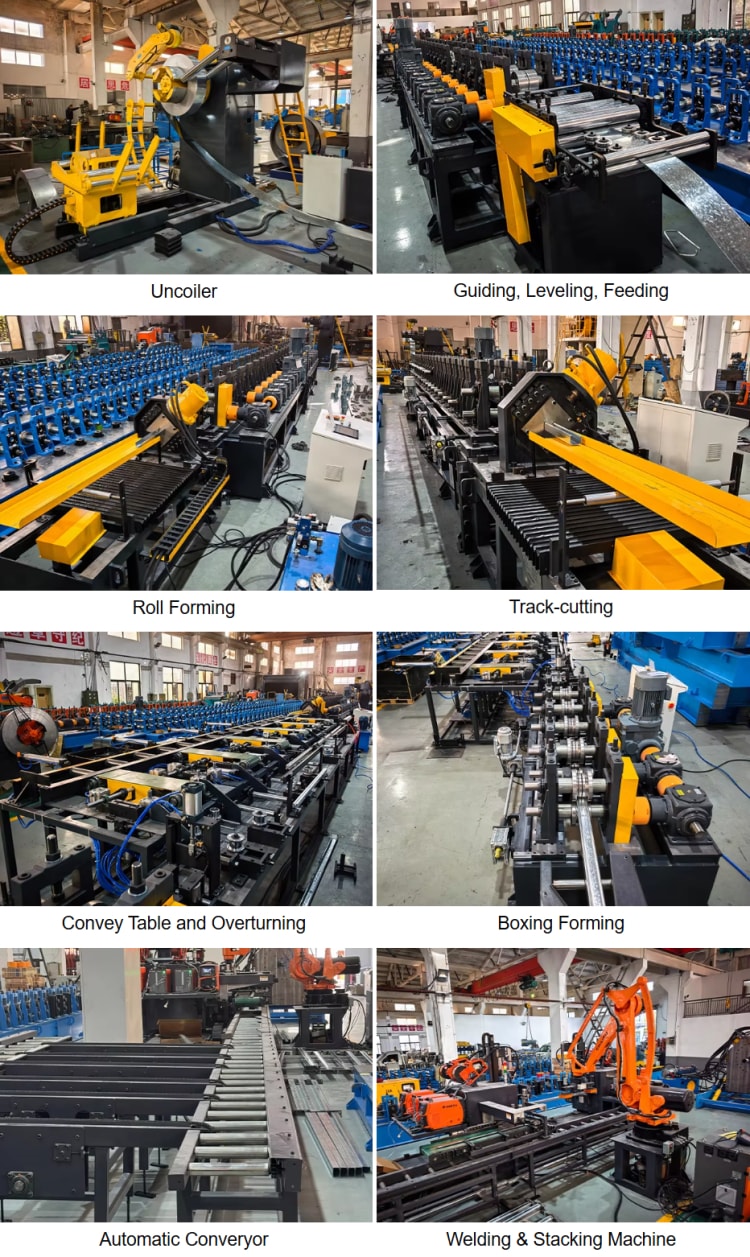

Electric uncoiling – Feed guiding and leveling – Roll Forming machine(gearbox drive system) – Fly cutting – Automatic conveying and turning table – Boxing machine(gearbox drive system) – Output table—Auto welding and stacking.

Our intelligent roll forming machine could make various sizes of beam with thickness 1.5-3.0mm. Uncoiling, feeding, roll forming, welding, cutting etc process can be automatically realized on one line. Meantime, we have the roll forming machine to make step beam, upright rack and shelf boards. All these are components of Pallet racking system.

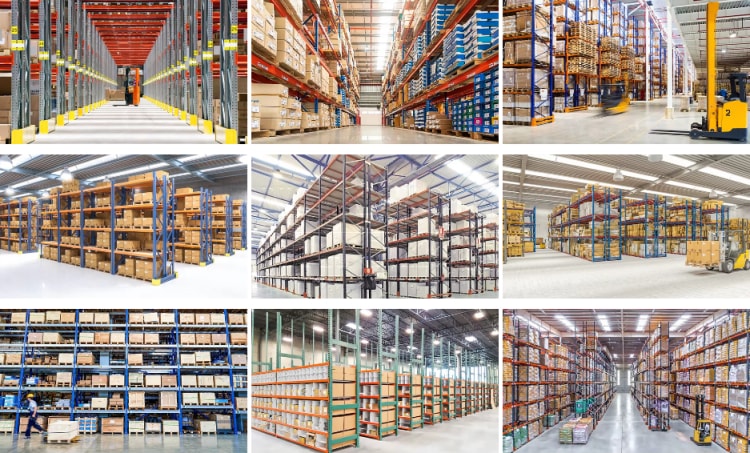

In warehouse pallet racking system, we are able to manufacture more machines like Step beam roll forming machine, Upright rack roll forming machine and shelf panel (box plate) roll forming machine etc.

We make different solutions according to customers’ drawing, tolerance and budget, offering professional one-to-one service, adaptable for your all requirements. Whichever line you choose, the quality of SUNWAY Machinery will ensure you obtain perfectly functional profiles.

Profile Drawings

Production Line

Product Details

Product Parameters

| Automatic Box Beam Roll Forming Line | ||

|

Machinable Material

|

A) Galvanized Coil |

Thickness(MM): 1.5-3.0 as per customer

|

| B) Cold/Hot-rolled Steel | ||

| C) Carbon Steel | ||

| Yield Strength | 250 – 350 Mpa | |

| Tensil Stress | 350 Mpa-500 Mpa | |

| Nominal Forming Speed(M/Min) | 10-20 | * Or According To Your Requirment |

| Forming Station | 18-20 | * According To Your Profile Drawings |

| Decoiler | Manual Decoiler | * Hydraulic Decoiler (Optional) |

| Driving System | Chain Drive | * Gearbox Drive (Optional) |

| Machine Structure | Steel Plates Welded | * Cast Iron Stands (Optional) |

| Rollers’ Material | GCr 15 | * Cr12Mov (Optional) |

| Cutting System | Hydraulic Cut | * Saw Cut (Optional) |

| Boxing Unit | By Chain | * By Gearbox (Optional) |

| Welding Efficiency | Specification 50*100≥25 seconds/pcs, specification 50*120-140≥30 seconds/pcs, Specification 50*160≥35 seconds/pcs (except for beams with unilateral error of >1.5 mm) |

|

| Welding & Stacking Process | Stack the hanging pieces in order on the automatic hanging piece feeding platform, then input the signal, the machine starts to automatically load the hanging pieces, and at the same time, the robot automatically grabs the crossbeam to the specified position of the machine platform, starts welding, first welds the two sides, rotates 90 degrees and then welds the two sides to complete the welding, rotates to another station, and the robot takes the material to the finished product stacking, and the robot takes the material again, and the above actions are repeated. All the above actions are controlled and operated by the dedicated system for the crossbeam automatic line |

|

| Machine Color | Industrial Blue | * Or According To Your Requirment |

Application